基于有机工质及CO2的跨临界动力循环研究进展

0 引 言

全球变暖已成为世界共识,为将全球温升控制在2 ℃以内,多国发布了适合自身国情的低碳发展路径及时间表。现阶段,CO2排放主要来自化石能源的燃烧,故提高能源利用效率及加强可再生能源的开发是实现碳减排的关键举措。在能源利用过程中,能量基本以热能的形式存在。按照温度高低,可将热能依次划分为高温热能(≥500 ℃)、中温热能(230~500 ℃)及低温热能(<230 ℃)[1]。在自然界及工业生产过程中存在大量的中低温热能,具有分布广及种类多的特点[2-3]。有效利用这部分热能是提高一次能源利用率、推进可再生能源替代化石能源、实现碳中和的重要手段。

热力循环是实现中低温热能高效转换的技术手段之一,受到广泛关注[4-5]。针对热功转换,根据工质所处的压力,热力循环可分为亚临界、跨临界和超临界动力循环。亚临界循环和跨临界循环的主要区别在于定压吸热过程。不同于亚临界循环中工质的恒温蒸发,跨临界循环中工质在超临界状态下吸热,可与热源形成良好的温度匹配,以减少换热不可逆损失。同时,由于超临界流体温压的相互解耦,使加热器出口工质温度独立于加热压力。此外,由于临界温度较低的工质更适用于跨临界循环,工质的选择范围更广。另一方面,在相同热源工况下,跨临界循环可以比亚临界循环获得更高的净输出功和![]() 效率[6-7]。对于超临界动力循环,系统始终在流体的超临界状态下运行,其压缩起点的温度和压力控制对系统的净输出功影响较大,且通常用于回收利用高温余热[8]。因此,在3种动力循环中,跨临界循环具有吸热过程温度匹配良好和温压相互解耦、可用工质范围广、效率高及系统操作简单等优点,更适用于中低温热能的回收利用。

效率[6-7]。对于超临界动力循环,系统始终在流体的超临界状态下运行,其压缩起点的温度和压力控制对系统的净输出功影响较大,且通常用于回收利用高温余热[8]。因此,在3种动力循环中,跨临界循环具有吸热过程温度匹配良好和温压相互解耦、可用工质范围广、效率高及系统操作简单等优点,更适用于中低温热能的回收利用。

近年来,涌现大量有关跨临界动力循环的研究报道,包括不同热源驱动下的循环构建及优化[9-10]、动态分析及控制策略[11]、高效换热器及透平部件的设计[6,12]等。通过仿真、试验等方法分析论证了跨临界动力循环在利用发动机尾气/工业烟气的余热[13]、地热[14]、太阳能[15-16]等热源的可行性和优越性。如石凌峰[13]应用跨临界动力循环回收内燃机排气和缸套水余热,构建了4种基本热力循环,设计并搭建了一套4.6 kW量级样机系统,可实现4种循环结构的简易切换。RAO等[16]针对太阳能驱动的跨临界动力循环系统,建立了云扰动下基本循环及回热循环的动态仿真模型。以关键词“Subcritical power cycle”和“ORC”、“Transcritical power cycle”、“Supercritical power cycle”在Scopus 数据库中进行检索,发现近年来有关动力循环的论文数量明显增多,论文作者以中国、美国、伊朗和英国学者居多。在已发表的综述文章中,有诸多关于亚临界[17-18]和超临界[19-21]动力循环的文章,但缺乏对跨临界动力循环研究进展的总结分析。因此,笔者将以跨临界动力循环为主线,首先回顾现有循环结构,介绍循环的稳态及动态仿真模型,根据不同的循环工质(有机工质、CO2及CO2混合工质)综述了国内外跨临界动力循环的最新理论和试验研究进展。在此基础上,笔者探讨了跨临界动力循环将要面临的挑战以及今后的发展方向。

1 跨临界动力循环结构及仿真模型

1.1 循环结构

热力循环是工程热力学永恒的研究方向,新型热力循环的构建是提高热电转换性能的关键途径。简单跨临界动力循环由绝热压缩、定压吸热、绝热膨胀和定压放热4个热力过程组成。在简单循环上增设回热器,回收透平出口工质的高温余热,不仅能降低冷凝器的热负荷,还可进一步提高系统热效率[22]。SHI等[23]通过试验对比以CO2作为工质的简单和回热循环,发现回热循环的净功、热效率和![]() 效率分别比简单循环高42.4%、71.0%和48.9%。对于存在高低温双热源的场景,可增设预热器充分利用低温余热,以提高系统效率,常用于回收利用发动机烟气和缸套水余热。简单循环在引入了回热器、预热器后,构成回热循环、预热循环以及预回热循环,如图1所示。

效率分别比简单循环高42.4%、71.0%和48.9%。对于存在高低温双热源的场景,可增设预热器充分利用低温余热,以提高系统效率,常用于回收利用发动机烟气和缸套水余热。简单循环在引入了回热器、预热器后,构成回热循环、预热循环以及预回热循环,如图1所示。

图1 基本跨临界动力循环结构

Fig.1 Structure of the basic transcritical power cycle

石凌峰等[13,24]针对4种基本的跨临界动力循环结构,以净输出功、![]() 效率及经济性指标为目标建立MAP图,根据不同内燃机应用工况,筛选出具有最优性能的循环结构。为提高回热器内高压侧和低压侧工质流体换热温度的匹配程度,可采用分流的形式降低高压侧工质的质量流量,从而降低高压侧工质的热容。KIM等[25]提出分流回热循环,工质在泵增压后分流,一部分进入回热器吸热,另一部分进入加热器进一步吸收热源的余热,如图2(a)所示。结果表明,分流循环的

效率及经济性指标为目标建立MAP图,根据不同内燃机应用工况,筛选出具有最优性能的循环结构。为提高回热器内高压侧和低压侧工质流体换热温度的匹配程度,可采用分流的形式降低高压侧工质的质量流量,从而降低高压侧工质的热容。KIM等[25]提出分流回热循环,工质在泵增压后分流,一部分进入回热器吸热,另一部分进入加热器进一步吸收热源的余热,如图2(a)所示。结果表明,分流循环的![]() 损失远小于简单回热循环。WU等[26-28]在回热循环的基础上,通过增加回热支路,提出多级回热循环,如图2(b)和(c)所示。通过热力学和

损失远小于简单回热循环。WU等[26-28]在回热循环的基础上,通过增加回热支路,提出多级回热循环,如图2(b)和(c)所示。通过热力学和![]() 经济比较研究,得到了不同热源温度范围内最佳的循环结构。

经济比较研究,得到了不同热源温度范围内最佳的循环结构。

图2 改进回热循环结构

Fig.2 Structure of the improved recuperative cycle

近年来,由一个顶循环和一个底循环组合而成的联合循环成为了研究热点,具体循环结构的选择通常与热源温度有关。联合循环在无额外消耗能源的条件下,提高了热源的利用率和系统热效率。目前已有大量关于跨临界循环和亚临界[29]、跨临界[30]、超临界[31]、卡琳娜[32]及斯特林[33]循环等组成的联合循环研究。一般地,顶循环和底循环之间有3种连接方式。第1种是热源侧耦合,即热源流体依次流经顶循环和底循环并进行热交换。以跨临界CO2动力循环和卡琳娜循环耦合为例,典型循环结构如图3(a)所示[32]。第2种是工质侧耦合,即通过中间换热器连接顶循环和底循环,底循环工质回收利用顶循环冷凝热,或共用动力部件如泵和透平,降低系统成本。以有机朗肯循环和跨临界CO2动力循环的联合为例,典型循环结构如图3(b)所示[29]。第3种是混合耦合,即热源侧和工质侧均耦合连接。以跨临界动力循环和亚临界动力循环耦合为例,典型循环结构如图3(c)所示[31]。超临界CO2(S-CO2)动力循环被认为是回收高温热源最具应用前景的能量转换技术[7,34],但是其冷却温度仍然较高且余热利用程度不足。因此,出现了大量将跨临界动力循环作为底循环与S-CO2再压缩循环耦合的研究[15,31,35-37]。ZHOU等[37]提出S-CO2再压缩循环和改进型回热循环的联合结构,如图4所示。在跨临界循环中,工质经过泵压缩后进行分流,一部分进入回热器,另一部分进入预热器,从而提高系统性能。

图3 联合循环示意

Fig.3 Combined cycle

图4 S-CO2再压缩循环与跨临界循环的联合结构

Fig.4 Combined structure of the S-CO2 recompression cycle and the transcritical cycle

联合循环虽能提高系统性能,但由于系统部件增多,使系统质量、占地面积、经济成本等随之增加,难以应用于对循环系统的空间和质量有较高要求的场合,如海上平台、移动车辆等[28,38]。对此, MOROZ等[39]提出复合循环方法,即共用2个循环压缩机、回热器和冷凝器等系统部件,以提高系统的紧凑性,如图5给出的复合循环示例。

