煤化工VOCs中苯的静电纺丝纳米纤维吸附研究进展

Research progress on adsorption of benzene within VOCs from coal chemical industry by electrospinning nanofibers

0 引 言

挥发性有机化合物(Volatile Organic Compounds,VOCs)是目前国内外大气污染的主要来源之一[1-2]。通常,VOCs是沸点在常压,260 ℃以下、室温饱和蒸气压大于70 Pa且易挥发的有机化合物,不仅造成严重的大气污染,还具有一定毒性,危害人体健康[3-4]。

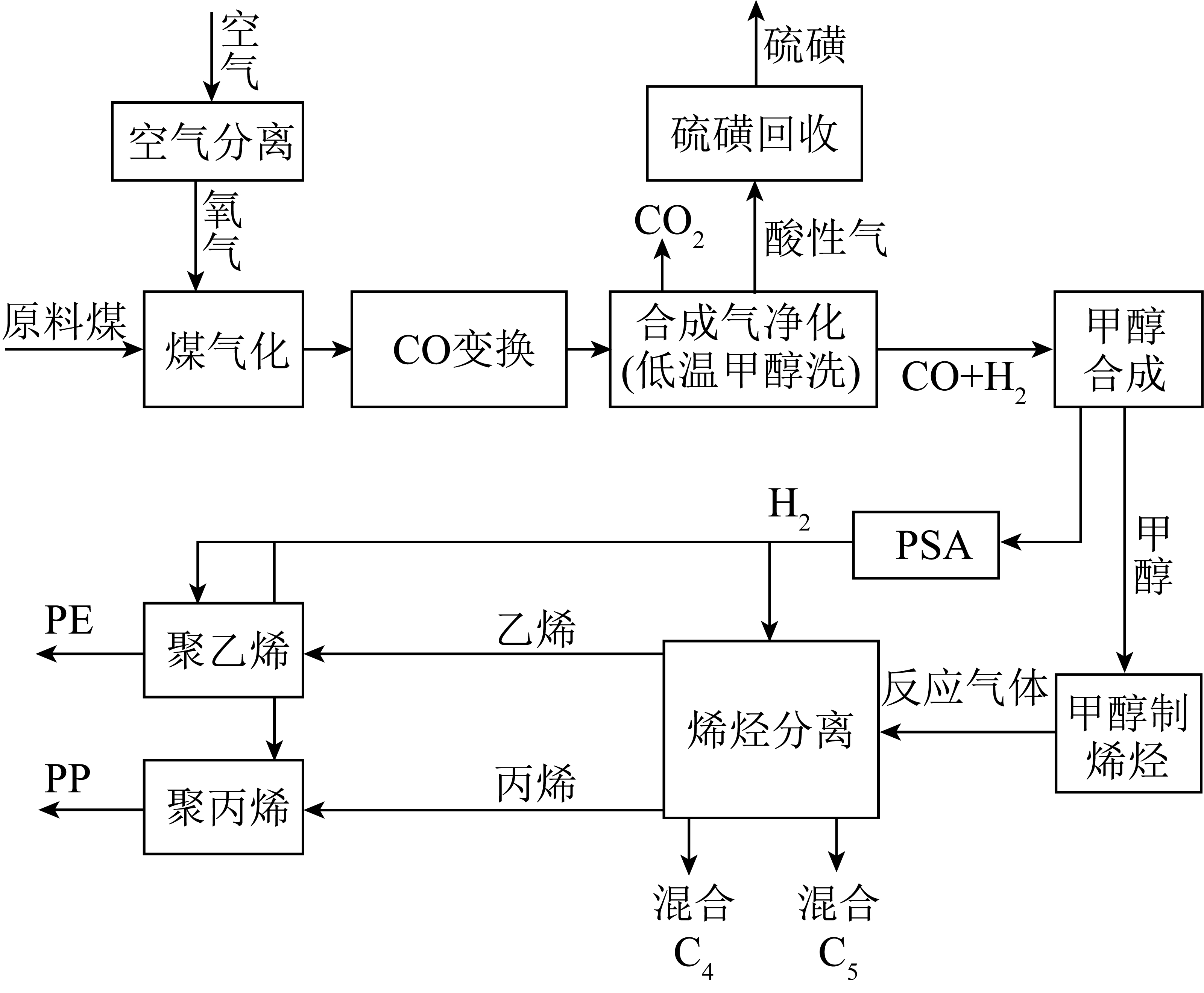

煤化工产业快速发展的同时,传统煤化工的煤焦化过程、低温干馏和现代煤化工行业的基础煤气化、液化过程,伴随大量挥发性有机化合物的排放。煤化工VOCs排放具有排放节点多、差异大、组分复杂等特征[5]。煤化工过程中产生的废气主要来源于煤制焦和煤制气2个过程[6],如煤制气工艺中,罐区VOCs大多为无组织排放,回收难度大,且VOCs多为易溶于水的醇类;低温甲醇洗排气量大、主要成分为甲烷等低碳烃,且含有CO2和H2S。煤焦化工艺中,VOCs来源广泛,种类众多(含有大量苯系物、氨和硫化氢),毒性大,对环境污染严重[7]。作为VOCs的代表之一,苯对人体健康、环境空气乃至臭氧层有严重影响[8-9],且可造成光化学烟雾污染并生成毒性更大的二次污染物[10-11],对苯进行有效处理成为研究重点。

