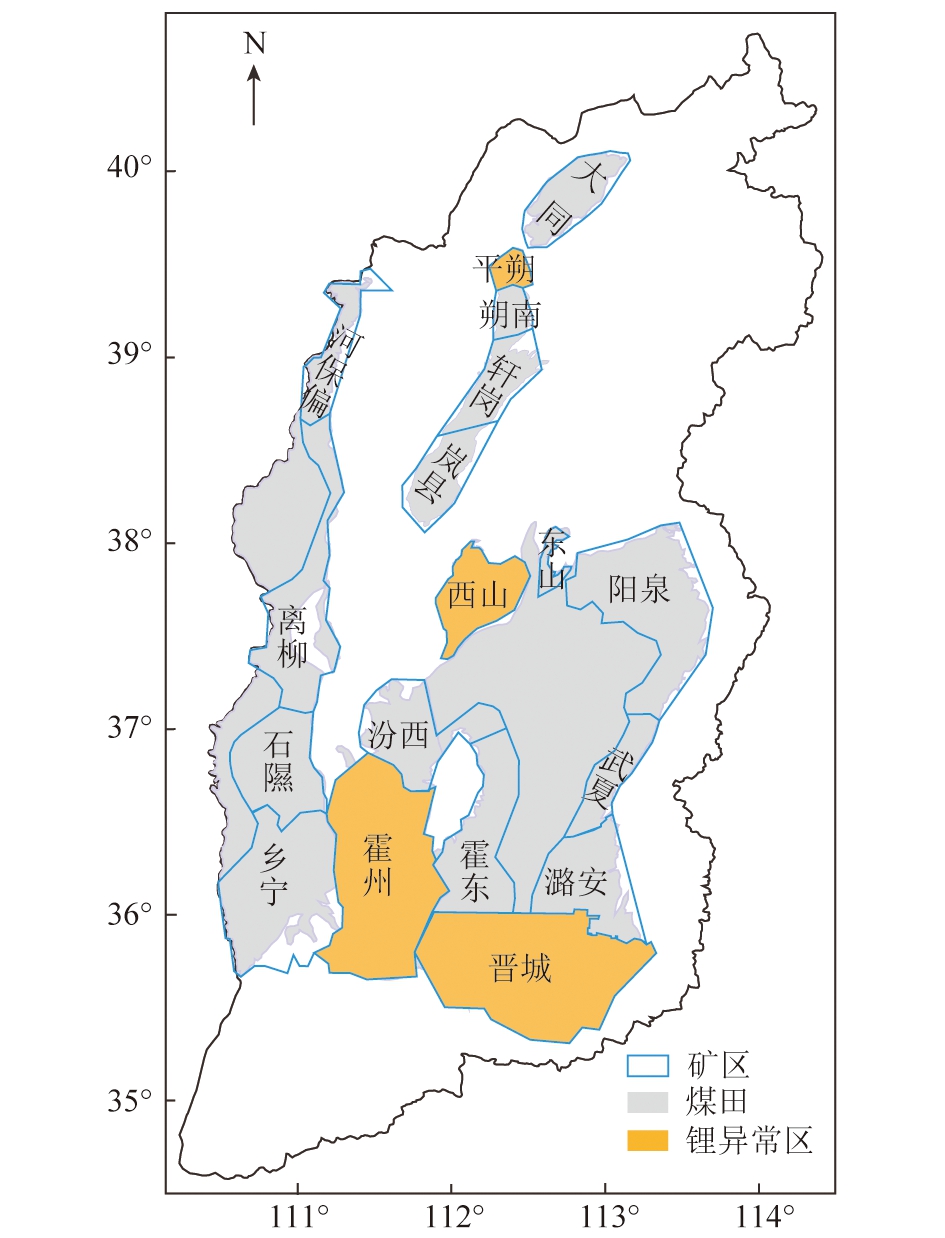

“燃煤低碳利用与重金属污染控制”专题

燃煤电站锅炉掺氨燃烧与排放特性综述

0 引 言

燃煤电站锅炉是我国主要的CO2排放源之一,在“碳达峰、碳中和”目标下,燃煤电站锅炉碳减排受到重视。氨气是一种实现可再生能源大规模可靠存储的储能介质,作为燃料利用不会造成碳排放。氨作为优良的无碳燃料,与煤掺混燃烧受到广泛关注[1-3]。燃煤掺氨(NH3)燃烧可行性较高。与其他技术相比,燃煤掺氨燃烧可利用现有燃煤电厂的低NOx燃烧系统,且由于炉膛内燃烧环境温度高,既能有效降低CO2排放,又能大大提高氨燃烧稳定性[4-7]。因此,在燃煤电站锅炉掺烧氨气能从源头降低CO2生成量,有望在短期内实现有效的碳减排。

然而,燃煤掺氨燃烧的应用也存在技术性问题。研究表明氨气燃烧特性差,且存在NOx排放高的风险。但在燃煤锅炉提供的燃烧及炉内环境条件下,氨气着火和燃烧效果、NOx排放水平及现有控制燃煤锅炉NOx排放的空气分级技术在掺烧氨气时对NOx的控制效果等有待验证。为此,笔者针对氨煤掺烧过程中潜在问题进行探讨,同时进行了燃煤掺氨燃烧试验,分析了空气分级燃烧技术在燃煤掺氨燃烧中的应用,揭示了不同掺氨比例、温度、掺氨位置时燃煤掺氨燃烧产物的变化规律。

