燃煤电厂协同处置生活垃圾及二噁英排放试验

0 引 言

随着我国经济快速发展和城镇化率提高,城镇生活垃圾产量飞速增加[1-2]。根据住建部发布的《2021年城乡建设统计年鉴》,2021年,我国城镇生活垃圾产量已达2.49亿t,较2020年上升6%,生活垃圾处理逐渐成为城市发展进程中的一个大难题。目前生活垃圾主流处置方式有填埋、堆肥、焚烧等,垃圾填埋占用大量土地资源,且填埋处理过程中产生的甲烷是温室气体排放的主要组成部分,垃圾填埋会破坏环境[3-4]。垃圾堆肥基于垃圾分类收集,我国主要为混合垃圾,不宜直接堆肥,因此该技术很难推广。在现有垃圾处理方法中,焚烧处理因优于填埋和堆肥等其他垃圾处理方法而受到广泛关注[5]。与垃圾填埋和堆肥相比,垃圾焚烧可有效降低垃圾体积和质量[6],消除垃圾中致病菌、病毒、寄生虫等。此外,焚烧过程产生的热能可回收利用[7]。2021年,全国城镇生活垃圾焚烧处理量已达2.1亿t,根据“十四五”规划,截至2025年底,城镇生活垃圾焚烧处理能力要达到约80万t/d,城市生活垃圾焚烧处理能力占比65%左右[8]。

然而,垃圾焚烧同时会产生大量有害燃烧副产品,如部分燃烧的灰烬、微粒和二噁英等有机污染物,特别是二噁英,其毒性大、脱除成本很高[9]。常规垃圾焚烧发电机组由于机组容量小、蒸汽参数低、回热循环不完善等,发电效率(14%~28%)远低于大型燃煤发电机组[10-12]。因此,为提高垃圾处理能力,降低垃圾发电成本,2017年底国家能源局和环境保护部联合发布了《关于开展燃煤耦合生物质发电技改试点工作的通知》,提出利用现有煤电机组,协同处理垃圾,提高垃圾处理规模,降低存量煤电煤耗。燃煤电厂协同耦合生活垃圾焚烧发电不仅能保证燃烧稳定,提高发电效率,同时减少了单独建设垃圾焚烧炉投资成本。目前,燃煤耦合生物质发电经数年发展,成效显著。污泥耦合国内已有大量运行案例[13-14],农林生物质耦合已有数个示范项目[15-17],然而鲜见大型燃煤电站锅炉耦合生活垃圾发电案例分析。

生活垃圾与大型燃煤机组耦合主要有直接耦合、间接耦合和并联耦合3种方式。相比直接耦合与并联耦合,间接耦合方式处理生活垃圾产生的污染小,垃圾处理彻底,且可直接利用现有垃圾焚烧气化炉及燃煤机组的烟气处理系统,投资成本较低,是一种经济可行的垃圾耦合路线。目前间接耦合已有工程案例和技术路线,如烟台龙源电力股份有限公司在国电乐东电厂建设的30 t/d生活垃圾气化耦合发电系统[18];哈电集团哈尔滨锅炉厂有限责任公司研发的蒸汽侧、烟气侧垃圾双链耦合燃煤发电技术[19];南京理工大学张睿课题组[20]提出的垃圾先焚烧处理,烟气与燃煤机组耦合技术等。

二噁英排放是垃圾处置要考虑的重要因素[21]。垃圾焚烧过程中二噁英主要有高温气相反应和低温异相催化反应2种生成途径[22-23]。高温气相反应是一些含C、H的低沸点有机物在高温下与多氯联苯、氯苯、氯酚和脂肪族化合物等耦合环化、取代、氯化生成二噁英[24]。低温异相合成包括从头合成和前驱物合成。从头合成是指燃烧后的残碳、氢、氧和氯等元素在飞灰中催化金属作用下,通过环化、氧化、氯化等反应生成二噁英[25]。前驱物合成是烟气中携带的氯酚、氯苯等二噁英前驱物被飞灰中CuCl2、FeCl3等催化重整从而生成二噁英[26-27]。由于生活垃圾中氯含量较高,导致垃圾处理过程中二噁英排放较高,主要集中在烟气和飞灰中[28-29]。关于垃圾焚烧过程中二噁英控制和消除一直是研究重点。陈怀俊等[30]系统论述了垃圾焚烧处置过程中二噁英的形成过程,并针对现有焚烧过程中二噁英控制技术和焚烧后飞灰处置技术进行介绍分析,二噁英控制分为入炉前的分类预处理、入炉中的燃烧参数控制和抑制剂添加以及尾部烟道中二噁英生成抑制;马瀚程等[31]利用燃煤耦合垃圾焚烧试验台针对耦合垃圾焚烧烟气粉煤灰中二噁英的浓度变化进行研究,结果表明,与燃煤未耦合垃圾焚烧烟气产生的粉煤灰相比,燃煤耦合垃圾焚烧后,煤粉炉烟气和灰渣中二噁英毒性当量降低;吕家扬等[32]对市政污泥与生活垃圾协同焚烧二噁英的排放特性进行研究,掺烧市政污泥可提高燃料中硫/氯,从而抑制二噁英合成。相比垃圾单独处置,将垃圾与燃煤机组、污泥等固废协同处置有助于降低二噁英排放。

基于以上研究,笔者设计了一条新的燃煤火电机组垃圾无氧热解耦合处置工艺,将垃圾干化、热解变为热解油气和垃圾炭后,再与燃煤锅炉耦合。与垃圾气化相比,热解特别是无氧热解由于自身温度较低,更能彻底控制二噁英排放,且热解耗能也远低于气化。另外由于目前间接耦合技术受制于耦合本身,当电厂停机检修时,生活垃圾无法处理,而本工艺可解决该问题,既可将生活垃圾与燃煤机组协同运行,还可解耦实现生活垃圾单独处置,灵活性更强。

