燃煤耦合垃圾焚烧技术中试试验

0 引 言

随着城市化和工业化的高速发展,城市生活垃圾产量逐年增加[1],预计到2050年,全球垃圾产量将达到约350亿t[2],垃圾焚烧仍有很大的发展空间。但传统垃圾焚烧发电厂存在热效率低、环保成本高、投资大等问题[3-5],大幅限制其发展。与此同时,全世界范围内存在大量燃煤电厂,受减碳政策影响,这些燃煤机组长期无法满负荷运行[6],面临淘汰。针对垃圾焚烧需求增加和燃煤机组负荷空置这一矛盾现象,一些学者提出了燃煤耦合垃圾焚烧发电的技术路线,通过利用现有煤电机组协同处理垃圾,降低垃圾焚烧成本,提高垃圾焚烧规模,降低存量煤电煤耗,降低燃煤电厂碳排放[7-8]。

燃煤耦合垃圾焚烧发电技术可分为3类:直接耦合、间接耦合和平行耦合。直接耦合是将垃圾与煤直接掺混燃烧[9-12],其优点在于垃圾转化率较高、耦合方式简单及可能存在煤与垃圾间的正向协同效应[13];其缺点在于垃圾焚烧产生有害物质腐蚀锅炉受热面,飞灰和底渣PCDD/Fs毒性上升,导致危废处理成本增加[11-12]。间接耦合是将垃圾在单独的焚烧炉内焚烧,再将焚烧烟气送入燃煤锅炉内。其优点在于燃料适应性好、对飞灰和底渣影响较小[14]。平行耦合是将垃圾在单独焚烧炉焚烧生产蒸汽,并将蒸汽送入原燃煤机组蒸汽循环中发电。优点在于垃圾替煤率较高、对燃煤锅炉无影响,缺点在于垃圾焚烧炉仍需配置余热锅炉和烟气净化设备,投资较高,且热效率低于其他2种耦合方式[15]。相比直接耦合和平行耦合,间接耦合优势和市场吸引力更明显。张勇等[16]搭建了30 t/d 燃煤锅炉耦合垃圾发电中试试验系统,将垃圾处理与燃煤电站相耦合,充分利用燃煤电站充足的热量和能源,增加垃圾处理效果,实现垃圾高效减量处置。刘贺等[17]研究了在空气气氛下神华煤掺烧几种典型固废的结渣特性,研究发现少量掺烧固废后,煤灰仍能保持疏松多孔的特性,锅炉可平稳运行。史兵权等[18]采用数值模拟方法,对220 t/h四角切圆煤粉锅炉进行烟气侧燃煤耦合垃圾模拟研究,结果表明耦合垃圾后会对炉膛内部温度分布产生影响,炉膛出口截面处的温度会随垃圾替煤率的增加而升高。

但垃圾焚烧会产生大量二噁英类物质(PCDD/Fs)[19]。研究表明,PCDD/Fs是一种具有极强致癌性的化合物,对人类发育系统和免疫系统的损害极大,严重威胁人体健康[20]。此外,由于PCDD/Fs化学性质稳定,分解温度较高,在自然条件下难以降解,会长期存在于环境中,对大气、水体和土壤造成污染[21]。目前,为控制PCDD/Fs排放,主要采用入炉前控制、燃烧过程控制和燃烧后控制。在入炉前控制阶段,可采用干燥、水热碳化、低温热解等方法对垃圾进行预处理,或添加煤等物质来增加垃圾热值。对于含水率高的城市生活垃圾可进行干燥,加速其碳化,提高热值和燃烧效率,也可降低处理成本[22],还可在焚烧过程中喷入抑制剂[23-27]。MA等[28]发现S/CaO混合抑制剂的添加可分解PCDD/Fs或其前驱物,并减弱PCDD/Fs形成中的氯化过程,对六氯代和七氯代PCDD/Fs的抑制作用最为显著。CHEN等[29]使用硫脲作为PCDD/Fs的抑制剂,并详细研究抑制机理,发现在燃烧后区域,硫脲中的S元素和N元素抑制金属催化剂,因此对从头合成的抑制作用大于氯酚合成的抑制作用;燃烧后控制则主要采用活性炭喷射结合布袋除尘的组合脱除烟气中的PCDD/Fs[30-31]。目前,垃圾焚烧发电厂通常采用烟气急冷与活性炭喷射相结合的方法控制PCDD/Fs,即先将垃圾焚烧烟气进行快速冷却,跨过PCDD/Fs的de nova再合成温度区间[32],然后向烟气中喷入活性炭吸附残余的PCDD/Fs。但该方法需消耗大量的冷却水和价格昂贵的活性炭,还会产生大量的危废活性炭,成本较高[33]。因此,寻找一种低成本、高效率的方法控制PCDD/Fs的排放是燃煤耦合垃圾焚烧发电技术的关键研究点。