图5 复合循环结构示意

Fig.5 Structure of the complex cycle

综上所述,目前跨临界动力循环系统结构形式多样,但已有的循环结构仅凭研究者的经验构建,难以得到适用于不同条件的最佳循环结构。对此,学者们[40-42]提出了循环形式的智能构建方法,即采用二进制编码表征各热力过程,并基于智能算法对热力过程进行拓扑组合,以优化得到最佳循环构型。如天津大学赵力团队[40]设计了一套2层算法来实现循环结构的智能构建,将循环简化为传热部分和基本配置部分,并对3个案例进行分析,发现循环功率分别增加了47.97、46.5和42.59 kJ/kg。因此,智能构建将循环构建和智能算法相结合或将成为热力循环的研究热点。

1.2 热力学模型

1.2.1 稳态模型

针对提出的多种新型跨临界动力循环结构,学者们基于热力学第一定律和第二定律进行了相应的数学建模。为简化循环模型,大部分研究多限于稳态工况[5,6,30-31,43-46],并做出以下假设:

① 忽略管道和换热器热损失和压降[6,44-45],或取某一定值[31,35];② 泵、压缩机和透平机具有恒定的等熵效率[43,45,47];③ 给定换热器的窄点温差[35,45,48-49];④ 冷凝器出口的工质处于饱和液态[47,50]。

值得注意的是,在对加热器进行热力建模时,通常已知工质进出口温度、热源进口温度及质量流量,从而基于窄点温差确定工质的质量流量[49]。然而,对于跨临界动力循环,工质在整个加热过程中都处于超临界状态,且工质的比热随温度和压力变化很大。因此,加热器内温度窄点理论上可发生在任意位置。对此,在数学建模时,通常将加热过程划分为n段,逐段求解并得到每段的最小温差,从而确定温度窄点位置和热源出口温度,以得到工质质量流量。否则,改变热源的出口温度值,重新迭代计算[45,51]。

在热力学建模中,基于质量守恒、能量守恒和![]() 平衡方程建立各个部件模型[19,30,47],一般形式如下:

平衡方程建立各个部件模型[19,30,47],一般形式如下:

∑min=∑mout,

(1)

∑Q ∑minhin=∑mouthout ∑W,

(2)

∑Ein=∑Eout ∑W EL,

(3)

在忽略动能和势能的条件下,任意一个状态点的![]() 可表示为

可表示为

Ei=mi[hi-h0-T0(si-s0)],

(4)

式中,m为质量流量;h为比焓;s为比熵;E为![]() 值;Q和W分别为功和热量;in、out分别为流进和流出控制体;0为环境状态;EL为

值;Q和W分别为功和热量;in、out分别为流进和流出控制体;0为环境状态;EL为![]() 损。

损。

跨临界动力循环的关键部件有透平、泵、加热器、回热器和冷凝器,表1列出了每个部件的能量及![]() 方程。

方程。

表1 主要部件的热力学模型

Table 1 Thermodynamic model of the main components

注:η为效率;TPPTD为窄点温度;ηP、ηTur、QC、QR和QH分别为泵、透平、冷凝器、回热器和加热器的功;Thf、Tlf、Tg和Tf分别为高温流体、低温流体、热源和流体温度。

基于上述部件的性能建模,循环净功、热效率、热回收效率和![]() 效率分别为

效率分别为

Wnet=∑WTur-∑WP,

(5)

ηth=Wnet/QH×100%,

(6)

(7)

(8)

式中,Wnet、ηth、ηre和ηex分别为净功、热效率、余热回收效率和![]() 效率。

效率。

1.2.2 动态模型

由于热源及环境工况的波动,热力系统的运行将偏离设计工况。当波动较大时,热力系统甚至可能无法正常运行。因此,除建立稳态模型,还必须建立相应的动态模型,以对系统的变工况运行进行模拟分析。针对跨临界动力循环,泵及膨胀机的响应较快,可认为无惯性延迟,常采用稳态模型进行建模[52-53]。相比动力部件,回热器、加热器、冷凝器等换热部件的响应时间较长,直接决定系统的动态变化特性。因此,在动态建模中,研究者主要考虑换热器的动态响应模型[54]。

换热器的动态建模方法主要有分布参数法、移动边界法和集总参数法[55]。依据传热流体所处相态,分布参数法和集总参数法适用于单相流体的传热,而移动边界法主要用于多相流体的传热建模。因此,针对跨临界动力循环,换热器的动态建模常采用分布参数法和移动边界法。

分布参数法由集总参数法发展而来,适用于跨临界动力循环中加热器及回热器的动态建模。该方法将换热器划分为多个微元段,每个微元段内的流体物性参数可取该段进出口数值的平均值。在此基础上,换热器的任意微元段内质量平衡方程和能量平衡方程[53]可分别表示为

(9)

(10)

式中,![]() 为质量流量;V为微元段内流体体积;cp为流体定压比热;

为质量流量;V为微元段内流体体积;cp为流体定压比热;![]() 为单元段内流体平均密度;τ为时间;T为温度;f和i分别为流体和第i个微元段。

为单元段内流体平均密度;τ为时间;T为温度;f和i分别为流体和第i个微元段。

对于多相流体传热,移动边界法将换热器分成过冷区、两相区和过热区3个区域,适用于跨临界循环中冷凝器的动态建模。相比分布参数法,移动边界法中3个区域的相边界会随工况变化而发生移动。每个区域的质量和能量平衡方程[53]如下:

液相过冷区:

(11)

(12)

气液两相区:

(13)

(14)

气体过热区:

(15)

(16)

式中,A为截面面积;P为压力;l为各区域的长度;ρl、ρv分别为饱和液体、饱和气体; 分别为各区域进出口;l1、l2、l3分别为过冷区、两相区和过热区;hv为饱和蒸气的焓。

分别为各区域进出口;l1、l2、l3分别为过冷区、两相区和过热区;hv为饱和蒸气的焓。

1.3 经济模型

1.3.1 ![]() 经济模型

经济模型

![]() 经济是一种结合热力学和经济学的分析方法,各系统部件的

经济是一种结合热力学和经济学的分析方法,各系统部件的![]() 经济方程[56]一般可表示为

经济方程[56]一般可表示为

∑Cout Cw=∑Cin Cq Z,

(17)

Cj=cjEj,

(18)

Z=Ceq Cm,

(19)

式中,C和c分别为![]() 成本和

成本和![]() 单价;Cw和Cq分别为与做功、传热相关的

单价;Cw和Cq分别为与做功、传热相关的![]() 成本;Z为非能量成本,包括设备投资成本Ceq和经营管理成本Cm。

成本;Z为非能量成本,包括设备投资成本Ceq和经营管理成本Cm。

此外,![]() 经济模型涉及的关键参数表达式见表2[57],其中,i和n分别表示年利率和系统运行年限。

经济模型涉及的关键参数表达式见表2[57],其中,i和n分别表示年利率和系统运行年限。

表2 ![]() 经济模型参数表达式

经济模型参数表达式

Table 2 Parametric expressions of economic model

1.3.2 成本模型

为预估当年经济状况下热力系统的总投资成本,一般通过化工工厂成本指数(iCEPC)转化为参考年份的总投资成本[58]。

Ctotal,n=Ctotal,refiCEPC,total/iCEPC,n,

(20)

Ctotal,ref=∑Ci,

(21)

式中,Ctotal为总投资成本;n和ref分别为当年和参考年份。

系统各部件的投资成本取决于购买成本CPur和成本系数F,计算公式见表3[36]。

由表3可知,透平和压缩机的投资成本通过输出功与功耗估算,而加热器、回热器等换热设备的投资成本则通过换热面积进行估算。上述模型中K、B、D、F为相应系数。

表3 主要部件的投资成本模型

Table 3 Investment cost models for major components

基于系统成本的计算,单位发电成本[36]可定义为

(22)

式中,fk为操作、维护和保险成本系数;t为年运行小时数。

2 不同工质跨临界动力循环理论研究

2.1 有机工质跨临界动力循环

对于有机工质跨临界动力循环,工质的热力学性质对换热器内部热匹配有显著影响,直接决定循环系统性能。表4列出了常用工质的热力学和环境参数[17,20,29,59-61]。WANG等[62]研究了工质的临界压力、临界温度和干度对跨临界循环性能的影响。结果表明,较高的临界温度导致热源出口温度较高,热源利用率低,较低的临界温度导致透平出口温度较高,冷凝器换热恶化。较高的临界压力则会影响加热器内部的热匹配;在相同冷凝压力下,工质的温熵饱和蒸汽曲线斜率(k)越大,则冷凝器中过热度越大,对应的热匹配性越差。因此,在优选工质时,应尽量选择临界压力低、临界温度适中,且k较小的工质。此外,最佳的循环工质还与热源温度有关。WANG等[51]在不同热源温度下研究了跨临界动力循环的热匹配性能,提出了边界温度的概念。每种工质都存在一个边界温度,如R1234ze(E)、R227a、异丁烷、R245fa的边界温度分别为151.4、125.5、170.8和195.8 ℃。当热源温度高于边界温度时,跨临界动力循环使用该工质才具有更好的热力性能。

