专家述评

张守玉 教授

上海理工大学

张守玉,上海理工大学能源与动力工程学院教授、博士生导师,《洁净煤技术》《热能动力工程》《煤炭转化》《煤化工》等期刊编委。主要研究方向为生物质成型燃料制备等综合利用、锅炉灵活性研究及高碱煤燃烧沾污结渣等。曾获上海市启明星人才项目资助,作为项目负责人主持上海市自然科学基金、上海市地方高校建设项目等上海市科委的科研项目,作为学术骨干参与了国家重点基础研究规划项目(973)及“十二五”国家科技支撑计划项目等多项国家级科研项目。迄今共发表论文200余篇,其中SCI收录30余篇,Ei收录80余篇,获批发明专利6项。

水热处理畜禽粪便制生物燃料研究进展

0 引 言

随着国民经济的不断发展及居民生活水平的逐步提高,我国畜禽养殖业正向大规模工业化生产体系转变[1]。国家统计局数据显示,2021年我国畜牧业总产值约为3.99万亿元,较2012年提高了约50.6%[2]。畜牧业的快速发展导致粪便大量、集中产生,农业部数据显示,我国畜禽粪污的年产生量约38亿t,其中生猪、牛和家禽的粪污产量分别约18亿、14亿和6亿t,分别约占畜禽粪污总量的47%、37%和16%[3]。畜禽粪便中含有大量的重金属和抗生素,将其直接回田易造成重金属和抗生素在土壤及植物体内富集,危害环境的同时也会通过食物链威胁人体健康[4]。同时,我国畜禽养殖与农业种植主体分离,不利于畜禽粪便的回田利用。

畜禽粪便的传统处理方式包括好氧堆肥、厌氧发酵、焚烧、热解等。畜禽粪便中高浓度的重金属会抑制好氧堆肥和厌氧发酵过程中微生物和酶的活性,导致处理效果较差[5-6]。此外,畜禽粪便中的抗生素在好氧堆肥及厌氧发酵过程中降解缓慢且降解情况较差[7-8]。焚烧、热解等技术处理畜禽粪便等高含水率的生物质时,前期需投入大量能量对其进行干燥处理,经济效益较差[9]。

水热处理技术是指在高压反应釜中,在一定温度下(180~260 ℃)以水为反应媒介处理生物质[10],可将高含水率的畜禽粪便类生物质转化为一种类似褐煤的生物燃料,有助于实现生物质在能源方面更广泛应用[9]。以燃煤锅炉为主的发电行业是我国CO2的最大排放来源,将生物燃料应用于发电行业,可有效降低燃煤电厂的CO2排放量,加快我国实现碳中和目标[11]。RO等[12]对基于动物粪便水热炭的燃烧行为研究后发现,燃煤锅炉中小比例掺烧动物粪便水热炭(10%的水热炭与90%的煤混合)与单独烧煤具有相似的燃烧特性。此外,水热处理还可固化并钝化重金属,并在短时间内降解几乎所有的抗生素[13-14],降低了畜禽粪便对环境的潜在污染风险。

目前,水热处理畜禽粪便制生物燃料的研究和发展总结较少,笔者以产出集中且产量最大的猪粪为代表,概述其主要组分及理化性质,讨论了传统处理方式的缺陷,进而着重介绍猪粪的水热处理方式,分析水热残渣的产率、燃烧特性及脱水性能,最后探讨水热残渣作生物燃料的应用前景,旨在为水热处理技术解决畜禽粪便能源化、无害化利用问题上提供新的研究思路。

1 猪粪组分及理化性质

1.1 猪粪组分

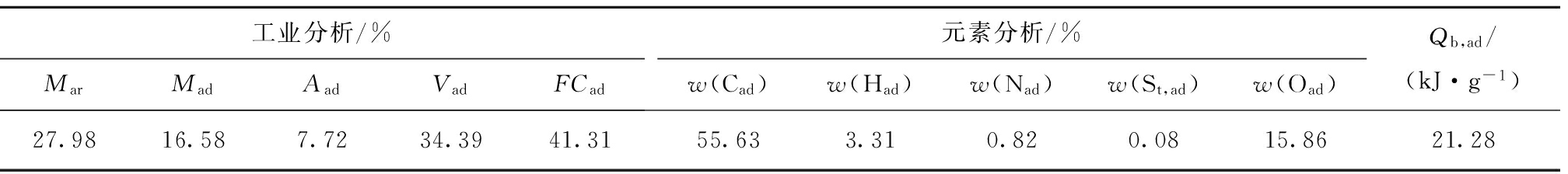

猪粪中的主要成分分析[15-18]及养分含量[19-22]见表1和2。

表1 猪粪中主要成分分析(干基)[15-18]

Table 1 Main composition analysis of swine manure(dry matter)[15-18]

表2 猪粪中主要养分分析(干基)[19-22]

Table 2 Main nutrients analysis of swine manure(dry matter) [19-22]

畜禽养殖场会在饲料中添加一定量的微量元素和抗生素,以提高畜禽的生长速率和抗病能力。畜禽粪便中的重金属(锌、铜)主要来自饲料中的微量元素添加剂[23]。猪粪中主要重金属及抗生素含量见表3和4。我国尚未规定猪粪及其肥料产品中重金属的标准限值,根据德国腐熟堆肥标准[24],猪粪中的锌、铜分别超标了72%~240%、217%~886%。兽药国际协调委员会认为土壤中抗生素生态毒害效应的触发值为0.1 mg/kg[25]。因此,猪粪直接回田会带来严重的潜在环境风险。

表3 猪粪中主要重金属分析[26-29]

Table 3 Main heavy metals analysis of swine manure[26-29]

表4 猪粪中主要抗生素分析[30-33]

Table 4 Main antibiotics analysis of swine manure[30-33]