1 现有燃煤电站锅炉碳减排技术途径

1.1 现有燃煤锅炉碳减排技术现状

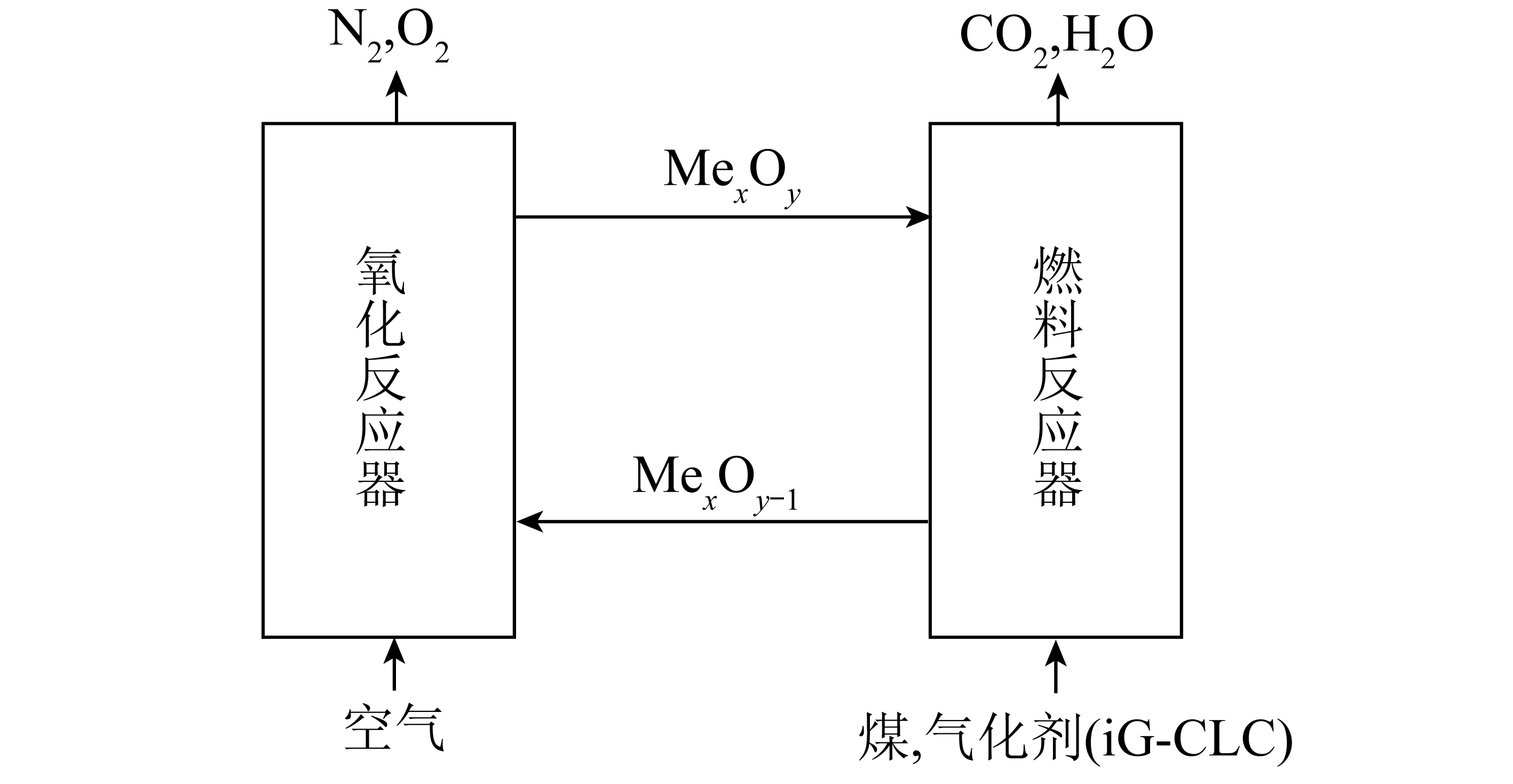

CO2捕集利用与封存(Carbon Capture Utilization and Storage,CCUS)是当前国内外高度重视的碳减排技术[8]。针对燃煤锅炉,该技术旨在从排放侧着手,将燃煤生成的CO2分离捕集,并运输到合适场地加以利用或封存。为提高燃煤烟气中CO2浓度以提高分离捕集效率,通常采用富氧燃烧技术[9-10]。对于常规燃烧产生的烟气,CO2浓度不高,化学吸收法[11-12]是较成熟且极有潜力的捕集技术。然而不论采用富氧燃烧技术还是常规燃烧配合化学吸收法实现碳捕集,最终分离捕集的大量CO2都依赖于封存技术加以处理[8],会随CO2运输封存技术和市场的不断成熟而普遍应用。

为从源头上减少燃煤电厂CO2生成,掺烧生物质[13-14]和可再生能源生产的氢气[15]是易实现的途径之一。然而,基于我国国情,形成一套完备的生物质燃料供给-消费产业链仍需长期发展过程[16]。同时,氢气在存储和运输方面的弊端严重限制了燃煤电厂掺氢燃烧的工业化应用。燃煤电厂掺烧生物质或氢气,本质都是提高可再生能源的利用率。因此,寻找一种利用太阳能和风能等可再生能源实现大规模工业生产且在存储、运输方面具有优势的零碳燃料,是短期内有效降低燃煤电厂煤耗,从而在源头上实现碳减排的关键。

1.2 掺氨燃烧实现有效碳减排

氨气作为可再生能源的优良载体,具有能量密度高、储能可靠性强及制备工艺成熟等优点,利用可再生能源生产的绿色氨气为完全零碳燃料。相比氢气,氨气在存储和运输方面的优势明显,其液化便捷、成本低、运输网络成熟、安全性等高,因此,近年来以实现碳减排为目标推进氨气的燃料化利用受到广泛关注[17-18]。

与CCUS技术不同,燃煤锅炉掺氨燃烧通过降低煤炭使用量从源头上实现CO2减排,随掺氨量增加,CO2排放量将线性下降。日本政府2014年开始实施的“内阁府战略创新促进计划(SIP):能源载体”项目明确提出将在燃煤电厂掺氨燃烧发电的规划,拟于2030年实现氨气替代燃煤发电厂20%的煤炭供应,并将进一步提升该比例至50%以上[17,19]。我国当前燃煤火力发电占比高,在现有机组掺氨燃烧能够在短期内实现高效碳减排,存在技术、市场、成本等限制。鉴于此,笔者对氢气的能量载体——氨气在燃煤锅炉中作为零碳掺烧燃料的燃烧和排放技术进行前瞻性分析,以期为实现燃烧电厂低碳和低氧排放提供技术发展方向。

2 氨燃料的特殊性

2.1 氨燃烧存在的问题

氨气燃烧的首要问题是燃烧特性差。相对其他气体燃料,其热值较低、着火温度高、着火延迟时间长、火焰传播速度低,常温条件下,难以获得稳定的氨火焰。针对燃气轮机燃烧室,采用特殊的稳燃结构能实现氨气稳定燃烧,但火焰分布很宽,释热率低,受壁面散热影响非常显著[20]。在壁面散热严重的情况下,即使整体处于贫燃料状态,燃烧室出口仍能检测到接近5 000×10-6的未燃尽氨气[21]。