表4 常用工质的热力学和环境参数

Table 4 Thermodynamic and environmental parameters of common fluids

针对跨临界动力循环,工质在超临界状态下吸热,可与热源形成良好的温度匹配,而工质在亚临界两相恒温冷凝,与冷源温度匹配性差。为提高工质与冷源的温度匹配程度,可将2种及以上有机工质组成混合物作为跨临界动力循环的工作流体,以利用非共沸混合工质相变过程的温度滑移实现换热流体间更好的温度匹配。YANG等[63]利用R1234yf/R32混合物作为低品位余热回收的工作流体,研究了跨临界动力循环系统的热经济性能。结果表明,在最佳质量分数下,R1234yf/R32(0.8∶0.2)的热经济性能分别比纯R1234yf和纯R32高1.46%和4.88%。ZHI等[64]将混合工质R600a/R601a和R134a/R245fa分别应用于图2(c)联合系统的跨临界和亚临界循环,发现在最佳配比下,混合工质的最大净输出功为97.95 kW,比纯工质的净输出功增加19.78%。

针对亚临界动力循环、跨临界动力循环、双压加热亚临界动力循环、双压加热跨临界动力循环4种结构,CHAGNON等[60]基于20种有机工质进行了优化分析,发现双压加热跨临界循环(图4(b))在大多数情况下具有最高的循环性能。SURENDRAN等[65]利用蒸汽再生器,改进了图4(b)循环结构,得到了图4(c)循环构型,以环戊烷作为工作流体,结果发现,改进后系统的净输出功比原有系统增加了16%。针对双压加热跨临界动力循环,ZHI等[45, 66-67]采用纯工质(R600、R600a、R601、R601a、R601b、R1233zd(E))和混合工质(R600a/R601a、R600/R601)进行了大量研究,结果发现,在有机工质中,R1233zd(E)的循环净输出功最大;当采用有机混合工质时,可提高系统的净输出功并降低系统的运行压力。值得注意的是,当以CO2为工质时,系统的最大净输出功将大幅提高,而系统的最大压力也随之提高。该研究显示了CO2相比有机工质在提高余热回收系统性能上的优越性,故2.2节将重点介绍跨临界CO2动力循环的研究进展。

2.2 CO2跨临界动力循环

在跨临界动力循环中,由于传统有机工质分解温度较低,且环境友好性差,故研究者一直致力于研发新型高效且稳定的环保工质。在已有工质中,CO2作为一种自然流体,具有环境友好(臭氧消耗潜能值为0,全球变暖潜能值为1)、热稳定性高、可与高温热源直接换热、易达到超临界状态(31.2 ℃、7.38 MPa)等优点[8],使其在跨临界动力循环中具有广阔的应用前景,受到广泛关注。将CO2应用于跨临界动力循环时,处在超临界状态下的CO2具有密度高、黏度低等特点,能够克服换热器内压降大和易堵塞等问题[8]。此外,超临界CO2的密度较高,可极大减小透平和换热器的尺寸,使系统更加紧凑[68]。由于CO2定压比热在临界温度附近存在极大值,故CO2跨临界动力循环在利用高温热源的同时具有高效回收低温余热的能力,从而实现热源深度开发,以提高系统的做功能力[12]。在实际应用中,CO2跨临界动力循环可更好适应热源的瞬时变化,使系统运行更加稳定,避免频繁启停。

针对CO2跨临界动力循环,常立文[69]分析了4种基本构型的热力经济性,发现预回热循环结构热力学性能最优,而回热循环具有最好的经济性。为深度开发热源,实现更高的系统热效率,联合循环成为CO2跨临界动力循环研究的热点[25,29,31,35-36],表5列出了联合循环的最新研究成果。此外,研究者也提出将跨临界动力循环与热泵循环[56]、喷射制冷循环[47-48]耦合,在供电的同时满足用户对供冷和供热的需求。相关研究表明,这种冷热电联供系统的热力性能和经济性优于单一系统[70]。针对舰船余热回收,ZHANG等[47]提出了一种CO2跨临界动力循环和喷射器制冷循环相耦合的联供系统。该系统有制冷和制热2种模式,对应的制冷量和供热量分别为863.3和960.5 kW,净输出功为202和272 kW。针对地热利用,ZARE等[71]提出了一种冷热电多联供系统,其净输出功、制冷量和供热量分别为25.61、22.05和42.11 kW。LIU等[56]将热泵循环耦合到CO2跨临界动力循环中,形成了一种地热驱动的新型热电联产系统,结果表明该系统最优的总产品单位成本、![]() 效率分别为23.53美元/GJ和37.17%。

效率分别为23.53美元/GJ和37.17%。

表5 基于CO2跨临界动力系统的联合循环研究

Table 5 Research on combined cycle based on CO2 transcritical power systems

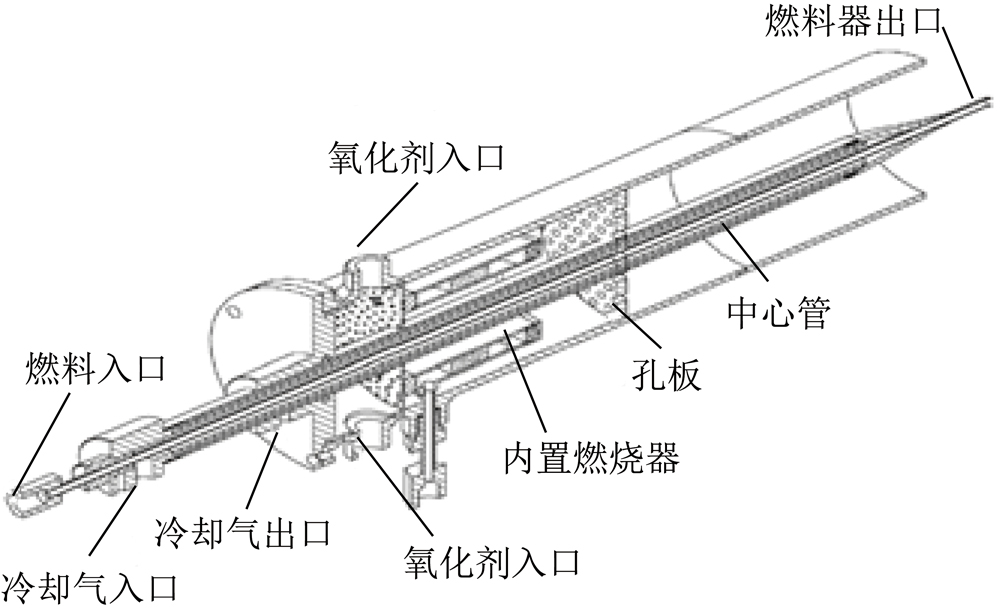

在利用太阳能等周期性波动的热源时,常将跨临界动力循环和压缩空气[70,72]、压缩CO2[73-74]等储能系统相结合,以提高系统运行稳定性。图6为两级跨临界压缩CO2储能系统[73],该系统在用电低谷时,将低压储罐内的CO2经过压缩、吸热后,储存于高压储罐内;在用电高峰时,再将高压储罐内的CO2进行发电,以实现电力的削峰填谷,从而缓解电网负荷的压力。

图6 两级跨临界CO2储能系统

Fig.6 Dual-stage transcritical CO2 energy storage system

针对CO2跨临界动力循环的动态特性,WU等[22]在地热驱动下研究了回热器对循环非设计性能的影响。结果发现,当地热水的质量流量和温度变化时,CO2跨临界回热循环的净输出功和热效率均高于基本循环。DU等[75]以最大净输出功为目标提出了一种新型控制方法,研究CO2跨临界动力循环的非设计性能,发现相比传统的滑压控制法和恒压控制法,新型控制法可分别提高净输出功15.07%及3.49%。此外,为提高系统适应热源变化的能力,LI等[76]开发了自适应流量控制策略,以主动控制系统工质流量。

由于CO2的临界温度与环境温度接近,难以用自然冷源对CO2跨临界动力循环进行冷凝,极大限制了CO2跨临界动力循环的工程应用[77]。对此,研究者从循环结构的角度出发[46,78-80],构建了新型自冷凝系统,如图7所示。

