污泥对高灰熔融温度煤灰熔融特性调控机制

0 引 言

我国富煤、贫油、少气的资源禀赋决定了煤炭在我国能源消耗结构中将长期占据主导地位[1-2]。气化是煤炭清洁高效利用的有效方式[3-4]。气流床气化因煤种适应性广、热效率高和产品纯度高等优点成为煤气化技术的首选[5-6]。气流床气化通常采用液态排渣,灰渣的流动性是影响气化炉能否稳定运行的关键[7-8]。灰渣流动性通常由2个关键参数决定:煤灰黏度和灰熔融温度[9-12]。气流床气化炉的操作温度一般要求高于煤灰流动温度(TF)50~100 ℃,以保证气化炉顺利排渣。但在实际工业过程中,对煤灰TF有一定限制(TF<1 380 ℃),煤灰黏度宜控制在2.5~25.0 Pa·s[13]。由于煤灰黏度测量周期长且成本较高,有研究者提出通过研究和测量灰熔融温度预测灰分排渣行为[14-15]。我国高灰熔融温度煤储量丰富(>57%),单独直接用于气流床气化难以满足液态排渣要求[16]。煤灰熔融温度与煤灰化学组成关系密切[17-18]。已有研究主要采取3种方法改善煤灰熔融特性,包括向煤中添加助熔剂、配煤及煤与生物质共气化[19-20]。

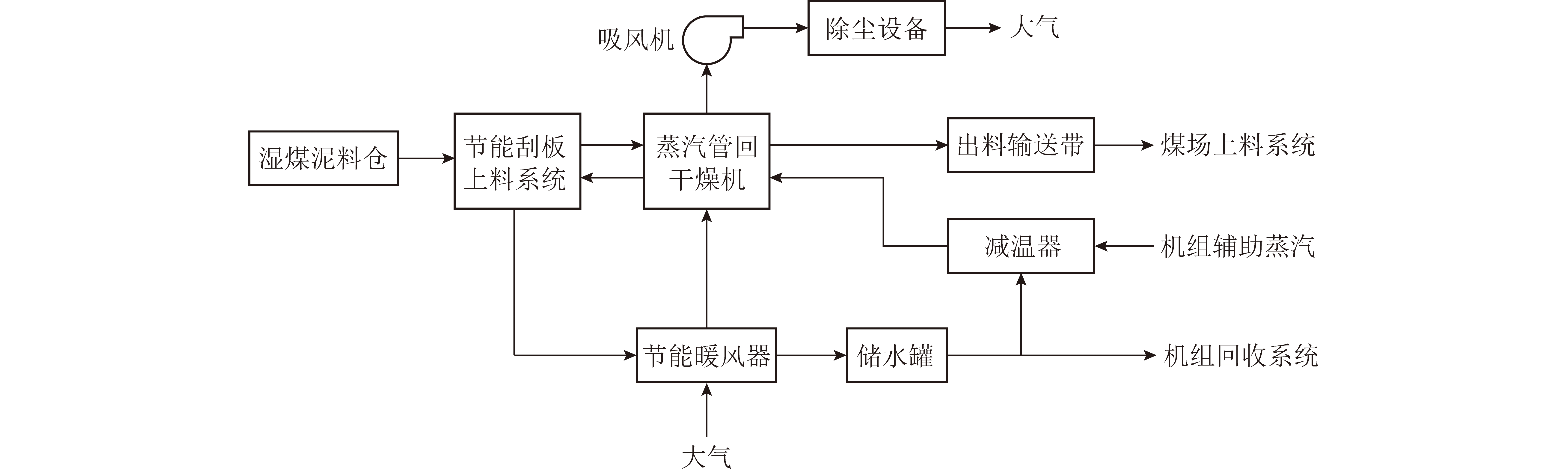

我国每年污泥产量约20亿t,工业污泥和城市污泥是我国污泥主要来源[21]。污泥产量巨大,直接排放会危害环境和人类健康[22]。填埋、土壤利用和焚烧是常见污泥处理方法,但易受空间和环境压力限制,且焚烧运行成本非常昂贵。制药污泥的焚烧运行成本占总成本的25%~65%[23-24]。 《中华人民共和国水污染防治法》强调了污泥处理政策由“重水轻泥”转变为“泥水并重”,污泥资源化利用和后续合理处置受到广泛关注。水热碳化后,部分污水污泥热值为12~20 MJ/kg,与褐煤热值(11.7~15.8 MJ/kg)相似[25-27]。污泥中含大量能量,而传统处理方式受多方面限制,因此将污泥进行热利用并回收能量是目前国内外资源化利用污泥的重要方式和研究热点[28-29]。由于部分污泥热值较低,有时需添加辅助燃料(如煤),污泥与煤在流化床中共烧可有效改善污泥燃烧性能,去除烟气中污染物(如NOx)和二噁英且有助于灰中重金属凝固[30-34]。气化是一种清洁、高效和大规模利用污水污泥的有前景的热利用方法[35-36]。为提高污泥气化产品质量并减少污染物、灰分和重金属含量,通常将污泥与煤共气化,多用于中试规模工厂[37]。相比煤单独气化,污水污泥与煤共气化CO2排放更少[38],具有污染物少、成本低和热效率高等优点。学者发现将污泥与煤混合热利用能改变煤灰熔融特性。FOLGUERAS等[39]将不同污泥加入高碱含量褐煤中,发现褐煤灰熔融温度降低,降低程度与污泥添加量有关。混合灰碱酸比(B/A)为0.7~2.0时,混合灰熔融温度最低。孙保民等[40]将城市污泥加入高钠煤中研究混合灰熔融特性,发现城市污泥中的磷会与其他物质反应,形成具有高熔点(MP)的含磷矿物,增加其灰熔融温度。

已有学者研究了低硅铝含量的城市污泥和褐煤混合物在共气化过程中的灰熔融特性[27],但鲜见城市污泥与高灰熔融温度、高硅铝含量高阶煤混合灰在共气化系统中的灰熔融特性研究。制药污泥单独热解[41]及制药污泥与其他固体燃料共热解研究较多[42],但制药污泥气化,特别是与高硅铝煤共气化研究很少。因此,笔者以高硅铝含量、高灰熔融温度焦作煤(JZ)为原料,将其煤灰分别与城市污泥(CS)灰和制药污泥(ZY)灰混合,研究混合灰的灰熔融特性,以期为煤与污泥气流床协同气化提供理论指导。

