超薄超小镍铁水滑石的声悬浮制备

0 引 言

近几十年来,全球气候变暖问题日益严重,且在未来若干年还将持续。目前,进入大气中的二氧化碳排放已过量。几年前,大气中二氧化碳浓度已达400×10-6[1],主要由化石燃料燃烧造成。全世界能源需求主要依赖石油、天然气和煤炭等化石燃料,均为不可再生能源[2-3]。据统计,全球能源需求预计在2030年和2050年将分别达到23和30 TW,凸显了清洁和可持续能源对二氧化碳减排的重要性[4-5]。氢气(H2)作为世界上最清洁的能源之一,其主要制备方式有甲烷蒸汽重整、煤气化和电催化分解水,但前2种制氢技术无法真正解决环境污染和二氧化碳排放问题[6]。而电催化分解水可提供可再生、清洁的氢气,是一种替代化石燃料很有前景的方式,被认为是可持续生产氢能源而不产生任何有害副产物的最合适的途径之一[7]。因此,笔者希望通过高效电解水制氢气、氧气,实现持续用氢作为未来主要的能源之一,从而实现降低二氧化碳排放的目标[8-10]。

电催化分解水有2个半反应,分别为析氢反应(Hydrogen evolution reaction, HER)和析氧反应(Oxygen evolution reaction, OER),通过电催化分解水可以有效获得氢能[11]。目前工业上,通过该方式制备氢气仅占4%,其原因主要在于电解效率较低,而OER作为电解水的半反应,研究其机理及开发高效的OER催化剂具有重要意义[12]。OER是四电子质子耦合反应,由2MO中间体或MOH中间体的分解产生O2,其中M为催化活性金属中心[13-15]。

碱性条件下:

M OH-![]() MOH e-,

MOH e-,

(1)

MOH OH-![]() MO H2O e-,

MO H2O e-,

(2)

MO OH-![]() MOOH e-,

MOOH e-,

(3)

MOOH OH-![]() MO2 e-,

MO2 e-,

(4)

MO2![]() M O2。

M O2。

(5)

OER在碱性条件下的这些反应步骤表明H2O和OH-离子在表面活性中心M上吸附。该活性位点M在OER期间经历氧化和还原反应循环,伴随O2分子释放,并再生新的表面活性位点用于下1个循环[16]。这表明具有可变和稳定氧化态的金属可作为OER的有效电催化剂,因此通过优化OER催化剂的选择性、反应性和稳定性,可提高该催化剂的催化反应速率。目前常见的贵金属电催化剂(RuO2和IrO2)具有优异的OER性能,但其高成本和低储备的缺点限制了其商业化应用[17-18]。

水滑石又名层状双金属氢氧化物(Layered double hydroxides, LDHs),是属于阴离子黏土的层状材料,金属阳离子和氧阴离子形成八面体,O—H基团顶点垂直于主层平面,连接形成层状结构[19-20]。LDHs结构可用[M1-x2 Mx3 (OH)2]x [Ax/nn-·mH2O]x-表示,其中A为层间插层的阴离子,x=M3 /(M2 M3 )为层电荷密度或物质的量比[21]。采用水热法制备的NixFe1-LDH(x=1,2,3)前体具有金属比例可调控和层状结构特性,中间层可容纳用于电荷补偿的有机或无机阴离子和水分子,以补偿由于同构取代而产生的过量正电荷[22-25]。ADACHI-PAGAON等[26]最早报道了LDHs的剥离,将十二烷基硫酸盐(DS)插层的ZnAl-LDH在丁醇或更高级醇(如戊醇和己醇)实现完全剥离。ZHOU等[27-28]利用还原性火焰焙烧的方法,使NiFe-LDH前体的层板厚度由4.5 nm降至3.5 nm,所得NiFe-LDH纳米片显示了优异的析氧反应性能。ZHANG等[29]将钼酸盐离子加入NiFe-LDH的制备中,可促使超薄NiFe-LDH纳米片生成,且这些超薄NiFe-LDH纳米片与普通NiFe-LDH相比,表现出更优异的电化学活性。将本文采用水热法制备的NixFe1-LDH(x=1,2,3)前体经超声悬浮处理,与其他过渡金属基催化剂,甚至是IrO2等贵金属催化剂相比,在电催化OER方面也表现出优异性能。这主要是由于超薄二维材料具有更便捷的电子传导路径,且超薄纳米结构可暴露更多的边缘活性位点,从而具有更强的催化性能。

声悬浮(Acoustic levitation, AL)是一种成熟的驱动技术,可在流体(空气或液体)中捕获[30]、剥离[31]和旋转[32]多种材料,如颗粒、液滴或细胞,而不需物理接触样品。在实践中,AL提供了一个无壁的非接触平台在小样品上进行试验[33-34]。利用超声波发射端和反射端间产生的高强度声辐射力抵消样品重力,进而使样品悬浮[35]。样品处于一个悬浮在空气中和无接触的状态,因此该技术减少了样品支架或容器(化学/细菌/病毒)产生污染的风险及避免了由于样品接触容器产生的常规机械支撑剪切力,可使超声波更好作用于样品[36-37]。在声悬浮环境中,由于超声波反复叠加形成的高声强驻波,加之合适的剥离剂,易打破层状材料的层间作用力,相比于传统的剥离方法,声悬浮法更易实现超薄超小纳米材料的快速制备。因此为得到超薄超小水滑石纳米片,采用超声悬浮技术作用于NiFe-LDH,希望能在有限时间内,采用最少的剥离剂,在较小能耗下实现超薄超小NiFe-LDH纳米片的快速制备,从而有效提高NiFe-LDH的OER活性。

1 试 验

1.1 试验仪器

H-1750高速台式离心机、2011 F45-11电子天平、GBS-VDP 20A超声悬浮仪、DHG-9070电热鼓风干燥箱、CHI660B电化学工作站、Ultima IV X-射线衍射仪、Dimension Icon原子力显微镜、FEI Talos F200x透射电子显微镜。