1 VOCs处理方法现状

VOCs常用处理方法有生物法[12]、等离子体法[13-14]、吸附法[15-16]、催化燃烧法[17-19]等。其中,吸附法整体效果好、使用广泛[20-21],研究相对较多。根据吸附时作用力的不同,吸附法又分为物理吸附(范德华力、偶极-偶极相互作用等分子间力)和化学吸附(涉及到电子转移、成键断键等化学键力)[22-24]。选择合适的吸附剂是VOCs吸附处理的核心,目前用于吸附VOCs的材料有静电纺丝纳米纤维、碳基材料、含氧材料如沸石和金属有机框架材料(Metal Organic Frameworks,MOFs)、分子筛、有机聚合物以及复合材料等[25-27],其中,静电纺丝纳米纤维因具有柔性结构、大比表面积、高孔隙率等优点受到广泛关注[28-30]。

2 静电纺丝纳米纤维

2.1 静电纺丝纤维性质

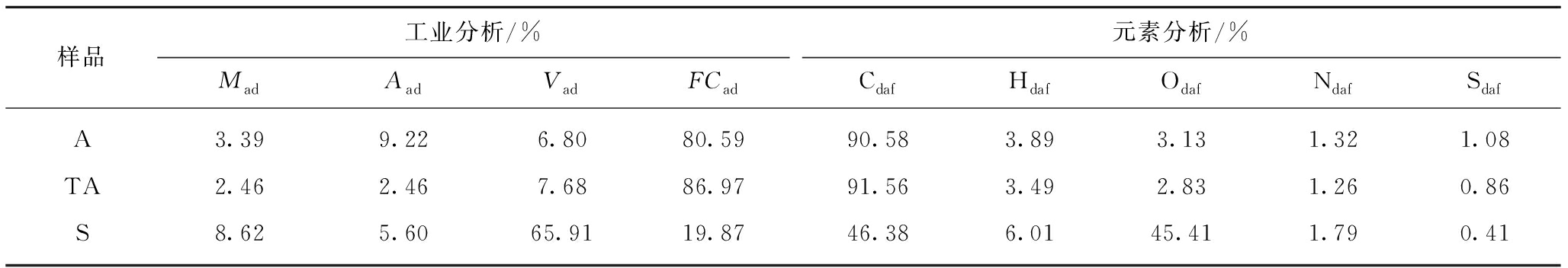

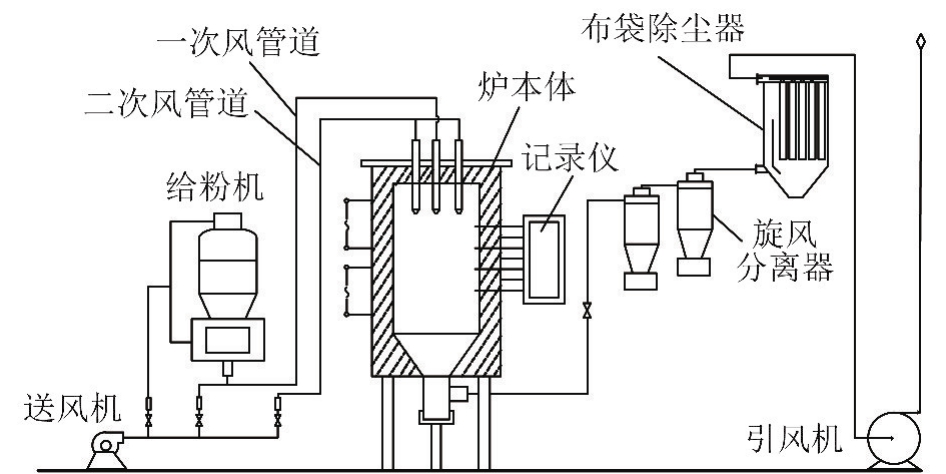

狭义的纳米纤维是指直径在纳米尺度范围内,即纤维直径d<100 nm的纤维[31]。纳米纤维尺寸效应显著,多应用于食品、医药、能源、电子、造纸、航空等领域[32-33]。纳米纤维的制造技术较多,静电纺丝技术以设备简易、纺丝加工成本较低、能纺原料种类多、过程可控等特点,在制备纳米纤维技术中占据绝对优势。对配制好的聚合物溶液加以10万~30万V高压,使其极化,随着电场力不断增大,聚合物溶液变成射流,在空间中不断固化,最终落在接收设备上,形成聚合物纤维膜[34-35](图1)。与常规纤维相比,静电纺丝纳米纤维具有尺寸更小、比表面积更大、孔隙率更高、制备过程可调控性好等特点,使其在气体过滤[36-37]、催化载体[38]、光学电子[39-40]等方面有巨大潜力。

图1 静电纺丝设备和过程示意

Fig.1 Device and process schematic graph of electrospinning

静电纺丝来源于Electrospinning,国内称为“电纺”或“静电纺”[41-42]。静电纺丝是通过高压电场的作用,使高分子聚合物溶液带电,当电荷在液滴表面的斥力大于表面张力时,聚合物的小液流即“射流”被喷射出来。这些射流沉积在收集板上以获得聚合物纤维。有学者研究了带电液体的相关性质,认为当电荷在液体表面的斥力大于表面张力时,会产生射流,并从理论上给出了产生射流的条件。随着研究的深入,研究人员发现随着电压不断增加,带电液滴尖端出现一个半球形的悬浮液滴,随后液滴变成圆锥体。当电荷继续积累并达到某一浓度值时,一股射流从锥尖喷出,这种现象被称为“泰勒锥”,并计算出锥角为49.3°[43]。静电纺丝技术的研究热潮始于20世纪80年代,BAUMGARTEN[44]对丙烯酸的二甲基甲酰胺溶液进行静电纺丝,最终获得直径小于1 μm的纤维。MARTIN和COCKSHOTT[45]对多组分溶液静电纺丝进行试验,将含有多种溶剂的溶液用一个喷嘴纺制,将聚合物纤维同时用多个喷嘴纺制并收集在一起,验证了多组分溶液静电纺丝的可行性。美国Donaldson公司推动了静电纺纤维在过滤行业的应用,制备出Ultra-web纳米纤维滤材[46]。