氨气燃烧另一个关键问题是高NOx排放风险[22]。不同于常规碳氢燃料,氨气含氮率高达82%,燃烧过程中NO主要通过燃料型机理生成。研究表明,氨气燃烧的NOx排放水平比常规碳氢燃料至少高一个数量级,实验室级别氨基础火焰的NO体积分数高达2 000×10-6[21],纯烧氨气的50 kW微型燃气轮机出口NO体积分数实测结果也超过1 000×10-6(16% O2)[22]。

氨气燃烧强度与NOx排放相互矛盾。理论研究表明,NO的生成依赖于活跃的O/H自由基池,而后者需要强烈的燃烧过程加以维持。结果表明氨火焰中NO和OH分布具有高度相关性[23-24],充分验证了NO生成与燃烧过程的高度耦合关系。在利用甲烷、氢气等燃烧特性更好的气体燃料与氨气掺烧时,氨气燃烧强度显著提升,但NOx排放也明显增加。

当前关于氨气燃烧及NOx排放特性的大量研究多以燃气轮机为应用背景,涉及的燃料也仅限于气体燃料,因此,氨气燃烧特性的改善及其与NOx排放控制之间的协调面临很大挑战。对于燃煤锅炉,炉内燃烧条件与燃气轮机存在显著差异,且煤粉和氨气差异明显,在燃煤锅炉中掺氨燃烧面临的问题与基于燃机得出的结论不尽相同。

2.2 燃煤锅炉内部氨燃烧强化

相比气体燃料,煤粉着火、燃烧和燃尽特性更差,因此,保证煤粉高效燃烧的燃煤锅炉内部的高温燃烧环境更有利于氨气燃烧。利用燃煤锅炉系统富余的热能预热氨气和空气,有利于提高氨气的着火和燃烧特性;炉内温度普遍高于1 000 ℃,且在燃烧器区域壁面铺设卫燃带能获得更高的局部壁温[25],炉内高温热环境也是氨气高效燃烧的保障。

提高初始温度是强化氨燃烧的重要手段之一,图1以绝热层流预混火焰传播速度为例说明了预热对氨燃烧的强化效果,散点为试验数据[26-27],最高温度仅175 ℃。笔者利用ChemkinPro的层流火焰计算模型计算了更高温度条件下的数据,反应机理选用Okafor 2019机理[17],计算域长5 cm,考虑了Soret扩散和多元扩散,但未包含辐射。提高初始温度可显著提升火焰传播速度,预热温度达到400 ℃ 时,氨/空气预混火焰传播速度超过常温下甲烷火焰的水平。进一步增加初始温度至600 ℃,火焰传播速度达80 cm/s量级。

图1 初始温度对氨火焰传播速度的影响

Fig.1 Effects of initial temperature on ammonia flame speed

同样通过将反应物预热到较高温度水平,笔者在常温大空间内成功获得了氨/空气非预混射流火焰,结果如图2所示。高预热温度实现了燃烧反应强度提升,氨火焰稳定附着在不锈钢制的喷口处,随氨气流量增加,火焰根部到喷口的距离未发生明显变化。即便预热温度升高到600 ℃(氨气自着火温度为650 ℃),在常温大空间内未获得稳定性更差的氨/空气预混火焰。

图2 氨/空气非预混预热燃烧试验台及初始温度550 ℃下不同氨气供给量的火焰图像

Fig.2 Non-premixed ammonia/air preheat combustion facility and flame images at 550 ℃ and various ammonia flow rates

笔者将燃烧器置于一台电阻炉内,通过电炉提供高温热环境,配合预热,炉温达400 ℃时即成功获得了稳定的氨/空气预混火焰。炉温400~600 ℃下获得稳定氨/空气预混火焰的分布情况如图3所示,可知贫燃条件下火焰稳定性较差,当量比低于0.9 时火焰无法稳定。同时,增大氨气流量使预混气流速增加,流速增大到一定程度时火焰吹熄。提高炉温使火焰稳定性增强,火焰能在更高的来流速度下保持稳定,随炉温升高,稳定火焰分布范围显著拓宽。

图3 不同炉温下稳定氨/空气预混火焰的分布

Fig.3 Map of successfully obtained ammonia/air premixed flames at various furnace temperatures

总之,燃煤锅炉提供的高水平预热条件及炉内高温热环境都有利于强化氨气燃烧,氨气燃烧特性差可能不会成为制约其在燃煤锅炉掺烧的主要因素。然而,炉内优越的燃烧条件可能导致NO生成量大幅增加,同时煤粉燃烧形成的复杂气氛也可能影响氨气在炉内的转化,因此,燃煤锅炉掺氨炉内燃烧效果和NOx排放特性需进一步深入研究。

3 燃煤掺氨燃烧及NOx排放研究

3.1 燃煤掺氨燃烧及燃尽特性

氨作为优良的无碳燃料,与煤的掺混燃烧备受关注[1-7]。燃煤掺氨(NH3)燃烧的技术路线可行性高[4]。与其他技术相比,燃煤掺氨燃烧可利用现有燃煤电厂的低NOx燃烧系统,由于炉膛内燃烧环境温度高,既能有效降低CO2排放,又能大大提高氨燃烧稳定性。