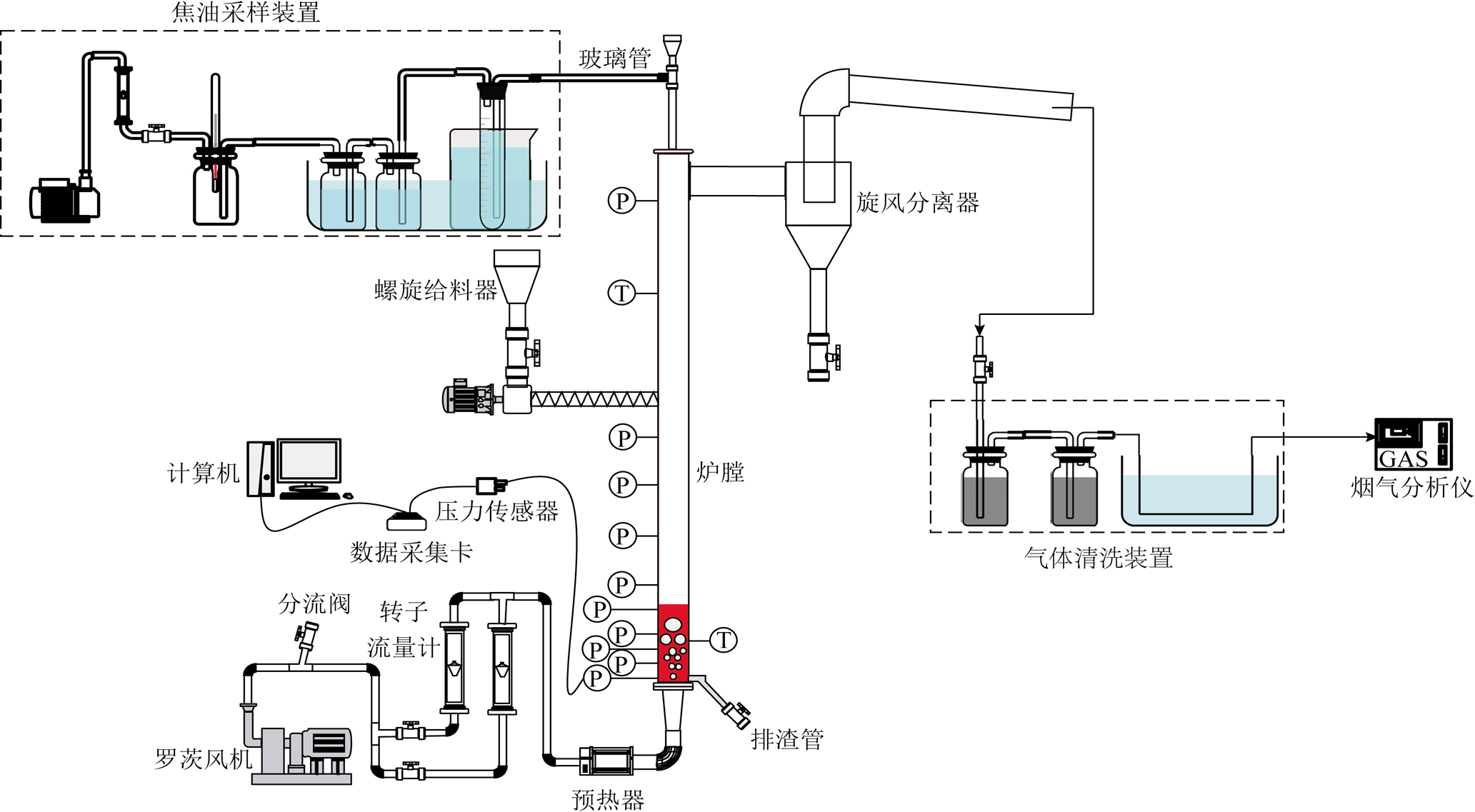

1 试 验

1.1 试验原料

CS和ZY来自山东省菏泽市污水处理厂。高灰熔融温度JZ煤来自河南焦作。3种样品被粉碎成粒径小于200 μm的颗粒,其工业分析和元素分析见表1。由表1可知,污泥灰分和挥发分较高,而固定碳含量远低于煤。

表1 污泥和煤的工业分析和原料分析

Table 1 Proximate and ultimate analyses of coal and sludge

注:a为差减法所得;b为总含量。

1.2 混合灰的制备

3种样品灰均按照GB/T 1574—2001《煤灰成分分析方法》制备。将CS灰和ZY灰分别与JZ灰混合,2种混合灰中污泥灰质量分数分别为5%、10%、15%、20%和25%,对混合灰进行灰熔融温度测定和后续分析。

1.3 灰熔融特征温度的测定

按照GB/T 30726—2014《固体生物质燃料灰熔融性测定方法》,在还原性气氛(φ(CO2)∶φ(CO)=2∶3)下,采用ALHR-2 AFT分析仪测定了混合灰的熔融温度。升温过程如下:先将灰锥以20 ℃/min升温速率加热至900 ℃,以5 ℃/min速率继续加热。升温过程中根据灰锥形状变化记录4个特征温度。

1.4 高温渣样的制备

采用高温卧式管式炉制备高温渣样。操作步骤为:先将填充约2.0 g混合灰的坩埚置于刚玉舟内,将刚玉舟推入卧式管式炉加热区位置,拧上法兰;打开CO2和CO阀门,通过调节气体流量控制器控制混合气气体组成为φ(CO2)∶φ(CO)=2∶3,使整个管式炉始终处于弱还原性气氛中,打开排气口使混合气排出管式炉防止憋压,将管式炉以20 ℃/min升温速率加热至900 ℃,以5 ℃/min升温速率继续加热至目标温度;最后关闭气体阀门,打开法兰迅速拉出刚玉舟放入液氮中激冷。

1.5 灰化学组成分析

采用X射线荧光光谱仪(XR-1800,日本岛津)分析样品灰化学组成。测量操作条件为50 kV和40 mA。

1.6 矿物质组成分析

采用X射线衍射仪(D/max rB,Rigaku,日本)分析制取的渣样矿物质组成,操作条件为:40 kV和100 mA,Kα1=0.154 08 nm。扫描范围2θ为10°~80°,步长为0.01°,扫描速度为5(°)/min。