我国对静电纺丝的研究比较滞后,张锡玮等[47]论述了静电纺丝法纺制纳米级聚丙烯腈纤维毡的方法,分析了纺丝工艺条件与纤维直径及成纤后溶剂残留量的关系,并研究了以二甲基甲酰胺及适量丙酮为复合溶剂对纤维各方面性质的影响。袁晓燕等[48]以丙酮为溶剂,用静电纺丝法制备了聚丙交酯(PLA)及其与己内酯共聚物(PUA-CL)的超细纤维。研究了电压、溶液质量分数及流量对超细纤维形态和直径的影响。我国静电纺丝技术方面的专利源于21世纪初,但相关研究还只在实验室阶段,企业需增加投资,与高校、科研院所合作,以尽快实现静电纺丝工艺的产业化应用[46]。

2.2 静电纺丝纤维用于气体污染物吸附

静电纺丝由于其独特的优越性,在空气过滤吸附领域得到广泛应用。ZAINAB等[49]以聚丙烯腈/聚乙烯吡咯烷酮(PAN/PVP)复合溶液为纺丝液,采用PVP为制孔模板,选择PAN作为富碳富氮前体。碳化前从静电纺丝PAN/PVP纤维基质中选择性去除PVP会产生高度粗糙和多孔的PAN纳米纤维,经碳化后,形成多孔碳纳米纤维(PCNF)。合成的PCNF对CO2气体分子表现出高度选择性,对CO2吸收量高达3.11 mmol/g。SONG等[50]在相同条件下生产了一系列传统多孔碳纤维(Conventional Porous Carbon Fibers,CPCF)和超细多孔碳纤维(Ultrafine Porous Carbon Fibers,UPCF),并对UPCF进行了改进。与CPCF相比,UPCF具有较高的表面积和微孔体积,对SO2吸附能力更好。改性UPCF后,优化了UPCF的表面化学活性和孔隙结构,进一步提高了UPCF对SO2的吸附能力。改性试剂的最佳质量分数为10%。KIM等[51]将PAN和ZnO的前驱体混合溶于N,N-二甲基甲酰胺(DMF)中进行静电纺丝,600 ℃热处理后制备了柔性ZnO/CNFs复合材料,发现ZnO/CNFs复合材料的脱硫能力对ZnO含量非常敏感,ZnO质量分数为25.7%时CNFs脱硫性能最佳。张思远[52]通过静电纺丝、预氧化和炭化制备ZnO/活性炭复合纳米纤维材料,利用SEM、EDS等得出碳化温度650 ℃下、质量分数5%的纤维材料的烟气脱硫能力最好。

3 静电纺丝纳米纤维用于苯的吸附

3.1 单一静电纺丝纳米纤维

为了脱除苯污染物,SUN等[53]利用静电纺丝法制备得到了聚苯乙烯(PS)和PAN纳米纤维,对所制备的纤维进行了苯的吸附性能测试和对比。经测试得出,PS和PAN纳米纤维对苯的吸附容量分别为9.82和2.57 mg/g。PS和PAN纳米纤维对苯的吸附能力存在一定差异,这是由于PAN中极性基团—CN的存在使PAN具有适度的可湿表面,不适合疏水性有机物质。因此,预期PAN纳米纤维对芳香族化合物的吸附较少。而PS具有芳香环,与目标分子结构相似,因此PS纤维与芳香族化合物之间易快速、稳定结合。

除聚合物纳米纤维外,由聚合物纳米纤维衍生而来的活性炭纤维(Activated Carbon Nanofibers,ACNFs)同样被用作苯的高效吸附材料[54]。BAI等[55]采用静电纺丝法和水蒸气活化法处理聚丙烯腈纳米纤维,得到了活性炭纤维,并对其进行吸附性能测试。研究发现静态吸附测试中ACNFs对苯的吸附容量为84 cm3/g,而ACFs为68 cm3/g。2种样品的孔结构和比表面积特别接近,说明ACNFs中直径更小的纤维表面具有更小更多的吸附位点,有利于纤维材料对苯的吸附。此外,对比了不同活化条件下ACNFs的吸附性能,发现随着烧失率从30%提高到80%,ACNFs对苯的吸附量从53 cm3/g增加到104 cm3/g。这是因为随着烧失率的提高,吸附材料的孔结构发生变化,产生了更大的比表面积和更高的孔隙率。