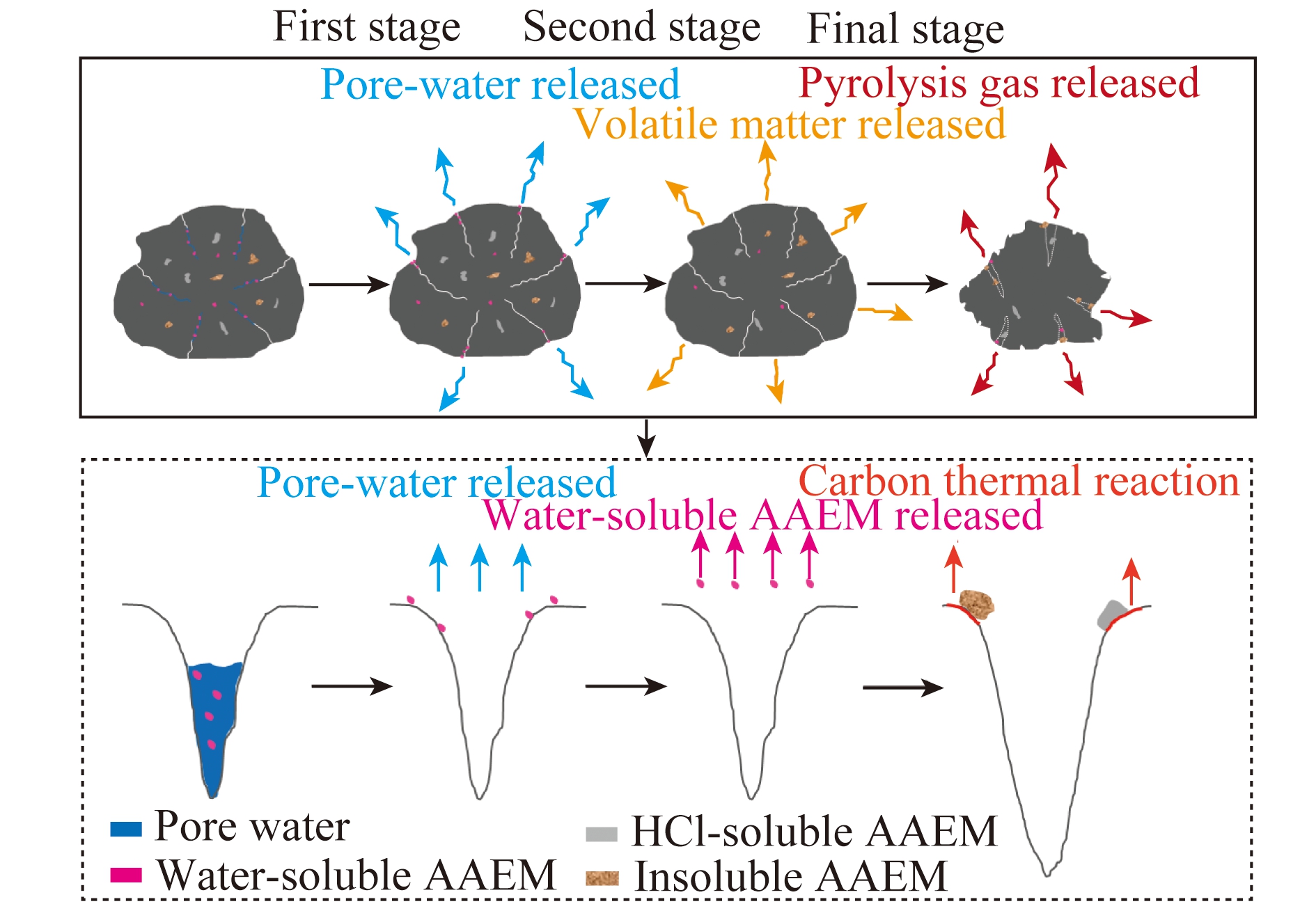

ISHIHARA等[1-2]采用含详细化学反应的零维数值计算模型对某工业1 000 MW煤粉锅炉进行研究。不同掺氨比例下NH3排放和未燃尽碳归一化产量的计算结果如图4所示(6% O2下,UC为不同掺氨比例下未燃尽碳与灰分 未燃尽碳的比值,下标0表示NH3为0共烧的情况,即完全燃煤)。可知燃煤掺氨燃烧过程中,在出口处均无氨气存在,掺入的氨可完全燃尽。输入相同热量时,有效降低CO2排放。虽然氨能在锅炉中燃尽,但掺入氨会影响煤燃烧,随掺氨比例提高,焦炭消耗受到抑制,未燃尽碳的量增加,说明煤的燃尽位置会延后。

图4 不同掺氨比NH3的排放和未燃尽碳归一化产量[2]

Fig.4 Effect of the NH3 co-firing ratio on NH3 emissions and normalized unburned carbon emissions[2]

3.2 燃煤掺氨燃烧NOx排放研究

3.2.1 燃煤掺氨燃烧NOx排放特性

由于氨分子中氮含量高,燃煤掺氨燃烧时NOx形成和排放备受关注。CARDOSO等[28]建立了二维Euler-Lagrange数值模型,模拟研究了反应器位置和空气分级燃烧对NO产量的影响,以及NH3对反应器温度分布和辐射流量的影响。CHEN等[5-7]运用量子化学理论阐述了燃煤锅炉氨煤混合燃烧NOx的还原理论。文献[29]在40 MWth氨煤混合燃烧试验台上进行了掺氨比例0~25%(按热值)的氨煤混合试验。发现在无燃尽风条件下,锅炉运行氧量3.7%、主燃区当量比1.21时锅炉NOx质量浓度(6% O2)如图5所示。说明燃煤掺氨燃烧会大大提高锅炉NOx排放。

图5 不同掺氨比例下燃煤掺氨燃烧NOx排放增量[29]

Fig.5 NOx emission increment of ammonia/coal co-firing under different ammonia co-firing ratios[29]

笔者在一台可控恒定壁温的45 kW电加热燃烧炉中进行了掺氨比例0~100%(按热值)的氨煤掺烧试验。选用国内电厂常用烟煤作为试验对象,氨低位发热量为18.6 MJ/kg[4,30]。图6为不同温度下,对某种煤掺氨的NOx体积分数增幅α(%):

图6 不同掺氨比例下燃煤掺氨燃烧NOx排放增幅

Fig.6 NOx emission increment of ammonia/coal co-firing under different ammonia co-firing ratios

(1)

式中,i为氨掺烧比例,%;C(NOi)为氨掺烧i时NOx排放体积分数,10-6;C(NO0)为纯烧煤时NOx排放体积分数,10-6。

由图6可知,燃煤掺氨燃烧会增加NOx排放,但α随掺氨比例增加呈非线性增加。掺氨比例为20%、30%时,NOx排放量增量较少。这是由NH3的选择性非催化还原反应(SNCR)和煤焦异相还原反应共同作用导致。

尾气中未检测到NH3和CO,表明试验过程中掺入的NH3可完全燃尽,还原区中气化生成的CO被完全燃烧。这与第3.1节中ISHIHARA等[1-2]研究结论相符,利用化学动力学计算得出只有在大比例(掺氨比例80%)掺氨条件下才会有极其微量氨出现在燃烧器出口。

3.2.2 燃煤掺氨燃烧NO生成和还原机理

焦油是煤中氮的主要载体,煤中氮在热解阶段随焦油释放,主要以吡咯、吡啶的结构形式释放[31-32]。1 127 ℃以上焦油热裂解促使氮主要以HCN形式快速释放。HCN在炉膛内主要通过 反应生成HNO,HNO是影响NO浓度的主要基团。氨转化主要有2种反应途径,均以NH2自由基为主要中间体,一种是