1.2 NixFe1-LDH(x=1,2,3)前体的合成

将NiCl2·6H2O和FeCl3以物质的量比1∶1,2∶1,3∶1溶解于25 mL去离子水中,记为溶液A;配置1 mol/L的NaOH溶液,记为溶液B;称取0.6 g尿素溶解于50 mL去离子水中,记为溶液C。将溶液A和溶液B同时逐滴滴入快速搅拌的溶液C中,使其pH保持在9左右,搅拌30 min。最后将该溶液加入聚四氟乙烯反应釜中,将反应釜放入烘箱,保持90 ℃水热晶化12 h,冷却。将得到的溶液静置,离心,倒去上清液;用无水乙醇和去离子水1∶1混合液离心洗涤3次,再用无水乙醇离心洗涤2次;于60 ℃恒温干燥箱中烘干12 h,用玛瑙研钵中研磨得到NixFe1-LDH(x=1,2,3)前体产物。

1.3 超薄超小NixFe1-LDH(x=1,2,3)的制备

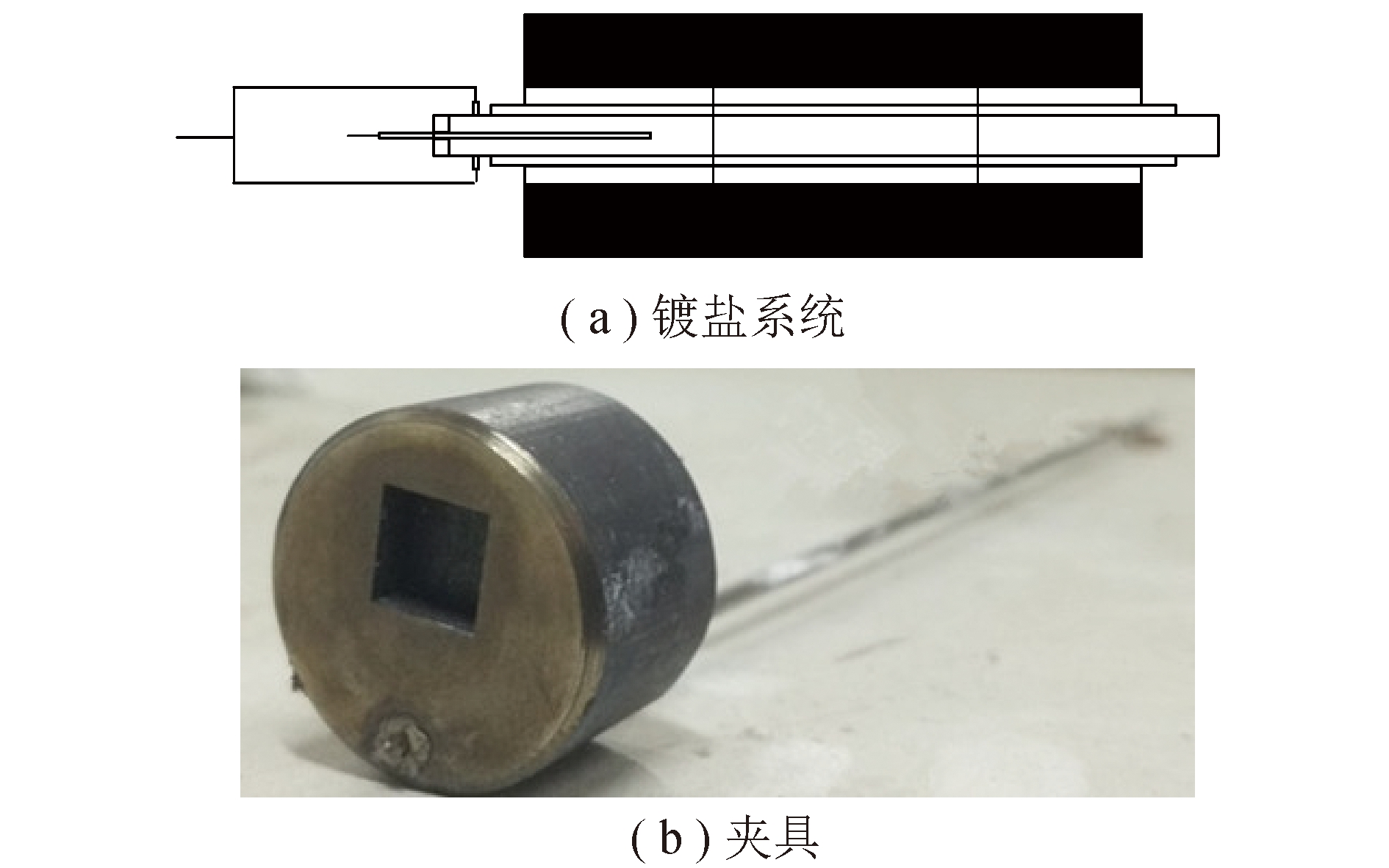

将10 mg的NixFe1-LDH(x=1,2,3)前体分散于1 mL甲酰胺中,配制成质量浓度约10 mg/mL的分散液;取1滴分散液置于声悬浮仪器,声悬浮谐振频率为19 799 Hz,设定功率在375 W,悬浮时间分别为5、10、20 min。待分散液悬浮完成,收集得到超薄水滑石纳米材料。根据超声悬浮时间不同,将合成的LDH分别命名为NixFe1-LDH-5 min(x=1,2,3),NixFe1-LDH-10 min(x=1,2,3),NixFe1-LDH-20 min(x=1,2,3),其合成过程如图1所示。