1.7 热力学平衡计算

基于吉布斯能量最小化理论,利用FactSage软件模拟了混合灰中无机物转化行为。通过Equilib模块获得理论矿物组成和液相组成。此外,选择phase diagram模块获得了JZ-CS混合灰的SiO2-Al2O3-CaO三元相图。

1.8 红外光谱(FT-IR)分析

采用衰减全反射红外光谱法(BRUKER D2,德国)研究1 600~400 cm-1熔渣样品晶体结构信息。红外光谱表征的操作条件为25 ℃。

2 结果与讨论

2.1 样品灰熔融特性分析

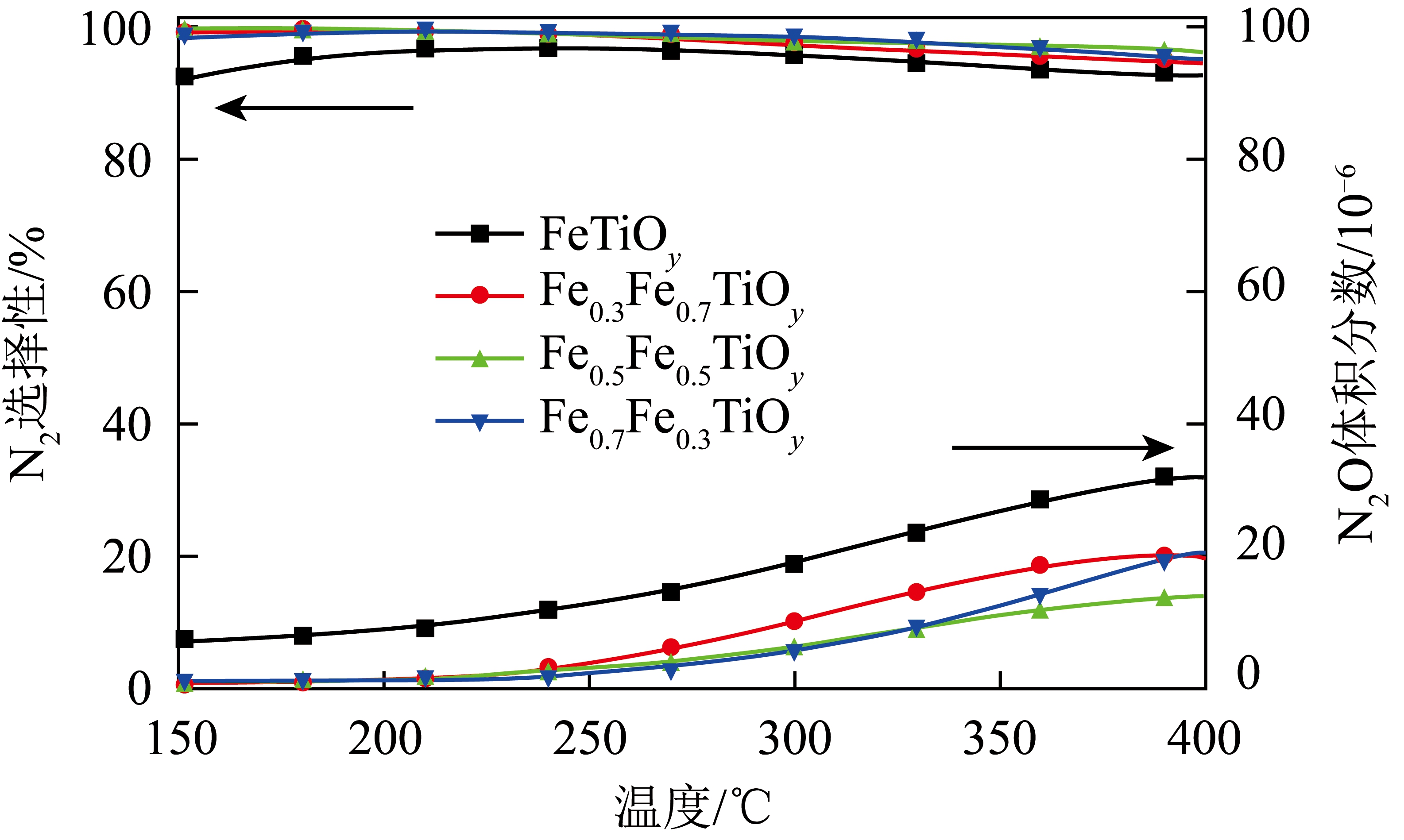

3种试验样品的灰熔融温度和化学组成见表2。JZ煤灰的4种特征温度均高于1 500 ℃;2种污泥的灰熔融温度值均较低,ZY灰的4种特征温度均高于CS灰。CS和ZY灰的理论矿物质组成如图1所示。由表2和图1(a)可知,CS灰中主要碱性氧化物为CaO,Ca2 可破坏硅酸盐网络结构,减少高聚物数量[43-45]。Ca2 在升温过程中参与钙长石和单斜辉石生成反应,随后钙长石和单斜辉石在低温下熔融,导致CS灰具有较低的灰熔融温度。由表2和图1(b)可知,ZY灰中主要碱性氧化物为Fe2O3,且灰中SiO2(2.00%)和Al2O3(1.13%)较低,其B/A远高于CS灰。在弱还原性气氛下,大部分Fe2O3被还原成FeO。升温过程中,只有小部分FeO参与到结晶反应中生成少量铁尖晶石并在低温下熔融,还有大量剩余高熔点Fe2O3(熔点1 560 ℃)和FeO(熔点1 420 ℃)未参与结晶反应而以氧化单体形式存在于灰渣中,在较高温度下才能熔融。因此,ZY灰的灰熔融温度高于CS灰。

图1 CS和ZY灰的理论矿物质组成

Fig.1 Compositions of theoretical mineral of CS and ZY ashes

表2 煤灰和污泥灰的熔融温度和化学组成

Table 2 Ash fusion temperature and compositions of

coal and sludge ashes

注:TD为变形温度;TS为软化温度;TH为半球温度;TF为流动温度;碱酸比B/A=(w(Fe2O3) w(CaO) w(MgO) w(Na2O) w(K2O) w(SO3))/(w(SiO2) w(Al2O3) w(TiO2))。