垃圾与其他原料掺混焚烧是近年来提出的一种减排PCDD/Fs的方法。当混合不同类型的原料时,混合物中热值和元素组成均会发生变化[34],通过调整合适的混合比例,可减少PCDD/Fs生成量。CONESA等[35-36]研究发现,使用高硫(S)含量的生活污泥作为抑制剂,可使PCDD/Fs排放量大幅下降,这主要是由于污泥中S元素或碱性物质含量较高,可与Cl元素反应生成硫酸盐、碱金属氯化物等化合物,降低了Cl参与二噁英合成的可能性,从而显著抑制PCDD/Fs生成。而与市政污泥相比,赤泥作为电解铝的产物,主要由CaO和SiO2组成[37]。此外,还含有Fe2O3和Al2O3,及少量MgO、Na2O和TiO2。因此将赤泥与垃圾掺混焚烧,可能更好抑制PCDD/Fs生成。

笔者将针对燃煤耦合垃圾焚烧发电技术开展中试研究,分析耦合垃圾焚烧对燃煤锅炉运行特性及污染物排放特性的影响,探讨掺混赤泥后抑制PCDD/Fs生成效果。研究成果将为燃煤耦合垃圾焚烧发电技术的深度开发和工程示范提供理论指导。

1 试 验

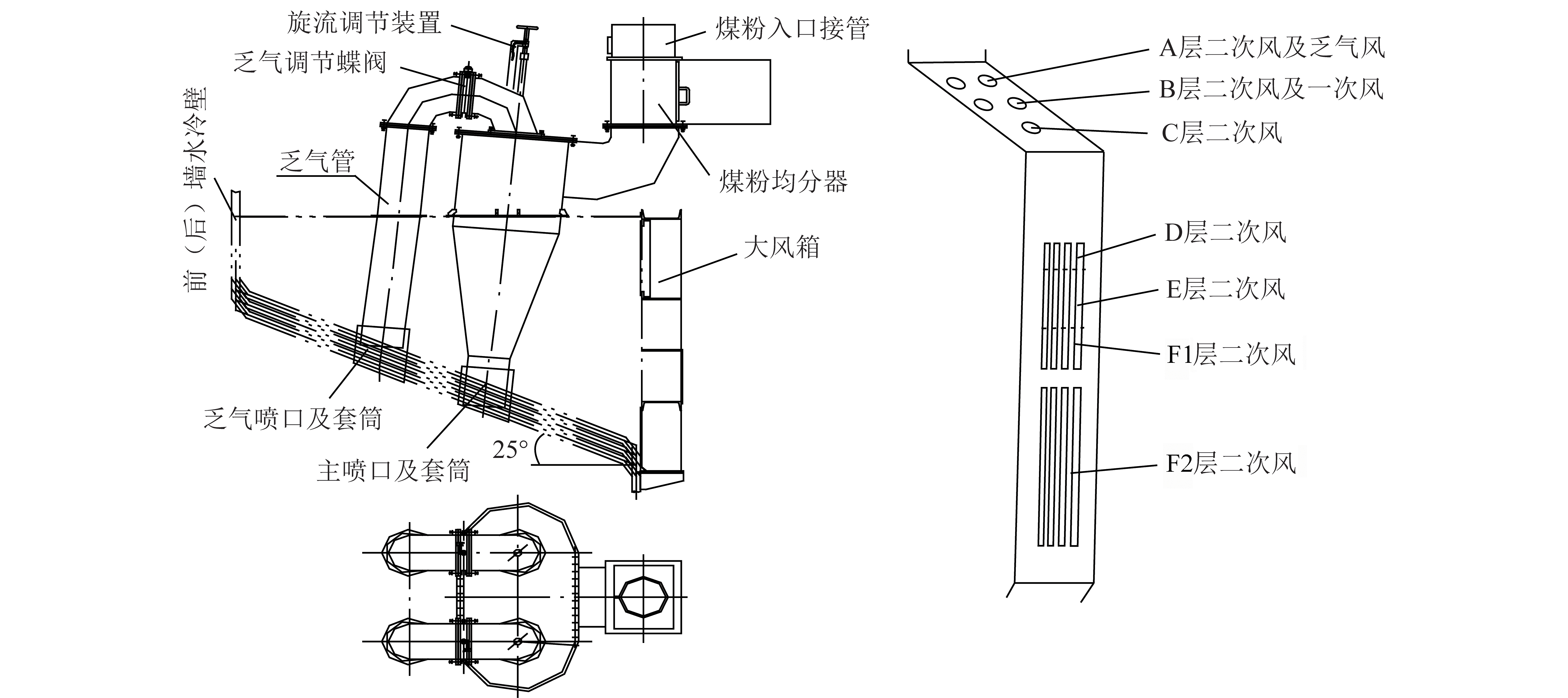

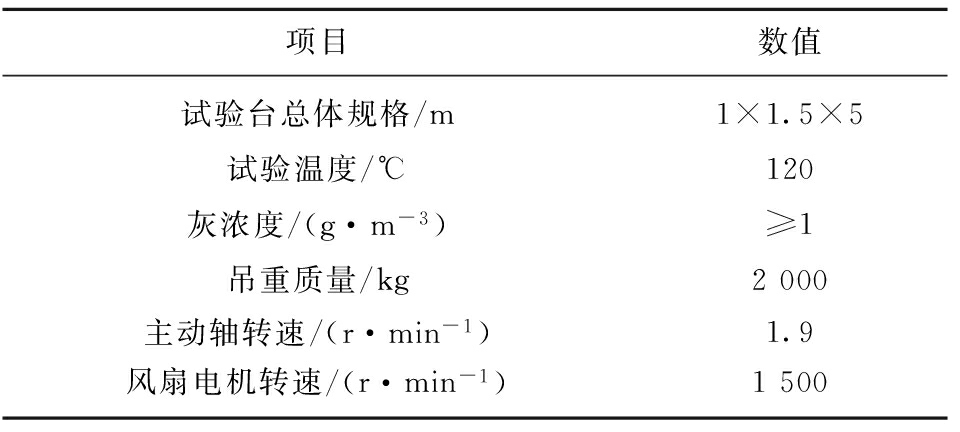

1.1 试验系统

在一台100 kW燃煤耦合垃圾焚烧中试试验台上开展,系统如图1所示。垃圾通过螺旋给料机送入电加热回转窑焚烧炉。当炉膛温度超过设定温度(700 ℃)后,电加热模块停止加热。垃圾焚烧烟气通过燃烧器区上部通入煤粉炉内。煤粉炉采用旋流燃烧器,一次风携带煤粉吹入煤粉炉内,二次风通过燃烧器也送入煤粉炉内。煤粉炉尾部设有空气预热器,用于加热二次风。煤粉炉炉膛各处和风烟管路上设有热电偶,以检测系统内各处温度。烟气取样点设置于回转窑和煤粉炉烟气出口处。SO2和NOx采用烟气分析仪测取(350,Testo,Germany),PCDD/Fs由第三方检测机构采用国标测取,并转换为体积分数11% O2标准下的数值。