1.2 猪粪理化性质

猪粪的理化性质见表5。MAU等[34]研究发现,电导率(Electro Conductibility,EC)与盐分含量相关,过高的盐分不利于植物生长,当EC为1.30 mS/cm左右时最合适。化学需氧量(Chemical Oxygen Demand,COD)是评价水质的重要指标,GB 18596—2001《畜禽养殖业污染物排放标准》[35]中规定了集约化畜禽养殖业水污染物的COD最高允许日均排放质量浓度为400 mg/L。

表5 猪粪基本理化性质[19-20,22,26,32,36-37]

Table 5 Physical and chemical properties of swine manure[19-20,22,26,32,36-37]

注:a干燥基。

2 猪粪传统处理方式

2.1 好氧堆肥技术

HAO等[38]研究发现,粪便中约一半的碳、氮等资源在好氧堆肥过程中以温室及有害气体排放到周围空气中,环境友好性及可持续性较低。HE等[39]研究发现,堆肥适温期时,由于重金属随淋溶液流出导致猪粪中重金属锌和铜总量均降低。此外,GUO等[5]研究了不同铜质量分数(300、600、900 mg/kg)对猪粪堆肥过程中微生物代谢的影响,较高的铜含量会对微生物的代谢能力产生抑制作用,且随着铜含量的增加,抑制作用增强,不利于微生物群落对复杂大分子碳源的利用,导致猪粪好氧堆肥效果较差。腐熟肥料中未被降解的抗生素对环境存在污染风险,BAO等[40]研究发现,金霉素在猪粪堆肥过程中的降解率仅为27%。

2.2 厌氧发酵技术

ALVAREZ等[41]研究了四环素类抗生素对猪粪中温厌氧发酵后甲烷产量的影响,10~100 mg/L的土霉素和金霉素会使甲烷产量减少56%~62%。BENABDALLAH等[42]研究发现,猪粪厌氧发酵过程中产生的氨气会抑制厌氧发酵的进行,进而导致发酵效果较差。含抗生素沼液的回田利用易引起抗生素耐药基因的传播,并通过食物链对人类健康造成潜在危害。

综上,由于好氧堆肥及厌氧发酵技术的诸多缺陷,近年来水热处理技术在畜禽粪便等高含水率生物质废弃物处理问题上的应用逐步得到关注[27-28,37,43]。水热处理技术不仅能实现水热产物的高值化利用[12,28,34,43-47],还有利于畜禽粪便的无害化处理[8,13-14,26]。

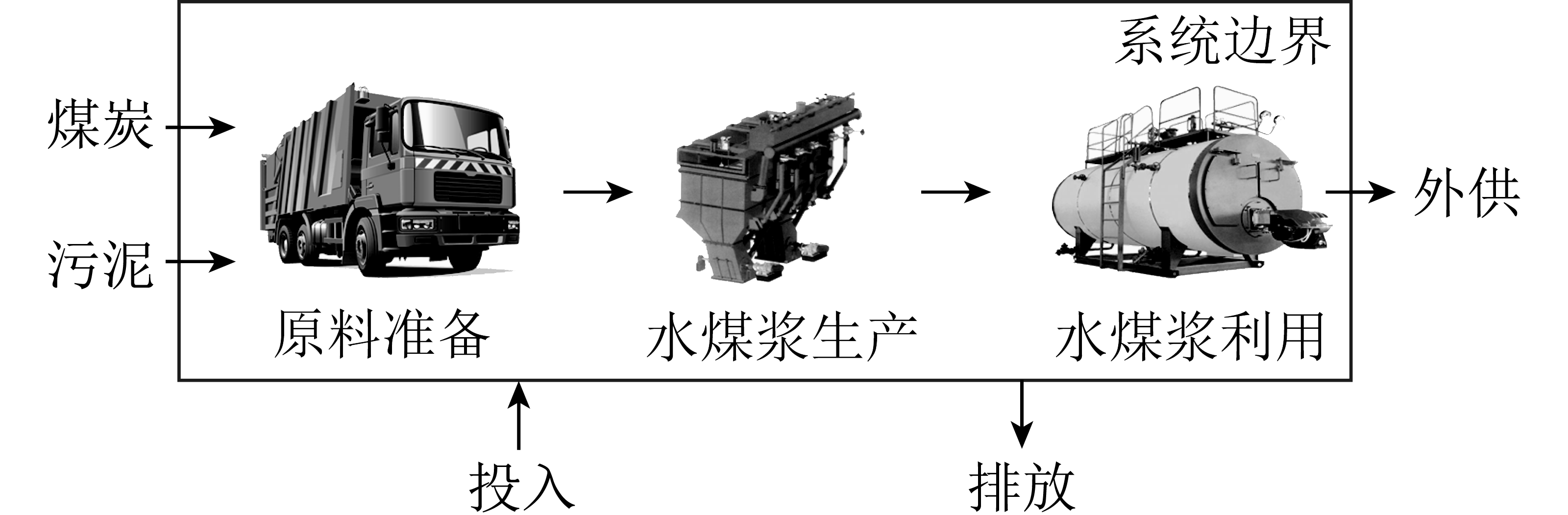

3 水热处理技术

水热处理已被证明是一种可有效将高含水率生物质废弃物转化为生物炭的技术手段[12,48-49],且温室气体排放量很少[50],但猪粪富含氮,水热过程可能会产生二氧化氮、一氧化氮和氨气等气体[22,51],对气相产物收集后管理,可显著降低其对环境的危害[52]。液相产物含有有机酸、酚类等化合物,与木醋液中的化合物种类相同或相似,精制后可作木醋液使用[53]。笔者基于猪粪主要成分,分析了猪粪水热处理后固、液产物可能的形成机制,如图1所示。

R1—水解反应;R2—脱水反应;R3—解聚反应;R4—异构化反应;R5—重排反应;R6—缩合反应;R7—直接炭化R8—反应;R9—脱氨反应;R10—脱羧反应;R11—熔解;R12—聚合反应;R13—表面扩散

图1 猪粪水热处理后固、液产物形成机制

Fig.1 Formation mechanism of solid and liquid products of swine manure after hydrothermal treatment