反应生成HNO,HNO是影响NO浓度的主要基团。氨转化主要有2种反应途径,均以NH2自由基为主要中间体,一种是 在贫燃料条件时占主导地位,另一种是

在贫燃料条件时占主导地位,另一种是 在富燃料条件时相关性更高。氨燃烧区过量空气比低于空气阶段燃烧,NH3转化率趋向于

在富燃料条件时相关性更高。氨燃烧区过量空气比低于空气阶段燃烧,NH3转化率趋向于

燃煤掺氨燃烧氮的主要转换途径如图7所示。气氛对NH3中氮转化影响很大,氧量充足的条件下,NH3燃烧生成大量NO,然而在缺氧条件下,NH3表现出较强的还原NO能力,可有效还原氨煤掺烧过程中生成的NO[33-35]。

图7 氨煤掺烧氮转化反应路径

Fig.7 Reaction path for the conversion of NH3/coal-N under the conditions of the present work

3.3 燃煤掺氨燃烧NOx排放控制方法

3.3.1 燃煤掺氨燃烧氨的掺混方式

氨喷入方式及喷入位置显著影响NOx排放。TAMURA等[3]将氨的喷入分为与煤预混后喷氨和利用氨枪单独喷氨,其中氨枪喷氨又分为燃烧器内插和侧壁喷氨。利用1.2 MW煤粉卧式燃烧炉进行了燃煤掺氨燃烧研究,对比了预混与单独喷氨对NOx排放量的影响,如图8所示(6% O2)。结果发现在燃烧器侧,氨煤混合通入或从氨枪中单独通入时NOx排放量低于从侧壁喷入。这是因为侧壁面通入NH3可降低NOx停留时间,不利于NOx还原。

图8 不同燃煤混氨方式燃煤掺氨燃烧NOx排放增量[3]

Fig.8 NOx emission increment of ammonia/coal co-firing under different ammonia co-firing ratios[3]

ISHIHARA等[1-2]将氨喷入位置分为主燃区、燃尽区、下游1区和下游2区,其中主燃区又分为与空气预混喷入(Combustion Air)和在火焰区(FZ)喷入,如图9所示(MZ为混合区,RCZ为再循环区,PFZ为后火焰区,RDZ为还原区,Q1~Q4为每个区域的局部吸热)。采用含详细化学反应的零维数值计算模型对某工业1 000 MW煤粉锅炉进行研究,分析了不同氨喷入位置对NOx排放的影响。结果表明在火焰区喷入NH3时NO排放较低,由3方面因素导致:① 火焰区处于富NH3状态,NO排放相对较低;② NH3的掺入使火焰区温度降低,这可能导致热力型NOx产率降低;③ 由于火焰区初始温度较高,超过2 000 K,NH3会在焦炭氧化前转化为NO,这部分NO会与焦炭发生异相还原反应。

图9 燃煤锅炉的反应系统[1-2]

Fig.9 Reactor network representing of coal-fired boiler[1-2]

综上发现,氨喷入方式与喷入位置影响NO的主要原因是由于不同喷入条件会影响其气氛组成、燃烧温度、气流速度,从而影响NOx排放。尤其在还原气氛中喷入时,会激活氨的SNCR,使氨趋向于还原NO的方向进行,减少NOx排放。

3.3.2 现有空气分级燃烧系统对燃煤掺氨燃烧NOx排放的控制能力

空气分级燃烧是减少燃煤电厂NOx排放的最有效技术之一[36-42]。该技术将炉膛在轴向上分成主燃烧区、还原区和燃尽区。燃料首先在主燃烧区燃烧,由于氧气不足减少NOx的产生。在还原区,由煤热解产物(HCN、NH3、NCO、煤焦等)将燃料-N转化为N2。在燃尽区,通过注入燃尽空气将燃料燃尽。FAN等[43-44]将这种技术称为整体空气分级技术,可大大减少NOx排放,但工业应用中普遍存在炉膛结渣、高温腐蚀和不完全燃烧等问题。

氨作为燃料直接燃烧存在燃烧性能差和NOx排放过多等问题。燃煤掺氨燃烧过程中氨燃烧特性较好,但NOx排放量大幅增加。为实现高效燃烧和有效控制NOx排放,同时减少对现有锅炉设备的改造成本,利用现有燃煤锅炉整体空气分级燃烧系统进行氨煤掺烧是行之有效的技术路线。

为研究炉内整体空气分级燃烧系统对燃煤掺氨燃烧的NOx排放水平及控制能力,笔者在前述燃烧炉中进行了某种煤在不同分级工况下掺氨比例为0~100%的氨煤掺烧空气分级燃烧试验。

图10为1 100 ℃,在不同燃尽风通入位置,利用空气分级燃烧造成的NOx减排提升率μ(%),具体为

图10 不同燃尽风通入位置燃煤掺氨燃烧NOx减排提升率

Fig.10 NOx emission reduction improvement rate of ammonia/coal co-firing under different burnout air addition positions

(2)

式中,CNon为一定温度、掺氨比例下不分级燃烧NOx排放体积分数,10-6;CStaged为与不分级燃烧相应温度和掺氨比例下分级燃烧NOx排放体积分数,10-6。

由图10可知,空气分级燃烧可有效减少NOx排放,与不分级燃烧相比,高位布置燃尽最高可减少NOx排放浓度85%。通过延后燃尽风的通入位置,可提高NOx减排提升率。这是由于燃尽风通入位置延后可以延长还原区长度,气流和煤粉颗粒在还原区停留时间越长,NOx还原更彻底,从而使出口处NO浓度降低,提高NOx减排提升率。

燃尽风通入位置在中位燃尽风喷口时,不同炉膛内部燃烧温度下燃煤掺氨燃烧NOx减排提升率如图11所示。说明温度升高,通过空气分级燃烧造成的NOx减排提升率会降低,温度升高不利于NO控制。

图11 不同炉膛内部燃烧温度下燃煤掺氨燃烧NOx减排提升率

Fig.11 NOx emission reduction improvement rate of ammonia/coal co-firing under different combustion environmental temperature

4 燃煤掺氨燃烧其他问题分析

燃煤掺氨燃烧除燃烧稳定性和NOx排放问题外,还会影响锅炉燃煤机组运行参数、还原区CO和H2S等气氛浓度等。

4.1 燃煤掺氨燃烧对锅炉主要参数的影响

王一坤等[45]基于能量守恒定律对某电厂300 MW等级燃煤机组进行研究,通过锅炉热力校核计算分析了不同工况下,机组掺烧NH3比例在20%~100%时对燃煤机组的影响。发现大比例掺氨后,机组排烟温度上升,导致锅炉热效率下降;机组原有受热面布置基本能满足需求,但由于烟气量增大,引风机需扩容改造;对于机组原有脱硝和脱硫系统影响较小,但亚微米级气溶胶颗粒增加,需增设捕集系统。