图1 超薄超小NiFe-LDH的合成示意

Fig.1 Schematic synthesis of ultra-thin andultra-small NiFe-LDH

1.4 电化学测试

使用三电极系统,电化学工作站为CHI660B,铂片作为对电极,饱和Ag/AgCl作为参比电极,玻碳电极作为工作电极,电解液为1 mol/L KOH。电位转换以可逆氢电极(RHE)为标准,按Nernst方程(ERHE=EAg/AgCl 0.197 V 0.059 1pH),测试前需通入一定量氮气(N2)排除电解液中氧气和二氧化碳等因素影响。线性伏安扫描曲线(LSV)扫速为5 mV/s,电化学阻抗光谱(EIS)测量在10-2~105 Hz。测量中,电催化剂分散液如下:500 μL的催化剂悬浮液 20 μL 5% nafion溶液 480 μL乙醇,经超声悬浮,形成均匀分散液。取5 μL分散液滴在玻碳电极上(直径3 mm),静置烘干后即为工作电极。

2 结果与讨论

2.1 结构表征

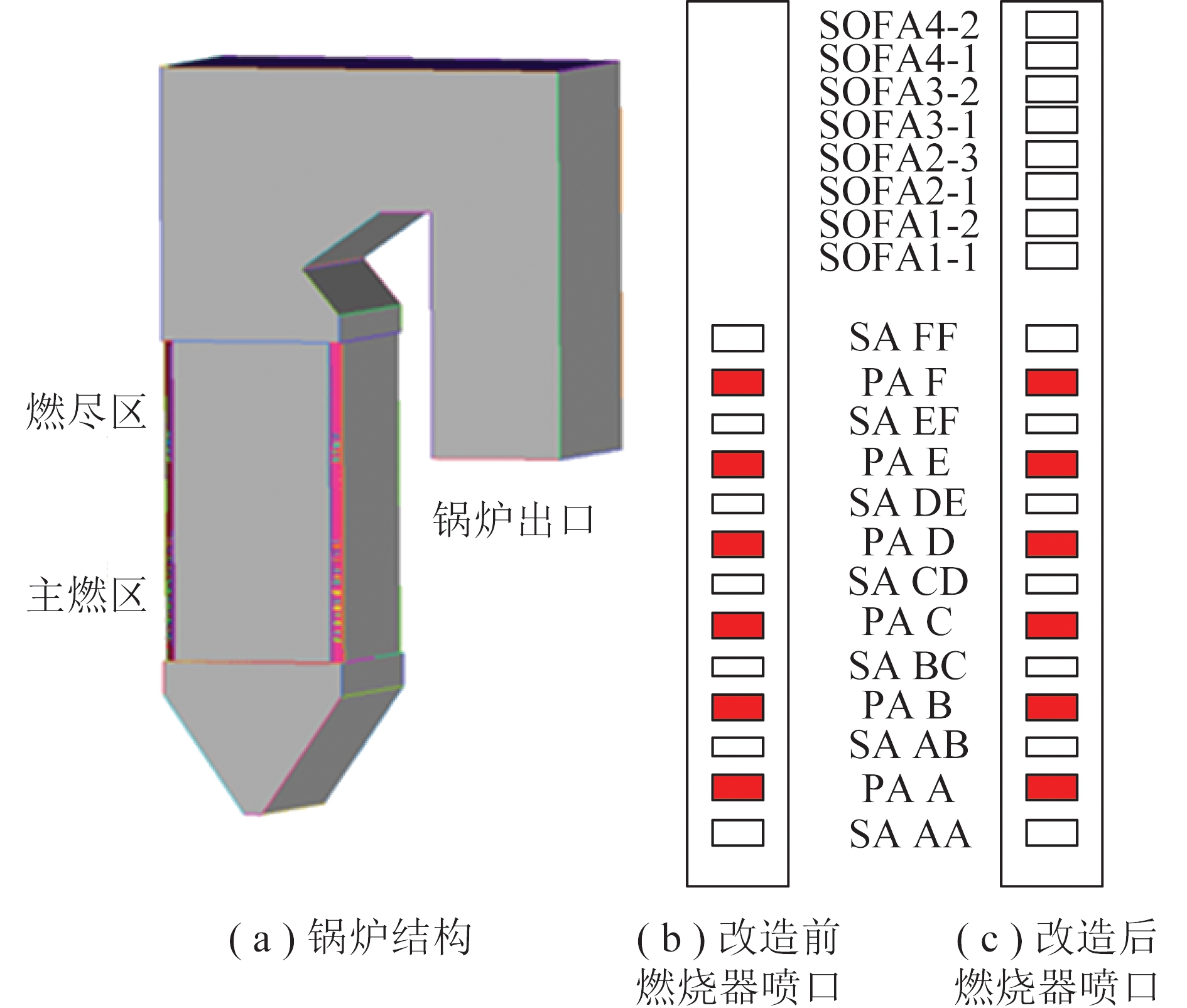

NixFe1-LDH(x=1,2,3)前体的X射线衍射(XRD)结果如图2所示。11.2°、22.5°处有明显特征衍射峰,对应于水滑石(003)、(006)峰,说明在不同镍铁物质的量比下成功合成镍铁水滑石。镍铁物质的量比为1∶1时,镍铁水滑石衍射峰强度较低、样品结晶性较差;镍铁物质的量比为2∶1时,镍铁水滑石衍射峰较尖锐、样品结晶性最好。

图2 不同镍铁物质的量比的NixFe1-LDH(x=1,2,3)前体的XRD图谱

Fig.2 XRD patterns of NixFe1-LDH (x=1, 2, 3) precursors with different NiFe molar ratios