3.1 水热残渣产率及性质

3.1.1 水热残渣产率

猪粪水热残渣产率随水热温度升高呈下降趋势,如图2所示。在类似水热条件下,奶牛粪便和家禽粪便的水热残渣产率均低于猪粪水热残渣[22,54-55]。周思邈等[37]研究了温度对畜禽粪便水热残渣产率的影响,结果表明,生猪、奶牛和肉鸡水热残渣产率分别由180 ℃时的67.34%、64.55%和54.61%降至240 ℃时的54.30%、49.33%和45.83%。

图2 不同水热温度下猪粪水热残渣产率

Fig.2 Yield of residue of swine manure at different hydrothermal temperatures

水热处理过程中,粪便原料中的半纤维素、纤维素、木质素、蛋白质及脂类等成分会发生水解、解聚、脱水、脱氨、脱羧等反应,导致有机物的降解和溶解,形成液相及气相产物[9,56]。随水热温度升高,不溶性大分子降解更加充分,且过高的水热温度会导致水热残渣的二次降解,使残渣产率逐渐降低[57]。脂类和蛋白质在较低的水热温度下会依次发生水解,生成脂肪酸和氨基酸等水溶性化合物。半纤维素热稳定性低于纤维素和木质素,于180 ℃时开始发生解聚反应,当水热温度为200 ℃时,半纤维素中的b-(1-4)糖苷键断裂,形成低聚糖和单糖,进一步降解形成5-羟甲基糠醛等[58]。纤维素在水热过程中的分解路径与半纤维素类似,但纤维素分子内和分子间的氢键作用较强,使其热稳定性高于半纤维素[59]。当水热温度高于200 ℃时,纤维素开始分解为低聚物,初步水解产物发生脱水反应,糖苷键、C—O键及C—C键开始断裂,生成以5-羟甲基糠醛为主的中间产物[60]。木质素的空间结构最稳定,200 ℃时开始分解,木质素中的β—O—4键和C—C键最先断裂,而苯环结构上的其他化学键没有变化,生成单体和二聚体酚类化合物[61]。但由于芳香结构的热稳定性较高,木质素受水热处理影响较小,仅少量分解。

3.1.2 水热残渣燃烧特性及脱水性能

猪粪水热残渣的氢碳比和氧碳比均随水热反应的进行不断减小,在范式图中可达到褐煤区域[62]。TOUFIQ等[63]研究发现,水热过程会促进脱羟基和脱羧基反应的进行,大量氢、氧元素被脱除,富集碳元素。较低的挥发分与固定碳比值可提高水热残渣燃烧时的稳定性[64]。周思邈等[37]研究发现,猪粪水热残渣的挥发分含量与褐煤相当,且随水热温度升高,挥发分与固定碳比值逐渐降低。矿质元素和重金属元素的富集作用使水热残渣中灰分含量随水热温度升高而增加,但大量碱金属溶解进入残液中,提高了灰分的熔点,降低了水热残渣燃烧时的结渣风险[49]。GASCO等[65]将猪粪在200~240 ℃水热处理后发现,水热残渣的EC较猪粪原料降低约35%~65%。水热处理可提高猪粪的高位热值,LIU等[66]研究发现,水热处理过程中的脱水、脱羧反应使残渣中碳氢键、碳氧键等低键能化学键减少,而碳碳键等高能键增加,提高了水热残渣的高位热值。XIONG等[22]对猪粪在200~280 ℃水热处理后发现,水热残渣的高位热值随水热温度升高逐渐升高,由12.4 MJ/kg升至16.0 MJ/kg,可达到褐煤水准。

水热处理可提高猪粪水热残渣的着火温度,降低水热残渣贮存时潜在的火灾和爆炸风险,其原因可能是水热处理降低了水热残渣的挥发分产率及反应活性[67]。综合燃烧特性指数是反应样品燃烧特性的重要指标,数值越高,样品的燃烧特性越好[68]。周思邈等[37]研究发现,猪粪水热残渣的着火温度及综合燃烧特性指数随水热温度升高呈先升高后降低趋势,并在210 ℃取得最大,分别为273.91 ℃及5.32×10-7 %2/(min2·℃3),较猪粪原料分别提高了13.38%及13.68%。

猪粪中存在的水可大致分为自由水和结合水,前者经机械脱水后易脱除。提高水热残渣脱水性能的基本原则是将结合水尽可能多的转化为自由水。已有研究表明,水热处理技术能改善水热残渣的脱水性能[36,69-70]。ZHANG等[70]研究发现,水热处理通过破坏絮体和细胞结构,大量结合水被释放出来并以更易被机械脱水除去的自由水形式存在,从而改善了水热残渣的脱水性能。FERRENTINO等[36]对猪粪原料及猪粪水热残渣进行毛细吸水时间测试,评估脱水性能,结果表明,水热温度190 ℃下残渣的毛细吸水时间较猪粪原料缩短了约85.63%,排除总固体浓度的影响后,脱水时间缩短了83%。水热处理也可改善残渣的干燥性能,盛聪[26]研究发现,以水热残渣干燥到10%的含水率为基准,水热温度为200 ℃下得到的残渣需约75 min,干燥时间较猪粪原料缩短了约80%。综合考虑残渣的脱水性能和干燥性能,水热处理是一种极具前景的处置高含水率生物质废弃物的技术手段。

3.1.3 水热残渣重金属质量分数

随水热温度升高,猪粪水热残渣中重金属(锌、铜等)含量增多,表明水热处理对重金属有一定的富集作用,如图3所示。郑孟杰等[13]研究发现,水热残渣总质量随水热温度升高逐渐下降,使水热残渣中重金属的相对含量增加。水热处理还可降低残渣中重金属的浸出率及生态毒性,从而降低水热残渣利用时对环境的潜在风险。LU等[71]采用毒性浸出试验评估猪粪及其水热残渣中重金属的潜在风险,结果表明,水热温度为230 ℃下的残渣中锌和铜的可浸出浓度较猪粪原料分别降低了37.14%和90.88%。LANG等[72]对猪粪进行220 ℃水热处理后发现,残渣中锌和铜的浸出率较猪粪原料分别降低了80.10%和92.29%,且水热过程中氧化钙的加入可进一步降低重金属浸出率。