CARDOSO等[28]通过建立二维欧拉-拉格朗日数值模型,描述了煤氨在中试流化床反应器中的共烧过程。发现随掺氨比增加,气体温度降低,辐射通量降低。掺氨量10%~20%的传热率与燃煤相似,说明掺烧20%的NH3不会对温度和辐射通量造成不利影响。

XU等[46]对某600 MWe燃煤电厂机组锅炉系统燃煤工况和氨煤共烧工况进行模拟,分析了燃煤掺氨对烟气排放、热特性、![]() 损失和

损失和![]() 效率的影响。结果表明燃煤掺氨燃烧会降低总烟气量,提高烟气含水量和排放速率,烟气比热容随之增大。与燃煤工况相比,随燃煤掺氨比例增加,炉内

效率的影响。结果表明燃煤掺氨燃烧会降低总烟气量,提高烟气含水量和排放速率,烟气比热容随之增大。与燃煤工况相比,随燃煤掺氨比例增加,炉内![]() 损失增大,说明氨燃烧过程的不可逆损失大于煤。但在氨煤共烧条件下,换热器和风机的

损失增大,说明氨燃烧过程的不可逆损失大于煤。但在氨煤共烧条件下,换热器和风机的![]() 损失降低。综合来看,在氨煤共烧工况下,锅炉系统的

损失降低。综合来看,在氨煤共烧工况下,锅炉系统的![]() 效率略下降(燃煤:53.82%,氨煤共烧:53.27%~53.22%),说明燃煤电厂共烧氨不会显著影响热经济性。

效率略下降(燃煤:53.82%,氨煤共烧:53.27%~53.22%),说明燃煤电厂共烧氨不会显著影响热经济性。

4.2 炉内CO还原气氛特征

空气分级燃烧在还原区氧浓度趋向于0,在还原区检测到较高浓度CO,由CO2和焦炭气化生成[47-48]。还原区中CO存在及空气分级燃烧中焦炭的异相还原反应,对于减少NOx排放至关重要[49-50]。

空气分级燃烧模式下,不同掺氨比例时还原区CO峰值浓度如图12所示。与纯煤燃烧相比,燃煤掺氨燃烧可提高还原区CO峰值水平。这是由于添加氨会提高还原区H2O浓度,较高H2O含量有助于在焦炭中形成微孔,提高活性碳位点,促进气化反应活性[51-52]。因此,燃煤掺氨燃烧炉内的CO峰值浓度提高。

图12 不同掺氨比例下还原区CO的峰值

Fig.12 Peak value of CO in reduction zone under different ammonia co-firing ratio

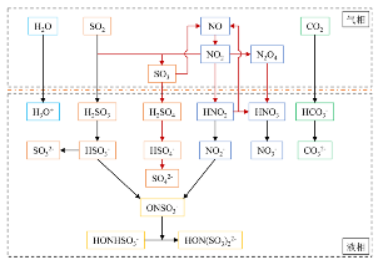

4.3 炉内H2S气氛特征

空气分级燃烧在还原区,还原性气氛虽能有效降低主燃烧区形成的NOx,但这些还原性气体也可以将SO2转化为H2S[53-55]。高浓度H2S会加速水冷壁管腐蚀,特别是在工质温度高、工质压力极高的超临界或超超临界锅炉中[56]。燃煤掺氨燃烧带来的H2S变化对锅炉安全运行至关重要。笔者发现空气分级燃烧模式下,不同掺氨比例下还原区H2S的峰值浓度变化如图13所示,可知随掺氨量提高,还原区H2S峰值浓度呈下降趋势,因此,氨煤共烧过程中H2S对水冷壁管的腐蚀可能存在缓解趋势。

图13 不同掺氨比例下还原区H2S的峰值

Fig.13 Peak value of H2S in reduction zone under different ammonia co-firing ratio

5 结语与展望

对可持续能源和绿色环境的需求激发了对无碳燃料的探索。发展绿色可持续的无碳燃烧系统对于世界各国履行温室气体排放的法律和环境义务,以及缓解不断增加的CO2排放造成的全球变暖至关重要。氨(氢质量分数为17.6%)作为一种无碳燃料在发电、运输和供热系统中备受关注。然而从技术层面,与典型碳氢燃料相比,氨的低燃烧特性和高NOx排放限制其实际应用。燃煤掺氨燃烧是近期兴起的减少燃煤电站CO2排放的技术路线,日本、中国已通过工业尺度的试验研究验证了燃煤锅炉掺氨燃烧技术的可行性,该技术已成为实现大幅碳减排的最具潜力的技术发展路线。

1)燃煤锅炉提供的炉内高温热环境有利于强化氨气燃烧,氨气燃烧特性差不会成为制约其在燃煤锅炉掺烧的主要因素。利用现有燃煤系统,在无需重大设备改造的前提下,通过调整燃煤混氨方式、优化空气分级燃烧工况可大幅降低NOx排放浓度。根据试验煤种,空气分级燃烧工况下,燃尽风中、高位布置且燃尽风占总风量30%以上、燃煤掺氨比例控制在20%~30%(按热值)时,燃烧炉尾部烟气中NOx排放浓度可控制在与煤空气分级燃烧相当的水平。

2)大比例掺氨后,NOx排放浓度仍很高,尤其在锅炉高负荷对应的高炉温燃烧条件下,限于NOx排放浓度的法规限制,氨掺烧比例不能太高,会限制CO2减排力度。因此,未来需继续在炉内NOx深度减排技术上创新发展以及为CO2大幅减排而适当折中NOx排放限制等方面开展工作,实现燃煤发电“碳达峰、碳中和”的目标。

[1] ISHIHARA S,ZHANG J,ITO T.Numerical calculation with detailed chemistry of effect of ammonia co-firing on NO emissions in a coal-fired boiler [J]. Fuel,2020,266:116924.

[2] ISHIHARA S,ZHANG J,ITO T. Numerical calculation with detailed chemistry on ammonia co-firing in a coal-fired boiler:Effect of ammonia co-firing ratio on NO emissions [J]. Fuel,2020,274:117742.

[3] TAMURA M,GOTOU T,ISHII H,et al. Experimental investigation of ammonia combustion in a bench scale 1.2 MW-thermal pulverised coal firing furnace [J]. Applied Energy,2020,277:115580.