图1 中试台示意

Fig.1 Schematic diagram of the pilot-test bench

1.2 试验样品

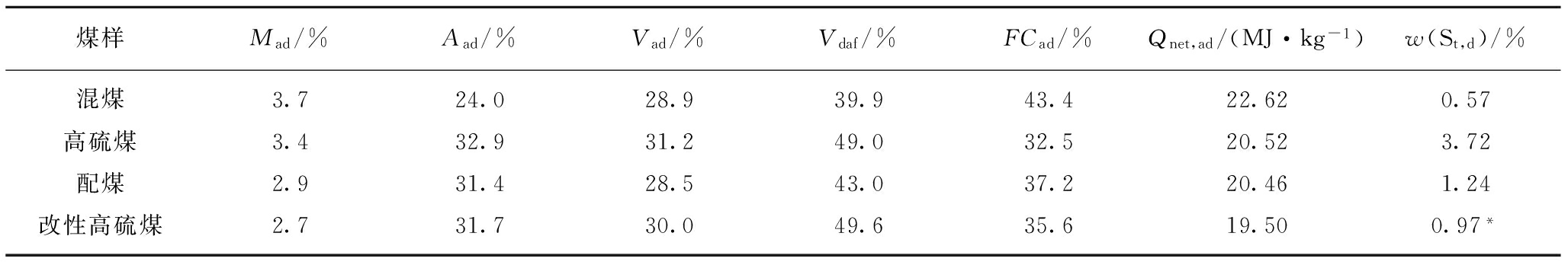

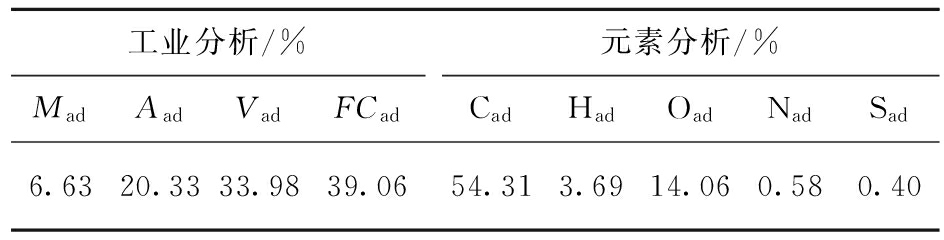

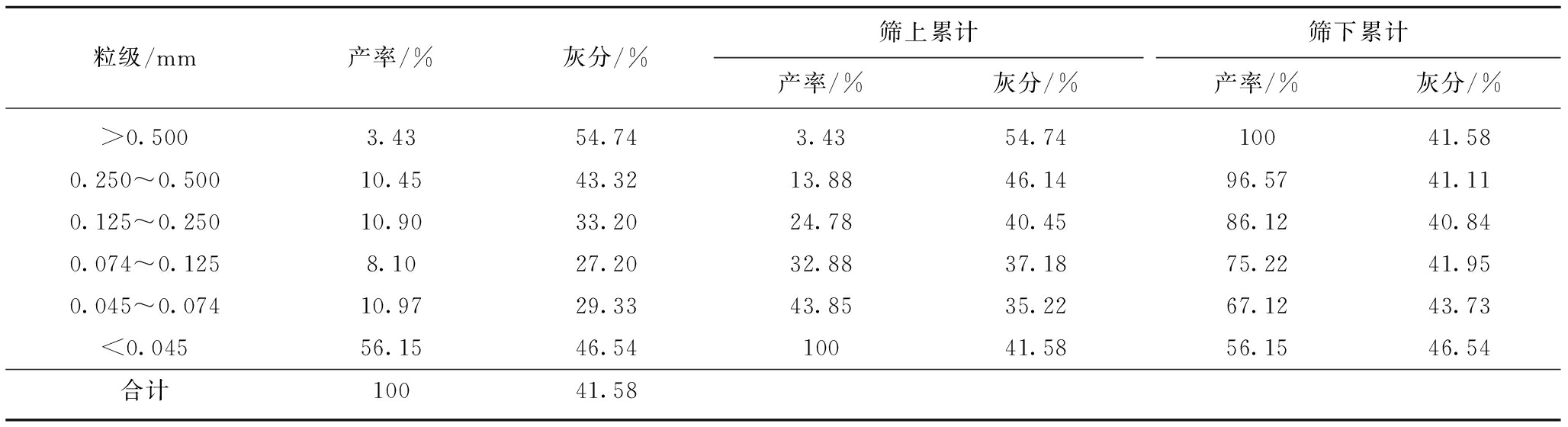