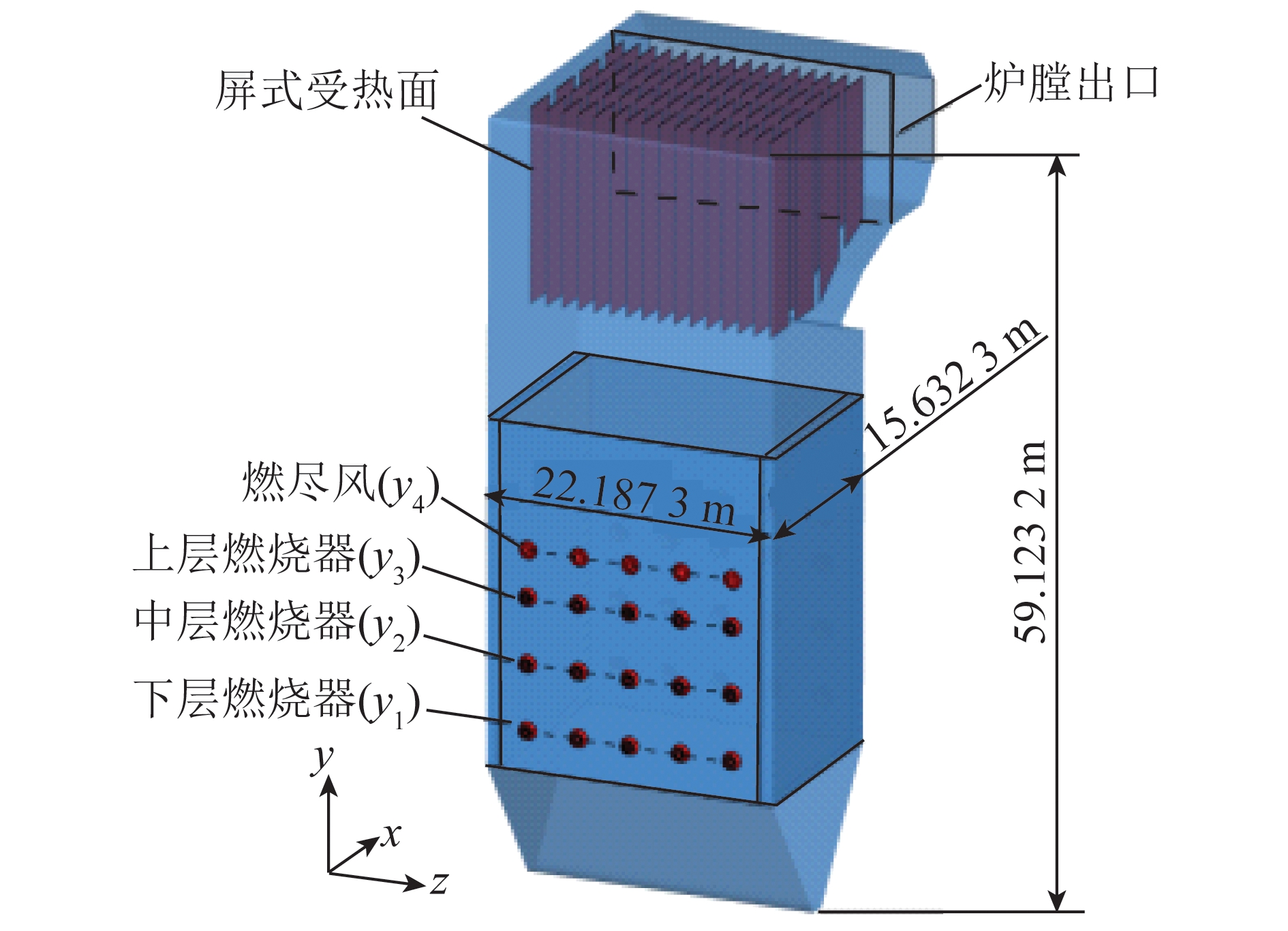

由透射电子显微镜(TEM)(图3(a))可知未经超声悬浮的Ni1Fe1-LDH前体尺寸较大,且团聚严重,横向尺寸约1 500 nm。Ni1Fe1-LDH前体的高分辨透射电镜(HRTEM)显示出明显的晶格条纹,约0.20 nm,对应水滑石的(018)晶面(图3(b))。此外,图3(c)和3(d)中通过原子力显微镜(AFM)对Ni1Fe1-LDH前体进行测量,厚度约25.66 nm。

图3 Ni1Fe1-LDH前体的TEM图、HRTEM图、6AFM图以及对应高度

Fig.3 TEM image, HRTEM image, AFM image and corresponding height map of Ni1Fe1-LDH precursor

声悬浮技术超声剥离后,水滑石形貌发生明显变化。图4(a)为Ni1Fe1-LDH前体超声剥离20 min后的TEM图,与前体相比,尺寸明显减小,且分散较均匀,平均横向尺寸约10 nm。图4(b)中Ni1Fe1-LDH-20 min的HRTEM发现了与水滑石结构(015)晶面相对应的0.23 nm晶格条纹,证明超声悬浮剥离后所得到的超薄超小纳米片的水滑石结构得以保留。在图4(c)和4(d)中通过AFM测量Ni1Fe1-LDH-20 min纳米片的厚度分别为0.649和0.812 nm,该厚度为单层水滑石厚度,2个测量结果的差值可能是由于水滑石层板上吸附了阴离子、H2O等造成测量结果偏厚。与Ni1Fe1-LDH前体相比,其横向尺寸与厚度均明显减小。可知经超声悬浮剥离后得到的超薄超小的Ni1Fe1-LDH-20 min纳米片结构有望为催化反应提供丰富的活性边缘位点。

图4 超薄超小Ni1Fe1-LDH-20 min纳米片的TEM图、HRTEM图、AFM图以及对应的高度

Fig.4 TEM image,HRTEM image, AFM image and corresponding height map of ultra-thin and ultra-small Ni1Fe1-LDH-20 min nanosheets