目前国内燃煤火电机组耦合垃圾的技术方案报道较少,且鲜见在实际电厂耦合垃圾后二噁英排放数据报道。鉴于此,笔者首次完成国内某2×55 MW燃煤机组垃圾无氧热解耦合技术方案设计,并在该机组上开展垃圾热解产物耦合现场试验(总体协同处置垃圾质量比4%),重点测试垃圾无氧热解耦合后烟气中二噁英排放特性,相关方案和测试结果可为我国探索大型燃煤火电机组耦合生活垃圾可行性提供指导意义。

1 工艺路线与现场试验

1.1 燃煤火电机组垃圾无氧热解灵活性耦合处置工艺路线

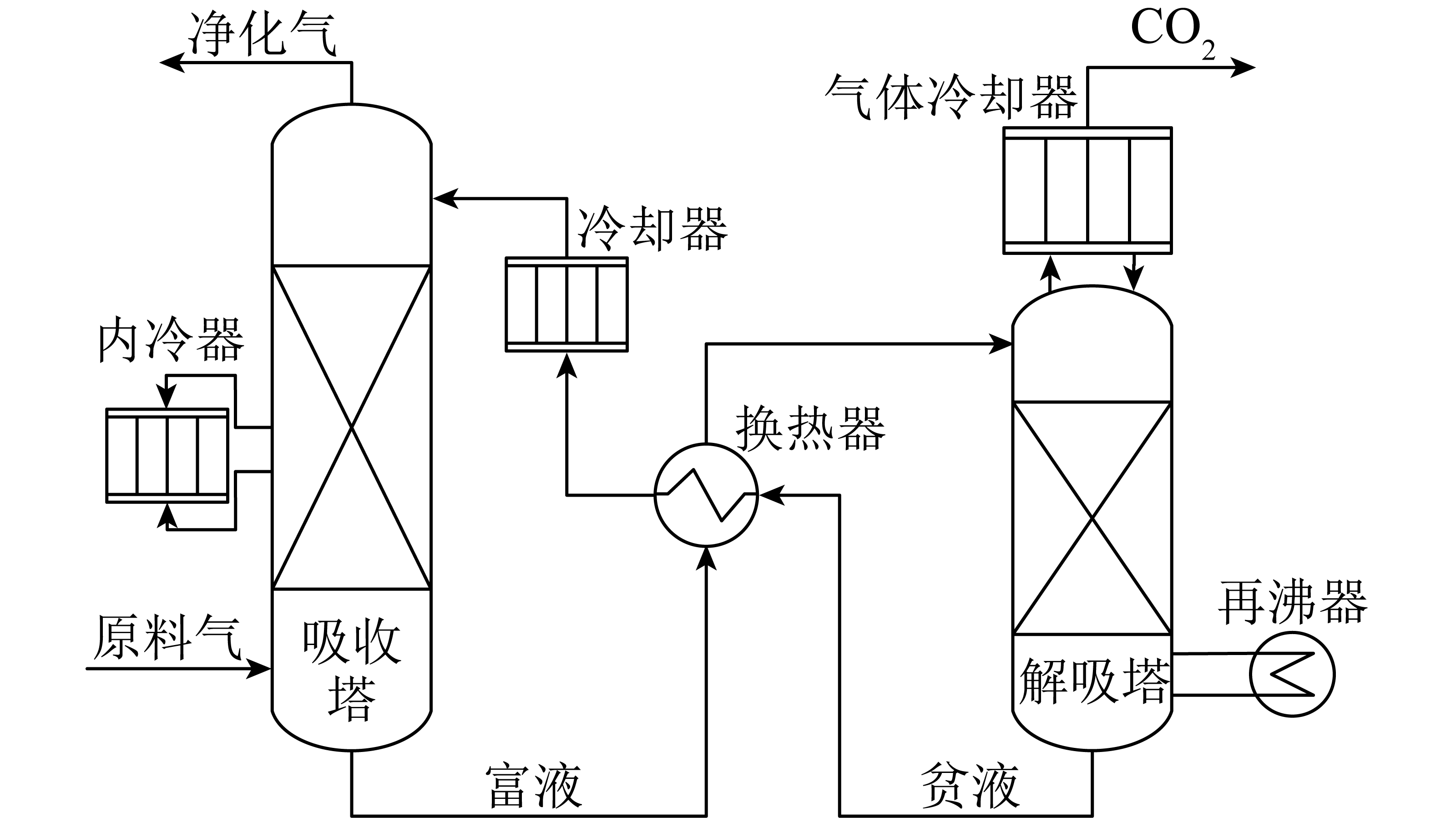

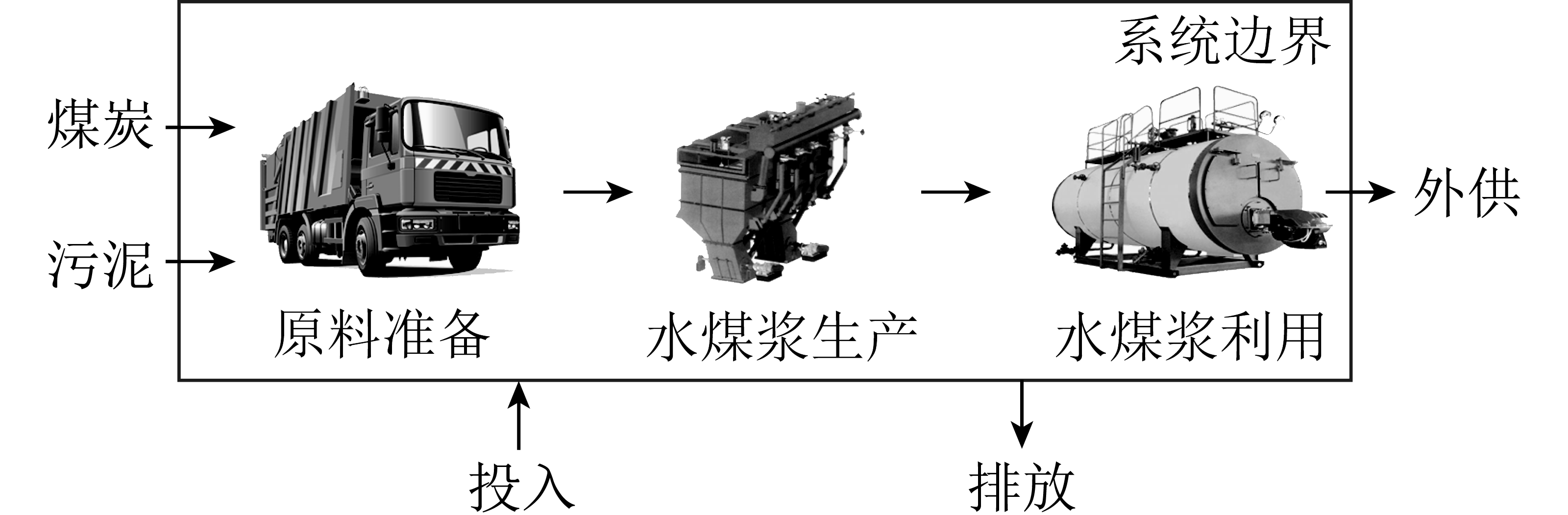

燃煤火电机组垃圾无氧热解灵活性耦合处置工艺路线如图1所示。生活垃圾就近运输至垃圾处理厂垃圾储池储存,简单破碎后送入干燥窑炉和热解窑炉干燥和热解,生成的热解油气一部分送入燃煤锅炉燃烧,为避免热解油气在管道运输过程中发生沉积、结焦和堵塞,沿程抽取锅炉烟气为伴热保证油气温度始终在300 ℃以上。另一部分进入热风炉燃烧,利用热风炉中高温烟气为热解和干化提供热量,最终从干燥窑炉出来的烟气重新送进锅炉燃烧。残余固态物质经磁选、涡选后分离回收其中金属,再通过玻选将破碎玻璃片分离,筛选后收集剩余的垃圾炭。垃圾炭可与煤粉混合送入锅炉中燃烧发电。考虑燃煤机组可能存在停机检修问题,工艺路线也可灵活调整,热解油气不再分为2部分,而是全部送入热风炉燃烧,为垃圾热解干化提供能量,从而保证垃圾处理系统独立运行,不受燃煤机组影响。

图1 燃煤火电机组耦合生活垃圾无氧热解灵活性处置工艺路线

Fig.1 Process route for flexible disposal of anaerobic pyrolysis of domestic waste coupled with coal-fired thermal power units