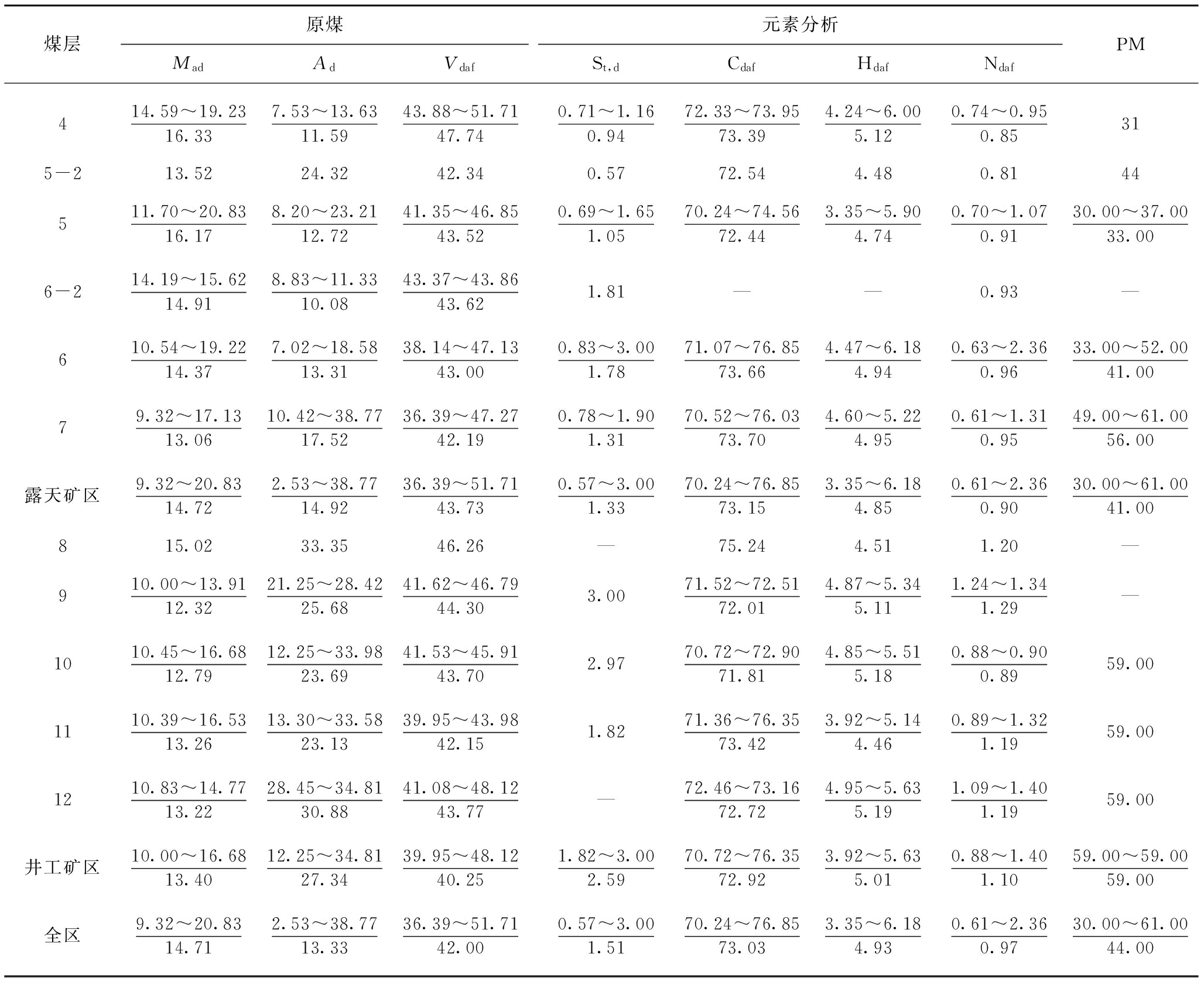

试验采用河北某地烟煤,垃圾根据典型城市生活垃圾成分配制,按照厨余∶木质∶塑料∶纸张=5∶2∶2∶1。赤泥购自河南恒源新材料有限公司。试验前将煤炭破碎筛分至0.1~0.2 mm。煤、垃圾和赤泥的工业、元素和热值分析结果见表1。