[4] ZHANG J,ITO T,ISHII H,et al. Numerical investigation on ammonia co-firing in a pulverized coal combustion facility:Effect of ammonia co-firing ratio [J]. Fuel,2020,267:117166.

[5] CHEN P,WANG H,JIANG B,et al. An experimental and theoretical study of NO heterogeneous reduction in the reduction zone of ammonia co-firing in a coal-fired boiler:Influence of CO[J]. Fuel Processing Technology,2022,231:107184.

[6] CHEN P,FANG Y,WANG P,et al. The effect of ammonia co-firing on NO heterogeneous reduction in the high-temperature reduction zone of coal air-staging combustion:Experimental and quantum chemistry study [J]. Combustion and Flame,2022,237:111857.

[7] CHEN P,JIANG B,WANG H,et al. Experimental and theoretical calculations study on heterogeneous reduction of NO by char/NH3 in the reduction zone of ammonia co-firing with pulverized coal:Influence of mineral Fe [J]. Fuel,2022,310:122374.

[8] LIU L,MA Q,LI Y,et al. Development of carbon capture,utili-zation and storage technology in China [J]. Chinese Journal of Engineering Science,2021,23(6):70-80.

[9] LEI M,ZHANG Y,HONG D,et al. Characterization of nitrogen and sulfur migration during pressurized coal pyrolysis and oxy-fuel combustion [J]. Fuel,2022,317:123484.

[10] ZHANG Z,LI X,LUO C,et al. Investigation on the thermodynamic calculation of a 35 MWth oxy-fuel combustion coal-fired boiler [J]. International Journal of Greenhouse Gas Control,2018,71:36-45.

[11] NICOTERA I,POLICICCHIO A,CONTE G,et al. Quaternized polyepichlorohydrin-based membrane as high-selective CO2 sorbent for cost-effective carbon capture [J]. Journal of CO2 Utilization,2022,63:102135.

[12] FURCAS F E,PRAGOT W,CHACARTEGUI R,et al. Sodium carbonate-based post combustion carbon capture utilising trona as main sorbent feed stock [J]. Energy Conversion and Management,2020,208:112484.

[13] PICCIANO P,AGUILAR F X,BURTRAW D,et al. Environmental and socio-economic implications of woody biomass co-firing at coal-fired power plants [J]. Resource and Energy Economics,2022,68:101296.

[14] LIU Q,ZHONG W,YU A,et al. Co-firing of coal and biomass under pressurized oxy-fuel combustion mode:Experimental test in a 10 kWth fluidized bed [J]. Chemical Engineering Journal,2022,431:133457.

[15] ISHIMOTO Y,VOLDSUND M,NEKSÅ P,et al. Large-scale production and transport of hydrogen from Norway to Europe and Japan:Value chain analysis and comparison of liquid hydrogen and ammonia as energy carriers [J]. International Journal of Hydrogen Energy,2020,45(58):32865-32883.

[16] SUN R,LIU T,CHEN X,et al. A biomass-coal co-firing based bi-level optimal approach for carbon emission reduction in China [J]. Journal of Cleaner Production,2021,278:123318.

[17] KOBAYASHI H,HAYAKAWA A,SOMARATHNE K D,et al.Science and technology of ammonia combustion [J]. Proceedings of the Combustion Institute,2019,37(1):109-133.

[18] CESARO Z,IVES M,NAYAK-LUKE R,et al. Ammonia to po-wer:Forecasting the levelized cost of electricity from green ammonia in large-scale power plants [J]. Applied Energy,2021,282:116009.

[19] STAGNI A,CAVALLOTTI C,ARUNTHANAYOTHIN S,et al. An experimental,theoretical and kinetic-modeling study of the gas-phase oxidation of ammonia [J]. Reaction Chemistry & Engineering,2020,5(4):696-711.

[20] WEI X,ZHANG M,AN Z,et al. Large eddy simulation on flame topologies and the blow-off characteristics of ammonia/air flame in a model gas turbine combustor [J]. Fuel,2021,298:120846.

[21] OKAFOR E C,TSUKAMOTO M,HAYAKAWA A,et al. Infl-uence of wall heat loss on the emission characteristics of premixed ammonia-air swirling flames interacting with the combustor wall [J]. Proceedings of the Combustion Institute,2021,38(4):5139-5146.

[22] KURATA O,IKI N,MATSUNUMA T,et al. Performances and emission characteristics of NH3-air and NH3-CH4-air combustion gas-turbine power generations [J]. Proceedings of the Combustion Institute,2017,36(3):3351-3359.

[23] ZHU X,KHATEEB A A,GUIBERTI T F,et al. NO and OH* emission characteristics of very-lean to stoichiometric ammonia-hydrogen-air swirl flames [J]. Proceedings of the Combustion Institute,2021,38(4):5155-5162.

[24] SOMARATHNE K D K A,OKAFOR E C,SUGAWARA D,et al. Effects of OH concentration and temperature on NO emission characteristics of turbulent non-premixed CH4/NH3/air flames in a two-stage gas turbine like combustor at high pressure [J]. Proceedings of the Combustion Institute,2021,38(4):5163-5170.

[25] 周俊虎,赵晓辉,刘建忠,等. 锅炉内卫燃带上高熔点灰渣沉积机理分析 [J]. 中国电机工程学报,2008,28(14):20-26.

ZHOU Junhu,ZHAO Xiaohui,LIU Jianzhong,et al. Analysis on deposition mechanism of ash with high ash fusion temperatures on the heat-insulation layer in boiler [J]. Proceedings of the CSEE,2008,28(14):20-26.

[26] HAN X,WANG Z,HE Y,et al. The temperature dependence of the laminar burning velocity and superadiabatic flame temperature phenomenon for NH3/air flames [J]. Combustion and Flame,2020,217:314-320.

[27] HAN X,WANG Z,COSTA M,et al. Experimental and kinetic modeling study of laminar burning velocities of NH3/air,NH3/H2/air,NH3/CO/air and NH3/CH4/air premixed flames [J]. Combustion and Flame,2019,206:214-226.

[28] SOUSA CARDOSO J,SILVA V,EUSÉBIO D,et al. Numerical modelling of ammonia-coal co-firing in a pilot-scale fluidized bed reactor:Influence of ammonia addition for emissions control [J]. Energy Conversion and Management,2022,254:115226.