1.2 现场试验

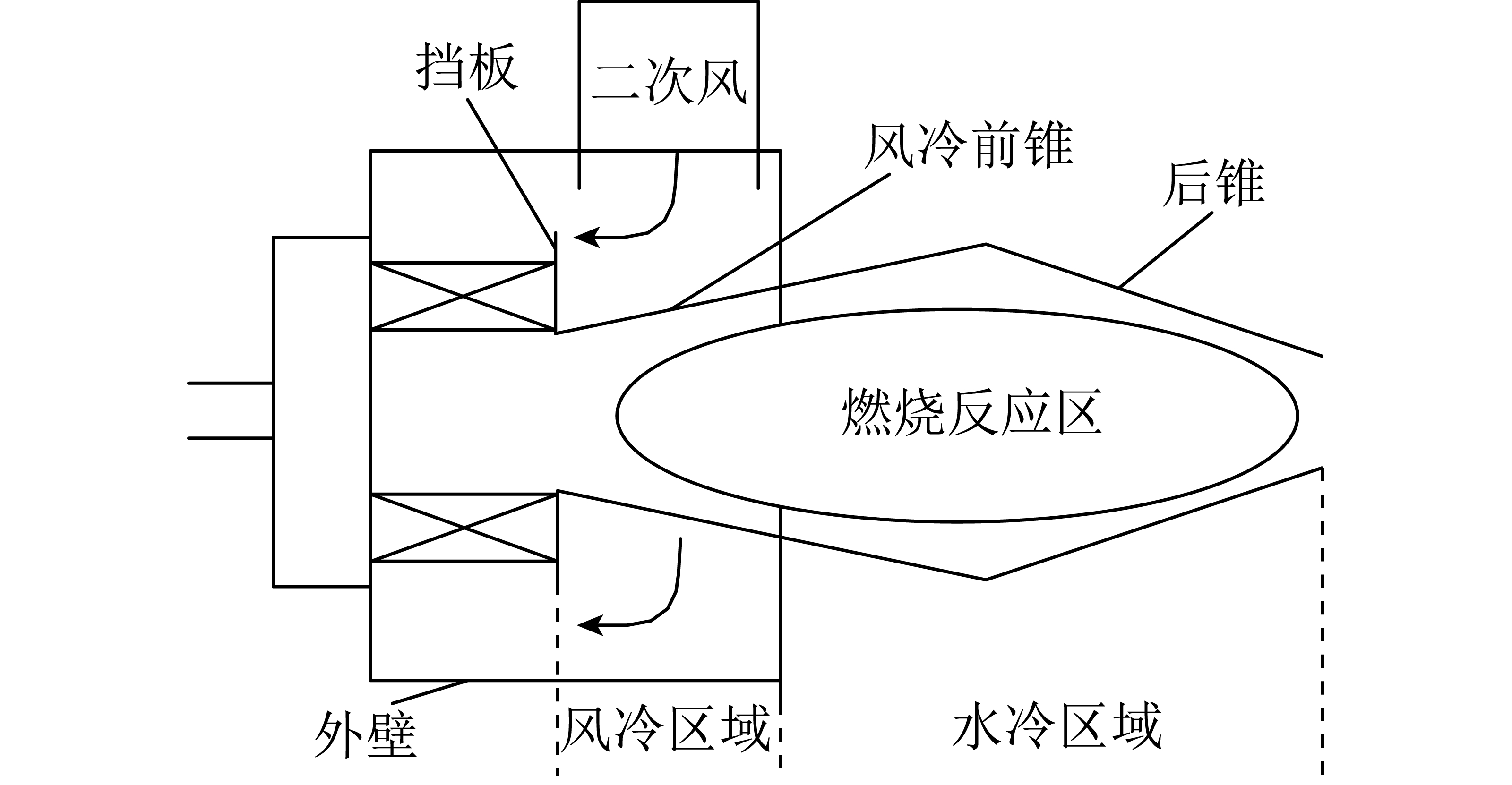

本文为示范性研究,将长期工业化运行的200 t/d垃圾无氧热解示范项目得到的富集氯的垃圾热解炭运输到2×55 MW燃煤火电机组现场进行耦合掺烧,并测试二噁英排放特性。200 t/d垃圾无氧热解现场运行照片如图2所示,其中生活垃圾无氧热解装置利用生活垃圾热解产生的热解油气燃烧为整个系统供热,同时产生垃圾炭;垃圾炭经破碎后再与煤粉按照一定比例掺混进入锅炉燃烧发电。有关垃圾无氧热解工艺介绍可参考文献[33]。目前该试验系统运行良好,部分处理产物如垃圾中铁、铜、铝等金属可直接回收利用。

图2 现场运行设备

Fig.2 On-site operating equipment

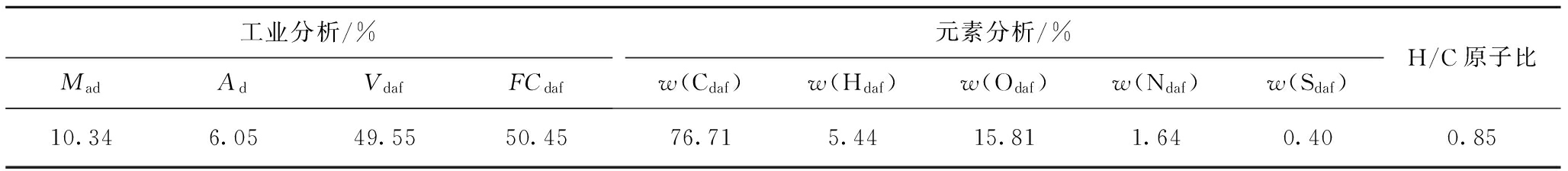

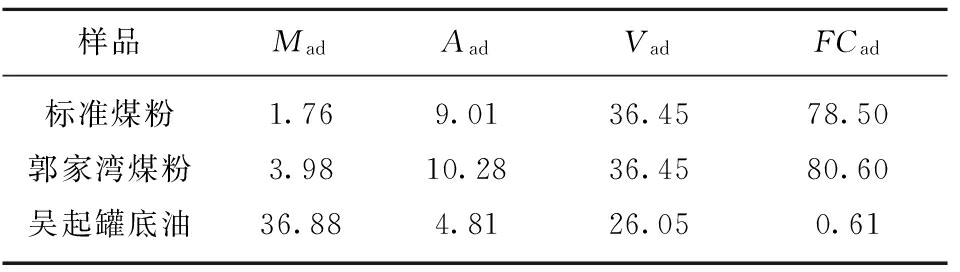

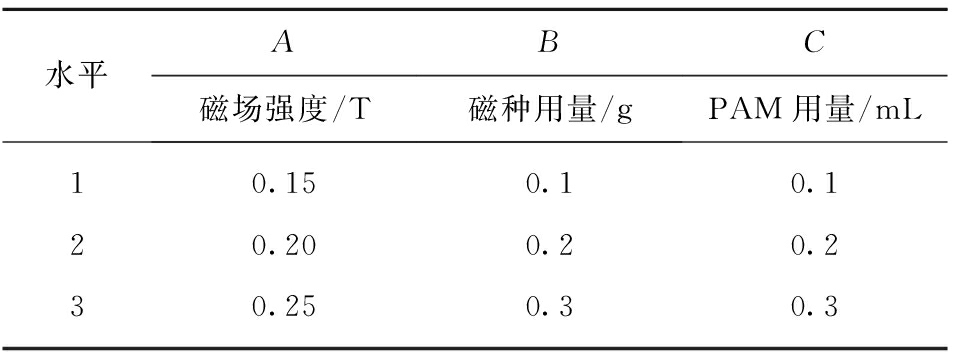