苯吸附过程中,高湿度环境中的水蒸气会在吸附剂的活性位点上与苯发生竞争吸附,影响吸附剂对苯的吸附行为[56]。表面化学性质对含碳材料的气体吸附剂性能有重大影响[57-58]。表面功能化可以改变碳表面的反应性和选择性,对特定有机分子的吸附起重要作用。BAI等[59]通过静电纺丝和蒸气活化制备得到了碳纳米纤维,并在HNO3和HNO3/H2SO4混合酸中进行了氧化后处理。根据SEM和Raman光谱表征发现,氧化后处理的纳米纤维表面形貌和石墨结构程度均受到酸氧化的影响。氮吸附/脱附等温线表明,经过氧化后碳纳米纤维的比表面积和孔体积减小(由562 m2/g降低到HNO3处理的520 m2/g和HNO3/H2SO4处理的383 m2/g)。XPS光谱表明,氧化纳米纤维比原始纳米纤维具有更高的表面氧含量(由11.5%增加到HNO3处理的13.7%和HNO3/H2SO4处理的17.3%)。由水吸附等温线可知,氧化处理后的碳纳米纤维具有更高的水吸附容量,表明表面极性和亲水性在氧化处理后得到改善。此外,苯、丁酮和乙醇的吸附等温线表明,由于表面极性的增加,表面氧化增强了丁酮和乙醇在纳米纤维上的吸附趋势,提高了极性有机化合物的吸附选择性。

除对表面性质改性外,静电纺碳纳米纤维对苯吸附性能的提升还在于对其孔结构的优化。BAI等[60]通过调控静电纺碳纳米纤维的直径,优化了静电纺碳纳米纤维对苯的吸附行为。以酚醛树脂为原料,采用静电纺丝、热固化、一步碳化等方法制备了不同直径的微孔炭超细纤维(PCUFs),并评价了其对苯和水的吸附性能。随着纺丝溶液中溶剂DMF含量增加,纤维静电纺固化过程中发生了更多的劈裂现象,如图2所示。初生纤维的平均直径从1.1 μm(纺丝液中溶剂只含乙醇,样品命名为PCUF0)减小为0.33 μm(纺丝液中溶剂乙醇∶DMF质量比为7∶3,样品命名为PCUF30)。此外,由于比表面积、微孔体积和疏水性的改善,直径较小的碳超细纤维表现出对苯吸附的增强和对水吸附的降低。PCUF0、PCUF010(纺丝液中溶剂乙醇∶DMF质量比为9∶1)和PCUF30的水接触角分别为128°、136°和139°,而普通活性炭纤维下降到极低(21°)。结果表明,PCUFs比普通活性炭纤维表现出更大的疏水性,从PCUF0到PCUF30,疏水性略增加。PCUF0、PCUF10和PCUF30的苯吸附量分别为63.5、66.8和73.9 cm3/g,PCUF30对苯具有最好的吸附性能。吸附量从PCUF0到PCUF30,增加了16%。此外,与普通聚丙烯腈基静电纺丝活性炭纳米纤维相比,碳超细纤维相对发达的疏水性使其对苯具有比水更高的吸附倾向。

图2 不同溶剂组分下静电纺丝纳米纤维的直径对比[60]

Fig.2 Diameter comparison of electrospun nanofibers under different solvent components[60]

综上,单一静电纺丝纳米纤维对苯的吸附经历了从简单纤维、表面改性纤维、结构改性纤维等过程,对苯的吸附性能也随着纤维表面化学性质和微观孔隙结构的不断优化而逐步上升。然而,随着VOCs排放量不断增大以及环保要求逐渐严格,对静电纺丝纳米纤维的吸附性能也提出了更高要求。

3.2 复合静电纺丝纳米纤维

在静电纺丝纳米纤维中引入功能材料是提高其苯吸附性能的另一个有效方式,金属有机框架材料(MOFs)[61-64]、分子筛[65-66]、石墨烯[67]等因均匀分散的活性位点、大比表面积和高孔隙率受到广泛关注。刘国强等[68]通过溶剂热法制备金属有机骨架-氧化石墨烯(MOF-GO)复合材料。该材料对苯和乙醇有较高的吸附容量,最大吸附容量分别达到72和77 cm3/g。结果表明,吸附性能和容量不仅受孔结构的影响,其表面特性对吸附也有重要影响。JHUNG等[69]以微波为加热源合成得到了MIL-101,且对比了不同微波辐照时间对材料性质和苯吸附性能的影响。研究发现,当微波辐射时间为40 min时,得到的MIL-101(40)对苯的吸附性能优于微波辐射时间1、2 min的样品,表明在一定范围内延长微波辐射时间有助于提升MIL-101的苯吸附性能。同时,为了进一步明确MIL-101的性能,在相近条件下测试了活性炭、HZSM-5分子筛以及SBA-15分子筛的苯吸附性能,并与MIL-101进行对比。结果表明,30 ℃时MIL-101(40)对苯的吸附量为16.7 mmol/g(吸附时的分压P/P0=0.5),大于现有报道的其他材料的最高值12.4 mmol/g。

基于此,YANG等[70]结合静电纺丝技术和金属有机框架得到了衍生的多孔碳纤维,由于其巨大的表面积、高孔隙率以及足够的杂原子掺杂活性位点,在吸附挥发性有机化合物方面表现出巨大应用潜力(图3)。由于分层多孔结构和丰富的含氮物种活性位点的协同作用,在N2气氛中制造的氮掺杂碳纳米纤维(N-CF-N2)对苯的吸附容量提高到了694 mg/g(纯PAN:37 mg/g、ZIF-8/PAN:37 mg/g、ZIF-8粉末:381 mg/g、N-CF-Ar:336 mg/g、N-CF-N2:694 mg/g)。与N-CF-N2相比,在Ar气氛中制备的氮掺杂分级碳纳米纤维(N-CF-Ar)对苯的吸附作用较小,这归因于热解过程中Ar原子轰击导致孔结构破坏。表明制备的N-CF-N2具有成本效益高、可规模化生产和吸附能力优异等优点,在吸附VOCs方面应用前景广阔,拓展了静电纺丝技术的潜力和复合纤维在挥发性有机气体吸附中的作用。