图3 猪粪原料和不同水热温度下水热残渣中锌、铜质量分数

Fig.3 Zn and Cu mass fraction in swine manure raw materials and swine manure residue at different hydrothermal temperatures

3.2 水热残液性质及应用

水热残液是猪粪水热处理的副产物,其EC高于猪粪原料,ZHAO等[49]研究表明,水热处理过程促进了猪粪中碱基离子解离进入液相,导致水热残液中含大量溶质。猪粪水热残液的COD在7 700~13 400 mg/L[22],XU等[73]研究发现,随水热温度升高,原料中微溶性大分子有机物逐渐水解成小分子有机物,水热残液中有机物的分解速率通常快于有机物的水解速率,导致水热残液的COD下降。水热残液的COD高于GB 5084—2005《农田灌溉水质标准》[74],可考虑将其进行厌氧发酵处理[75]。USMAN等[47]研究水热残液应用时指出,200 ℃水热温度下得到的秸秆水热残液厌氧发酵后,1 g COD可产生314 mL甲烷。

已有研究表明,将水热残液适当稀释,以满足当地植物生长需求,可将其用作原位液体肥料[34-45]。YUAN等[45]研究发现,猪粪水热残液中可溶性钾、可溶性氮及可溶性磷的含量分别为59.7~247.8、409.2~547.3及108.4~128.8 mg/L,分别为猪粪原料的1.17~4.87、1.83~2.45及2.34~2.78倍,对小松菜种子使用残液或其稀释样品培养时,其发芽指数均可大于100%。FENG等[46]将杨树锯末和麦秸的水热残液进行水稻土柱试验后发现,施用水热残液后水稻产量较未施用时提高了4.30%~26.00%,且能将氨气的累积挥发量降低10%左右,作为化学氮肥的潜力巨大。但需注意水热残液中可能含有的呋喃、吡啶、吡嗪类等毒性成分的污染风险[76]。刘玉学等[76]研究发现,经发酵处理后的猪粪在水热300 ℃条件下得到的残液毒性成分消失,可提高水热残液作液态肥料的安全性。

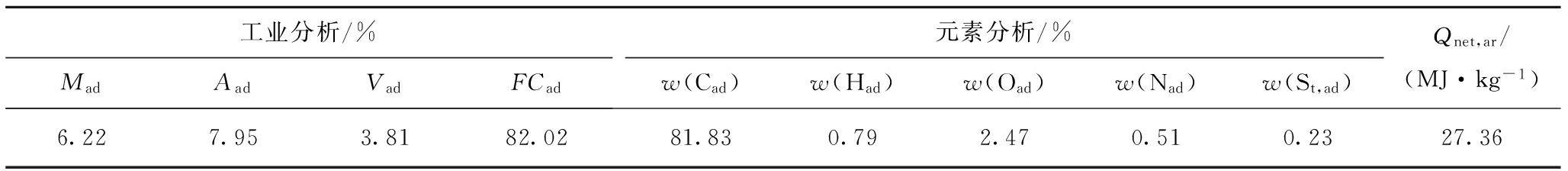

4 水热残渣作生物燃料应用

猪粪含水率高、高位热值低、固定碳含量低及挥发分含量高,导致其作为生物燃料的应用前景不容乐观。经水热处理后,猪粪水热残渣的固定碳含量、高位热值及综合燃烧特性指数等均有提高,挥发分及碱金属含量降低,脱水及干燥性能有所改善,使与褐煤相当的水热残渣有制备生物燃料的潜力。猪粪水热残渣与褐煤的燃烧参数对比见表6。此外,粪便中的半纤维素、纤维素和木质素在水热处理过程中发生解聚、水解等反应,破坏了木质纤维素的结构,提高了水热残渣的可研磨性[9]。

表6 猪粪水热残渣与褐煤燃烧参数对比[22,27,37,76]

Table 6 Comparison of combustion parameters between swine manure hydrothermal residue and lignite[22,27,37,76]

4.1 水热残渣与煤共燃

现阶段,火力发电仍是我国电力系统的“压舱石”。然而,化石燃料的过度使用极易引起CO2大量排放,2019年,我国火力发电排放的CO2量为4.3 Gt,占全国总排放量的41%[77],严重阻碍了我国碳达峰和碳中和目标的实现。生物质来源广泛、储量丰富,且与煤电、石油、天然气等传统能源相比,生物质的碳排放强度可忽略不计。LI等[11]对生物质热电联产改造燃煤电厂分析后发现,对现有煤粉炉适当改造便可实现燃煤锅炉掺烧生物质。畜禽粪便类生物质因其水分高、热值低,掺烧时易对燃煤锅炉内燃烧稳定性产生不利影响。水热处理后的粪便残渣具备良好的燃烧特性,与煤共燃是其高效利用的前景之一。RO等[12]研究了动物粪便水热残渣与煤在不同混合比例下的燃烧特性,结果表明,随水热残渣占比增加,着火温度及燃尽温度较煤单独燃烧逐渐降低,当80%的水热残渣与20%的煤混合时,其着火温度及燃尽温度分别为218和540 ℃,较煤单独燃烧分别降低了约41.55%及13.32%。ZHANG等[78]研究发现,水热残渣因其碳微晶结构更无序,且孔隙结构更发达,导致随水热残渣占比增加,共燃时的燃烧反应逐渐增强。通过控制过量空气系数等手段调整水热残渣与煤混合物在燃烧室中的停留时间,适应水热残渣与煤共燃引起的燃烧特性改变,使锅炉稳定运行。