试验煤粉和生活垃圾的工业分析和元素分析见表1,其中生活垃圾Mad为55%,锅炉所用的煤粉为劣质煤,Mad为1.93%。干燥窑炉温度控制在120~200 ℃,热解窑炉温度在350~450 ℃。热解过程固相产率在25%~30%。现场试验时生活垃圾处理量为200 t/d,生活垃圾耦合比为4%。试验过程中对生活垃圾热解的气液相产物进行现场取样分析,收集燃煤机组产生的飞灰和烟气,测定二噁英含量。

表1 煤粉和生活垃圾的燃料特性

Table 1 Fuel properties of pulverized coal and domestic waste

注:*表示由差减法获得。

1.3 二噁英测定

考虑到富氯垃圾炭耦合焚烧后潜在的二噁英排放,试验将烟气取样位置选在终端烟囱出口处,飞灰取样位置在炉膛后半段。本次采样测试委托陕西省环保集团测试,分别检测纯烧燃煤和垃圾耦合比4%时的燃煤锅炉烟气和飞灰中二噁英含量。烟气中二噁英采样和检测方法按照HJ 77.2—2008《环境空气和废气 二噁英类的测定 同位素稀释高分辨气相色谱-高分辨质谱法》进行,飞灰中二噁英采样和检测方法按照HJ 77.3—2008《固体废物 二噁英类的测定 同位素稀释高分辨气相色谱-高分辨质谱法》进行。现场采样装置为ZR-3720废气采样器,其中的石英纤维滤膜和吸附材料聚氨基甲酸乙酯泡沫(PUF)可对烟气和飞灰进行过滤和吸附。