2.2 电化学分解水测试

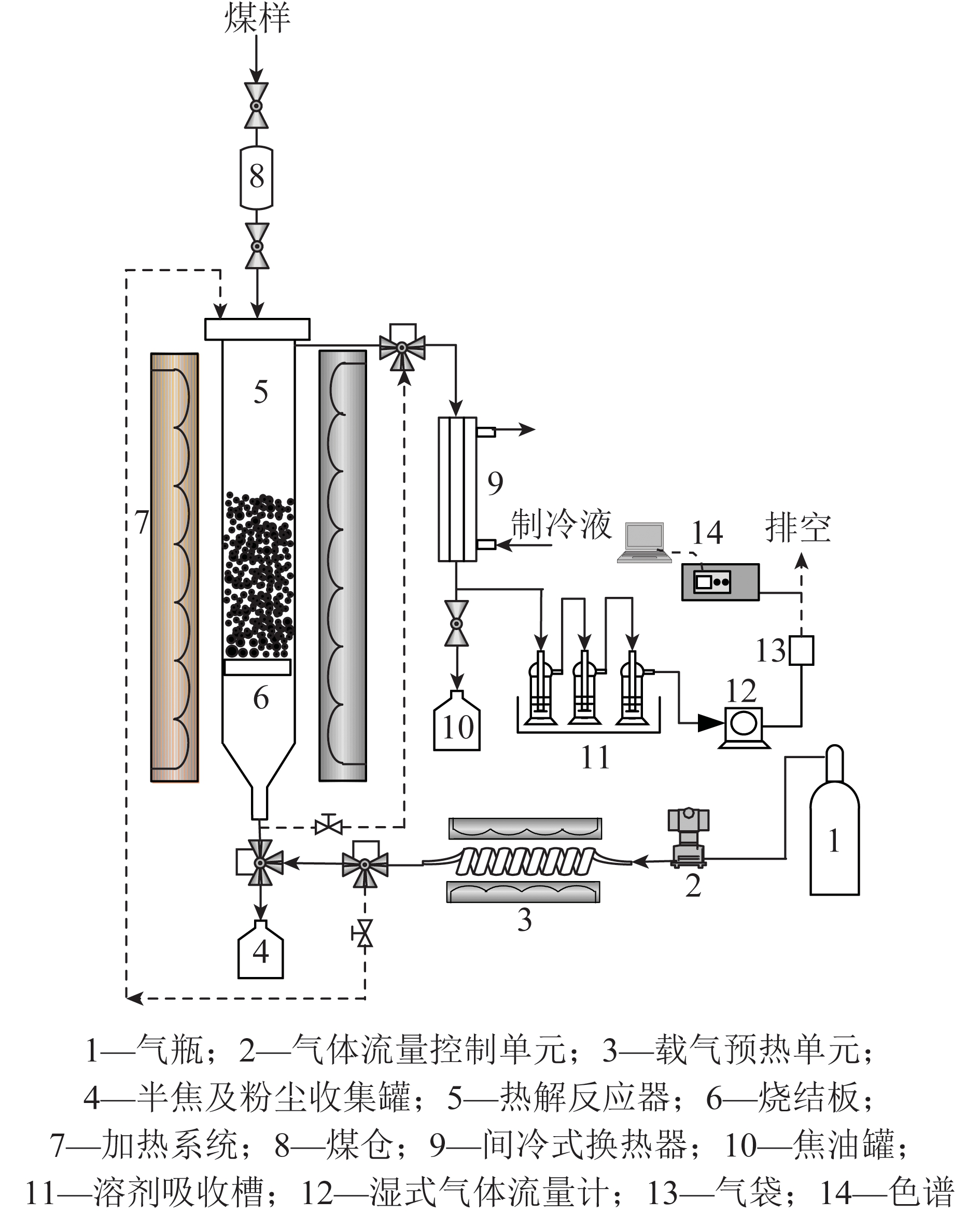

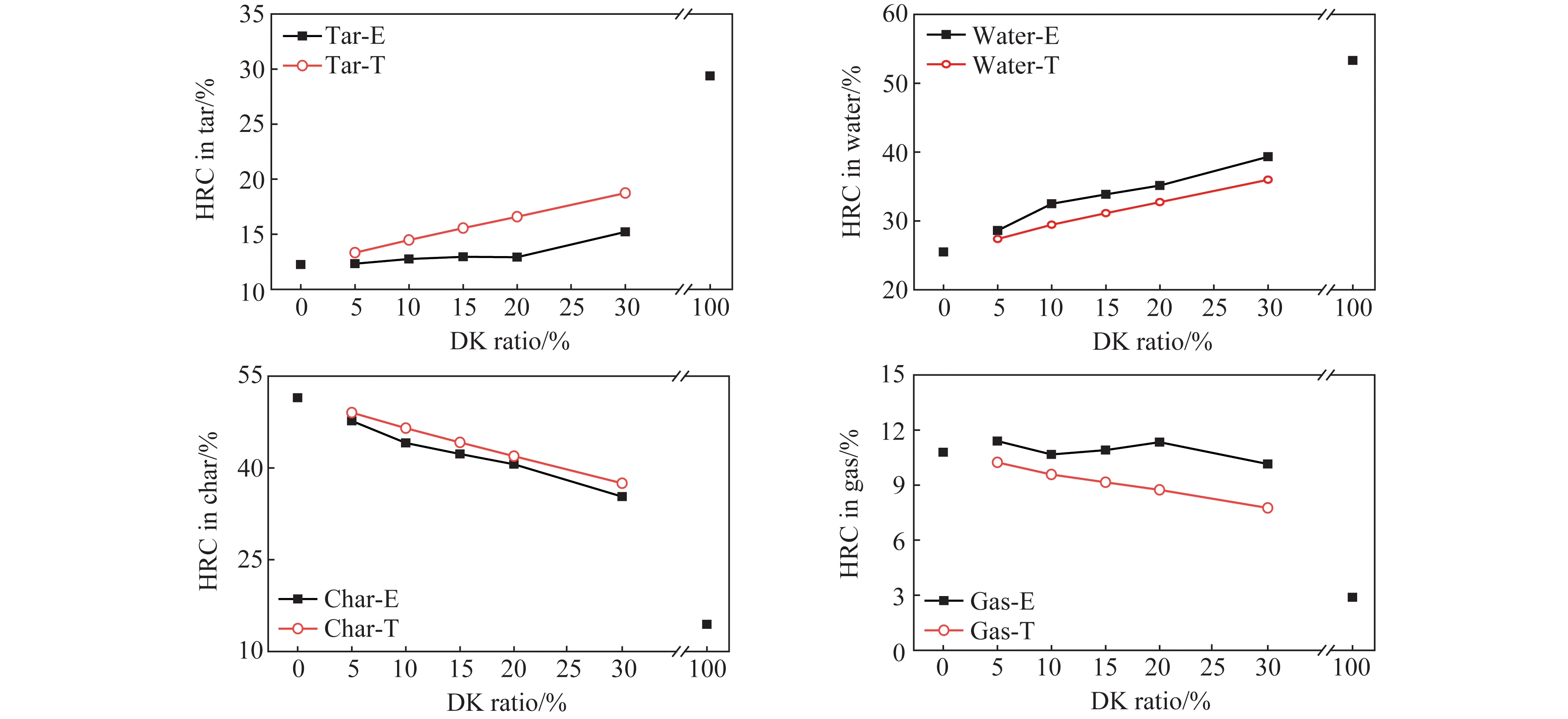

使用标准的三电极系统,在碱性电解质(1 mol/L KOH)中检测所有样品的电催化OER性能。根据图5(a),随超声悬浮时间增加,极限电流密度逐渐提高。过电位为570 mV时,Ni1Fe1-LDH-20 min的极限电流密度可达150 mA/cm2,相比Ni2Fe1-LDH-20 min极限电流密度79 mA/cm2和Ni3Fe1-LDH-20 min极限电流密度83 mA/cm2,表现出最高的极限电流密度。由图5(b)可知,电流密度10 mA/cm2时,所有样品的过电位呈如下规律:Ni1Fe1-LDH-20 min(309 mV)

图5 NixFe1-LDH(x=1,2,3)前体,NixFe1-LDH-5 min(x=1,2,3),NixFe1-LDH-10 min(x=1,2,3),NixFe1-LDH-20 min(x=1,2,3)的LSV曲线,10 mA/cm2下的过电位,Tafel曲线电化学阻抗图谱EIS

Fig.5 NixFe1-LDH (x=1,2,3) precursor,NixFe1-LDH-5 min (x=1,2,3),NixFe1-LDH-10 min (x=1,2,3),NixFe1-LDH-20 min (x=1,2,3)LSV curve of OER test, sweep rate 5 mV/s, overpotential at 10 mA/cm2 overpotential at 10 mA/cm2,Tafel curve for OER test, electrochemical impedance profile EIS

2.3 电化学活性表面积测试

为进一步证明NixFe1-LDH(x=1,2,3)前体经超声悬浮后催化性能提高,根据循环伏安(CV)曲线,在0.15~0.25 V不同扫描速率下,用双层电容(Cdl)对NixFe1-LDH(x=1,2,3)前体和NixFe1-LDH-20 min(x=1,2,3)进行电化学活性表面积(ECSA)测试。图6中Δj=(ja-jc)/2(ja为0.2 V电压下的最高电流密度;jc为0.2 V电压下最低电流密度;Δj为在0.2 V电压下电流密度变化),NixFe1-LDH(x=1,2,3)前体电化学活性表面积(ECSA)依次为Ni1Fe1-LDH前体(0.000 42 mF/cm2),Ni2Fe1-LDH前体(0.000 33 mF/cm2),Ni3Fe1-LDH前体(0.000 59 mF/cm2),远小于Ni1Fe1-LDH-20 min(0.001 02 mF/cm2),Ni2Fe1-LDH-20 min(0.000 63 mF/cm2),Ni3Fe1-LDH-20 min(0.000 70 mF/cm2)。