图7 自冷凝循环结构

Fig.7 Structure of self-condensing cycle

图7(a)~(c)在原循环结构的基础上,添加了一个节流阀和气液分离器,以实现CO2冷凝。相关原理为:透平出口的CO2首先在冷凝器中被环境冷却至低温气态,经节流阀进一步降温冷却后进入气液分离器,最后分离出的低压气体经压缩机或喷射器增压后与主流混合,而分离出的低温液体则进入跨临界动力循环完成升压、吸热及做功等热力过程。图7(d)通过热源依次驱动跨临界动力循环及制冷循环,将CO2跨临界动力循环和溴化锂吸收式制冷循环相结合[78]。制冷循环为跨临界动力循环提供冷量来冷凝CO2,同时采用自然水源对吸收器进行冷却。除了采用自冷凝系统对CO2跨临界动力循环进行冷凝外,研究者也将CO2跨临界动力循环与液化天然气再气化系统耦合[81],以最大限度利用液化天然气冷能,同时实现CO2的低温冷凝,如图8所示[29]。经过加压的液化天然气首先吸收CO2冷凝热至高压气体,然后经透平膨胀做功,最后进入天然气管道。相关研究表明,使用液化天然气作为CO2跨临界动力循环的冷源时,整个系统的输出功可提高20%,热效率和![]() 效率可提高2%[67]。