[29] 牛涛,张文振,刘欣,等. 燃煤锅炉氨煤混合燃烧工业尺度试验研究[J]. 洁净煤技术,2022,28(3):193-200.

NIU Tao,ZHANG Wenzhen,LIU Xin,et al. Industrial-scale experimental investigation of ammonia-coal cofiring in coal-fired boiler [J]. Clean Coal Technology,2022,28(3):193-200.

[30] ELBAZ A M,WANG S,GUIBERTI T F,et al. Review on the recent advances on ammonia combustion from the fundamentals to the applications[J]. Fuel Communications,2022,10:100053.

[31] GLARBORG P,JENSEN A D,JOHNSSON J E. Fuel nitrogen conversion in solid fuel fired systems [J]. Progress in Energy & Combustion Science,2003,29(2):89-113.

[32] CHEN J C,CASTAGNOLI C,NIKSA S.Coal devolatilization dur-ing rapid transient heating. 2. Secondary pyrolysis [J]. Energy & Fuels,1992,6(3):264-271.

[33] CHEN J,FAN W,WU X,et al. Effects of O2/CO/CO2 on NH3 reducing NO at 1 073-1 773 K in different flow reactors.Part Ⅰ:The effect of O2 [J]. Fuel,2021,283:119335.

[34] CHEN J,FAN W,FENG G,et al. Mixing effects on NO reduction by NH3 at intermediate and elevated temperatures in flow reactors [J]. Fuel,2021,305:121530.

[35] CHEN J,FAN W,WU X,et al. Experimental study of NH3 transformation in the CO/O2/CO2 system at 1 073-1 773 K[J]. Fuel Processing Technology,2021,217:106829.

[36] JIANG Y,LEE B,OH D,et al. Influence of various air-staging on combustion and NOx emission characteristics in a tangentially fired boiler under the 50% load condition [J]. Energy,2022,244:123167.

[37] FAN W,LIN Z,LI Y,et al. Effect oftemperature on NO release during the combustion of coals with different ranks[J]. Energy & Fuels,2010,24(3):1573-1583.

[38] LI Y,FAN W,WANG Y,et al. Characteristics of char gasification in staged oxygen-enriched combustion in a down flame furnace [J]. Energy & Fuels,2016,30(3):1675-1684.

[39] FAN W,LIN Z,LI Y,et al. Effect of air-staging on anthracite combustion and NOx formation [J]. Energy & Fuels,2009,23(1):111-120.

[40] LI S,XU T,SUN P,et al. NOx and SOx emissions of a high sulfur self-retention coal during air-staged combustion [J]. Fuel,2008,87(6):723-731.

[41] COSTA M,AZEVEDO J L T. Experimental characterization of an industrial pulverized coal-fired furnace under deep staging conditions [J]. Combustion Science and Technology,2007,179(9):1923-1935.

[42] MUNIR S,NIMMO W,GIBBS B M. The effect of air staged,cocombustion of pulverised coal and biomass blends on NOx emissions and combustion efficiency [J]. Fuel,2011,90(1):126-135.

[43] FAN W,LIN Z,KUANG J,et al. Impact of air staging along furnace height on NOx emissions from pulverized coal combustion [J]. Fuel Processing Technology,2010,91(6):625-634.

[44] WANG J,FAN W,LI Y,et al. The effect of air staged combustion on NOx emissions in dried lignite combustion [J]. Energy,2012,37(1):725-736.

[45] 王一坤,邓磊,王涛,等. 大比例掺烧NH3对燃煤机组影响分析 [J]. 洁净煤技术,2022,28(3):185-192.

WANG Yikun,DENG Lei,WANG Tao,et al. Analysis of the effect of large proportional NH3 blending on coal-fired units [J]. Clean Coal Technology,2022,28(3):185-192.

[46] XU Y,WANG H,LIU X,et al. Mitigating CO2 emission in pulverized coal-fired power plant via co-firing ammonia:A simulation study of flue gas streams and exergy efficiency [J]. Energy Conversion and Management,2022,256:115328.

[47] MACKRORY A J,TREE D R. Measurement of nitrogen evolution in a staged oxy-combustion coal flame [J]. Fuel,2012,93:298-304.

[48] FAN W,LI Y,GUO Q,et al. Coal-nitrogen release and NOx evolution in the oxidant-staged combustion of coal [J]. Energy,2017,125:417-426.

[49] KUANG M,LI Z,LIU C,et al. Experimental study on combustion and NOx emissions for a down-fired supercritical boiler with multiple-injection multiple-staging technology without overfire air [J]. Applied Energy,2013,106:254-261.

[50] KUANG M,ZHAO X,WANG J,et al. Upgrading the strengthened low-NOx and high-burnout combustion performance by staging the hopper air in a down-fired furnace [J]. Fuel,2021,294:120582.

[51] LIANG C,WANG X,LYU Q. Experimental investigation on fluidized modification in gasification of preheated coal using oxygen and steam [J]. Fuel,2021,304:121375.

[52] JENA M K,AKHTAR M A,KUMAR V,et al. Studies into the kinetic compensation effects of Loy Yang Brown coal during gasification in a steam environment:A mechanistic view [J]. Chemical Engineering Journal Advances,2021,8:100159.

[53] LI Z,CHEN H,ZHANG Z. Experimental and modeling study of H2S formation and evolution in air staged combustion of pulverized coal [J]. Proceedings of the Combustion Institute,2021,38(4):5363-5371.

[54] SHIRAI H,IKEDA M,ARAMAKI H. Characteristics of hydrogen sulfide formation in pulverized coal combustion [J]. Fuel,2013,114:114-119.

[55] COLOM-DíAZ J M,MILLERA  ,BILBAO R,et al. Conversion of H2S/O2/NO mixtures at different pressures:Experiments and kinetic modeling [J]. Fuel,2021,290:120060.

,BILBAO R,et al. Conversion of H2S/O2/NO mixtures at different pressures:Experiments and kinetic modeling [J]. Fuel,2021,290:120060.

[56] XU H,ZHOU S,ZHU Y,et al. Experimental study on the effect of H2S and SO2 on high temperature corrosion of 12Cr1MoV [J]. Chinese Journal of Chemical Engineering,2019,27(8):1956-1964.

Review on combustion and emission characteristics of coal-fired utility boilers ammonia/coal co-firing

移动阅读

WANG Xin,CHEN Jun,FAN Weidong.Review on combustion and emission characteristics of coal-fired utility boilers ammonia/coal co-firing[J].Clean Coal Technology,2022,28(8):25-34.