4.2 共水热处理

猪粪与农林废弃物(木屑、秸秆等)共水热处理可降低水热残渣的灰分含量,提高固定碳含量及高位热值。LANG等[28]对猪粪与木屑、玉米秸秆共水热处理后发现,与猪粪单独水热处理相比,猪粪与木屑在混合比为1∶3条件下水热处理后的残渣灰分量降低了67.74%,固定碳含量提高了140.74%,高位热值提高了4.16%;猪粪与玉米秸秆在混合比为1∶3条件下水热处理后的残渣灰分含量降低了61.24%,固定碳含量提高了132.26%,高位热值提高了4.80%。LI等[79]研究了猪粪与纤维素的共水热处理,相同水热处理条件下,猪粪与纤维素质量比为3∶1混合后得到的水热残渣的灰分含量较猪粪单独水热处理降低了25.03%,高位热值提高了16.83%;当质量比为1∶3时,灰分降低了72.56%,高位热值提高了53.66%。此外,猪粪的共水热处理还可改善残渣的燃烧特性。LANG等[80]采用热重分析法研究了猪粪与玉米秸秆共水热处理后残渣的燃烧行为,与猪粪单独水热处理相比,猪粪与玉米秸秆的混合比为1∶3时得到的水热残渣的着火温度提高了4.72%,燃尽温度降低了6.75%,综合燃烧特性指数提高了155.80%。

4.3 经济性分析

原料选择、工艺参数、物流供应等选择优化均对畜禽粪便水热处理经济性的提高具有重要意义[81]。研究发现,不同种类畜禽粪便的最佳水热条件存在差异。XIONG等[22]研究发现,猪粪在水热温度260 ℃,固液比为0.1 g/mL,停留时间为30 min条件下处理较为适宜。WU等[55]研究了温度对牛粪水热残渣性能的影响,结果表明,水热处理牛粪的最适宜温度为200~220 ℃。

水热处理自身是一个放热过程,耗能较低,大幅降低了的运行成本[82],但目前主要是将实验室规模生产的水热残渣的各项理化性质指标用于水热处理工艺的经济性分析,水热处理的工业化应用仍然面临诸多挑战。MAU等[34]计算家禽粪便水热处理过程中的能量平衡时发现,当固液比为1∶5,水热温度180 ℃时,水热处理过程输入总能量仅占水热残渣燃烧释放能量的35%。在畜禽粪便水热处理工艺中,将水热处理后闪蒸出的蒸汽用于前期粪便的预热以实现余热回收,可进一步降低水热过程的能量输入,提升整体工艺的经济性。水热处理能将畜禽粪便等高含水率的废弃生物质无害化、资源化利用,有必要将水热处理作为一种环境可持续发展的技术手段深入研究。

5 结语与展望

畜禽粪便的资源化利用问题亟待解决,以猪粪为代表,对水热处理畜禽粪便制备生物燃料的相关研究进展进行概述。水热处理后得到的残渣在范式图中可达到褐煤区域,挥发分及高位热值也可达褐煤水准,且较低的碱金属含量,良好的脱水及干燥性能,使其具有制备生物燃料的潜力。未来可从以下几个方面对水热处理畜禽粪便制生物燃料进行深入探究:

1)探索将畜禽粪便水热残渣成型后制备生物质成型燃料,进一步提高其能量密度及机械强度,提升燃料品质的同时降低运输成本。

2)探究畜禽粪便与农林废弃物共水热处理的最优条件,如原料种类、混合比例及水热条件等,使水热残渣的产率及燃烧特性等参数取得最佳值。

3)采用Aspen Plus流程模拟软件对畜禽粪便水热处理工艺进行设计及参数优化,为畜禽粪便水热处理技术的工业化应用提供模型及理论支持。

[1] QIAN Y,SONG K H,HU T,et al.Environmental status of livestock and poultry sectors in China under current transformation stage [J].Science of the Total Environment,2018,622-623:702-709.

[2] 中华人民共和国统计局.中国统计年鉴(2022) [M].北京:中国统计出版社,2022.

[3] 刘天旭,陈昭辉,刘继军.畜禽养殖粪污处理研究进展 [J].黑龙江畜牧兽医,2022(17):26-30.

LIU Tianxu,CHEN Zhaohui,LIU Jijun.Research progress of manure treatment in livestock and poultry breeding [J].Heilongjiang Animal Science and Veterinary Medicine,2022(17):26-30.

[4] QIAN M R,WU H Z,WANG J M,et al.Occurrence of trace elements and antibiotics in manure-based fertilizers from the Zhejiang Province of China [J].Science of the Total Environment,2016,559:174-181.

[5] GUO X L,GU J,GAO H,et al.Effects of Cu on metabolisms and enzyme activities of microbial communities in the process of composting [J].Bioresource Technology,2012,108:140-148.

[6] ORTNER M,RACHBAUER L,SOMITSCH W,et al.Can bioavailability of trace nutrients be measured in anaerobic digestion?[J].Applied Energy,2014,126:190-198.

[7] WU X F,WEI Y S,ZHENG J X,et al.The behavior of tetracyclines and their degradation products during swine manure composting [J].Bioresource Technology,2011,102(10):5924-5931.

[8] 陈理,马艳芳,张紫嘉,等.猪粪水热预处理和厌氧消化条件下的典型抗生素降解性能 [J].农业机械学报,2022,53(S2):260-269.

CHEN Li,MA Yanfang,ZHANG Zijia,et al.Typical antibiotics degradability of pig manure under hydrothermal pretreatment and anaerobic digestion [J].Transactions of the Chinese Society for Agricultural Machinery,2022,53(S2):260-269.

[9] FUNKE A,ZIEGLER F.Hydrothermal carbonization of biomass:A summary and discussion of chemical mechanisms for process engineering [J].Biofuels Bioproducts &Biorefining,2010,4(2):160-177.

[10] HITZL M,CORMA A,POMARES F,et al.The hydrothermal carbonization (HTC) plant as a decentral biorefinery for wet biomass [J].Catalysis Today,2015,257:154-159.