图3 N-CF-N2纳米纤维制备示意[70]

Fig.3 Schematic of preparation of N-CF-N2 nanofibers[70]

分子筛具有比表面积大、孔容高等特点,能有效选择吸附VOCs。目前在VOCs吸附领域广泛使用的分子筛大致分为微孔(A型、X型、Y型等)和介孔分子筛(MCM-41、SBA-15、KIT-6等)[71]。由于具有协同作用,WU等[72]以静电纺丝技术合成复合纤维,并作为挥发性有机化合物的吸附剂。采用静电纺丝方法制备了嵌入微孔NaY沸石的新型分层结构PVP多孔纤维。进一步优化了静电纺丝电压和流速以及NaY沸石的粒径等参数,以制备具有均匀形态和优异性能的复合纤维。在优化工艺下合成的大比表面积复合纤维具有优异的苯吸附容量(667 mg/g),这归因于由多孔PVP和微孔NaY沸石构成的分级结构产生的协同效应。说明制备的VOCs复合纤维具有低成本和大规模生产优势,应用潜力广阔,为沸石/聚合物复合纤维的实际应用设计和利用提供了思路。

多种具有高比表面积、孔隙率和功能化的材料以原位或后处理方式引入静电纺丝过程中,大大提升了静电纺丝纳米纤维复合材料的吸附性能。但如何提高这些材料的负载量并使其在静电纺丝纳米纤维表面或体相中均匀分散,充分发挥其吸附特性,是未来工作重点。

4 结语与展望

环境恶化是21世纪最紧迫的挑战之一,寻求优异的气体污染物净化材料成为学术界和工业界的共同目标。静电纺丝纳米纤维材料成本低、设备简单、净化效果好,能满足当前环保要求。利用静电纺丝纳米纤维开发先进的功能性纳米结构材料被广泛应用于VOCs的净化。但静电纺丝纳米纤维材料应用于VOCs净化的探索时间较短,仍存在一些问题:① 大多数静电纺丝聚合物纳米纤维和碳纳米纤维为脆性,机械强度不足,不适合实际应用;② 目前用于气体净化的纳米纤维材料的静电纺丝工艺基本涉及有机溶剂,这些溶剂往往有毒、有腐蚀性,危害环境;③ 静电纺丝工艺速率较慢,单位时间生产成品数量和规模较小。

静电纺丝技术将在以下方面进一步发展:① 在基础研究领域,逐步系统整合理论分析模型,将泰勒锥射流收集全过程模型化,实现对纺丝过程的深入理解和有效预测与控制。② 纺丝材料将向功能化方向扩展,特别是在功能化改性方面。多功能纳米纤维的高比表面积为其性能提升提供了巨大的空间。③ 目前实验室纺丝工艺比较简单,但与纺丝过程的稳定可控还有一定距离,导致向工业流程过渡需要更多的时间成本。未来,静电纺丝纳米纤维材料在气体污染物净化,特别是VOCs净化领域的应用将更加广泛,同时静电纺丝工艺会越来越成熟,这有助于环境的可持续发展,实现绿色环保的大规模工业化生产。

[1] 江梅,邹兰,李晓倩,等. 我国挥发性有机物定义和控制指标的探讨[J]. 环境科学,2015,36(9):3522-3532.

JIANG Mei,ZOU Lan,LI Xiaoqian,et al. Definition and control indicators of volatile organic compounds in China[J]. Environmental Science,2015,36(9):3522-3532.

[2] ZHANG X M,XUE Z G,LI H,et al. Ambient volatile organic compounds pollution in China[J]. Journal of Environmental Sciences,2017,55:69-75.

[3] KAMAL M S,RAZZAK S A,HOSSAIN M M. Catalytic oxidation of volatile organic compounds (VOCs):A review[J]. Atmospheric Environment,2016,140:117-134.

[4] MA Xiuwei,YANG Linjun,WU Hao,et al. Removal of volatile organic compounds from the coal-fired flue gas by adsorption on activated carbon[J]. Journal of Cleaner Production,2021,302(15):126925.

[5] 魏长河,孙玉壮,黄泽春,等. 煤液化高浓度污水处理厂中VOCs污染水平及其归趋[J]. 煤炭学报,2016,41(3):735-742.

WEI Changhe,SUN Yuzhuang,HUANG Zechun,et al. Occurrence and fate of VOCs in high concentration wastewater treatment plant of coal liquefaction[J]. Journal of China Coal Society,2016,41(3):735-742.

[6] 张凤莲. 以煤为原料的合成氨企业挥发性有机物排放特征研究[J]. 洁净煤技术,2019,25(6):1-9.

ZHANG Fenglian. Study on the emission characteristics of volatile organic compounds (VOCs) from coal-based ammonia plant[J]. Clean Coal Technology,2019,25(6):1-9.

[7] 李辉,王登辉,惠世恩. 煤化工VOCs治理技术应用现状及展望[J]. 洁净煤技术,2021,27(1):144-154.

LI Hui,WANG Denghui,HUI Shien,et al. Application status and prospects of coal chemical VOCs treatment technology[J]. Clean Coal Technology,2021,27(1):144-154.