效率可提高2%[67]。

图8 液化天然气再气化系统结构

Fig.8 LNG regasification system

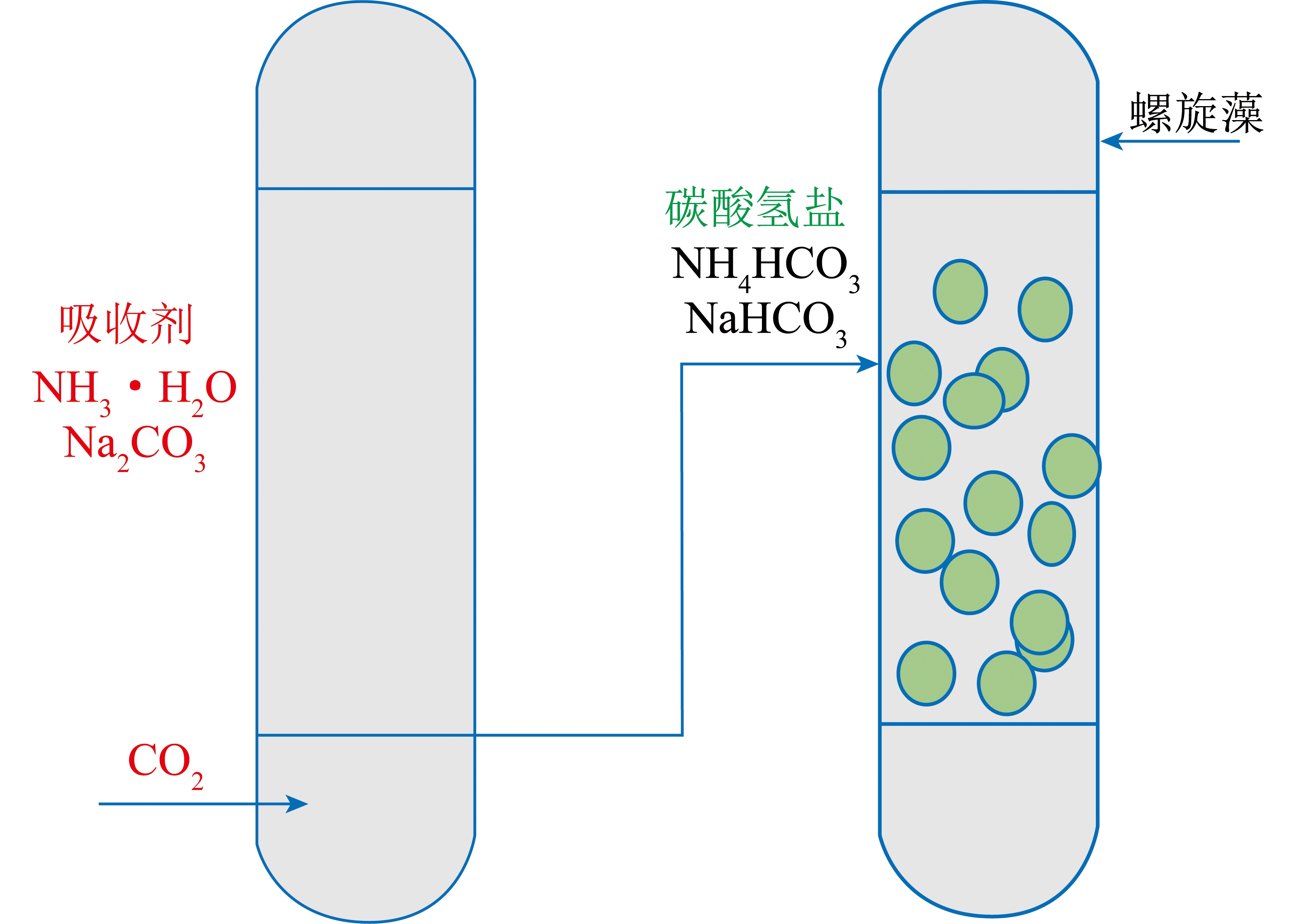

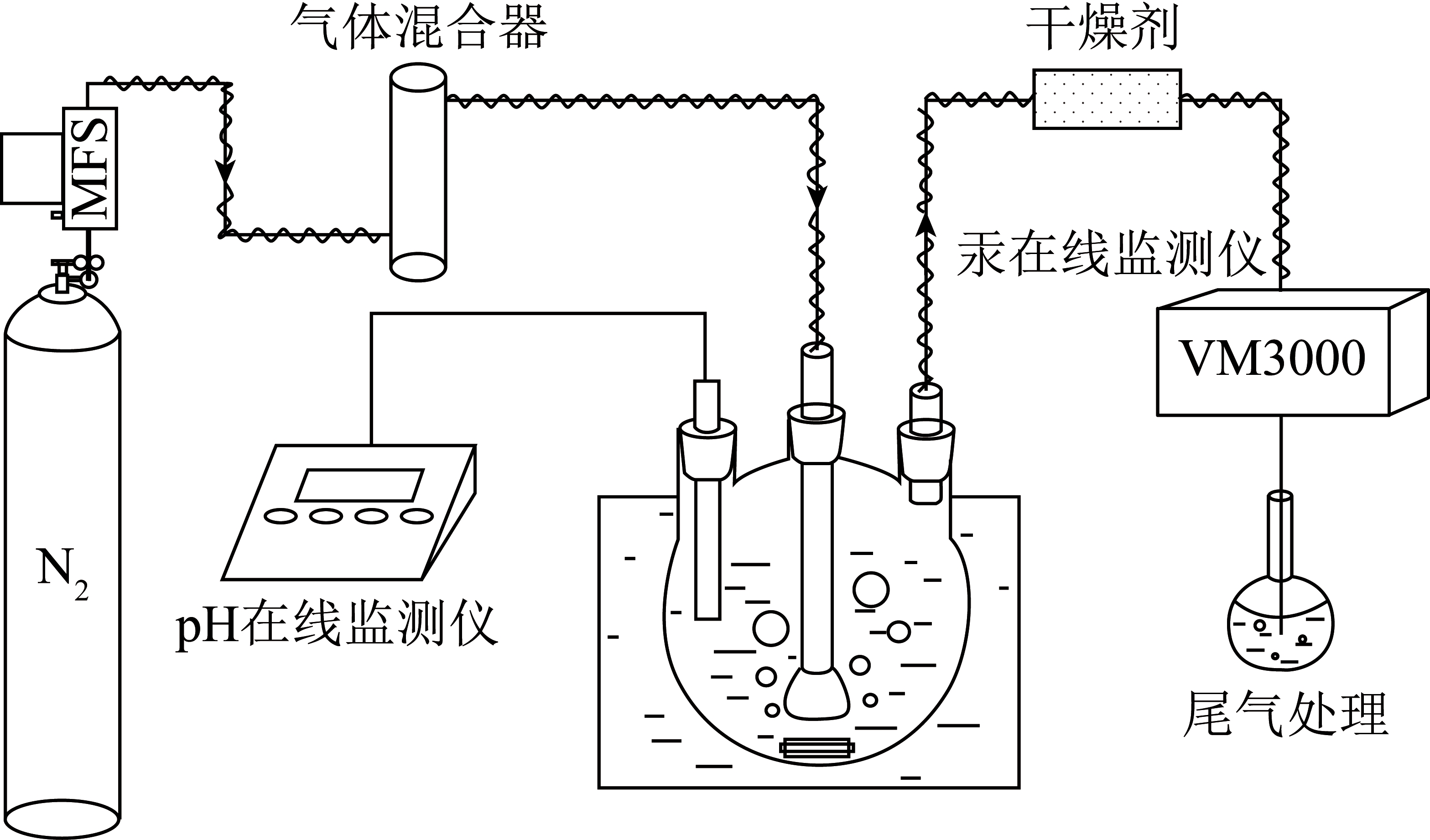

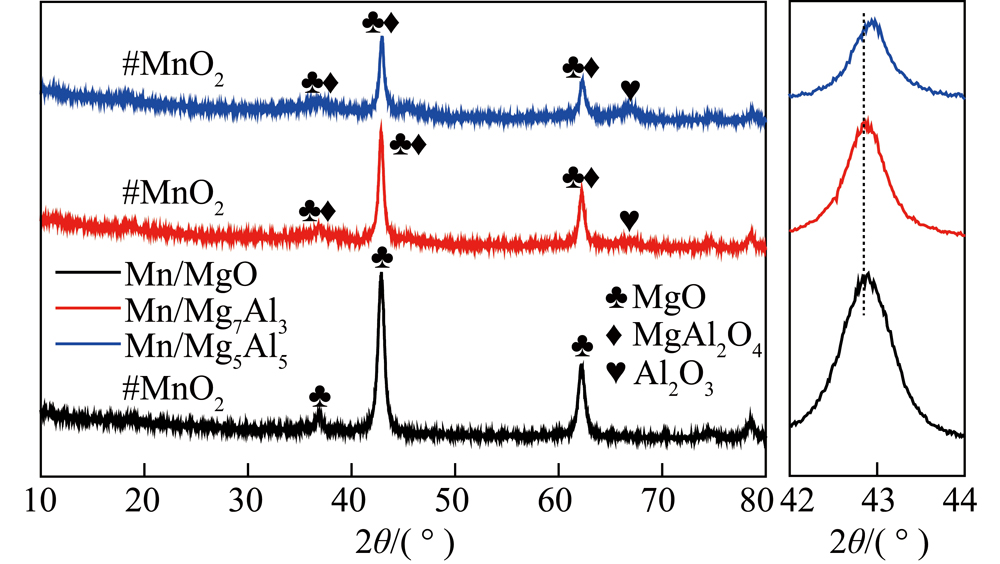

2.3 CO2混合工质跨临界动力循环

近年来,为降低CO2跨临界动力循环的运行压力,研究者提出将CO2与有机工质混合,以形成CO2混合工质。相比于CO2,CO2混合工质具有较高的临界温度,可以提高跨临界动力循环冷凝温度的上限[43]。相比于纯有机工质,CO2混合工质可以抑制有机组分的毒性及燃爆特性[82-83]。针对CO2混合工质,喻志刚[84]以P-R状态方程为基础,建立了相应的物性预测模型,并通过试验测得了预回热跨临界动力循环中混合工质CO2/R134a(0.6∶0.4,物质的量比)的冷凝温度为36.3 ℃,可以满足环境冷源冷却的要求。在众多有机工质中,为选择最优的有机工质与CO2混合,常遵循以下3个标准初选出候选工质[50,61,85]:① 有机工质的全球变暖潜能值GWP低于150和臭氧消耗值ODP为0;② CO2混合工质的最大温度滑移值应小于50 ℃,以避免分馏;③ 有机工质的临界温度要大于特定值,以实现CO2混合工质的常温冷凝。

表6总结了CO2混合工质跨临界动力循环的研究。可以发现,目前研究主要针对基本跨临界动力循环结构。

表6 CO2混合工质跨临界动力循环研究

Table 6 Research on the trans-critical power cycle of CO2 mixtures

续表

同时,在众多的候选工质中[50, 61, 85],SHU等[61]发现与CO2跨临界动力循环相比,采用CO2/R32(0.7∶0.3,物质的量比)作为工作流体的跨临界动力循环的最佳运行压力降低了1.4 MPa,净输出功增加了8.8%。XIA等[85]发现低温热源驱动的跨临界动力循环中,CO2/R32的![]() 效率最高,CO2/R161的经济性能最好;而对于高温热源,CO2/丙烷作为工质的循环经济性能最佳。LIU等[88]研究了CO2/R134a不同混合比例对循环系统性能的影响,发现当R134a比例增加时,系统的净输出功、热效率和

效率最高,CO2/R161的经济性能最好;而对于高温热源,CO2/丙烷作为工质的循环经济性能最佳。LIU等[88]研究了CO2/R134a不同混合比例对循环系统性能的影响,发现当R134a比例增加时,系统的净输出功、热效率和![]() 效率先增大后减小。这主要是因为R134a的比例越高,混合物的温度滑移越大,从而影响与冷源的温度匹配,导致不可逆损失增加和

效率先增大后减小。这主要是因为R134a的比例越高,混合物的温度滑移越大,从而影响与冷源的温度匹配,导致不可逆损失增加和![]() 效率降低。S

效率降低。S NCHEZ等[87]研究混合物质量分数对循环性能的影响时,发现混合物中有机工质的质量分数越大,则循环的热力学性能越好,但基于GWP值对循环的净输出功进行统一标准量化后,发现与纯有机工质相比,纯CO2具有明显优势。综上所述,相比于CO2,CO2混合工质在跨临界动力循环中具有更好的热力经济性。

NCHEZ等[87]研究混合物质量分数对循环性能的影响时,发现混合物中有机工质的质量分数越大,则循环的热力学性能越好,但基于GWP值对循环的净输出功进行统一标准量化后,发现与纯有机工质相比,纯CO2具有明显优势。综上所述,相比于CO2,CO2混合工质在跨临界动力循环中具有更好的热力经济性。

针对CO2混合工质跨临界动力循环的动态特性,WANG等[89-90] 以CO2/R134a(0.7∶0.3,物质的量比)为工质建立了相应的动态模型。结果发现,系统的动态响应时间主要受换热器的换热性能和工质热惯性的影响。在非设计条件下,预热器有利于降低系统参数波动,而回热器则会加剧系统不稳定性,增大系统参数的波动幅度及响应时间。为实现系统的稳定运行,研究者提出了最优控制策略,并在不同条件下比较了恒温、恒压和最优控制策略的系统运行特性。结果表明,CO2混合工质中有机物占比越小,系统的动态响应时间越少,更有利于系统的稳定运行[91]。

3 不同工质跨临界动力循环试验

相比于理论研究,已有的跨临界动力循环试验研究较少,拥有试验台架的主要机构有清华大学、天津大学及中科院。清华大学张信荣团队[92-94]最早搭建了以太阳能驱动的CO2跨临界动力循环系统,包括真空管太阳能集热器、CO2泵、冷凝器和膨胀阀等部件。因未找到合适的膨胀机,试验数据基于膨胀阀获得,后续性能分析以假定的膨胀机效率开展,所得结果为估算值而非实测值。对此,针对CO2跨临界动力循环,HUANG等[95]设计制造了一种具有传统碳环机械密封和角接触陶瓷球轴承的部分进气轴流式涡轮膨胀机,并研究了该膨胀机的热力性能,发现膨胀机的最大效率可达53.43%。而对于有机工质,LANDELLE等[96]基于R134a改装了涡旋膨胀机,试验结果表明该涡旋膨胀机最大效率可达66.5%。

表7和表8列出了近年来不同工质跨临界动力循环的试验研究及结果,目前试验研究的跨临界动力循环主要为图1的4种基本循环,而对于理论研究中具有较高热力性能的复杂循环仍未有相关的试验研究。对于CO2混合工质跨临界动力循环,仅有天津大学搭建了相应的试验平台。此外,在跨临界动力循环试验中,研究者常用热水或导热油充当系统热源,并采用冷水机组产生的低温冷却水作为循环冷源。

表7 有机工质试验

Table 7 Experimental studies on organics

表8 CO2及其混合工质试验

Table 8 Experimental studies on CO2 and mixtures of CO2

续表

4 结语及展望

1)跨临界动力循环系统结构形式多样,已有的循环结构仅凭研究者的经验构建,尚无统一的系统构建法则,同时针对各循环构型的性能评价统一准则至今还未明确。因此,探索热力系统综合评价机制,并尝试与人工智能有机结合,以实现系统的智能构建,将成为热力循环的研究热点。

2)为平衡工质的热力性能及环境性能,CO2混合工质将成为跨临界动力循环研究的热点。作为循环分析的前提,CO2混合工质物性与有机工质种类及其质量分数密切相关。因此,如何准确预测CO2混合工质物性及高效优选适用于跨临界动力循环的有机工质还需进一步研究。

3)现有跨临界动力循环试验研究仅针对简单的基本循环。由于系统关键部件效率不高,导致试验系统的性能与理论研究相差甚远。因此,亟需研发相应的系统关键部件并针对多种循环结构展开试验研究。

[1] 张帆. 工艺限制下工业烟气余热回收利用的研究[D]. 北京: 北京建筑大学, 2020.