[11] LI J,WANG R,LI H R,et al.Unit-level cost-benefit analysis for coal power plants retrofitted with biomass co-firing at a national level by combined GIS and life cycle assessment [J].Applied Energy,2021,285:116494.

[12] RO K S,LIBRA J A,BAE S,et al.Combustion behavior of an-imal-manure-based hydrochar and pyrochar [J].ACS Sustainable Chemistry &Engineering,2019,7:470-478.

[13] 郑孟杰,靳红梅,张松贺,等.猪粪沼渣水热炭中重金属浸出特征研究 [J].农业环境科学学报,2018,37(1):157-164.

ZHENG Mengjie,JIN Hongmei,ZHANG Songhe,et al.The leaching characteristics of heavy metals from hydrochars of digested swine manure [J].Journal of Agro:Environment Science,2018,37(1):157-164.

[14] GONG P C,LIU H L,WANG M M,et al.Characteristics of hydrothermal treatment for the disintegration of oxytetracycline fermentation residue and inactivation of residual antibiotics [J].Chemical Engineering Journal,2020,402:126011.

[15] VARDON D R,SHARMA B K,SCOTT J,et al.Chemical properties of biocrude oil from the hydrothermal liquefaction of Spirulina algae,swine manure,and digested anaerobic sludge [J].Bioresource Technology,2011,102(17):8295-8303.

[16] XIU S N,SHAHBAZI A,SHIRLEY V,et al.Hydrothermal pyrolysis of swine manure to bio-oil:Effects of operating parameters on products yield and characterization of bio-oil [J].Journal of Analytical and Applied Pyrolysis,2010,88:73-79.

[17] LU J W,WATSON J,ZENG J L,et al.Biocrude production and heavy metal migration during hydrothermal liquefaction of swine manure [J].Process Safety and Environmental Protection,2018,115:108-115.

[18] LI H G,LU J W,ZHANG Y H,et al.Hydrothermal liquefaction of typical livestock manures in China:Biocrude oil production and migration of heavy metals [J].Journal of Analytical and Applied Pyrolysis,2018,135:133-140.

[19] 张树清,张夫道,刘秀梅,等.规模化养殖畜禽粪主要有害成分测定分析研究 [J].植物营养与肥料学报,2005(6):116-123.

ZHANG Shuqing,ZHANG Fudao,LIU Xiumei,et al.Determination and analysis on main harmful composition in excrement of scale livestock and poultry feedlots [J].Journal of Plant Nutrition and Fertilizers,2005(6):116-123.

[20] GAO X Z,YANG F Y,CHENG J W,et al.Emission of volatile sulphur compounds during swine manure composting:Source identification,odour mitigation and assessment [J].Waste Management,2022,153:129-137.

[21] 王婧,赵万余,吴鸿亿,等.猪粪资源化利用的研究进展 [J].黑龙江畜牧兽医,2022(17):31-36.

WANG Jing,ZHAO Wanyu,WU Hongyi,et al.Research progress on resource utilization of pig manure [J].Heilongjiang Animal Science and Veterinary Medicine,2022(17):31-36.

[22] XIONG J B,PAN Z Q,XIAO X F,et al.Study on the hydrothermal carbonization of swine manure:The effect of process parameters on the yield/properties of hydrochar and process water [J].Journal of Analytical and Applied Pyrolysis,2019,144:41-85.

[23] WEI X C,LIU D F,LI W J,et al.Biochar addition for accelerating bioleaching of heavy metals from swine manure and reserving the nutrients [J].Science of the Total Environment,2018,631/632:1553-1559.

[24] 穆虹宇,庄重,李彦明,等.我国畜禽粪便重金属含量特征及土壤累积风险分析 [J].环境科学,2020,41(2):986-996.

MU Hongyu,ZHUANG Zhong,LI Yanming,et al.Heavy metal contents in animal manure in China and the related soil accumulation risks [J].Environmental Science,2020,41(2):986-996.

[25] KARCI A,BALCIOGLU I A.Investigation of the tetracycline,sulfonamide,and fluoroquinolone antimicrobial compounds in animal manure and agricultural soils in Turkey [J].Science of the Total Environment,2009,407(16):4652-4664.

[26] 盛聪.猪粪水热炭重金属污染特性及其环境风险 [D].杭州:浙江农林大学,2019.

[27] 李飞跃,吴旋,李俊锁,等.温度对畜禽粪便水热炭产率及特性的影响 [J].环境工程学报,2019,13(9):2270-2277.

LI Feiyue,WU Xuan,LI Junsuo,et al.Effects of temperature on hydrothermal carbonization yield and characteristics of livestock manure [J].Chinese Journal of Environmental Engineering,2019,13(9):2270-2277.

[28] LANG Q Q,GUO Y C,ZHENG Q F,et al.Co-hydrothermal carbonization of lignocellulosic biomass and swine manure:hydrochar properties and heavy metal transformation behavior [J].Bioresource Technology,2018,266:242-248.

[29] ZENG X Y,XIAO Z H,ZHANG G L,et al.Speciation and bioavailability of heavy metals in pyrolytic biochar of swine and goat manures [J].Journal of Analytical and Applied Pyrolysis,2018,132:82-93.

[30] 丁工尧.天津市养殖场粪污中抗生素与抗性基因污染特征的分析 [D].哈尔滨:东北农业大学,2021.

[31] 柴玉峰,钟慧,陈梅雪,等.猪粪中21种常见抗生素的同步提取检测方法研究及应用 [J].环境化学,2022,41(4):1252-1260.

CHAI Yufeng,ZHONG Hui,CHEN Meixue,et al.Research and application of detection method of simultaneous extraction and detection of 21 common antibiotics from pig manure [J].Environmental Chemistry,2022,41(4):1252-1260.

[32] 林辉,马军伟,孙万春,等.光照对畜禽粪便中抗生素降解和微生物的影响 [J].中国环境科学,2021,41(1):263-272.

LIN Hui,MA Junwei,SUN Wanchun,et al.Effect of light illumination on antibiotic degradation and microbial community in manure [J].China Environmental Science,2021,41(1):263-272.