表1 煤、垃圾和赤泥的工业、元素和热值分析

Table 1 Proximate and ultimate analyses of coal, waste and red mud

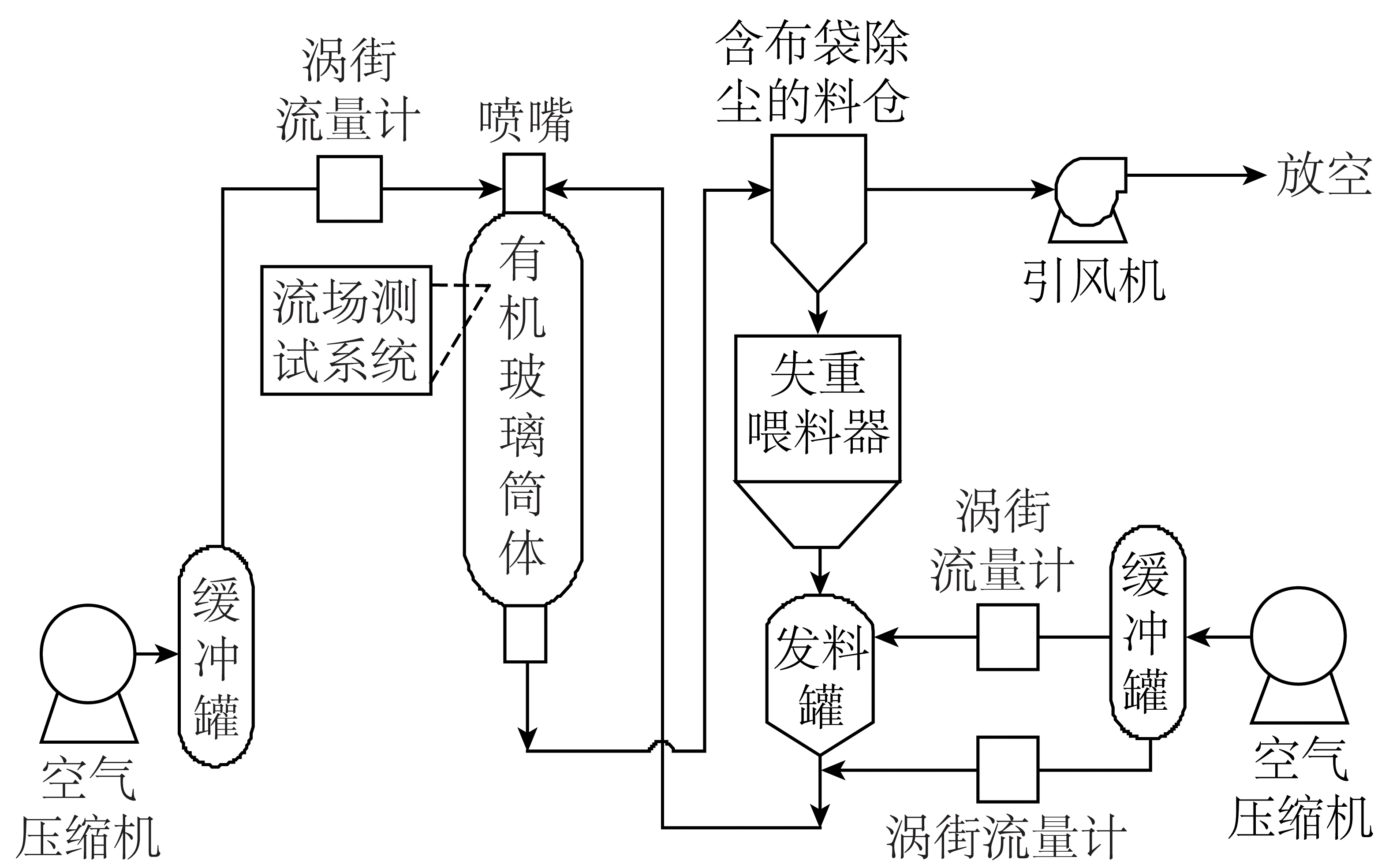

1.3 试验工况

试验共有3个工况,煤粉炉过量空气系数为1.4,回转窑过量空气系数为1.5。垃圾替煤率以热值计,由于替煤率较高时,会对煤粉燃烧产生一定影响,使整个系统发电效率较差,同时NO排放增多。替煤率较低时,对垃圾处理规模较小,难以实现垃圾规模化处理[18,38],因此在试验中垃圾替煤率设为10%。选用赤泥作为二噁英抑制剂,由于生活垃圾中含有纤维素成分的木屑、报纸等物质会对垃圾中的塑料成分燃烧起促进作用[39-40],进而可能促进二噁英生成。综合考虑赤泥的热值后,选择生活垃圾中直接按质量20%掺混赤泥。试验工况见表2。