2.2 污泥对煤灰熔融特性的影响

2种污泥对JZ灰熔融温度的影响如图2所示。2种污泥可明显降低JZ煤灰的熔融温度;随污泥灰加入,2种混合灰的熔融温度呈非线性变化,且JZ-ZY混合灰的熔融温度降幅明显大于JZ-CS混合灰。CS灰和ZY灰的添加量分别为15%和10%时,2种混合灰的TF降至1 380 ℃以下,满足气流床气化液态排渣要求。因此,可推测ZY灰对高灰熔融温度JZ的灰熔融特性具有更好调控作用。由表1可知,污泥灰的灰分远高于煤,而ZY灰分低于CS,灰分过高会加大能耗和氧耗。因此,从调控效果和经济性角度考虑,ZY更适合作为调节高灰熔融温度JZ灰熔融特性添加剂。

图2 添加不同比例污泥灰的混合灰熔融温度变化

Fig.2 Ash fusion temperature variations in mixed ashes with

different sludge ash mass ratios

2.3 混合灰的理论矿物质组成模拟

利用Factsage软件模拟了特定压力和气氛下不同灰的理论矿物质和液相组成变化。不同混合比例JZ-CS混合灰在加热过程中矿物和液相组成变化如图3、4所示。由图3可知,随着CS灰添加比例增加,液相含量增加。由图4可知,900 ℃时液相主要成分为磷、硅和钙;随温度升高,液相中这3种元素消失,固相开始析出。随CS灰添加比例增加,钙长石(CaAl2Si2O8)增加,莫来石(Al6Si2O13)含量逐渐降低;石英(SiO2)、硫化亚铁(FeS)、长石类矿物质和磷酸铝(AlPO4)在1 100~1 200 ℃开始熔化,随温度升高,这些矿物质在较窄温度范围内快速熔化;约1 300 ℃时,大多数石英、硫化亚铁、长石类矿物质和磷酸铝熔融到液相中,从而降低了煤灰熔融温度。

图3 JZ-CS混合灰的理论矿物质组成

Fig.3 Compositions of theoretical mineral of JZ-CS mixed ashes

图4 JZ-CS混合灰的液相组成

Fig.4 Compositions of theoretical mineral of JZ-CS mixed ashes

不同混合比例的JZ-ZY混合灰的矿物质和液相组成变化如图5、6所示。由图5可知,含10%、15%、20%和25% ZY灰的JZ-ZY混合灰中出现了铁尖晶石(FeAl2O4)和铁堇青石(Fe2Al4Si5O18),这可能是由于混合灰中铁含量增加所致。Fe2 与含硫物质和氧化铝反应生成硫化亚铁和铁尖晶石;在900~1 100 ℃,铁尖晶石与氧化硅和氧化铝反应生成铁堇青石;随ZY灰添加比例增加,铁尖晶石和铁堇青石含量增加,莫来石含量逐渐降低;大部分铁尖晶石在900~1 000 ℃转化为铁堇青石;随温度升高,铁堇青石在很窄温度范围内熔化成液相[13]。铁尖晶石和铁堇青石含量增加导致莫来石减少,这可能是由于FeO增加使复杂的硅酸盐结构变为更简单结构,使硅酸盐体系变得松散,导致莫来石减少。由图6可知,随ZY灰添加比例增加,灰渣中熔融到液相中FeO显著增加,这可能是ZY灰能有效降低JZ煤灰熔融温度的主要原因。整个加热过程中,未发生磷析出和含磷结晶相形成,降低了升温过程中的固体含量。此外,ZY灰添加比例为20%时,混合灰的熔融温度小于ZY灰,这是由于ZY灰的单一氧化物在一些特定温度下大于JZ-ZY混合灰固相含量(对比图1(b)与图5(d)),如1 200 ℃时,ZY灰中固相质量分数大于40%,而JZ-ZY混合灰固相质量分数约20%。比较图3、4与图5、6发现,升温过程中,相同混合比例时JZ-CS混合灰中固相和莫来石相对含量高于JZ-ZY混合灰,液相相对含量低于JZ-ZY混合灰;1 500 ℃时,ZY灰占25%的混合灰达到全液相状态,CS灰占25%的混合灰中仍有部分莫来石。

图5 JZ-ZY混合灰的理论矿物质组成

Fig.5 Compositions of theoretical mineral of JZ-ZY mixed ashes

图6 JZ-ZY混合灰的液相组成

Fig.6 Compositions of theoretical mineral of JZ-ZY mixed ashes

2.4 混合灰的SiO2-Al2O3-CaO 三元相图分析

不同污泥灰添加比例的混合灰在三元相图中的位置可揭示升温过程中矿物质组成总体变化趋势。鉴于CS灰中CaO含量高及JZ煤灰中SiO2和Al2O3含量高(表2),使用SiO2-Al2O3-CaO三元相图模拟矿物质组成和全液相温度变化进行辅助分析,如图7所示。可知不同添加比例的JZ-CS混合灰落在莫来石区域;随CS灰添加比例增加,混合灰落点呈现向钙长石区移动的趋势,全液相温度(所有结晶相熔化为液相的温度)等温线逐渐降低;JZ灰全液相温度落点接近1 750 ℃等温线,CS灰添加比例为25%的混合灰全液相温度落点在1 600~1 650 ℃等温线之间。表明随CS灰添加比例增加,混合灰完全熔融成液相的温度逐渐降低,因此灰熔融温度逐渐降低。三元相图仅将混合灰中含量较高的3种组分(SiO2、Al2O3和CaO)作为基本数据以模拟矿物质的组成和变化,但未考虑铁、钠和硫等元素,因此可能与实际结果存在一定偏差。