图6 过电位窗口为0.15~0.25 V下与Ag/AgCl之间的CV曲线及计算出的ECSA值

Fig.6 An overpotential window of 0.15-0.25 V vs. Ag/AgCl CV curves and the calculated ECSA value

显然,NixFe1-LDH(x=1,2,3)前体经20 min超声悬浮后为OER提供了更大的电化学活性面,这有助于提高OER的活性。其中,Ni1Fe1-LDH-20 min相比较未超声的电化学活性表面积增加最大,达到了Ni1Fe1-LDH前体的2.4倍,进一步证明了经过超声悬浮的Ni1Fe1-LDH-20 min具有较好的电催化活性。

2.4 电化学分解水OER参数对比

由以上电化学试验可知,超声悬浮时间为20 min时,Ni1Fe1-LDH-20 min在OER反应中表现出高活性,且使用超声悬浮具有超声时间短、剥离剂用量少等优点。HAN等[38]将0.2 mg的h-BN晶体加入5 mL 1,2-二氯乙烷溶液中,并超声处理1 h进行剥离,实现了由单晶透明h-BN的液相超声剥离出少层BNNSs。ZHANG等[39]在200 mL的N-甲基吡咯烷酮(NMP)中加入约200 mg石墨,超声处理2 h,利用NMP的溶剂交换在乙醇中获得石墨烯的分散液。可以看出普通超声处理具有超声时间长、剥离剂用量大等缺点。本文仅使用20 μL甲酰胺作为剥离剂,超声悬浮20 min即可达到剥离出单层水滑石的效果,因此从节能减排角度考虑,超声悬浮剥离相比一般的超声有一定优势。表1总结了电流密度在10 mA/cm2时,其他文献报道的电解水析氧催化剂与本文报道的Ni1Fe1-LDH-20 min的催化性能参数对比。表明Ni1Fe1-LDH-20 min在电解水析氧反应方面表现出比其他非贵金属电催化剂更优异的性能,且与其他文献中贵金属氧化物相比,在过电位方面Ni1Fe1-LDH-20 min的OER性能优于IrOx/C。

表1 电解水催化剂OER催化性能参数对比

Table 1 Comparison of OER catalytic performance parameters for water electrolysis catalysts

注:η为在基准电流密度为10 mA/cm2时的过电位。

3 结 论

1)采用水热法合成了NixFe1-LDH(x=1,2,3)前体,对Ni1Fe1-LDH前体和Ni1Fe1-LDH-20 min的形貌和厚度进行表征。试验发现,通过超声悬浮技术仅用20 μL甲酰胺在20 min内成功将Ni1Fe1-LDH前体由横向尺寸为1 500 nm、厚度为25.66 nm的形貌状态剥离为分散较均匀,横向尺寸10 nm、厚度低至0.649 nm的超薄超小水滑石纳米片,实现了超薄超小水滑石的绿色、快速、低能耗制备。