表2 试验工况

Table 2 Experimental conditions

2 结果与讨论

2.1 燃烧特性

对中试试验系统不同温度检测点处的温度进行实时监控,典型温度曲线如图2所示。试验持续约12 h。可知燃烧室区温度(101)最高,在全煤粉工况下可达1 433.18 ℃,回转窑在投入垃圾焚烧后温度升至约800 ℃,预热空气温度(110)超过200 ℃,最高可达289.65 ℃。由图2还可知在耦合10%的垃圾后,煤粉炉燃烧室和炉膛下区域温度(102)略下降,经过短时间工况稳定后,燃烧室区域炉膛中心温度平均值下降26.59 ℃,炉膛下区域中心的平均温度下降16.04 ℃,这是由于煤粉主要燃烧区域是燃烧室和炉膛下区域,当炉膛热负荷降低,煤粉通入量减小,放热量减少,温度降低,同时垃圾焚烧烟气温度低于煤粉燃烧烟气温度,烟气混合后会降低煤粉燃烧烟气温度,因此炉膛测量温度略下降。炉膛上区域(103、104、106测温点)温度略上升,平均温度升高33.33 ℃。总体来看,在耦合垃圾焚烧后,整个煤粉炉炉膛温度分布更加均匀。

图2 试验系统监测点温度变化

Fig.2 Temperature distribution of monitoring points

2.2 SO2和NOx污染物排放特性

不同工况下回转窑和煤粉炉烟气中SO2浓度如图3所示。在全煤粉工况时煤粉炉排烟中SO2质量浓度达1 066 mg/m3,垃圾替代10%的煤粉后,SO2在煤粉炉排烟中浓度降至931 mg/m3。而回转窑尾部烟气中SO2质量浓度为131 mg/m3,远小于煤粉炉烟道中SO2浓度,这是由于垃圾S元素含量小于烟煤中。垃圾焚烧烟气通入煤粉炉中会对耦合垃圾工况下煤粉炉内的SO2有一定稀释作用,导致煤粉炉出口烟气中SO2浓度降低。但从图3中还可以看出,垃圾中掺混赤泥后,回转窑尾部烟气中SO2质量浓度升高至667 mg/m3,掺混后的垃圾焚烧烟气通入煤粉炉中使煤粉炉尾部烟气降至796 mg/m3,说明掺混赤泥会促进垃圾焚烧阶段SO2生成,但焚烧烟气中的某些成分会抑制煤粉燃烧SO2的生成。

图3 不同工况下烟气中SO2质量浓度

Fig.3 SO2 concentration in flue gas

图4为不同工况下烟气出口处NOx质量浓度,可知在全煤工况下煤粉炉出口处的NOx质量浓度为137 mg/m3,耦合10%的垃圾后,NOx在煤粉炉出口烟气中的质量浓度降至106 mg/m3,而此时回转窑出口烟气中NOx质量浓度为208 mg/m3,高于全煤工况中煤粉炉中NOx浓度,这是由于垃圾中N含量较高,燃料型NOx的生成量增加。但垃圾焚烧烟气通入煤粉炉后反而降低了煤粉炉中的NOx质量浓度,说明垃圾焚烧烟气中某些成分也会降低煤粉燃烧过程中NOx生成。在掺混20%赤泥后,垃圾焚烧烟气中NOx质量浓度升至309 mg/m3,同时煤粉炉烟气中NOx质量浓度升至130 mg/m3。

图4 不同工况下烟气中NOx质量浓度

Fig.4 NOx concentration in flue gas

2.3 二噁英排放特性

不同工况下回转窑和煤粉炉排烟中PCDD/Fs当量浓度如图5所示。在全煤工况下,煤粉炉尾部的烟气中PCDD/Fs质量浓度为0.1 ng/m3,耦合掺烧10%垃圾后,回转窑尾部烟气质量浓度为3.88 ng/m3,但经煤粉炉高温热分解,PCDD/Fs质量浓度降至0.17 ng/m3,分解率为95.62%。但此时煤粉炉烟气中PCDD/Fs质量浓度仍超过GB 18485—2014《生活垃圾焚烧污染控制标准》中规定的PCDD/Fs浓度排放限值0.1 ng/m3。

图5 不同工况下烟气中二噁英的毒性当量浓度

Fig.5 PCDD/Fs concentration in flue gas

为进一步降低烟气中PCDD/Fs浓度,在垃圾中掺混质量分数20%赤泥。掺混后,回转窑排烟中PCDD/Fs质量浓度降至1.24 ng/m3,下降68.04%,而煤粉炉烟气中PCDD/Fs质量浓度降至0.003 4 ng/m3,相比不掺混赤泥工况下降98%。掺混赤泥后煤粉炉排烟中PCDD/Fs质量浓度远低于0.1 ng/m3,还符合DB31/1291—2021《燃煤耦合污泥电厂大气污染物排放标准》中规定的0.02 ng/m3的排放限值。

3 结 论

1)煤粉炉在耦合10%的垃圾后,炉膛温度分布更均匀,燃烧室和炉膛下区域温度下降约30 ℃,而炉膛上区域温度升高约35 ℃。

2)耦合垃圾焚烧对煤粉炉中的SO2和NOx生成存在部分抑制作用,但机理尚不明确。

3)耦合垃圾后,煤粉炉高温可有效热分解垃圾焚烧产生的PCDD/Fs,但煤粉炉烟气中PCDD/Fs排放浓度仍未达到国家标准;采用在垃圾中掺烧20%赤泥的方法,可显著降低垃圾焚烧产生的PCDD/Fs,掺烧后煤粉炉烟气中PCDD/Fs排放浓度降至0.003 4 ng/m3,满足现有燃煤耦合污泥焚烧的排放标准。

[1] AMBAYE T G, DJELLABI R, VACCARI M, et al. Emerging technologies and sustainable strategies for municipal solid waste valorization: Challenges of circular economy implementation[J]. Journal of Cleaner Production, 2023,423: 138708.