图7 JZ-CS混合灰在SiO2-Al2O3-CaO三元相图中的位置

Fig.7 Positions of JZ-CS mixtures in SiO2-Al2O3-CaO ternary

phase diagram

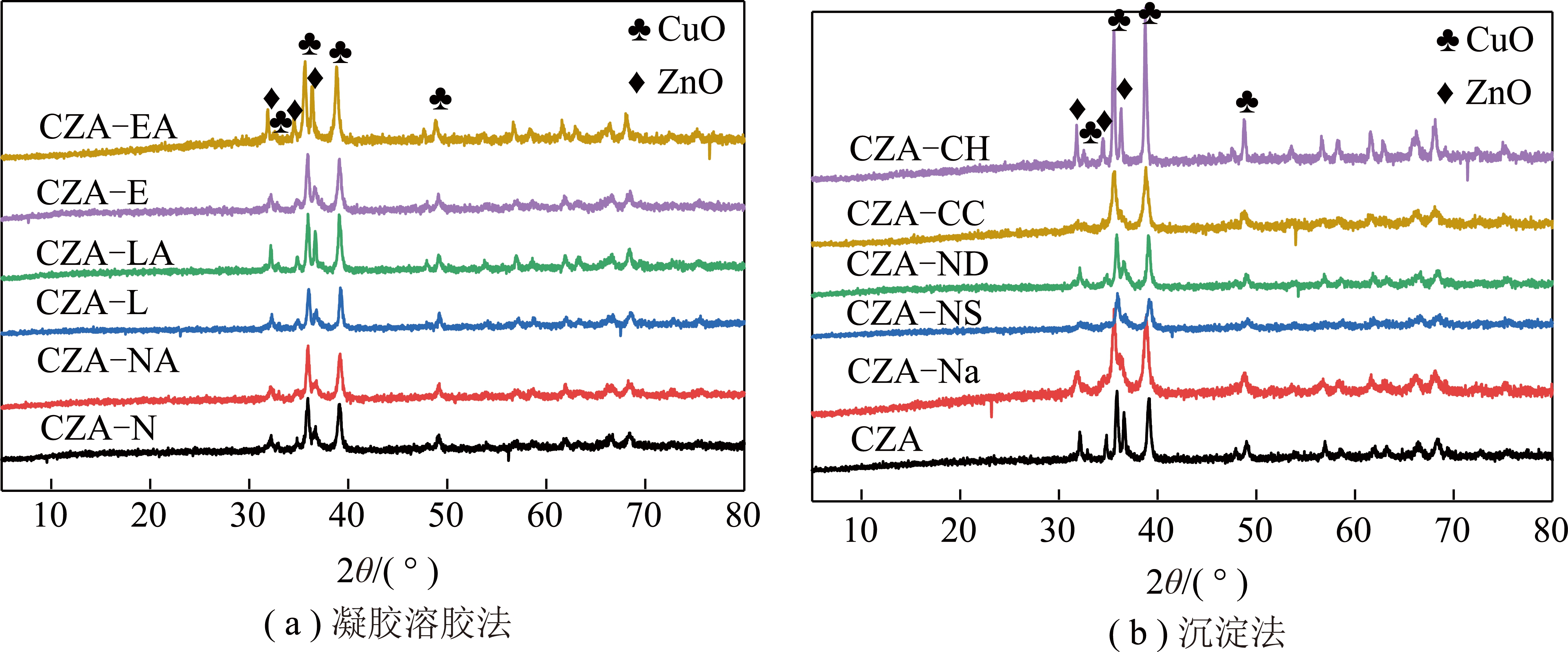

2.5 混合灰矿物质组成的演变

1 200 ℃时不同污泥灰添加比例的JZ-CS和JZ-ZY混合灰的XRD结果如图8所示。由图8(a)可知,添加5% CS灰的JZ-CS混合灰的矿物质主要为石英、磷酸铝、莫来石、钙长石和钠长石;随CS灰添加比例增加,钙长石衍射峰变强,莫来石和石英衍射峰强度变弱。莫来石和石英均为高熔点矿物质(莫来石熔点约1 860 ℃,石英熔点约1 723 ℃)[46],莫来石最高占据分子轨道能(HOMO)和最低占据分子轨道能(LUMO)差值很大(ΔE=6.116 eV),在较高温度下可稳定存在。Ca2 被认为是煤灰中一种受体,可进入莫来石晶格并破坏部分Al—O键,导致莫来石转变为具有较低结合键能的钙长石。因此,随CS灰添加比例增加,混合灰中钙含量增加,钙长石量逐渐增加。长石矿物可与石英形成低熔点共熔物[13],温度升高时,参与形成低共熔物的钙长石含量增加,导致结晶矿物相对含量降低。由图8(a)和热力学模拟理论矿物质组成(图3、4)可知,1 200 ℃时只有部分钙长石熔化成液态,仍可从XRD图中观察到明显钙长石的衍射峰。

图8 不同污泥灰质量比的JZ-CS和JZ-ZY混合灰的XRD图

Fig.8 XRD patterns of JZ-CS and JZ-ZY mixed ashes with

different sludge ash mass ratios

由图8(b)可知,ZY灰添加比例为5%的JZ-ZY混合灰的矿物质主要为石英、莫来石和钙长石;随ZY灰添加比例增加,一些含磷矿物质和铁尖晶石逐渐出现。模拟结果中的固相没有含磷矿物质,这可能是因为模拟软件计算处于完全平衡状态,但实际操作条件下很难实现完全平衡,因此,XRD测量结果与模拟结果之间存在一些差异。ZY灰添加比例分别为10%、15%、20%和25%的JZ-ZY混合灰中出现了低熔点铁尖晶石[13],这与图5、6模拟结果一致。但铁尖晶石的衍射峰强度始终较弱,这可能是由于1 200 ℃时低熔点的铁尖晶石已熔化成液相,其中可能还包括铁系矿物质与其他矿物质发生了低温共熔[13]。Fe2O3在弱还原气氛中还原为FeO,FeO易与CaO、SiO2和Al2O3生成低熔点共熔物,从而增加液相含量[47-48]。随ZY灰添加比例增加,混合灰中晶相衍射峰强度和数量总体明显降低,说明混合灰熔融程度随之增大。涉及到的反应如下:

2SiO2 3Al2O3![]() Al6Si2O13,

Al6Si2O13,

(1)

Al2O3 2SiO2 CaO![]() CaAl2Si2O8,

CaAl2Si2O8,

(2)

P2O5 Al2O3![]() 2AlPO4,

2AlPO4,

(3)

Al2O3 6SiO2 Na2O![]() 2NaAlSi3O8,

2NaAlSi3O8,

(4)

FeO Al2O3![]() FeAl2O4。

FeAl2O4。

(5)

由图8(a)、8(b)可知,随污泥灰添加JZ-ZY混合灰中高熔点石英和莫来石衍射峰强度的降低程度及总晶相的衍射峰强度降低程度明显高于JZ-CS混合灰。污泥灰添加量为10%时,JZ-ZY混合灰的石英衍射峰强度大幅降低,而JZ-CS混合灰变化不明显。添加15%、20%和25% ZY灰的JZ-ZY混合灰中结晶相的衍射峰数量和强度明显低于相同比例下JZ-CS混合灰中结晶相的衍射峰数量和强度,这可能是由于ZY灰对JZ灰熔融温度的调节效果优于CS灰。