[2] HE W F, ZHU W P, XIA J R, et al. A mechanical vapor compression desalination system coupled with a transcritical carbon dioxide Rankine cycle[J]. Desalination, 2018, 425: 1-11.

[3] 朱杰人, 曹先常, 陈志良, 等. 低品位热能有机朗肯循环发电技术进展[J]. 制冷技术, 2021, 49(1): 73-80.

ZHU Jieren, CAO Xianchang, CHEN Zhiliang, et al. Review on the progress of organic Rankine cycle generation technology using low-grade heat energy[J]. Refrigeration, 2021, 49(1): 73-80.

[4] GE Y T, LI L, LUO X, et al. Performance evaluation of a low-grade power generation system with CO2 transcritical power cycles[J]. Applied Energy, 2018, 227: 220-230.

[5] ZHAO Dongpeng, ZHAO Ruikai, DENG Shuai, et al. Transcritical carbon dioxide power cycle for waste heat recovery: A roadmap analysis from ideal cycle to real cycle with case implementation[J]. Energy Conversion and Management, 2020, 226: 113578.

[6] MENG Fanxiao, WANG Enhua, ZHANG Bo, et al. Thermo-economic analysis of transcritical CO2 power cycle and comparison with Kalina cycle and ORC for a low-temperature heat source[J]. Energy Conversion and Management, 2019, 195: 1295-1308.

[7] KIZILKAN Onder, KHANMOHAMMADI Shoaib, YAMAGUCHI Hiroshi. Two-objective optimization of a transcritical carbon dioxide based Rankine cycle integrated with evacuated tube solar collector for power and heat generation[J]. Applied Thermal Engineering, 2021, 182: 116079.

[8] YU Aofang, SU Wen, LIN Xinxing, et al. Recent trends of supercritical CO2 Brayton cycle: Bibliometric analysis and research review[J]. Nuclear Engineering and Technology, 2021,53(3):699-714.

[9] MOSAFFA A H, GAROUSI FARSHI L. Novel post combustion CO2 capture in the coal-fired power plant employing a transcritical CO2 power generation and low temperature steam upgraded by an absorption heat transformer[J]. Energy Conversion and Management, 2020, 207: 112542.

[10] LIN Xinxing, CHEN Chonghui, YU Aofang, et al. Performance comparison of advanced transcritical power cycles with high-temperature working fluids for the engine waste heat recovery[J]. Energies, 2021, 14(18):5886.

[11] LI Hang, YANG Yi, CHENG Ziyang, et al. Study on off-design performance of transcritical CO2 power cycle for the utilization of geothermal energy[J]. Geothermics, 2018, 71: 369-379.

[12] SONG Jian, LI Xiaoya, REN Xiaodong, et al. Thermodynamic and economic investigations of transcritical CO2 cycle systems with integrated radial-inflow turbine performance predictions[J]. Applied Thermal Engineering, 2020, 165: 114604.

[13] 石凌峰. 内燃机余热回收跨临界CO2动力循环理论与实验研究[D]. 天津: 天津大学, 2018.

[14] HASSANI MOKARRAM N, MOSAFFA A H. Investigation of the thermoeconomic improvement of integrating enhanced geothermal single flash with transcritical organic Rankine cycle[J]. Energy Conversion and Management, 2020, 213: 112831.

[15] KHATOON Saboora, KIM Manhoe. Performance analysis of car-bon dioxide based combined power cycle for concentrating solar power[J]. Energy Conversion and Management, 2020, 205: 112416.

[16] RAO Z H, PENG C Y, WANG Y Q, et al. Response behaviors of CO2 transcritical Rankine cycle based parabolic trough solar power plant to cloud disturbance[J]. Applied Thermal Engineering, 2021, 189: 116722.

[17] DAI Xiaoye, SHI Lin, QIAN Weizhong. Review of the working fluid thermal stability for Organic Rankine Cycles[J]. Journal of Thermal Science, 2019, 28(4): 597-607.

[18] PARK Byungsik, USMAN Muhammad, IMRAN Muhammad, et al. Review of Organic Rankine Cycle experimental data trends[J]. Energy Conversion and Management, 2018, 173: 679-691.

[19] LIAO Gaoliang, LIU Lijun, E Jiaqiang, et al. Effects of technical progress on performance and application of supercritical carbon dioxide power cycle: A review[J]. Energy Conversion and Management, 2019, 199: 111986.

[20] MOHAMMED RAMY H, ALSAGRI ALI Sulaiman, WANG Xiaolin. Performance improvement of supercritical carbon dioxide power cycles through its integration with bottoming heat recovery cycles and advanced heat exchanger design: A review[J]. International Journal of Energy Research, 2020, 44(9): 7108-7135.

[21] XU J, LIU C, SUN E, et al. Perspective of SCO2 power cycles[J]. Energy, 2019, 186:115831.

[22] WU Chuang, WANG Shunsen, LI Jun. Parametric study on the effects of a recuperator on the design and off-design performances for a CO2 transcritical power cycle for low temperature geothermal plants[J]. Applied Thermal Engineering, 2018, 137: 644-658.

[23] SHI Lingfeng, SHU Gequn, TIAN Hua, et al. Experimental investigation of a CO2-based Transcritical Rankine Cycle (CTRC) for exhaust gas recovery[J]. Energy, 2018, 165: 1149-1159.

[24] SHU Gequn, SHI Lingfeng, TIAN Hua, et al. Configurations selection maps of CO2 -based transcritical Rankine cycle (CTRC) for thermal energy management of engine waste heat[J]. Applied Energy, 2017, 186: 423-435.

[25] KIM Youngmin, SOHN Jeonglak, YOON Euisoo. Supercritical CO2 Rankine cycles for waste heat recovery from gas turbine[J]. Energy, 2017, 118: 893-905.

[26] WU Chuang, YAN Xiaojiang, WANG Shunsen, et al. System optimisation and performance analysis of CO2 transcritical power cycle for waste heat recovery[J]. Energy, 2016, 100: 391-400.

[27] WANG Shunsen, WU Chuang, LI Jun. Exergoeconomic analysis and optimization of single-pressure single-stage and multi-stage CO2 transcritical power cycles for engine waste heat recovery: A comparative study[J]. Energy, 2018, 142: 559-577.

[28] WALNUM Harald Taxt, NEKSÅ Petter, NORD Lars O, et al.Modelling and simulation of CO2 (carbon dioxide) bottoming cy-cles for offshore oil and gas installations at design and off-design conditions[J]. Energy, 2013, 59: 513-520.

[29] SADREDDINI Amirhassan, ASHJARI Muhammad Ali, FANI Maryam, et al. Thermodynamic analysis of a new cascade ORC and transcritical CO2 cycle to recover energy from medium temperature heat source and liquefied natural gas[J]. Energy Conversion and Management, 2018, 167: 9-20.

[30] MOHAMMADKHANI Farzad, YARI Mortaza. A 0D model for diesel engine simulation and employing a transcritical dual loop Organic Rankine Cycle (ORC) for waste heat recovery from its exhaust and coolant: Thermodynamic and economic analysis[J]. Applied Thermal Engineering, 2019, 150: 329-347.

[31] CAO Yue, REN Jingqi, SANG Yiqian, et al. Thermodynamic analysis and optimization of a gas turbine and cascade CO2 combined cycle[J]. Energy Conversion and Management, 2017, 144: 193-204.

[32] ABDOLALIPOURADL Mehran, KHALILARYA Shahram, JAF-ARMADAR Samad. Exergoeconomic analysis of a novel integrated transcritical CO2 and Kalina 11 cycles from Sabalan geothermal power plant[J]. Energy Conversion and Management, 2019, 195: 420-435.

[33] AKBARI Nozar. Introducing and 3E (energy, exergy, economic) analysis of an integrated transcritical CO2 Rankine cycle, Stirling power cycle and LNG regasification process[J]. Applied Thermal Engineering, 2018, 140: 442-454.

[34] MANJUNATH K, SHARMA O P, TYAGI S K, et al. Thermodynamic analysis of a supercritical/transcritical CO2 based waste heat recovery cycle for shipboard power and cooling applications[J]. Energy Conversion and Management, 2018, 155: 262-275.

[35] ZHANG Qiang, OGREN Ryan M, KONG Songcharng. Thermo-economic analysis and multi-objective optimization of a novel waste heat recovery system with a transcritical CO2 cycle for offshore gas turbine application[J]. Energy Conversion and Management, 2018, 172: 212-227.