2 结果与讨论

2.1 垃圾热解产物分析

生活垃圾热解气体成分见表2,焦油成分见表3。热解气体主要组成为H2O、H2、CO、CO2、CH4和C2H4。焦油元素组成以C为主,其次为O和H,Cl质量分数仅为0.09%。

表2 热解气体成分

Table 2 Pyrolysis gas composition %

表3 焦油成分

Table 3 Tar composition %

生活垃圾热解产生的垃圾炭的工业分析和灰成分分析见表4、5,可知垃圾炭品质较好,其热值为9.41 MJ/kg。同时垃圾炭中氯含量很高,达到7.35%,说明热解过程中生活垃圾中氯大部分被富集在垃圾炭中。

表4 垃圾炭的燃料特性

Table 4 Fuel properties of waste charcoal

注:*表示由差减法获得。

表5 垃圾炭灰分组成

Table 5 Ash composition of waste charcoal %

2.2 垃圾热解油气燃烧的二噁英排放

试验测得生活垃圾无氧热解系统排烟的二噁英质量浓度为0.11 ng/m3(以TEQ计,下同),出口烟气流速为17 372 m3/h,以该2×55 MW机组燃煤锅炉为基准进行耦合计算,锅炉负荷为35 t/h,炉膛出口氧量为4%。假设标准工况下烟气密度为1.34 kg/m3(标况下,下同),则锅炉烟气量约2.48×105 m3/h(标况下,下同)。在垃圾无氧热解协同处置系统中,若热解系统烟气全部通入燃煤锅炉,在煤粉锅炉1 300 ℃以上高温灼烧下烟气中二噁英会分解大部分,即使假设其不会减少,则无氧热解系统烟气对最终煤粉锅炉烟气形成的新增二噁英质量浓度也仅为0.007 7 ng/m3。相关研究表明,二噁英在850 ℃以上保留时间超过2 s分解率达99.99%以上[34-35]。但在炉膛低温换热区二噁英还会重新合成,尤其在250~450 ℃[36-37],生成量占二噁英总生成量的70%以上[35]。考虑到二噁英在高温下分解和低温下重新合成,假设二噁英重新生成比为70%,则二噁英实际新增量应在0~5.4×10-3 ng/m3。

2.3 生活垃圾耦合试验的二噁英排放

按照图1工艺路线进行生活垃圾耦合掺烧试验和煤粉纯烧试验,生活垃圾耦合比为4%,并测试最终烟囱排放的烟气和飞灰中二噁英含量,测试结果如图3~5所示。煤粉纯烧时,烟气中二噁英主要组成为2,3,7,8-T4CDF和1,2,3,4,6,7,8-H7CDF,毒性贡献最大为2,3,7,8-T4CDF和2,3,4,7,8-P5CDF;飞灰中二噁英含量最多为1,2,3,4,6,7,8-H7CDF,毒性贡献最大为2,3,4,7,8-P5CDF。掺烧生活垃圾时,烟气中2,3,7,8-T4CDF含量明显增多,1,2,3,4,6,7,8-H7CDF含量减少。毒性贡献最大仍为2,3,7,8-T4CDF和2,3,4,7,8-P5CDF。飞灰中二噁英主要组成为1,2,3,4,6,7,8-H7CDF,相比煤粉纯燃烧,二噁英含量有所减少。相应地,飞灰中二噁英毒性也有所下降。

图3 烟气中二噁英的实测浓度与毒性当量浓度

Fig.3 Measured concentration and toxic equivalent concentration of dioxins in flue gas

图4 飞灰中二噁英的实测浓度与毒性当量浓度

Fig.4 Measured concentration and toxic equivalent concentration of dioxins in fly ash

图5 不同工况下烟气中二噁英含量

Fig.5 Dioxins content in flue gas under different working conditions

不同工况下烟气中二噁英含量(其中热解油气纯烧的二噁英排放考虑二噁英再生成作用取得最大值)如图5所示。煤粉纯烧时,测得烟气中二噁英总质量浓度为6.05×10-3 ng/m3;掺烧4%垃圾时,烟气中二噁英总质量浓度为5.34×10-3 ng/m3,二噁英总量在掺烧前后无明显变化,加上热风炉烟气进入锅炉带来的新增二噁英,二噁英最大总质量浓度分别为1.145×10-2、1.074×10-2 ng/m3,仍满足GB 18485—2014《生活垃圾焚烧污染控制标准》规定的0.1 ng/m3限值要求,且低于最新出台的上海市地方标准DB 31/1291—2021《燃煤耦合污泥电厂大气污染物排放标准》中规定的二噁英排放量0.02 ng/m3。

正常垃圾焚烧炉烟气中二噁英质量浓度为0.013~0.100 ng/m3。煤粉纯烧时,飞灰中二噁英总质量分数为2.77 ng/kg;掺烧4%垃圾时,飞灰中二噁英总质量分数为1.30 ng/kg,掺烧生活垃圾后飞灰中二噁英含量减少。这与马瀚程等[31]研究结果一致,黄晨等[38]研究表明在燃煤锅炉中掺烧少量生活垃圾,烟气和飞灰中二噁英含量不会增加,但掺烧比超过20%时,二噁英含量明显增加。陆胜勇等[39]通过引入二噁英质量平衡方法,发现垃圾与煤在流化床焚烧炉内混烧能较大程度破环原生垃圾中二噁英。LU等[40-41]在实际条件和实际焚烧炉中发现生活垃圾与煤混烧可减少二噁英生成。