2)当电流密度达10 mA/cm2时,Ni1Fe1-LDH-20 min的过电位为309 mV,相比Ni1Fe1-LDH前体的过电位673 mV,降低了364 mV,说明通过超声悬浮技术制得的超薄超小Ni1Fe1-LDH-20 min纳米片电催化分解水析氧反应的活性有大幅度提高。

3)随超声悬浮时间增加,电催化性能逐渐提高,悬浮时间达20 min时,纳米片成为单层,且电催化活性最高。为实现电化学分解水大规模产氢的先进电极设计提供了新思路,为优化能源利用、降低二氧化碳排放提供了新的方向。

[1] FRIEDLINGSTEIN P, O′SULLIVAN M, JONES M W,et al. Global carbon budget 2023[J]. Earth System Science Data, 2023, 15(12):5301-5369.

[2] SOLARZ J,  M, OSTANT W, et al. Trends in energy security education with a focus on renewable and nonrenewable sources[J]. Energies, 2022, 15(4):1351.

M, OSTANT W, et al. Trends in energy security education with a focus on renewable and nonrenewable sources[J]. Energies, 2022, 15(4):1351.

[3] 张军营,崔向峥,王志康,等. 煤燃烧非常规污染物排放控制[J]. 洁净煤技术, 2023, 29(10):1-16.

ZHANG Junying, CUI Xiangzheng, WANG Zhikang, et al. Emission control of unconventional pollutants during coal combustion[J]. Clean Coal Technology, 2023, 29(10):1-16.

[4] LEWIS N S, NOCERA D G. Powering the planet: Chemical challenges in solar energy utilization[J]. Proceedings of the National Academy of Sciences of the United States of America, 2006, 103(43):15729-15735.

[5] YUAN J, SHI X P, HE J L. LNG market liberalization and LNG transportation: Evaluation based on fleet size and composition model[J]. Applied Energy, 2024, 358:122657.

[6] 王利峰. 我国煤气化技术发展与展望[J]. 洁净煤技术, 2022, 28(2):115-121.

WANG Lifeng. Development and prospect of coal gasification technology in China[J]. Clean Coal Technology, 2022, 28(2):115-121.

[7] 任静,谭玲,赵宇飞,等. 超薄二维材料光/电催化CO2还原的最新进展[J]. 化工学报,2021, 72(1):398-424.

REN Jing, TAN Ling, ZHAOYufei, et al. Latest development of ultrathin two-dimensional materials for photocatalytic and electrocatalytic CO2 reduction[J]. CIESC Journal, 2021, 72(1):398-424.

[8] SHI Y M, ZHANG B. Recent advances in transition metal phosphide nanomaterials: Synthesis and applications in hydrogen evolution reaction[J]. Chemical Society Reviews, 2016, 45(6):1529-1541.

[9] FABBRI E, HABEREDER A, WALTAR K, et al. Developments and perspectives of oxide-based catalysts for the oxygen evolution reaction[J]. Catalysis Science &Technology, 2014, 4(11):3800-3821.

[10] ANANTHARAJ S, EDE S R, SAKTHIKUMAR K, et al. Recent trends and perspectives in electrochemical water splitting with an emphasis to sulphide, selenide and phosphide catalysts of Fe, Co and Ni: A review[J]. ACS catalysis, 2016, 6(12):8069-8097.

[11] WANG S, LU A, ZHONG C J. Hydrogen production from water electrolysis: Role of catalysts[J]. Nano Convergence, 2021, 8(1):4.

[12] 张轩,王凯,樊昕晔,等. 电解水制氢成本分析[J]. 现代化工,2021,41(12):7-11.

ZHANG Xuan, WANG kai, FAN Xinye, et al. Cost analysis on hydrogen production via water electrolysis[J]. Modern Chemical Industry, 2021,41(12):7-11.

[13] ZHUO Q M, ZHAN S Q, DUAN L L, et al. Tuning the O—O bond formation pathways of molecular water oxidation catalysts on electrode surfaces via second coordination sphere engineering[J]. Chinese Journal of Catalysis, 2021, 42(3):460-469.

[14] LIAO P, KEITH J A, CARTER E A. Water oxidation on pure and doped hematite (0001) surfaces: Prediction of Co and Ni as effective dopants for electrocatalysis[J]. Journal of the American Chemical Society, 2012, 134(32):13296-13309.

[15] MATSUMOTO Y, SATO E. Electrocatalytic properties of transition metal oxides for oxygen evolution reaction[J]. Materials Chemistry and Physics, 1986, 14(5):397-426.

[16] FABBRI E, HABEREDER A, WALTAR K, et al. Developments and perspectives of oxide-based catalysts for the oxygen evolution reaction[J]. Catalysis Science &Technology, 2014, 4(11):3800-3821.

[17] AUDICHON T, NAPPORN T W, KOKOH K B, et al. IrO2 coated on RuO2 as efficient and stable electroactive nanocatalysts for electrochemical water splitting[J]. The Journal of Physical Chemistry C, 2016, 120(5):2562-2573.

[18] ZHANG J, WANG T, POHL D, et al. Interface engineering of MoS2/Ni3S2 heterostructures for highly enhanced electrochemical overall-water-splitting activity[J]. Angewandte Chemie International Edition, 2016, 55(23):6702-6707.

[19] POUL L, JOUINI N, FIÉVET F. Layered hydroxide metal acet-ates (metal=Zinc, Cobalt, and Nickel): Elaboration via hydrolysis in polyol medium and comparative study[J]. Chemistry of Materials, 2000, 12(10):3123-3132.

[20] TAYLOR H F W. Segregation and cation-ordering in sjgrenite and pyroaurite[J]. Mineralogical Magazine, 1969, 37(287):338-342.