[33] LI Y X,ZHANG X L,LI W,et al.The residues and environment-

al risks of multiple veterinary antibiotics in animal faeces [J].Environmental Monitoring and Assessment,2013,185(3):2211-2220.

[34] MAU V,QUANCE J,POSMANIK R,et al.Phases′ characterist-

ics of poultry litter hydrothermal carbonization under a range of process parameters [J].Bioresource Technology,2016,219:632-642.

[35] 环境保护部.畜禽养殖业污染物排放标准:GB 18596—2001 [S].北京:环境保护部,2001.

[36] FERRENTINO R,SACCHI G,SCRINZI D,et al.Valorization of swine manure for a circular approach through hydrothermal carbonization [J].Biomass and Bioenergy,2023,168:106689.

[37] 周思邈,韩鲁佳,杨增玲,等.碳化温度对畜禽粪便残渣燃烧特性的影响 [J].农业工程学报,2017,33(23):233-240.

ZHOU Simiao,HAN Lujia,YANG Zengling,et al.Influence of hydrothermal carbonization temperature on combustion characteristics of livestock and poultry manures [J].Transactions of the Chinese Society of Agricultural Engineering,2017,33(23):233-240.

[38] HAO X,CHANG C,LARNEY F J.Carbon,nitrogen balances and greenhouse gas emission during cattle feedlot manure composting [J].Journal of Environmental Quality,2004,33:37-44.

[39] HE M M,LI W H,LIANG X Q,et al.Effect of composting process on phytotoxicity and speiciation of copper,zinc and lead in sewage sludge and swine manure [J].Waste Management,2009,29(2):590-597.

[40] BAO Y Y,ZHOU Q X,GUAN L Z,et al.Depletion of chlortetracycline during composting of aged and spiked manures [J].Waste Management,2009,29(4):1416-1423.

[41] ALVAREZ J A,OTERO L,LEMA J M,et al.The effect and fate of antibiotics during the anaerobic digestion of pig manure [J].Bioresource Technology,2010,101(22):8581-8586.

[42] BENABDALLAH E H T,ASTALS S,GALI A,et al.Ammonia influence in anaerobic digestion of OFMSW [J].Water Science &Technology A:Journal of the International Association on Water Pollution Research,2009,59(6):1153-1161.

[43] HEILMANN S M,MOLDE J S,TIMLER J G,et al.Phosphorus reclamation through hydrothermal carbonization of animal manures [J].Environmental Science &Technology,2014,48(17):10323-10329.

[44] EKPO U,ROSS A B,CAMARGO-VALERO M A,et al.A comparison of product yields and inorganic content in process streams following thermal hydrolysis and hydrothermal processing of microalgae,manure and digestate [J].Bioresource Technology,2016,200:951-960.

[45] YUAN T,CHENG Y F,HUANG W W,et al.Fertilizer potential of liquid product from hydrothermal treatment of swine manure [J].Waste Management,2018,77:166-171.

[46] FENG Y F,HE H Y,LI D T,et al.Biowaste hydrothermal carbonization aqueous product application in rice paddy:Focus on rice growth and ammonia volatilization [J].Chemosphere,2021,277:130233.

[47] USMAN M,CHEN H H,CHEN K F,et al.Characterization and utilization of aqueous products from hydrothermal conversion of biomass for bio-oil and hydro-char production:A review [J].Green Chemistry,2019,21:1553-1572.

[48] BERGE N D,KAMMANN C,RO K S,et al.Environmental applications of hydrothermal carbonization technology:biochar production,carbon sequestration,and waste conversion [M].New York:John Wiley &Sons,Ltd.,2013.

[49] ZHAO P T,SHEN Y F,GE S F,et al.Clean solid biofuel production from high moisture content waste biomass employing hydrothermal treatment [J].Applied Energy,2014,131:345-367.

[50] DANSO-BOATENG E,HOLDICH R G,SHAMA G,et al.Kinetics of faecal biomass hydrothermal carbonisation for hydrochar production [J].Applied Energy,2013,111:351-357.

[51] DANSO-BOATENG E,SHAMA G,WHEATLEY A D,et al.Hydrothermal carbonisation of sewage sludge:Effect of process conditions on product characteristics and methane production [J].Bioresource Technology,2015,177:318-327.

[52] BERGE N D,LI L,FLORA J R V,et al.Assessing the environmental impact of energy production from hydrochar generated via hydrothermal carbonization of food wastes [J].Waste Management,2015,43:203-217.

[53] WANG C W,ZHANG S Y,WU S Y,et al.Multi-purpose production with valorization of wood vinegar and briquette fuels from wood sawdust by hydrothermal process [J].Fuel,2020,282:118775.

[54] GHANIM B M,PANDEY D S,KWAPINSKI,et al.Hydrothermal carbonisation of poultry litter:Effects of treatment temperature and residence time on yields and chemical properties of hydrochars [J].Bioresource Technology,2016,216:373-380.

[55] WU K,GAO Y,ZHU G K,et al.Characterization of dairy manure hydrochar and aqueous phase products generated by hydrothermal carbonization at different temperatures [J].Journal of Analytical and Applied Pyrolysis,2017,127:335-342.

[56] CAO X Y,RO K S,CHAPPELL M,et al.Chemical structures of swine-manure chars produced under different carbonization conditions investigated by advanced solid-state 13C nuclear magnetic resonance (NMR) spectroscopy [J].Energy Fuels,2011,25:388-397.

[57] CHEN X J,LIN Q M,HE R D,et al.Hydrochar production from watermelon peel by hydrothermal carbonization [J].Bioresource Technology,2017,241:236-243.

[58] HOEKMAN S K,BROCH A,ROBBINS C,et al.Process Development Unit (PDU) for Hydrothermal Carbonization (HTC) of lignocellulosic biomass [J].Waste &Biomass Valorization,2014,5(4):669-678.