2.6 污泥对煤渣结构的影响

添加不同污泥灰混合灰的红外光谱分析结果如图9所示。1 090 cm-1处峰值归因于不对称的Si—O—Si拉伸振动[49]。由图9(a)、9(b)可知,JZ-CS混合灰的FT-IR图中,在1 090、557和460 cm-1处推测为莫来石的振动峰,对于JZ-ZY混合灰,1 090、550和457 cm-1处推测为莫来石的振动峰[50]。添加污泥灰将增加煤灰中碱性氧化物含量,使Si—O—Si键解聚,并与碱性阳离子N2 结合形成Si—O—N2 [51]。随污泥灰含量增加,莫来石Si—O—Si 的槽逐渐变浅,表明网络结构稳定性降低,导致灰熔融温度降低[52-53]。随污泥灰含量增加,JZ-ZY混合灰Si—O—Si的槽深度相比JZ-CS混合灰明显变浅,这是ZY灰相比CS灰能更有效降低高灰熔融温度JZ煤灰熔融温度的原因[52-54]。

图9 不同污泥灰比例混合灰的FT-IR结果

Fig.9 FT-IR result of mixed ash with different sludge ash

mass ratios

2.7 摩尔离子势α与熔融温度的关系

近年来,学者对离子势和灰熔融温度的关系进行研究,发现具有高离子势元素的添加剂会提高灰熔融温度,而具有低离子势元素的添加剂会降低灰熔融温度[55],并建立了有关离子势的TF预测公式[56]。为更定量表达整个灰系统对高灰熔融温度JZ灰熔融温度的影响,引入离子势相关参数——摩尔离子势α:

(6)

式中,wi为氧化物i的质量分数;Mi为氧化物i的相对分子质量;Ii为相应氧化物i阳离子的离子势,nm-1;i为Mg2 、Fe2 、Ca2 、Ti4 、Si4 、Al3 、Fe3 、K 、Na 和P5 [56-58]。

气化炉灰渣中基本不存在硫元素,因此式(6)中也将硫元素去除。HE等[59]研究了气氛对铁的氧化价态和煤渣黏度行为的影响,通过湿化学法对气化炉弱还原气氛下灰渣中铁的氧化价态进行分析,发现大部分Fe2O3在弱还原气氛中被还原成FeO,即w(FeO)/(w(FeO) w(Fe2O3))≈0.8,并且使灰渣呈较低黏度值,换算可得FeO物质的量为Fe2O3物质的量的8.89倍。n(FeO)/n(Fe2O3)=8.89常用于热力学相图计算[60]。

不同混合灰组成及α值见表3,α与煤灰熔融温度的关系如图10所示,可知2种混合灰的4种特征温度与α呈线性正相关。表明随污泥灰添加,灰渣摩尔离子势α降低,灰熔融温度随之降低;对比JZ-CS混合灰,JZ-ZY混合灰的α值降低更快,因此灰熔融温度降低更明显。

图10 α与熔融温度的关系

Fig.10 Relationship between a and ash fusion temperature

表3 不同污泥灰比例的混合灰组成

Table 3 Ash compositions of mixed ashes with different sludge ash mass ratios

3 结 论

1)ZY灰和CS灰均能有效降低JZ灰熔融温度,使其TF满足气流床气化炉液态排渣要求。ZY灰对JZ灰熔融特性的调控效果优于CS灰。由于CS和ZY灰分远高于JZ,且ZY灰分低于CS灰,灰分越多能耗氧耗越大,从经济性和调控效果角度考虑,ZY更适合作为调控高灰熔融温度JZ灰熔融特性的添加剂。

2)CS灰中CaO含量高,随CS灰比例增大,JZ-CS混合灰中的CaO与Al2O3和SiO2反应生成的长石类矿物质增多,莫来石和石英减少。长石类矿物质易与石英形成低熔点共熔物,导致混合灰的熔融温度降低。ZY灰中Fe2O3含量高,随ZY灰比例增大,混合灰中Fe2O3在还原性气氛下被还原成FeO,使铁尖晶石等铁系矿物质增多,铁系矿物质在低温下发生熔融导致灰熔融温度降低。

3)理论矿物质演变分析中,污泥灰添加量相同时,JZ-CS混合灰中固相相对含量高于JZ-ZY混合灰,液相相对含量低于JZ-ZY混合灰;随污泥灰比例增大,JZ-ZY混合灰中高熔点矿物质(石英和莫来石)的衍射峰强度及总晶相衍射峰强度的降低程度高于JZ-CS混合灰,相同比例下JZ-ZY混合灰中晶相衍射峰强度和数量低于JZ-CS混合灰。这是添加ZY灰降低JZ灰熔融温度效果更明显的原因。

4)摩尔离子势α与2种混合灰的4种特征温度均呈线性正相关。表明随污泥灰比例增加,灰渣α降低,灰的4种特征温度随之降低;对比JZ-CS混合灰,JZ-ZY混合灰α降幅更大,因此其灰熔融温度下降更明显。

[1] 谢和平,吴立新,郑德志.2025年中国能源消费及煤炭需求预测[J].煤炭学报,2019,44(7):1949-1960.

XIE Heping, WU Lixin, ZHENG Dezhi. Prediction on the energy consumption and coal demand of China in 2025[J]. Journal of China Coal Society, 2019, 44(7):1949-1960.

[2] YAN L, YUE G, HE B. Thermodynamic analyses of a biomass-

coal co-gasification power generation system[J]. Bioresource Technology, 2016, 205:133-141.

[3] 王辅臣. 煤气化技术在中国:回顾与展望[J]. 洁净煤技术,2021,27(1):1-33.

WANG Fuchen. Coal gasification technologies in China: Review and prospect[J]. Clean Coal Technology, 2021,27(1):1-33.

[4] WEI J, GONG Y, GUO Q, et al. Physicochemical evolution dur-ing rice straw and coal co-pyrolysis and its effect on co-gasification reactivity[J]. Bioresource Technology, 2017, 227:345-352.

[5] LABBAFAN A, GHASSEMI H. Numerical modeling of an E-Gas entrained flow gasifier to characterize a high-ash coal gasification[J]. Energy Conversion and Management, 2016, 112:337-349.

[6] GUO Q, ZHOU Z, WANG F, et al. Slag properties of blending coal in an industrial OMB coal water slurry entrained-flow gasifier[J]. Energy Conversion and Management, 2014, 86:683-688.

[7] 刘洁妤, 龚岩, 吴晓翔, 等. 多喷嘴对置式气化炉内颗粒挥发分火焰可视化研究[J]. 化工学报, 2021, 72(3): 1275-1282.