相关研究[42]表明,煤粉掺烧垃圾能降低二噁英生成主要是由于煤中硫物质的作用,煤与垃圾掺烧产生大量SO2,从而抑制二噁英生成。SO2抑制二噁英生成机理有:① SO2将生成二噁英的主要物质Cl2还原为HCl[43-44];② 使参与二噁英再生成反应的催化剂中毒[45-47];③ 使二噁英前驱物硫酸化[48]。试验煤种干基含硫量为2.16%,属于高硫煤,烟气中SO2质量浓度约3 464.64 mg/m3[49],远高于正常锅炉烟气中SO2浓度,掺烧垃圾过程中会抑制二噁英生成。因此掺烧4%垃圾时烟气和飞灰中二噁英含量均小于煤粉。但随垃圾掺混比例增加,煤占比减少,混合物热值降低,炉膛温度下降,二噁英等不完全燃烧产物生成量继续增加[50]。因此生活垃圾掺烧比例不能太大,利用本工艺路线按照掺混比4%协同处理生活垃圾对烟气和飞灰中二噁英排放量影响不大。

3 结 论

1)针对生活垃圾处理,提出了一种新的生活垃圾无氧热解灵活性耦合协同处置工艺方案,可实现生活垃圾协同处置,燃煤机组停炉检修时,仍能保证系统自平衡正常运行。

2)生活垃圾热解气体主要组成为H2、CO、CH4、CO2等,焦油中Cl含量很低,Cl主要富集在垃圾炭中。

3)基于提出的工艺方案,在国内某2×55 MW燃煤机组上开展垃圾热解产物耦合现场试验,重点测试该燃煤机组二噁英生成排放特性,结果表明,利用本工艺路线处理垃圾产生的二噁英含量远低于垃圾直接焚烧产生的二噁英含量。煤粉纯烧时,烟气中二噁英最大总质量浓度为1.145×10-2 ng/m3(以TEQ计,下同);垃圾掺烧比为4%时,烟气中二噁英最大总质量浓度为1.074×10-2 ng/m3,均满足排放标准。

[1] KHANDELWAL Harshit, DHAR Hiya, THALLA Arun Kumar, et al. Application of life cycle assessment in municipal solid waste management: A worldwide critical review[J]. Journal of Cleaner Production, 2019, 209: 630-654.

[2] 李扬, 李金惠, 谭全银,等. 我国城市生活垃圾处理行业发展与驱动力分析[J]. 中国环境科学, 2018, 38 (11): 4173-4179.

LI Yang, LI Jinhui, TAN Quanyin, et al. Development course and driving force of municipal solid waste disposal industryin China[J]. China Environmental Science, 2018, 38 (11): 4173-4179.

[3] HE Jiaxin, LIN Boqiang. Assessment of waste incineration power with considerations of subsidies and emissions in China[J]. Energy Policy, 2019, 126: 190-199.

[4] FERNANDEZ-GONZALEZ J M,GRINDLAY A L, SERRANO-BERNARDO F, et al. Economic and environmental review of waste-to-energy systems for municipal solid waste management in medium and small municipalities[J]. Waste Management, 2017, 67: 360-374.

[5] ZHOU Zhaozhi, CHI Yong, DONG Jun, et al. Model development of sustainability assessment from a life cycle perspective: A case study on waste management systems in China[J]. Journal of Cleaner Production, 2019, 210: 1005-1014.

[6] LOMBARDI L, CARNEVALE E, CORTI A. A review of technologies and performances of thermal treatment systems for energy recovery from waste[J]. Waste Management, 2015, 37: 26-44.

[7] 李文瀚, 马增益, 杨恩权,等. 循环流化床垃圾焚烧系统电除尘飞灰和布袋飞灰特性研究[J]. 中国电机工程学报, 2019, 39 (5): 1397-1405.

LI Wenhan, MA Zengyi, YANG Enquan, et al. Characteristics of electrostatic precipitator ash and bag filter ash from a circulating fluidized bed municipal solid waste incinerator[J]. Proceedings of the CSEE, 2019, 39 (5): 1397-1405.

[8] 国家发展和改革委员会, 住房城乡建设部. “十四五”城镇生活垃圾分类和处理设施发展规划[EB/OL].(2021-05-06)[2022-11-25].https://m.thepaper.cn/baijiahao_12851474.

[9] SU X W, ZHANG L, XIAO Y X, et al. Evaluation of a flue gas

cleaning system of a circulating fluidized bed incineration power plant by the analysis of pollutant emissions[J]. Powder Technology, 2015, 286: 9-15.

[10] 吴剑, 蹇瑞欢, 刘涛. 我国生活垃圾焚烧发电厂的能效水平研究[J]. 环境卫生工程, 2018, 26(3): 39-42.

WU Jian, JIAN Ruihuan, LIU Tao. Research on energy efficiency of municipal solid waste incineration plant in China[J]. Environmental Sanitation Engineering, 2018, 26 (3):39-42.

[11] LOMBARDI L, CARNEVALE E, CORTI A. A review of technologies and performances of thermal treatment systems for energy recovery from waste[J]. Waste Management, 2015, 37: 26-44.

[12] SINGH K, HACHEM-VERMETTE C. Influence of mixed-use neighborhood developments on the performance of waste-to-energy CHP plant[J]. Energy, 2019, 189: 116172.

[13] 王飞, 张盛, 王丽花. 燃煤耦合污泥焚烧发电技术研究进展[J]. 洁净煤技术, 2022, 28(3): 82-94.

WANG Fei, ZHANG Sheng, WANG Lihua. Research progress of coal-fired coupled sludge incineration power generation technology[J]. Clean Coal Technology, 2022, 28(3): 82-94.

[14] 李源, 郭志成, 赵鑫平,等. 燃煤机组耦合蒸气干化污泥能耗特性试验[J]. 洁净煤技术, 2022, 28 (3): 95-101.