[36] HOU Shengya, WU Yuandan, ZHOU Yaodong, et al.Performan-ce analysis of the combined supercritical CO2 recompression and regenerative cycle used in waste heat recovery of marine gas turbine[J]. Energy Conversion and Management, 2017, 151: 73-85.

[37] ZHOU Aozheng, LI Xuesong, REN Xiaodong, et al. Improvem-ent design and analysis of a supercritical CO2/transcritical CO2 combined cycle for offshore gas turbine waste heat recovery[J]. Energy, 2020, 210: 118562.

[38] SHI Lingfeng, SHU Gequn, TIAN Hua, et al. Assessment of waste heat recovery system for automotive engine with weight effect[J]. Energy, 2020, 193: 116663.

[39] MOROZ Leonid, BURLAKA Maksym, RUDENKO Oleksii, et al.

Evaluation of gas turbine exhaust heat recovery utilizing composite supercritical CO2 cycle[C]//International Gas Turbine Congress 2015. Tokyo: Leonid Moroz, 2015: 109-115.

[40] CHEN M, ZHAO R, ZHAO L, et al. Supercritical CO2 Brayton cycle: Intelligent construction method and case study[J]. Energy Conversion and Management, 2021, 246:114662.

[41] CARRARO G, DANIELI P, LAZZARETTO A, et al. A common thread in the evolution of the configurations of supercritical CO2 power systems for waste heat recovery[J]. Energy Conversion and Management, 2021, 237: 114031.

[42] 杨勇平,辛团团,许诚. 热力循环流程重构能效分析新方法:循环拆分法[J]. 中国电机工程学报, 2021, 41(20): 1-12.

YANG Yongping, XIN Tuantuan, XU Cheng. A new analytical method for process modification of thermal cycle: Cycle splitting method[J]. 2021, 41(20): 1-12.

[43] AQEL O A, WHITE M T, KHADER M A, et al. Sensitivity of transcritical cycle and turbine design to dopant fraction in CO2-based working fluids[J]. Applied Thermal Engineering, 2021, 190: 116796.

[44] VUTUKURU Ravindra, PEGALLAPATI Saikiran A, MADDALI Ramgopal. Thermodynamic studies on a solar assisted transcritical CO2 based tri-generation system with an ejector for dairy applications[J]. International Journal of Refrigeration, 2019, 108: 113-123.

[45] ZHI Lianghui, HU Peng, CHEN Longxiang, et al. Thermodynamic analysis of a novel transcritical-subcritical parallel organic Rankine cycle system for engine waste heat recovery[J]. Energy Conversion and Management, 2019, 197: 111855.

[46] XIA Jiaxi, WANG Jiangfeng, ZHOU Kehan, et al. Thermodynamic and economic analysis and multi-objective optimization of a novel transcritical CO2 Rankine cycle with an ejector driven by low grade heat source[J]. Energy, 2018, 161: 337-351.

[47] ZHANG Qiang, LUO Zewei, ZHAO Yongjie, et al. Thermodynamic analysis and multi-objective optimization of a transcritical CO2 waste heat recovery system for cruise ship application[J]. Energy Conversion and Management, 2021, 227: 113612.

[48] ZHANG Qiang, LUO Zewei, ZHAO Yongjie, et al. Performance assessment and multi-objective optimization of a novel transcritical CO2 trigeneration system for a low-grade heat resource[J]. Energy Conversion and Management, 2020, 204: 112281.

[49] TIAN Hua, LIU Lina, SHU Gequn, et al. Theoretical research on working fluid selection for a high-temperature regenerative transcritical dual-loop engine organic Rankine cycle[J]. Energy Conversion and Management, 2014, 86: 764-773.

[50] WU Chuang, WANG Shunsen, JIANG Xihang, et al. Thermodynamic analysis and performance optimization of transcritical power cycles using CO2-based binary zeotropic mixtures as working fluids for geothermal power plants[J]. Applied Thermal Engineering, 2017, 115: 292-304.

[51] WANG Mingtao, ZHANG Juan, ZHAO Songsong, et al. Performance investigation of transcritical and dual-pressure Organic Rankine Cycles from the aspect of thermal match[J]. Energy Conversion and Management, 2019, 197: 111850.

[52] WANG X, WANG R, BIAN X, et al. Review of dynamic performance and control strategy of supercritical CO2 Brayton cycle[J]. Energy and AI, 2021, 5: 100078.

[53] 倪佳鑫. 有机朗肯循环的动态仿真及变工况应用研究[D]. 天津:天津大学, 2019.

[54] LI X, SHU G, TIAN H, et al. Dynamic modeling of CO2 transcritical power cycle for waste heat recovery of gasoline engines[J]. Energy Procedia, 2017, 105:1576-1581.

[55] XING K, XIAO G, XU H, et al. Experimental and numerical investigation on the dynamic characteristics of a lab-scale transcritical CO2 loop[J]. Energy Conversion and Management, 2021, 245:114384.

[56] LIU Zhan, YANG Xuqing, LIU Xu, et al. Performance assessment of a novel combined heating and power system based on transcritical CO2 power and heat pump cycles using geothermal energy[J]. Energy Conversion and Management, 2020, 224: 113355.

[57] 王明华. 能源系统![]() 成本图示方法与应用研究[J]. 计算机与应用化学, 2017, 34(10):815-821.

成本图示方法与应用研究[J]. 计算机与应用化学, 2017, 34(10):815-821.

WANG Minghua. Study on the methodology and application of the graphic representation of the cost of an energy system[J]. Computers and Applied Chemistry, 34(10):815-821.

[58] AKBARI Ata D, MAHMOUDI Seyed M S. Thermoeconomic analysis & optimization of the combined supercritical CO2 (carbon dioxide) recompression Brayton/organic Rankine cycle[J]. Energy, 2014, 78: 501-512.

[59] 陈奇成, 徐进良, 苗政. 中温热源驱动有机朗肯循环工质研究[J]. 中国电机工程学报, 2013, 33(32): 1-7.

CHEN Qicheng, XU Jinliang, MIAO Zheng. Working fluid selection for medium temperature Organic Rankine Cycle[J]. Proceedings of the CSEE, 2013, 33(32):1-7.

[60] CHAGNON Lessard Noémie, MATHIEU Potvin François, GOSSELIN Louis. Optimal design of geothermal power plants: A comparison of single-pressure and dual-pressure organic Rankine cycles[J]. Geothermics, 2020, 86: 101787.

[61] SHU Gequn, YU Zhigang, TIAN Hua, et al. Potential of the transcritical Rankine cycle using CO2-based binary zeotropic mixtures for engine′s waste heat recovery[J]. Energy Conversion and Management, 2018, 174: 668-685.

[62] WANG Mingtao, ZHANG Juan, LIU Qiyi, et al. Effects of critical temperature, critical pressure and dryness of working fluids on the performance of the transcritical organic rankine cycle[J]. Energy, 2020, 202: 117663.

[63] YANG Minhsiung, YEH Ronghua, HUNG Tzuchen. Thermo-economic analysis of the transcritical Organic Rankine Cycle using R1234yf/R32 mixtures as the working fluids for lower-grade waste heat recovery[J]. Energy, 2017, 140: 818-836.

[64] ZHI Lianghui, HU Peng, CHEN Longxiang, et al. Parametric analysis and optimization of transcritical-subcritical dual-loop Organic Rankine Cycle using zeotropic mixtures for engine waste heat recovery[J]. Energy Conversion and Management, 2019, 195: 770-787.

[65] SURENDRAN Anandu, SESHADRI Satyanarayanan. Design and performance analysis of a novel Transcritical Regenerative Series Two stage Organic Rankine Cycle for dual source waste heat recovery[J]. Energy, 2020, 203: 117800.

[66] ZHI Lianghui, HU Peng, CHEN Longxiang, et al. Performance analysis and optimization of engine waste heat recovery with an improved transcritical-subcritical parallel Organic Rankine Cycle based on zeotropic mixtures[J]. Applied Thermal Engineering, 2020, 181: 115991.

[67] ZHI Lianghui, HU Peng, CHEN Longxiang, et al. Thermodynamic analysis of an innovative transcritical CO2 parallel Rankine cycle driven by engine waste heat and liquefied natural gas cold[J]. Energy Conversion and Management, 2020, 209: 112583.

[68] YU Aofang, SU Wen, LIN Xinxing, et al. Thermodynamic analysis on the combination of supercritical carbon dioxide power cycle and transcritical carbon dioxide refrigeration cycle for the waste heat recovery of shipboard[J]. Energy Conversion and Management, 2020, 221: 113214.

[69] 常立文. 内燃机余热回收CO2动力循环的理论探索[D]. 天津: 天津大学, 2018.

[70] LIU Zhan, YANG Xuqing, JIA Wenguang, et al. Thermodyn-amic study on a combined heat and compressed air energy storage system with a dual-pressure organic Rankine cycle[J]. Energy Conversion and Management, 2020, 221: 113141.