[8] 李竞草. 疏水性CDs@MOFs复合材料的制备及其苯吸附性能研究[D].太原:太原理工大学,2020.

[9] WOLKOFF P,WILKINS C K,CLAUSEN P A,et al. Organic compounds in office environments-sensory irritation,odor,measurements and the role of reactive chemistry[J]. Indoor Air,2006,16:7-19.

[10] COMETTO-MUNIZ J E,CAIN W S,ABRAHAM M H. Detection

of single and mixed VOCs by smell and by sensory irritation[J]. Indoor Air,2004,14:108-117.

[11] GEIGER H,BECKER K H,WIESEN P. Effect of gasoline formulation on the formation of photosmog:A box model study[J]. Journal of the Air and Waste Management Association,2003,53:425-433.

[12] 饶佳家,陈柄灿,孙兴福,等.生物法处理挥发性有机废气的研究.环境污染治理技术与设备,2004,5(9):56-60.

RAO Jiajia,CHEN Bingcan,SUN Xingfu,et al. Study on biological treatment of airstreams contaminated with VOCs[J]. Techniques and Equipment for Environmental Pollution Control,2004,5(9):56-60.

[13] FUTAMURA S,ZHANG A,EINAGA H,et al. Involvement of catalyst materials in nonthermal plasma chemical processing of hazardous air pollutants[J]. Catalysis Today,2002,72(3/4):259-265.

[14] 郑光云,候健,蒋洁敏,等.非平稳态等离子体降解流动态低浓度甲苯气体的研究[J].复旦大学学报,2001,40(4):364-367.

ZHENG Guangyun,HOU Jian,JIANG Jiemin,et al.Degradation of flowing low-density gaseous toluene by non-equilibrium plasma[J]. Journal of Fudan University,2001,40(4):364-367.

[15] 田洁,刘宝友.VOCs治理技术分析及研究进展[J].现代化工,2020,40(4):30-35.

TIAN Jie,LIU Baoyou.Analysis and advances on governance technologies for VOCs[J]. Modern Chemical Industry,2020,40(4):30-35.

[16] 刘井新.浅谈苯蒸汽回收的必要性和方法[J].炼油与化工,2010,21(2):20-22.

LIU Jingxin.Brief discussion of necessity and methods of benzene vapor recovery[J]. Refining and Chemical Industry,2010,21(2):20-22.

[17] 王恒远.低浓度苯在Cu-Mn-Ce催化剂上的催化燃烧特性研究[D].重庆:重庆大学,2017.

[18] LIOTTA L F. Catalytic oxidation of volatile organic compounds on supported noble metals[J]. Applied Catalysis B:Environmental,2010,100(3):403-412.

[19] NIU Q,LI B,XU X L,et al. Activity and sulfur resistance of CuO/SnO2/PdO catalysts supported on γ-Al2O3 for the catalytic combustion of benzene[J]. Rsc Advances,2014,4:51280-51285.

[20] 李智,王建英,王勇,等. NaY沸石分子筛在VOCs处理中的应用[J]. 环境工程学报,2020,14(8):2211-2221.

LI Zhi,WANG Jianying,WANG Yong,et al. Application of NaY zeolite molecular sieve in VOCs treatment[J]. Chinese Journal of Environmental Engineering,2020,14(8):2211-2221.

[21] 岳旭,王胜,高杨,等. VOCs在吸附剂上吸附性能的热力学研究[J]. 燃料化学学报,2020,48(6):752-760.

YUE Xu,WANG Sheng,GAO Yang,et al. Thermodynamics analysis on the adsorption behaviors of VOCs on various adsorbents[J]. Journal of Fuel Chemistry and Technology,2020,48(6):752-760.

[22] 王旭,吴玉帅,杨欣,等. 沸石分子筛用于VOCs吸附脱除的应用研究进展[J]. 化工进展,2021,40(5):2813-2826.

WANG Xu,WU Yushuai,YANG Xin,et al. Review of adsorptive removal of volatile organic compounds by zeolite[J]. Chemical Industry and Engineering Progress,2021,40(5):2813-2826.

[23] 刘强,卢文新,刘佳,等. 分子筛材料在VOCs治理中的应用研究进展[J]. 化肥设计,2020,58(3):5-8.

LIU Qiang,LU Wenxin,LIU Jia,et al. Research progress of molecular sieve materials application in VOCs treatment[J]. Chemical Fertilizer Design,2020,58(3):5-8.

[24] 苏炜,韩娜,陈政利,等. Hβ分子筛改性及其催化苯和氯化苄反应性能[J]. 石油学报(石油加工),2020,36(1):38-44.

SU Wei,HAN Na,CHEN Zhengli,et al. Modification of Hβ molecular sieve and its catalytic performance in benzylation[J]. Acta Petrolei Sinica(Petroleum Processing Section),2020,36(1):38-44.

[25] DEMIR M M,YILGOR I,YILGOR E E A,et al. Electrospinning of polyurethane fibers[J]. Polymer,2002,43(11):3303-3309.

[26] MO X M,XU C Y,KOTAKI M E A,et al. Electrospun P (LLA-CL) nanofiber:A biomimetic extracellular matrix for smooth muscle cell and endothelial cell proliferation[J]. Biomaterials,2004,25(10):1883-1890.

[27] PAWLOWSKI K J,BARNES C P,BOLAND E D,et al. Biomed-

ical nanoscience:Electrospinning basic concepts,applications,and classroom demonstration[J]. MRS Online Proceedings Library Archive,2004,827:17-28.