LI Yuan, GUO Zhicheng, ZHAO Xinping, et al. Experiment of energy consumption characteristic in a coal-fired power unit coupled with steam desiccation sludge[J]. Clean Coal Technology, 2022, 28(3): 95-101.

[15] 杨卧龙, 倪煜, 雷鸿. 燃煤电站生物质直接耦合燃烧发电技术研究综述[J]. 热力发电, 2021, 50(2): 18-25.

YANG Wolong, NI Yu, LEI Hong. Biomass direct coupled combustion power generation technology for coal fired power station: A review[J]. Thermal Power Generation, 2021, 50(2): 18-25.

[16] 云慧敏, 代建军, 李辉,等. 生物质耦合燃煤发电经济环境效益评估[J]. 化工学报, 2021, 72 (12): 6311-6327.

YUN Huimin, DAI Jianjun, LI Hui, et al. Economic and environmental assessment of biomass coupled coal-fired power generation[J]. CIESC Journal, 2021, 72 (12): 6311-6327.

[17] 郭慧娜, 吴玉新, 王学斌,等. 燃煤机组耦合农林生物质发电技术现状及展望[J]. 洁净煤技术, 2022, 28 (3): 12-22.

GUO Huina, WU Yuxin, WANG Xuebin, et al. Current status of power generation technology of the agriculture and forest biomass co-firing in coal-fired power plants[J]. Clean Coal Technology, 2022, 28 (3): 12-22.

[18] 王一坤, 贾兆鹏, 魏星,等. 燃煤电站耦合生活垃圾发电技术研究[J]. 热力发电, 2021, 50(11): 83-92.

WANG Yikun, JIA Zhaopeng, WEI Xing, et al. Study on power generation technology of coal-fired power station coupled with domestic waste[J]. Thermal Power Generation, 2021, 50 (11): 83-92.

[19] 哈锅之声.哈锅燃煤耦合垃圾发电技术率先通过国家能源局评审[EB/OL].(2017-12-08)[2022-11-25].https://huanbao.bjx.com.cn/news/20171208/866390.shtml.

[20] 史兵权, 史明哲, 张睿. 220 t/h锅炉烟气侧耦合垃圾焚烧数值模拟[J]. 洁净煤技术, 2022, 28(3): 150-158.

SHI Bingquan, SHI Zhiming, ZHANG Rui. Numerical simulation of flue gas side coupled municipal solid waste incineration in a 220 t/h boiler[J]. Clean Coal Technology, 2022, 28(3): 150-158.

[21] 谢丰, 王云刚, 颜枫,等. 生活垃圾焚烧过程中二噁英抑制剂研究进展[J]. 环境工程, 2022, 40(7): 222-231,247.

XIE Feng, WANG Yungang, YAN Feng, et al. Research progress of dioxin inhibitors for municipal solid waste incineration[J]. Environmental Engineering, 2022, 40(7): 222-231,247.

[22] TUPPURAINEN K, ASIKAINEN A, RUOKOJARVI P, et al. Perspectives on the formation of polychlorinated dibenzo-p-dioxins and dibenzofurans during municipal solid waste (MSW) incineration and other combustion processes[J]. Accounts of Chemical Research, 2003, 36 (9): 652-658.

[23] WEBER R, HAGENMAIER H. PCDD/PCDF formation in fluidized bed incineration[J]. Chemosphere, 1999, 38 (11): 2643-2654.

[24] STANMORE B R. The formation of dioxins in combustion systems[J]. Combustion and Flame, 2004, 136 (3): 398-427.

[25] NGANAI S, DELLINGER B, LOMNICKI S. PCDD/PCDF ratio in the precursor formation model over cuo surface[J]. Environmental Science & Technology, 2014, 48 (23): 13864-13870.

[26] ADDINK R, GOVERS H A J, OLIE K. Isomer distributions of polychlorinated dibenzo-p-dioxins/dibenzofurans formed during de novo synthesis on incinerator fly ash[J]. Environmental Science & Technology, 1998, 32 (13): 1888-1893.

[27] OOI T C, LU L M. Formation and mitigation of PCDD/Fs in iron ore sintering[J]. Chemosphere, 2011, 85 (3): 291-299.

[28] HSIEH Y K, CHEN W S, ZHU J N, et al. Healthrisk assessment and correlation analysis on PCDD/Fs in the fly ash from a municipal solid waste incineration plant[J]. Aerosol and Air Quality Research, 2018, 18 (3): 734-748.

[29] TANG Z W, HUANG Q F, YANG Y F. PCDD/Fs infly ash from waste incineration in China: A need for effective risk management[J]. Environmental Science & Technology, 2013, 47 (11): 5520-5521.

[30] 陈怀俊, 牛芳, 王乃继. 垃圾焚烧处置中二噁英和重金属污染控制技术进展[J]. 洁净煤技术, 2021, 27 (6): 59-75.

CHEN Huijun, NIU Fang, WANG Naiji. Research progress of dioxins and heavy metal pollution control technology in MSWI[J]. Clean Coal Technology, 2021, 27 (6): 59-75.

[31] 马瀚程, 詹明秀, 蔡鹏涛,等. 燃煤耦合垃圾焚烧灰渣的二噁英再合成实验研究[J]. 煤炭转化, 2020, 43 (6): 84-94.

MA Hancheng, ZHAN Mingxiu, CAI Pengtao, et al, Experimental study on dioxin re-synthesis of coal-fired coupled with waste incineration[J]. Coal Conversion, 2020, 43 (6): 84-94.

[32] 吕家扬, 林颖, 蔡凤珊,等. 市政污泥与生活垃圾协同焚烧的二噁英排放特征及毒性当量平衡[J]. 华南师范大学学报(自然科学版), 2020, 52(5): 31-40.

LU Jiayang, LIN Ying, CAI Fengshan, et al. PCDD/Fs emission and toxic equivalent balance of municipal sewage sludge cocombustion in a solid waste incinerator[J]. Journal of South China Normal University(Natural Science Edition), 2020, 52(5): 31-40.