[71] ZARE V, ROSTAMNEJAD TAKLEH H. Novel geothermal driven CCHP systems integrating ejector transcritical CO2 and Rankine cycles: Thermodynamic modeling and parametric study[J]. Energy Conversion and Management, 2020, 205: 112396.

[72] MENG Jia, WEI Mingshan, SONG Panpan, et al. Performance evaluation of a solar transcritical carbon dioxide Rankine cycle integrated with compressed air energy storage[J]. Energy Conversion and Management, 2020, 215: 112931.

[73] LIU Zhan, LIU Bin, GUO Jianzhang, et al. Conventional and advanced exergy analysis of a novel transcritical compressed carbon dioxide energy storage system[J]. Energy Conversion and Management, 2019, 198: 111807.

[74] LIU Zhan, CAO Feng, GUO Jianzhang, et al. Performance analysis of a novel combined cooling, heating and power system based on carbon dioxide energy storage[J]. Energy Conversion and Management, 2019, 188: 151-161.

[75] DU Yang, CHEN Haichao, HAO Muting, et al. Off-design performance comparative analysis of a transcritical CO2 power cycle using a radial turbine by different operation methods[J]. Energy Conversion and Management, 2018, 168: 529-544.

[76] LI Ligeng, TIAN Hua, SHI Lingfeng, et al. Adaptive flow assignment for CO2 transcritical power cycle (CTPC): An engine operational profile-based off-design study[J]. Energy, 2021, 225: 120262.

[77] 李冰. 自冷凝CO2跨临界动力循环研究[D]. 北京: 北京建筑大学, 2020.

[78] YANG Sheng, DENG Chengwei, LIU Zhiqiang. Optimal design and analysis of a cascade LiBr/H2O absorption refrigeration/transcritical CO2 process for low-grade waste heat recovery[J]. Energy Conversion and Management, 2019, 192: 232-242.

[79] PAN Lisheng, LI Bing, SHI Weixiu, et al. Optimization of the self-condensing CO2 transcritical power cycle using solar thermal energy[J]. Applied Energy, 2019, 253: 113608.

[80] LIU Zhan, LIU Zihui, CAO Xing, et al. Self-condensing transcritical CO2 cogeneration system with extraction turbine and ejector refrigeration cycle: A techno-economic assessment study[J]. Energy, 2020, 208: 118391.

[81] MEHRPOOYA Mehdi, ESFILAR Reza, MOOSAVIAN S M A. Introducing a novel air separation process based on cold energy recovery of LNG integrated with coal gasification, transcritical carbon dioxide power cycle and cryogenic CO2 capture[J]. Journal of Cleaner Production, 2017, 142: 1749-1764.

[82] 潘利生, 马月婧, 李腾, 等. 混合工质(R600/CO2)的可燃性研究[J]. 工程热物理学报, 2019, 40(4): 732-736.

PAN Lisheng, MA Yuejing, LI Teng, et al. Investigation on the flammability of the mixed working fluid (R600/CO2) [J]. Journal of Engineering Thermophysics, 2019, 40(4): 732-736.

[83] PAN Lisheng, MA Yuejing, LI Teng, et al. Investigation on the cycle performance and the combustion characteristic of two CO2-based binary mixtures for the transcritical power cycle[J]. Energy, 2019, 179: 454-463.

[84] 喻志刚. 内燃机余热回收CO2混合工质跨临界朗肯循环性能研究[D]. 天津: 天津大学, 2018.

[85] XIA Jiaxi, WANG Jiangfeng, ZHANG Gang, et al. Thermo-economic analysis and comparative study of transcritical power cycles using CO2-based mixtures as working fluids[J]. Applied Thermal Engineering, 2018, 144: 31-44.

[86] YANG Minhsiung. The performance analysis of the transcritical Rankine cycle using carbon dioxide mixtures as the working fluids for waste heat recovery[J]. Energy Conversion and Management, 2017, 151: 86-97.

[87] S NCHEZ Carlos J N, DA SILVA Alexandre K. Technical and environmental analysis of transcritical Rankine cycles operating with numerous CO2 mixtures[J]. Energy, 2018, 142: 180-190.

NCHEZ Carlos J N, DA SILVA Alexandre K. Technical and environmental analysis of transcritical Rankine cycles operating with numerous CO2 mixtures[J]. Energy, 2018, 142: 180-190.

[88] LIU Peng, SHU Gequn, TIAN Hua, et al. Experimental study on transcritical Rankine cycle (TRC) using CO2/R134a mixtures with various composition ratios for waste heat recovery from diesel engines[J]. Energy Conversion and Management, 2020, 208: 112574.

[89] WANG Rui, SHU Gequn, WANG Xuan, et al. Dynamic performance and control strategy of CO2-mixture transcritical power cycle for heavy-duty diesel engine waste-heat recovery[J]. Energy Conversion and Management, 2020, 205: 112389.

[90] WANG Rui, WANG Xuan, TIAN Hua, et al. Dynamic performance comparison of CO2 mixture transcritical power cycle systems with variable configurations for engine waste heat recovery[J]. Energies, 2020, 13(1): 32.

[91] SHU Gequn, WANG Rui, TIAN Hua, et al. Dynamic perform-ance of the transcritical power cycle using CO2 based binary zeotropic mixtures for truck engine waste heat recovery[J]. Energy, 2020, 194: 116825.

[92] ZHANG Xinrong, YAMAGUCHI Hiroshi, UNENO Daisuke. Experimental study on the performance of solar Rankine system using supercritical CO2[J]. Renewable Energy, 2007, 32(15): 2617-2628.

[93] ZHANG Xinrong, YAMAGUCHI Hiroshi. An experimental investigation on characteristics of supercritical CO2-based solar Rankine system[J]. International Journal of Energy Research, 2011, 35(13): 1168-1178.

[94] ZHANG Xinrong, YAMAGUCHI Hiroshi. A feasibility study of CO2-based Rankine Cycle powered by solar energy[J]. JSME International Journal, 2005, 48(3): 540-547.

[95] HUANG Guangdai, SHU Gequn, TIAN Hua, et al. Experiments on a small-scale axial turbine expander used in CO2 transcritical power cycle[J]. Applied Energy, 2019, 255: 113853.

[96] LANDELLE A, TANVERON N, REVELLIN R, et al. Experimental investigation of a transcritical Organic Rankine Cycle with scroll expander for low-temperature waste heat recovery[C]//International seminar on ORC power systems. Italy: Elsevier Ltd. 2017: 810-817.

[97] HSIEH Juiching, FU Benran, WANG Tawei, et al. Design and preliminary results of a 20 kW transcritical Organic Rankine Cycle with a screw expander for low-grade waste heat recovery[J]. Applied Thermal Engineering, 2017, 110: 1120-1127.

[98] LI L, GE Y T, LUO X, et al. Experimental analysis and comparison between CO2 transcritical power cycles and R245fa organic Rankine Cycles for low-grade heat power generations[J]. Applied Thermal Engineering, 2018, 136: 708-717.

[99] PAN Lisheng, LI Bo, WEI Xiaolin, et al. Experimental investigation on the CO2 transcritical power cycle[J]. Energy, 2016, 95: 247-254.

[100] SHI Lingfeng, SHU Gequn, TIAN Hua, et al. Experimental co-mparison between four CO2 -based transcritical Rankine cycle (CTRC) systems for engine waste heat recovery[J]. Energy Conversion and Management, 2017, 150: 159-171.

[101] SHI Lingfeng, SHU Gequn, TIAN Hua, et al. Ideal point de-sign and operation of CO2-based transcritical Rankine Cycle (CTRC) system based on high utilization of engine′s waste heats[J]. Energies, 2017, 10(11): 1692.

[102] LI Xiaoya, SHU Gequn, TIAN Hua, et al. Preliminary tests on dynamic characteristics of a CO2 transcritical power cycle using an expansion valve in engine waste heat recovery[J]. Energy, 2017, 140: 696-707.

[103] LI Xiaoya, SHU Gequn, TIAN Hua, et al. Experimental comparison of dynamic responses of CO2 transcritical power cycle systems used for engine waste heat recovery[J]. Energy Conversion and Management, 2018, 161: 254-265.

[104] PAN Lisheng, SHI Weixiu, WEI Xiaolin, et al. Experimental verification of the self-condensing CO2 transcritical power cycle[J]. Energy, 2020, 198: 117335.

Recent advances on transcritical power cycles based on organic fluids and CO2

移动阅读

CHEN Chonghui,OU Shaoduan,SU Wen,et al.Recent advances on transcritical power cycles based on organic fluids and CO2[J].Clean Coal Technology,2022,28(12):125-142.