[28] MATABOLA K P,MOUTLOALI R M. The influence of electrospinning parameters on the morphology and diameter of poly (vinyledene fluoride) nanofibers-effect of sodium chloride[J]. Journal of Materials Science,2013,48(16):5475-5482.

[29] ZHAO S,WU X,WANG L,et al. Electrospinning of ethyl-cyanoethyl cellulose/tetrahydrofuran solutions[J]. Journal of Applied Polymer Science,2004,91(1):242-246.

[30] PELIPENKO J,KRISTL J,JANKOVIC B,et al. The impact of relative humidity during electrospinning on the morphology and mechanical properties of nanofibers[J]. International Journal of Pharmaceutics,2013,456(1):125-134.

[31] 焦体峰,黄欣欣,展方可.静电纺丝制备纳米纤维材料及应用研究进展[J].燕山大学学报,2018,42(4):283-295.

JIAO Tifeng,HUANG Xinxin,ZHAN Fangke. Research progress and application in preparation of nanofiber materials by electrospinning[J]. Journal of Yanshan University,2018,42(4):283-295.

[32] 芦长椿.亚微米-纳米纤维的技术进展及应用现状[J].纺织导报,2019(12):48-52.

LU Changchun.The current status of submicro-nanofibers technology and application[J]. China Textile Leader,2019(12):48-52.

[33] 邹科,龙云泽,吴佑实.静电纺丝制备纳米纤维的进展及应用[J].合成纤维工业,2007,30(3):54-57.

ZOU Ke,LONG Yunze,WU Youshi. Progress and application of electrospun nanofibers[J]. China Synthetic Fiber Industry,2007,30(3):54-57.

[34] CUI Z Y,XU Y Y,ZHU L P,et al. Preparation of PVDF/PEO-PPO-PEO blend microporous membranes for lithium ion batteries via thermally induced phase separation process[J].Journal of Membrane Science,2008,325(2):957-963.

[35] 余韶阳,安瑛,李守猛,等.熔体微分离心静电纺丝技术批量制备纳米纤维[J].工程塑料应用,2018,46(11):53-57.

YU Shaoyang,AN Ying,LI Shoumeng,et al. Melt differential centrifugal electrospinning technology for batch preparation of nanofibers[J]. Engineering Plastics Application,2018,46(11):53-57.

[36] BAE H S,HAIDER A,SELIM K M K,et al. Fabrication of highly porous PMMA electrospun fibers and their application in the removal of phenol and iodine[J]. Journal of Polymer Research,2013,20(7):1-7.

[37] JING L,SHIM K,TOE C Y,et al. Electrospun polyacrylonitrile-ionic liquid nanofibers for superior PM2.5 capture capacity[J]. ACS Applied Materials & Interfaces,2016,8(11):7030-7036.

[38] DE VRIEZE S,VAN CAMP T,NELVIG A,et al. The effect of temperature and humidity on electrospinning[J]. Journal of Materials Science,2009,44(5):1357-1362.

[39] YANG A,CAI L,ZHANG R,et al. Thermal management in nanofiber-based face mask[J]. Nano Letters,2017,17(6):3506-3510.

[40] MIT-UPPATHAM C,NITHITANAKUL M,SUPAPHOL P. Ultrafine electrospun polyamide-6 fibers:Effect of solution conditions on morphology and average fiber diameter[J]. Macromolecular Chemistry and Physics,2004,205(17):2327-2338.

[41] 杨尚斌.聚丙烯酸超细纳米蛛网的制备及成形机理研究[D].上海:东华大学,2011.

[42] 周鹏.静电场中射流破裂为超高荷质比带电液滴的理论与实验研究[D].武汉:武汉科技大学,2007.

[43] 薛聪,胡影影,黄争鸣.静电纺丝原理研究进展[J].高分子通报,2009(6):38-47.

XUE Cong,HU Yingying,HUANG Zhengming. Recent development in study on mechanism of electrospinning[J]. Chinese Polymer Bulletin,2009(6):38-47.

[44] BAUMGARTEN P K. Electrostatic spinning of acrylic microfibers[J]. Journal of Colloid and Interface Science,1971,36(1):71-79.

[45] MARTIN G E,COCKSHOTT I D. Fibrillar product of electrostatically spun organic material:US4,043,331[P]. 1977-08-23.

[46] 中国知识产权研究会.各行业专利技术现状及其发展趋势报告2007—2008[M].北京:科学出版社,2008.

[47] 张锡玮,夏禾,徐纪钢,等.静电纺丝法纺制纳米级聚丙烯腈纤维毡[J].塑料,2000,29(2):16-19.

ZHANG Xiwei,XIA He,XU Jigang,et al. Nano-PAN fiber felt made by electrostatic spinning[J]. Plastics,2000,29(2):16-19.

[48] 袁晓燕,董存海,赵瑾,等.静电纺丝制备生物降解性聚合物超细纤维[J].天津大学学报,2003,36(6):707-709.

YUAN Xiaoyan,DONG Cunhai,ZHAO Jin,et al. Biodegradable polymeric ultrafine fibers by electrostatic spinning[J]. Journal of Tianjin University,2003,36(6):707-709.

[49] ZAINAB G,BABAR A A,ALI N,et al. Electrospun carbon nanofibers with multi-aperture/opening porous hierarchical structure for efficient CO2 adsorption[J]. Journal of Colloid and Interface Science,2020,561:659-667.