[2] ABBAS S Y, KIRWAN K, LU D. Exploring enablers and barriers to municipal solid waste (MSW) management technologies adoption in the Kingdom of Bahrain[J]. Journal of Environmental Protection, 2020, 11(5): 377-398.

[3] LOMBARDI L, CARNEVALE E, CORTI A. A review of technologies and performances of thermal treatment systems for energy recovery from waste[J]. Waste Management, 2015, 37: 26-44.

[4] SINGH K, HACHEM-VERMETTE C. Influence of mixed-use neighborhood developments on the performance of waste-to-energy CHP plant[J]. Energy, 2019, 189: 116172.

[5] 吴剑, 蹇瑞欢, 刘涛. 我国生活垃圾焚烧发电厂的能效水平研究[J]. 环境卫生工程, 2018, 26(3): 39-42.

WU Jian, JIAN Ruihuan, LIU Tao. Research on energy efficiency of municipal solid waste incineration plant in China[J]. Environmental Sanitation Engineering, 2018, 26(3): 39-42.

[6] SHI Mingzhe, ZHANG Rui, ZHANG Lijuan, et al. Effects of alkaliand alkaline earth metal species on the combustion characteristics and synergistic effects: Sewage sludge and its blend with coal[J]. Waste Management, 2022,146: 119-129.

[7] HAO Dong, JIANG Xuguang, LV G, et al. Co-combustion of tannery sludge in a commercial circulating fluidized bed boiler[J]. Waste Management, 2015, 46(12): 227-233.

[8] YE B, SHI B, SHI M, et al. Process simulation and comprehen-sive evaluation of a system of coal power plant coupled with waste incineration[J]. Waste Management &Research, 2021, 39(6): 828-840.

[9] CHYANG C, HAN Y, WU L, et al. An investigation on pollutant emissions from co-firing of RDF and coal[J]. Waste Management, 2010, 30(7): 1334-1340.

[10] LEE J, KIM D, KIM J, et al. Co-combustion of refuse derived fuel with Korean anthracite in a commercial circulating fluidized bed boiler[J]. Energy, 2010, 35(7): 2814-2818.

[11] MLONKA-M![]() DRALA A, DZIOK T, MAGDZIARZ A, et al. Coamposition and properties of fly ash collected from a multifuel fluidized bed boiler co-firing refuse derived fuel (RDF) and hard coal[J]. Energy, 2021, 234: 121229.

DRALA A, DZIOK T, MAGDZIARZ A, et al. Coamposition and properties of fly ash collected from a multifuel fluidized bed boiler co-firing refuse derived fuel (RDF) and hard coal[J]. Energy, 2021, 234: 121229.

[12] RIGAMONTI L, GROSSO M, BIGANZOLI L. Environmental assessment of refuse-derived fuel co-combustion in a coal-fired power plant[J]. Journal of Industrial Ecology, 2012, 16(5): 748-760.

[13] KARAGIANNIS J, FTIKOS C, NIKOLOPOULOS P. The use of wastes as alternative fuels in cement production[J]. Waste Management and the Environment IV, 2008, 109:105.

[14] SCHNEIDER M, ROMER M, TSCHUDIN M, et al. Sustainable cement production:Present and future[J]. Cement and Concrete Research, 2011, 41(7): 642-650.

[15] 杨晋萍, 史飞, 张雁茹. 电站燃煤锅炉掺烧生物质技术[J]. 电力技术, 2010(10): 13-17.

YANG Jinping, SHI Fei, ZHANG Yanru. Technology of biomass cofiring in coal boiler of power station[J]. Electric Power Technology, 2010(10): 13-17.

[16] 张勇, 王晓娜, 杜永斌, 等. 燃煤锅炉耦合垃圾发电试验研究[J].热力发电, 2023, 52(7): 167-173.

ZHANG Yong, WANG Xiaona, DU Yongbin, et al. Experimental research on power generation technology of coal-fired power station coupled with waste[J]. Thermal Power Generation, 2023, 52(7): 167-173.

[17] 刘贺, 刘建忠, 陈建, 等. 几种典型固废与神华煤掺烧的结渣特性[J]. 化工进展, 2022, 41(1): 443-452.

LIU He, LIU Jianzhong, CHEN Jian, et al. Slagging properties of several typical solid wastes mixed with Shenhua coal[J]. Chemical Industry and Engineering Progress, 2022, 41(1): 443-452.

[18] 史兵权, 史明哲, 张睿. 220t/h锅炉烟气侧耦合垃圾焚烧数值模拟[J]. 洁净煤技术, 2022, 28(3): 150-158.

SHI Bingquan, SHI Mingzhe, ZHANG Rui. Numerical simulation of flue gas side coupled municipal solid waste incineration in a 220 t/h boiler[J]. Clean Coal Technology, 2022, 28(3): 150-158.