LIU Jieyu, GONG Yan, WU Xiaoxiang, et al. Visualization study on particle volatile flame opposed multi-burner impinging entrained-flow gasifier[J]. CIESC Journal, 2021, 72(3): 1275-1282.

[8] SONG W, TANG L, ZHU X, et al. Fusibility and flow properties of coal ash and slag[J]. Fuel, 2009, 88:297-304.

[9] 吕俊复,史航,吴玉新,等. 烟气气氛对准东煤灰熔融特性影响的显微观察[J]. 煤炭学报,2021,46(1):263-273.

LYU Junfu, SHI Hang, WU Yuxin, et al. Influence of flue gas atmosphere on Zhundong coal ash melting characteristics through microscopic observation[J]. Journal of China Coal Society, 2021, 46(1):263-273.

[10] LIU X, YU G, XU J, et al. Viscosity fluctuation behaviors of coal

ash slags with high content of calcium and low content of silicon[J]. Fuel Process Technology, 2017, 158:115-122.

[11] 颜婷珪,白进,孔令学,等.煤灰流动性研究方法进展[J].洁净煤技术,2020,26(1):90-98.

YAN Tinggui, BAI Jin, KONG Lingxue, et al.Advances in research methods of coal ash fluidity[J].Clean Coal Technology, 2020, 26(1):90-98.

[12] XIN D, JIAN H, JIN B, et al. Ash fusion properties from molecular dynamics simulation: Role of the ratio of silicon and aluminum[J]. Energy &Fuels, 2016, 30:2407-2413.

[13] LI M, LI F, LIU Q, et al. Regulation of ash fusibility for high ash-fusion-temperature (AFT) coal by industrial sludge addition[J]. Fuel, 2019, 244:91-103.

[14] SASI T, MIGHANI M, ÖRS E, et al. Prediction of ash fusion behavior from coal ash composition for entrained-flow gasification[J]. Fuel Process Technology, 2018, 176:64-75.

[15] LI F, YU B, WANG G, et al. Investigation on improve ash fu-sion temperature (AFT) of low-AFT coal by biomass addition[J]. Fuel Process Technology, 2019,191:11-19.

[16] XIAO H, LI F, WANG Y. Regulation of ash fusion behaviors for high aluminum coal by high calcium coal addition[J]. Asia-Pacific Journal of Chemical Engineering, 2020, 15:e2404.

[17] HE C, BAI J, ILYUSHECHKIN A, et al. Effect of chemical

composition on the fusion behaviour of synthetic high iron coal ash[J]. Fuel, 2019;253:1465-1472.

[18] WANG J, LIU X, GUO Q, et al. Study on the fluidity of ash slag of liquefaction solid product and lignite co-gasification[J]. Asia-Pacific Journal of Chemical Engineering, 2022, 17(1):e2721.

[19] BENAVENTE V, FULLANA A. Low-cost additives to improve the fusion behaviour of hydrochar ash[J]. Fuel, 2021, 285:119009.

[20] LI Q, LIU X, ZHAO W, et al. Effects of sludge on the ash fusion behaviors of high ash-fusion-temperature coal and its ash viscosity predication[J].Journal of the Energy Institute, 2023, 108:101254.

[21] DENG S, TAN H, WANG X, et al. Ash fusion characteristics and mineral matter transformations during sewage sludge/petrochemical sludge co-firing with wheat straw[J]. Journal of Cleaner Production, 2020, 260;121103.

[22] LI F, ZHAO W, FAN H, et al. Effects of sludge on the ash fusion behaviors of corn stalk and its modification mechanisms[J]. Fuel, 2021, 293:120378.

[23] PEI J, YAO H, WANG H, et al. Effect of ultrasonic and ozone pre-treatments on pharmaceutical waste activated sludge′s solubilisation, reduction, anaerobic biodegradability and acute biological toxicity[J]. Bioresource Technology,2015,192:418-423.

[24] KAYA Y, ERSAN G, VERGILI I, et al. The treatment of pharmaceutical wastewater using in a submerged membrane bioreactor under different sludge retention times[J]. Journal of Membrane Science, 2013, 442:72-82.

[25] LI F, ZHAO C, FAN H, et al. Ash fusion behaviors of sugarcane bagasse and its modification with sewage sludge addition[J]. Energy, 2022, 251:123912.

[26] SAMOLADA M C, ZABANIOTOU A A. Comparative assessment of municipal sewage sludge incineration, gasification and pyrolysis for a sustainable sludge-to-energy management in Greece[J]. Waste Management, 2014, 34:411-420.

[27] SCHWITALLA D, REINMÖLLER M, FORMAN C, et al. Ash and slag properties for co-gasifification of sewage sludge and coal: An experimentally validated modeling approach[J]. Fuel Process Technology, 2018, 175:1-9.

[28] SYED-HASSAN S S A, WANG Y, HU S, et al. Therm-ochemical processing of sewage sludge to energy and fuel: Fundamentals, challenges and considerations[J]. Renewable and Sustainable Energy Reviews, 2017, 80:888-913.

[29] MATTHIAS S, THOMAS H, PETER Q. Thermal treatment of se-wage sludge in Germany: A review [J]. Journal of Environmental Management, 2020, 263:110-367.

[30] HAN X, NIU M, JIANG X, et al. Combustion characteristics of sewage sludge in a fluidized bed[J]. Industrial &Engineering Chemistry Research, 2012, 51:10565-10570.

[31] YAN J, CHEN T, LI X,et al. Evaluation of PCDD/Fs emission from fluidized bed incinerators co-fifiring MSW with coal in China[J]. Journal of Hazardous Materials[J]. Fuel, 2006, 135:47-51.

[32] 刘敬勇,孙水裕,陈涛. 固体添加剂对污泥焚烧过程中重金属迁移行为的影响[J]. 环境科学,2013, 34(3): 1166-1173.

LIU Jingyong, SUN Shuiyu, CHEN Tao. Effects of adsorbents on partitioning and fifixation of heavy metals in the incineration process of sewage sludge[J]. Environmental Science, 2013, 34(3): 1166-1173.

[33] KIJO-KLECZKOWSKA A, S′RODA K, KOSOWSKA-GOLACHOWSKA M, et al. Combustion of pelleted sewage sludge with reference to coal and biomass[J]. Fuel, 2016, 170:141-160.