[50] SONG X,WANG Z,LI Z,et al. Ultrafine porous carbon fibers for SO2 adsorption via electrospinning of polyacrylonitrile solution[J]. Journal of Colloid and Interface Science,2008,327(2):388-392.

[51] KIM S,BAJAJ B,BYUN C K,et al. Preparation of flexible zinc oxide/carbon nanofiber webs for mid-temperature desulfurization[J]. Applied Surface Science,2014,320:218-224.

[52] 张思远.ZnO/活性炭复合纳米纤维材料对烟气脱硫机理的研究[D].唐山:华北理工大学,2017.

[53] SUN J,KANG X J,MA Y Q,et al. The study of adsorption characteristics of electrospun polymer nanofibers for benzenes in water[J]. Water Science & Technology:A Journal of the International Association on Water Pollution Research,2011,64(2):528-533.

[54] SHIM W G,KIM C,LEE J W,et al. Adsorption characteristics of benzene on electrospun-derived porous carbon nanofibers[J]. Journal of Applied Polymer Science,2006,102(3):2454-2462.

[55] BAI Y,HUANG Z,WANG M,et al. Adsorption of benzene and ethanol on activated carbon nanofibers prepared by electrospinning[J]. Adsorption:Journal of the International Adsorption Society,2013,19(5):1035-1043.

[56] LI Z,JIN Y,CHEN T,et al. Trimethylchlorosilane modified activated carbon for the adsorption of VOCs at high humidity[J]. Separation and Purification Technology,2021,272:118659.

[57] HUNTER-SELLARS E,TEE J J,PARKIN I P,et al. Adsorption of volatile organic compounds by industrial porous materials:Impact of relative humidity[J]. Microporous and Mesoporous Materials,2020,298:110090.

[58] IIL A,ZH A,JHP B,et al. Competitive adsorption equilibrium modeling of volatile organic compound (VOCs) and water vapor onto activated carbon[J]. Separation and Purification Technology,2019,212:632-640.

[59] BAI Y,HUANG Z H,KANG F. Surface oxidation of activated electrospun carbon nanofibers and their adsorption performance for benzene,butanone and ethanol[J]. Colloids & Surfaces A Physicochemical & Engineering Aspects,2014,443:66-71.

[60] BAI Y,HUANG Z H,KANG F. Electrospun preparation of microporous carbon ultrafine fibers with tuned diameter,pore structure and hydrophobicity from phenolic resin[J]. Carbon,2014,66:705-712.

[61] 孙茜.金属-有机骨架材料MIL-101对典型挥发性有机物(VOCs)的吸附性能及机理[D]. 杭州:浙江大学,2011.

[62] XU G,ZHANG X,GUO P,et al. MnII-based MIL-53 analogues:

Synthesis using neutral bridging μ2-ligands and application in liquid-phase adsorption and separation of C6-C8 Aromatics[J]. Journal of the American Chemical Society,2010,132(11):3656-3657.

[63] HUANG C Y,SONG M,GU Z Y,et al. Probing the adsorption characteristic of metal-organic framework MIL-101 for volatile organic compounds by quartz crystal microbalance[J]. Environmental Science & Technology,2011,45(10):4490-4496.

[64] 赵雅婷.金属-有机骨架及其复合材料对挥发性有机化合物吸附/解吸性能和机理的研究[D].保定:河北大学,2019.

[65] 刘倩,杜昭,张美然. 分子筛吸附VOCs与微波脱附性能研究[J]. 河北科技大学学报,2020,41(2):164-171.

LIU Qian,DU Zhao,ZHANG Meiran.Study on adsorption properties of zeolites for VOCs and microwave desorption[J]. Journal of Hebei University of Science and Technology,2020,41(2):164-171.

[66] LI R,CHONG S J,ALTAF N,et al. Synthesis of ZSM-5/siliceous zeolite composites for improvement of hydrophobic adsorption of volatile organic compounds[J]. Frontiers in Chemistry,2019,7:505.

[67] GUO Z Y,HUANG J,XUE Z,et al. Electrospun graphene oxide/

carbon composite nanofibers with well-developed mesoporous structure and their adsorption performance for benzene and butanone[J]. Chemical Engineering Journal,2016,306:99-106.

[68] 刘国强,王明玺,黄正宏,等. GO/MOF复合材料的制备及其吸附苯和乙醇性能[J]. 新型炭材料,2015,30(6):566-571.

LIU Guoqiang,WANG Mingxi,HUANG Zhenghong,et al.Preparation of graphene/metal-organic composites and their adsorption performance for benzene and ethanol[J]. New Carbon Materials,2015,30(6):566-571.

[69] JHUNG S H,LEE J H,YOON J W,et al. Microwave synthesis of chromium terephthalate MIL-101 and its benzene sorption ability[J]. Advanced Materials,2007,19(1):121-124.

[70] YANG X,WU X,CHEN Z,et al. Hierarchically porous N-doped

carbon nanofibers derived from ZIF-8/PAN composites for benzene adsorption[J]. Journal of Applied Polymer Science,2020,138:e50431.

[71] 李梦瑶. HZSM-5分子筛用于间甲酚和对甲酚吸附分离的研究[D]. 太原:太原理工大学,2019.

[72] WU X H,YANG X,YANG H,et al. Hierarchically structured PVP porous fibers derived from the embedding of NaY zeolite synergize the adsorption of benzene[J]. Composites Part B:Engineering,2019,179:107542.