[21] MISHR A, GEETANJAL I, DAS H, et al. Layered double hydroxides: A brief review from fundamentals to application as evolving biomaterials[J]. Applied Clay Science, 2018, 153:172-186.

[22] KANEDA K, MIZUGAKI T. Design of high-performance heterogeneous catalysts using hydrotalcite for selective organic transformations[J]. Green Chemistry, 2019, 21(6):1361-13689.

[23] FORANO C, ABDELMOULA M, SABBAR E M, et al. Current trends in iron complexes intercalated Layered Double Hydroxides[J]. Current Inorganic Chemistry, 2015, 5(3):194-207.

[24] ZHANG Z J, ZHOU D B, LIAO J J, et al. Synthesis of high crystalline nickel-iron hydrotalcite-like compound as an efficient electrocatalyst for oxygen evolution reaction[J]. International Journal of Energy Research, 2019, 43(4):1460-1467.

[25] PRADNYA M B, PRADIP B S, GURWINDER S, et al. Recent advances in highly active nanostructured NiFe LDH catalyst for electrochemical water splitting[J]. Journal of Materials Chemistry A, 2021, 9:3180-3208.

[26] ADACHI-PAGANO M, FORANO C, BESSE J P. Delamination of layered double hydroxides by use of surfactants[J]. Chemical Communications, 2000(1):91-92.

[27] SAKITA A M P, VALLÉS E, NOCE D R, et al. Novel NiFe/NiFe-LDH composites as competitive catalysts for clean energy purposes[J]. Applied Surface Science, 2018, 447:107-116.

[28] ZHOU D, XIONG X, CAI Z, et al. Flame-ngraved nickel-iron layered double hydroxide nanosheets for boosting oxygen evolution reactivity[J]. Small Methods, 2018, 2(7):1800083.

[29] ZHANG X, MARIANOV A N, JIANG Y, et al. Hierarchically constructed silver nanowire@nickel-iron layered double hydroxide nanostructures for electrocatalytic water splitting[J]. ACS Applied Nano Materials, 2020, 3(1):887-895.

[30] TRINH E H. Compact acoustic levitation device for studies in fluid dynamics and material science in the laboratory and microgravity[J]. Review of Scientific Instruments, 1985, 56(11):2059-2065.

[31] KOYAMA D, NAKAMURA K. Noncontact ultrasonic transporta-tion of small objects over long distances in air using a bending vibrator and a reflector[J]. IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, 2010, 57(5):1152-1159.

[32] CHUNG S K, TRINH E H. Containerless protein crystal growth in rotating levitated drops[J]. Journal of Crystal Growth, 1998, 194(3/4):384-397.

[33] FORESTI D, NABAVI M, KLINGAUF M, et al. Acoustophoretic contactless transport and handling of matter in air[J]. Proceedings of the National Academy of Sciences of the United States of America, 2013, 110(31):12549-12554.

[34] XIE W J, CAO C D, LUE Y J, et al. Acoustic method for levitation of small living animals[J]. Applied Physics Letters, 2016, 89(21):214102.

[35] 解文军,声悬浮优化设计理论及其应用研究[D]. 西安:西北工业大学,2002.

[36] 贺诗华.新的生化痕量分析手段:超声悬浮技术[J]. 化学通报,2004, 67(11):808-812.

HE Shihua. Novel trace bioanalysis technology:Ultrasonic levitation[J]. Chemistry, 2004, 67(11):808-812.

[37] 贾串玲,超声驻波悬浮传输装置的研制与实验[D]. 哈尔滨:哈尔滨工业大学,2015.

[38] HAN W Q, WU L, ZHU Y, et al. Structure of chemically der-ived mono- and few-atomic-layer boron nitride sheets[J]. Applied Physics Letters, 2008, 93(22):223103.

[39] ZHANG X Y, HOU L L, CNOSSEN A, et al. One-pot functionalization of graphene with porphyrin through cycloaddition reactions[J]. Chemistry-A European Journal, 2011, 17(32):8957-8964.

[40] JIANG N, YOU B, SHENG M L, et al. Electrodeposited cobalt-phosphorous-derived films as competent bifunctional catalysts for overall water splitting[J]. Angewandte Chemie, 2015, 54(21):6251-6254.

[41] LIM C S, CHUA C K, SOFER Z, et al. Layered transition metal oxyhydroxides as tri-functional electrocatalysts[J]. Journal of Materials Chemistry, A. Materials for energy and Sustain-ability, 2015, 3(22):11920-11929.

[42] SALVADOR G, SILVA A L, SILVA L,et al. Enhanced activity of Pd/α-MnO2 for electrocatalytic oxygen evolution reaction[J]. International Journal of Hydrogen Energy, 2021, 46(53):26976-26988.

[43] ZHANG J Y, GUO B, LIANG J, et al. Au-Doped CuOx nanoparticles as electrocatalysts for oxygen evolution reaction[J]. ACS Applied Nano Materials, 2022, 5(5):6500-6504.

[44] SHERAZ A, WAHEED K W, NEMAT B F, et al. Fabrication of nanocage structured based electrocatalyst for oxygen evolution reactions[J]. Materials Letters, 2023, 331:133416.

[45] HU Z H, ZHOU Y, WU C Q, et al. Exploring the formation of CoO/ZnO heterostructure to enhance electrocatalytic oxygen evolution reaction[J]. Advanced Materials Interfaces, 2023, 10(16):2300091.

[46] SADHASIVAM T, NIMISHA B, MRUNAL B, et al. Fe2O3/Ni nanocomposite electrocatalyst on cellulose for hydrogen evolution reaction and oxygen evolution reaction[J]. International Journal of Molecular Sciences, 2023, 24(22):16282.

[47] ZHOU L J, HUANG X X, CHEN H, et al. A high surface area flower-like Ni-Fe layered double hydroxide for electrocatalytic water oxidation reaction[J]. Dalton Transactions, 2015, 44(25):11592-11600.

Preparation of ultra-thin and ultra-small nickel-iron layered double hydroxide by acoustic levitation

移动阅读