[59] ZHUANG X,ZHAN H,SONG Y,et al.Insights into the evolution of chemical structures in lignocellulose and non-lignocellulose biowastes during hydrothermal carbonization (HTC) [J].Fuel,2019,236:960-974.

[60] SEVILLA M,FUERTES A B.The production of carbon materials by hydrothermal carbonization of cellulose [J].Carbon,2009,47:2281-2289.

[61] LIU W J,JIANG H,YU H Q.Thermochemical conversion of lignin to functional materials:A review and future directions [J].Green Chemistry,2015,17:4888-4907.

[62] JENKINS B M,BAXTER L L,MILES T R.Combustion propertiesof biomass [J].Fuel Processing Technology,1998,54(1):17-46.

[63] TOUFIQ R M,FREITAS A,YANG X K,et al.Hydrothermal carbonization (HTC) of cow manure:Carbon and nitrogen distributions in HTC products [J].Environmental Progress &Sustainable Energy,2016,35(4):1002-1011.

[64] WANG C P,WANG F Y,YANG Q R,et al.Thermogravimetric studies of the behavior of wheat straw with added coal during combustion [J].Biomass and Bioenergy,2009,33(1):50-56.

[65] GASCO G,PAZ-FERREIRO J,ALVAREZ M L,et al.Biochars and hydrochars prepared by pyrolysis and hydrothermal carbonisation of pig manure [J].Waste Management,2018,79:395-403.

[66] LIU Z,QUEK A,HOEKMAN S K,et al.Production of solid biochar fuel from waste biomass by hydrothermal carbonization [J].Fuel,2013,103:943-949.

[67] 杨济凡,张守玉,曹忠耀,等.水热氧化预处理对棉秆成型颗粒理化性质的影响 [J].化工进展,2022,41(8):4417-4424.

YANG Jifan,ZHANG Shouyu,CAO Zhongyao,et al.Effect of hydrothermal oxidation pretreatment on physicochemical properties of cotton stalk shaped granules [J].Chemical Industry and Engineering Progress,2022,41(8):4417-4424.

[68] 熊绍武,张守玉,吴巧美,等.生物质炭燃烧特性与动力学分析 [J].燃料化学学报,2013,41(8):958-965.

XIONG Shaowu,ZHANG Shouyu,WU Qiaomei,et al.Investigation on combustion characteristics and kinetics of bio-char [J].Journal of Fuel Chemistry and Technology,2013,41(8):958-965.

[69] NEYENS E,BAEYENS J.A review of thermal sludge pre-treatment processes to improve dewaterability [J].Journal of Hazardous Materials,2003,98:51-67.

[70] ZHANG X P,ZHANG C,LI X,et al.A two-step process for sewage sludge treatment:Hydrothermal treatment of sludge and catalytic hydrothermal gasification of its derived liquid [J].Fuel Processing Technology,2018,180:67-74.

[71] LU X L,MA X Q,Q Z,et al.Co-hydrothermal carbonization of sewage sludge and swine manure:Hydrochar properties and heavy metal chemical speciation [J].Fuel,2022,330:125573.

[72] LANG Q Q,CHEN M J,GUO Y C,et al.Effect of hydrothermal carbonization on heavy metals in swine manure:Speciation,bioavailability and environmental risk [J].Journal of Environmental Management,2019,234:97-103.

[73] XU X W,JIANG E C.Treatment of urban sludge by hydrothermal carbonization [J].Bioresource Technology,2017,238:182-187.

[74] 中华人民共和国国家质量监督检验检疫总局,中国国家标准化管理委员会.农田灌溉水质标准:GB 5084—2005 [S].北京:中国标准出版社,2005.

[75] ARAGON-BRICENO C,ROSS A B,CAMARGO-VALERO M A.Evaluation and comparison of product yields and bio-methane potential in sewage digestate following hydrothermal treatment [J].Applied Energy,2017,208:1357-1369.

[76] 刘玉学,何莉莉,陈立天,等.基于猪粪水热炭化的生物炭性能及残液成分分析 [J].农业环境科学学报,2022,41(9):2064-2072.

LIU Yuxue,HE Lili,CHEN Litian,et al.Properties and residual liquid composition analysis of biochar obtained after hydrothermal carbonization of pig manure [J].Journal of Agro:Environment Science,2022,41(9):2064-2072.

[77] 周义,张守玉,郎森,等.煤粉炉掺烧生物质发电技术研究进展 [J].洁净煤技术,2022,28(6):26-34.

ZHOU Yi,ZHANG Shouyu,LANG Sen,et al.Research progress of biomass blending technology in pulverized coal furnace for power generation [J].Clean Coal Technology,2022,28(6):26-34.

[78] ZHANG N,WANG G W,ZHANG J L,et al.Study on co-combustion characteristics of hydrochar and anthracite coal [J].Journal of the Energy Institute,2019,93:1125-1137.

[79] LI Q Y,LIN H S,ZHANG S,et al.Co-hydrothermal carbonizat-

ion of swine manure and cellulose:Influence of mutual interaction of intermediates on properties of the products [J].Science of the Total Environment,2021,791:148134.

[80] LANG Q Q,ZHANG B,LIU Z G,et al.Co-hydrothermal carbonization of corn stalk and swine manure:Combustion behavior of hydrochar by thermogravimetric analysis [J].Bioresource Technology,2019,271:75-83.

[81] KUMAR A,SAINI K,BHASKAR T.Hydochar and biochar:Production,physicochemical properties and technoeconomic analysis [J].Bioresource Technology,2020,310:123442.

[82] MUMME J,ECKERVOGT L,PIELERT J,et al.Hydrothermal carbonization of anaerobically digested maize silage [J].Bioresource Technology,2011,102:9255-9260.

Research progress on bio-fuel prepared from livestock manure by hydrothermal treatment

移动阅读

ZHANG Shouyu,CHEN Xuyang,LIU Simeng,et al.Research progress on bio-fuel prepared from livestock manure by hydrothermal treatment[J].Clean Coal Technology,2023,29(5):1-10.