[19] 何祺东. 城市生活垃圾热处理中氯元素迁移特性的研究[D]. 上海:华南理工大学, 2020.

[20] MCKAY G. Dioxin characterisation, formation and minimisation during municipal solid waste (MSW) incineration[J]. Chemical Engineering Journal, 2002, 86(3): 343-368..

[21] 许鹏, 周品, 柏寄荣, 等. 二噁英形成机理研究进展[J]. 中国资源综合利用, 2022,40(6): 100-111.

XU Peng, ZHOU Pin, BAI Jirong, et al.Research progress on the formation mechanism of dioxin[J]. China Resources Comprehensive Utilization, 2022,40(6): 100-111.

[22] LIU H, WANG Y, ZHAO S, et al. Review on the current status of the co-combustion technology of organic solid waste (OSW) and coal in China[J]. Energy &Fuels, 2020, 34(12): 15448-15487.

[23] RUOKOJARVI P, ASIKAINEN A, RUUSKANEN J. Urea As a PCDD/F Inhibitor in Municipal Waste Incineration[J]. Journal of the Air &Waste Management Association, 2001, 51(3): 422-431.

[24] WU H L, LU S Y, LI X D, et al. Inhibition of PCDD/F by adding sulphur compounds to the feed of a hazardous waste incinerator[J]. Chemosphere, 2012, 86(4): 361-367.

[25] CHANG M B, CHENG Y C, CHI K H. Reducing PCDD/F formation by adding sulfur as inhibitor in waste incineration processes[J]. Science of the Total Environment, 2006, 366(2/3): 456-465.

[26] SAMARAS P, BLUMENSTOCK M, LENOIR D, et al. PCDD/F prevention by novel inhibitors: Addition of inorganic S- and N-compounds in the fuel before combustion[J]. Environmental Science &Technology, 2000, 34(24): 5092-5096.

[27] 翁志华. 固体废物焚烧中二噁英控制措施探讨[J]. 上海环境科学, 2011, 30(2): 82-89.

WENG Zhihua. An approach to dioxin control measures in the process of solid waste incineration[J]. Shanghai Environmental Sciences, 2011, 30(2): 82-89.

[28] MA H, DU N, LIN X, et al. Inhibition of element sulfur and calcium oxide on the formation of PCDD/Fs during co-combustion experiment of municipal solid waste[J]. Science of the Total Environment, 2018, 633: 1263-1271.

[29] CHEN Z, LIN X, LU S, et al. Suppressing formation pathway of PCDD/Fs by S-N- containing compound in full-scale municipal solid waste incinerators[J]. Chemical Engineering Journal, 2018,359:1391-1399.

[30] LIU W, TIAN Z, LI H, et al. Mono- to Octa-Chlorinated PCDD/Fs in stack gas from typical waste incinerators and their implications on emission[J]. Environmental Science &Technology, 2013, 47(17): 9774-9780.

[31] CHI K, CHANG S, HUANG C, et al. Partitioning and removal of dioxin-like congeners in flue gases treated with activated carbon adsorption[J]. Chemosphere, 2006, 64(9): 1489-1498.

[32] 曹玉春, 严建华, 李晓东, 等. 垃圾焚烧炉中二噁英生成机理的研究进展[J]. 热力发电, 2005, 34(9): 15-20.

CAO Yuchun, YAN Jianhua, LI Xiaodong, et al. Advancement in study on formation mechanism of dioxin in MSW incinerators[J]. Thermal Power Generation, 2005, 34(9): 15-20.

[33] LIU W, TIAN Z, LI H, et al. Mono- to Octa-Chlorinated PCDD/Fs in stack gas from typical waste incinerators and their implications on emission[J]. Environmental Science &Technology, 2013, 47(17): 9774-9780.

[34] ZHANG B, ZHANG X, JING M, et al. Generation characteristi-cs and control technology of organic pollutants during the co-combustion of municipal solid waste and industrial organic solid waste[J]. Environmental Chemistry, 2022, 41(5): 1809-1823.

[35] CONESA J A. Sewage sludge as inhibitor of the formation of persistent organic pollutants during incineration[J]. Sustainability, 2021, 13(19): 10935.

[36] WIKSTRÖM E, RYAN S, TOUATI A, et al. Importance of chlorine speciation on de novo formation of polychlorinated dibenzo-p-dioxins and polychlorinated dibenzofurans[J]. Environmental Science &Technology, 2003, 37(6): 1108-1113.

[37] LIU Y, LI B, LEI X, et al. Novel method for high-performance simultaneous removal of NOx and SO2 by coupling yellow phosphorus emulsion with red mud[J]. Chemical Engineering Journal, 2022, 428: 131991.

[38] 叶步青. 烟气循环式燃煤耦合垃圾焚烧系统的全流程模拟及综合评估[D]. 南京: 南京理工大学, 2019.

[39] 陈涛. 城市生活垃圾与花生壳的混燃特性及其碱金属的迁移研究专业硕士[D]. 合肥: 合肥工业大学, 2021.

[40] 刘煜康. 废塑料与生物质混合成型-热解成炭的特性研究[D]. 昆明: 昆明理工大学, 2020.

Pilot-test of coal-fired boiler coupling with waste incineration technology

移动阅读