[33] 王学斌, 周澳, 杨明辉,等. 燃煤电厂200 t/d生活垃圾无氧热解耦合协同处置优化研究[J]. 煤炭学报, 2022, 47(11): 3897-3905.

WANG Xuebin, ZHOU Ao, YANG Minghui, et al. Optimization study on 200 t/d garbage co-utilization in a coal-fired power plant through air-free pyrolysis process[J]. Journal of China Coal Society,2022,47(11):3897-3905.

[34] 罗国鹏, 张凯, 王进进,等. 垃圾焚烧炉二恶英排放的控制策略及催化塔的记忆效应[J]. 环境工程学报, 2022, 16 (7): 2241-2248.

LUO Guopeng, ZHANG Kai, WANG Jinjin, et al. Dioxin emission control of waste incinerator and memeory effect of catalytic tower[J]. Chinese Journal of Environmental Engineering, 2022, 16 (7): 2241-2248.

[35] 钱原吉, 吴占松. 生活垃圾焚烧炉中二噁英的生成和计算方法[J]. 动力工程, 2007, 27(4): 616-619.

QIAN Yuanji, WU Zhansong. Genesis of dioxin in garbage incinerators and a way of calculating its formation[J]. Journal of Power Engineering, 2007, 27(4): 616-619.

[36] EVERAERT K, BAEYENS J. The formation and emission of dio-xins in large scale thermal processes[J]. Chemosphere, 2002, 46 (3): 439-448.

[37] SONG G J, KIM S H, SEO Y C, et al. Dechlorination and destruction of PCDDs/PCDFs in fly ashes from municipal solid waste incinerators by low temperature thermal treatment[J]. Chemosphere, 2008, 71(2):248-257.

[38] 黄晨, 林晓青, 黄素华,等. 煤粉与生活垃圾共燃污染物排放特性实验研究[J]. 锅炉技术, 2018, 49(3): 69-73.

HUANG Chen, LIN Xiaoqing, HUANG Suhua, et al. The experimental study on pollution emission of mixed combustion of coal and garbage[J]. Boiler Technology, 2018, 49(3): 69-73.

[39] 陆胜勇, 吴海龙, 陈彤,等. 垃圾和煤混烧流化床焚烧炉的二恶英排放质量平衡[J]. 浙江大学学报(工学版), 2011, 45(12): 2188-2195.

LU Shengyong, WU Hailong, CHEN Tong, et al. Dioxin mass balance in fluidized ben incinerator co-firing municipal solid waste and coal[J]. Journal of Zhejiang University(Engineering Science), 2011, 45(12): 2188-2195.

[40] LU S Y, YAN J H, LI X D, et al. Laboratory-scale study of the suppression of PCDD/F emission during coal and MSW co-incineration[J]. Journal of Environmental Sciences, 2007, 19 (6):762-767.

[41] YAN J H, CHEN T, LI X D,et al. Evaluation of PCDD/Fs emission from fluidized bed incinerators co-firing MSW with coal in China[J].Journal of Hazardous Materials,2006,135(1/3): 47-51.

[42] ADDINK R, OLIE K. Mechanisms of formation and destruction of polychlorinated dibenzo-p-dioxins and dibenzofurans in heterogeneous systems[J]. Environmental Science & Technology, 1995, 29(6): 1425-1435.

[43] GRIFFIN R D. A new theory of dioxin formation in municipal solid-waste combustion[J]. Chemosphere, 1986, 15 (9/12):1987-1990.

[44] RAGHUNATHAN K, GULLETT B K. Role of sulfur in reducing PCDD and PCDF formation[J]. Environmental Science & Technology, 1996, 30 (6): 1827-1834.

[45] GULLETT B K, BRUCE K R, BEACH L O. Effect of sulfur-dioxide on the formation mechanism of polychlorinated dibenzodioxin and dibenzofuran in municipal waste combustors[J]. Environmental Science & Technology, 1992, 26 (10): 1938-1943.

[46] RYAN S P, LI X D, GULLETT B K, et al. Experimental study on the effect of SO2 on PCDD/F emissions: Determination of the importance of gas-phase versus solid-phase reactions in PCDD/F formation[J]. Environmental Science & Technology, 2006, 40 (22): 7040-7047.

[47] SHAO K, YAN J H, LI X D, et al. Inhibition of de novo synthesis of PCDD/Fs by SO2 in a model system[J]. Chemosphere, 2010,78 (10): 1230-1235.

[48] BUSER H R. Identification and sources of dioxin-like comp-ounds.1.Polychlorodibenzothiophenes and polychlorothianth-renes, the sulfur-analogs of the polychlorodibenzofurans and polychlorodibenzodioxins[J]. Chemosphere, 1992,25(1/2): 45-48.

[49] 苏丽清, 李美芬, 綦延波,等. 煤中可燃硫与烟气中SO2含量关系探讨[J]. 煤质技术, 2000(2): 30-32.

SU Liqing, LI Meifen, QI Yanbo, et al. Discussion on the relationship between combustible sulfur in coal and SO2 content in flue gas[J]. Coal Quality Technology, 2000(2):30-32.

[50] 李晓东, 尹雪峰, 陆胜勇,等. 原生垃圾和煤混烧时多环芳烃和二噁英的生成关联[J]. 工程热物理学报, 2006,27(4): 691-694.

LI Xiaodong, YIN Xuefeng, LU Shengyong, et al. The correlation between PAHs an dioxin formation during coal and municipal solid waste co-incineration process[J]. Journal of Engineering Thermophysics, 2006, 27(4): 691-694.

Experiment of co-disposal of domestic waste and dioxins emission in coal-fired power plants

WANG Xuebin,ZHOU Ao,MA Jiangdong,et al.Experiment of co-disposal of domestic waste and dioxins emission in coal-fired power plants[J].Clean Coal Technology,2023,29(1):161-168.