[34] ZHENG L, JIN J, LIU Z, et al. Ash formation characteristics in co-combusting coagulation sludge and Zhundong coal[J]. Fuel, 2022, 311:122571.

[35] TSVETKOV M V, PODLESNIY D N, FREYMAN V M, et al. Behavior of the sewage sludge ash under the conditions of high temperature processing[J]. Russian Journal of Applied Chemistry, 2020, 93(6):881-887.

[36] WU H, WANG J, LIU X, et al. Effects of phosphorous-based additive on flow properties of high silicon-aluminum coal ash [J]. Fuel, 2022, 328:125238.

[37] GAO N, KAMRAN K, QUAN C, et al. Thermochemical conversion of sewage sludge: A critical review[J]. Progress in Energy and Combustion Science, 2020, 79:100843.

[38] GARC A G, GONZALO A, S

A G, GONZALO A, S NCHEZ J L, et al. Influence of feedstock composition in fluidized bed co-gasification of mixtures of lignite, bituminous coal and sewage sludge [J]. Chemical Engineering Journal, 2013, 222:345-352.

NCHEZ J L, et al. Influence of feedstock composition in fluidized bed co-gasification of mixtures of lignite, bituminous coal and sewage sludge [J]. Chemical Engineering Journal, 2013, 222:345-352.

[39] FOLGUERAS M B, ALONSO M, FOLGUERAS J R. Modifica-tion of lignite ash fusion temperatures by the addition of different types of sewage sludge[J]. Fuel Process Technology, 2015, 131:348-355.

[40] 孙保民, 高满达, 苏逸峰,等. 城市污泥对五彩湾高钠煤灰熔融特性的影响[J]. 化工进展,2018(7),37(8):2991-3000.

SUN Baomin, GAO Manda, SU Yifeng, et al. Influence of sewage sludge on ash-melting characteristics during combustion of high sodium coal of Wucaiwan[J]. Chemical Industry and Engineering Progress, 2018, 37(8):2991-3000.

[41] LIU H, XU G, LI G. Pyrolysis characteristic and kinetic analysis of sewage sludge using model-free and master plots methods[J]. Process Safety and Environmental Protection, 2021, 149:48-55.

[42] YU Z, YOUSAF K, AHMAD M, et al. Efficient pyrolysis of gi-nkgo biloba leaf residue and pharmaceutical sludge (mixture) with high production of clean energy: Process optimization by particle swarm optimization and gradient boosting decision tree algorithm[J]. Bioresource Technology, 2020, 304:123020.

[43] LI M, XU J L, XIAO H, et al. Exploring influence of MgO/CaO on crystallization characteristics to understand fluidity of synthetic coal slags[J]. Chinese Journal of Chemial Engeering, 2023, 53:1-13.

[44] DAI X, BAI J, LI D, et al. Experimental and theoretical investigation on relationship between structures of coal ash and its fusibility for Al2O3-SiO2-CaO-FeO system[J]. Journal of Fuel Chemistry and Technology, 2019, 47:641-648.

[45] SHI W, LAABS M, REINMÖLLERC M, et al. In-situ analysis of the effect of CaO/Fe2O3 addition on ash melting and sintering behavior for slagging-type applications[J]. Fuel, 2021, 285:119090.

[46] MA X, LI F, MA M, et al. Regulation of ash fusibility characteristics for high ash fusion temperature coal by bean straw addition[J]. Energy &Fuels, 2018, 32:6678-6688.

[47] WU X, ZHOU T, CHEN Y, et al. Mineral melting behavior of Chinese blended coal ash under gasification condition[J]. Asia-Pacific Journal of Chemical Engineering, 2011, 6(2):220-230.

[48] MA X, LI F, MA M, et al. Fusion characteristics of blended ash from Chang zhi coal and biomass[J]. Journal of Fuel Chemistry and Technology, 2018, 46:129-137.

[49] BAI J, LI W, LI C, et al. Influences of mineral matter on high temperature gasification of coal char[J]. Journal of Fuel Chemistry and Technology, 2009, 37:134-138.

[50] BAI J, LI W, BAI Z. Effects of mineral matter and coal blend-ing on gasification[J]. Energy &Fuels, 2018, 32:1127-1131.

[51] LEHLOHONOLO M, ANTON S, GERHARD A. Molecular dynamics simulations of the structural properties and electrical conductivities of CaO-MgO-Al2O3-SiO2 melts[J]. Journal of Non-crystalline Solids, 2016, 452:194-202.

[52] LIU W, ZUO H. Effect of MnO and CaO substitution for BaO on the viscosity and structure of CaO-SiO2-MgO-Al2O3-BaO-MnO slag[J]. Journal of Non-crystalline Solids, 2021, 567:120940.

[53] LI F, ZHAO C, LI J, et al. Investigation on ash fusion behavior modification of wheat straw by sludge addition[J]. Journal of the Energy Institute, 2021, 98:1-10.

[54] WANF W, SHAO H, ZHOU L, et al. Rheological behavior of the CaO-Al2O3-based mold fluxes with different Na2O contents[J]. Ceramics International, 2020, 46:20880-20887.

[55] NEL M V, STRYDOM C A, SCHOBERT H H, et al. Reducing atmosphere ash fusion temperatures of a mixture of coal-associated minerals :The effect of inorganic additives and ashing temperature[J]. Fuel Process Technology, 2014, 124:78-86.

[56] LI F, XIAO H, FANG Y. Correlation between ash flow temperature and its ionic potentials under reducing atmosphere[J]. Applied Thermal Engineering, 2017, 110:1007-1010.

[57] LI Y, LI F, Ma M, et al. Prediction of ash flow temperature based on liquid phase mass fraction by FactSage[J]. Journal of the Energy Institute, 2020, 93:2228-2231.

[58] XIAO H, WANG Y, LI J. Prediction of coal ash fusibility based on metal ionic potential concentration [J]. Journal of the Energy Institute, 2021, 98:29-34.

[59] HE C, BAI J, KONG L, et al. Effects of atmosphere on the oxidation state of iron and viscosity behavior of coal ash slag[J]. Fuel, 2019, 243:41-51.

[60] WU H, WANG J, LIU X, et al. Synergistic effects and mechanism of the ternary flux system Fe2O3-CaO-MgO on the coal ash slag fluidity [J]. Fuels, 2023, 343:127963.

Investigationon regulation mechanism of sludge on the ash melting characteristics of coal with high ash fusion temperature (AFT)