330 MWe循环流化床锅炉掺烧污泥性能影响

0 引 言

作为石油开采、城市污水处理等过程的副产物,近年来污泥产量急剧增加。这些污泥含有大量难以消解的有机物、重金属或病原微生物,如不妥善处置,会对生态环境和人体健康产生严重影响。在常见的固废处置方法中,有的已明令禁止(如海洋倾倒),有的可能导致土壤和地下水污染(如填埋和堆肥法)。与其他方法相比,焚烧法处理速度快,减容率高,高温环境下可有效分解有毒有害物质、消灭致病微生物等,废弃物本身的少许热值可以回收,焚烧后的灰渣还可作为建材等二次利用。故焚烧法被认为是最具前景的污泥处理技术之一[1]。

作为洁净煤燃烧技术之一,循环流化床(CFB)锅炉燃料适应性广。由于炉内存有大量固体床料,炉温分布较均匀,稳燃性能好,燃烧效率高,CFB锅炉从原理上特别适合于污泥等低热值燃料的燃烧处理[2-3]。此外,CFB燃烧技术具有天然的低NOx排放优势,在燃烧过程中添加石灰石等脱硫剂还能有效脱除烟气中大部分SO2[4-5]。工程实践表明,CFB锅炉掺烧氮、硫含量较高的污泥后,常规大气污染物仍能满足超低排放要求[6-7]。而钙基脱硫剂还能吸附汞等重金属,实现多污染物协同治理[8]。还有研究指出掺烧城市污泥后能够改善CFB锅炉燃用无烟煤时的燃烧性能[9]。因此,将纯燃煤CFB电站锅炉或工业锅炉进行适当改造,掺烧一定比例的污泥,对减量化、无害化、资源化、稳定化利用固废,减少煤炭使用量,促进碳中和等具有重要意义。

与常规煤种相比,污泥粒度细、热值低、水分大,掺烧后可能对CFB锅炉燃烧等性能产生影响,有必要对燃料调整进行针对性分析。JANG等[3]借助30 kWth中试CFB试验台分析了焚烧污泥对燃烧性能的影响,包括温度和床压分布、灰渣和烟气化学组成等。曹通等[10]利用Fluent模拟分析了不同种类污泥与煤粉掺混后在CFB锅炉中的燃烧过程,并讨论了污泥掺混比例的影响。张自丽等[11]总结了煤与污泥混烧后硫氮转化机制及污染物排放规律。然而,鲜有研究关注掺烧污泥对CFB锅炉物料平衡特性的影响。且随着中小型锅炉的减容淘汰,不少大型电站锅炉也面临固废掺烧的现实需求。目前针对大型CFB锅炉掺烧污泥的工程实践还比较少。笔者以某330 MWe亚临界CFB锅炉为研究对象,借助自编程一维CFB模型对其掺烧污泥后的物料平衡特性进行预测和分析;然后结合实际运行数据详细讨论掺烧对锅炉性能的影响,从而为污泥掺烧锅炉设计和运行优化提供参考。

1 锅炉结构及主要参数

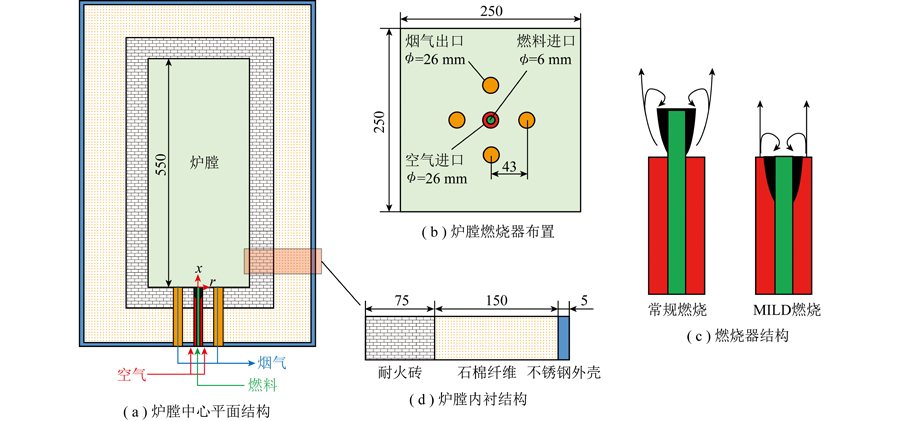

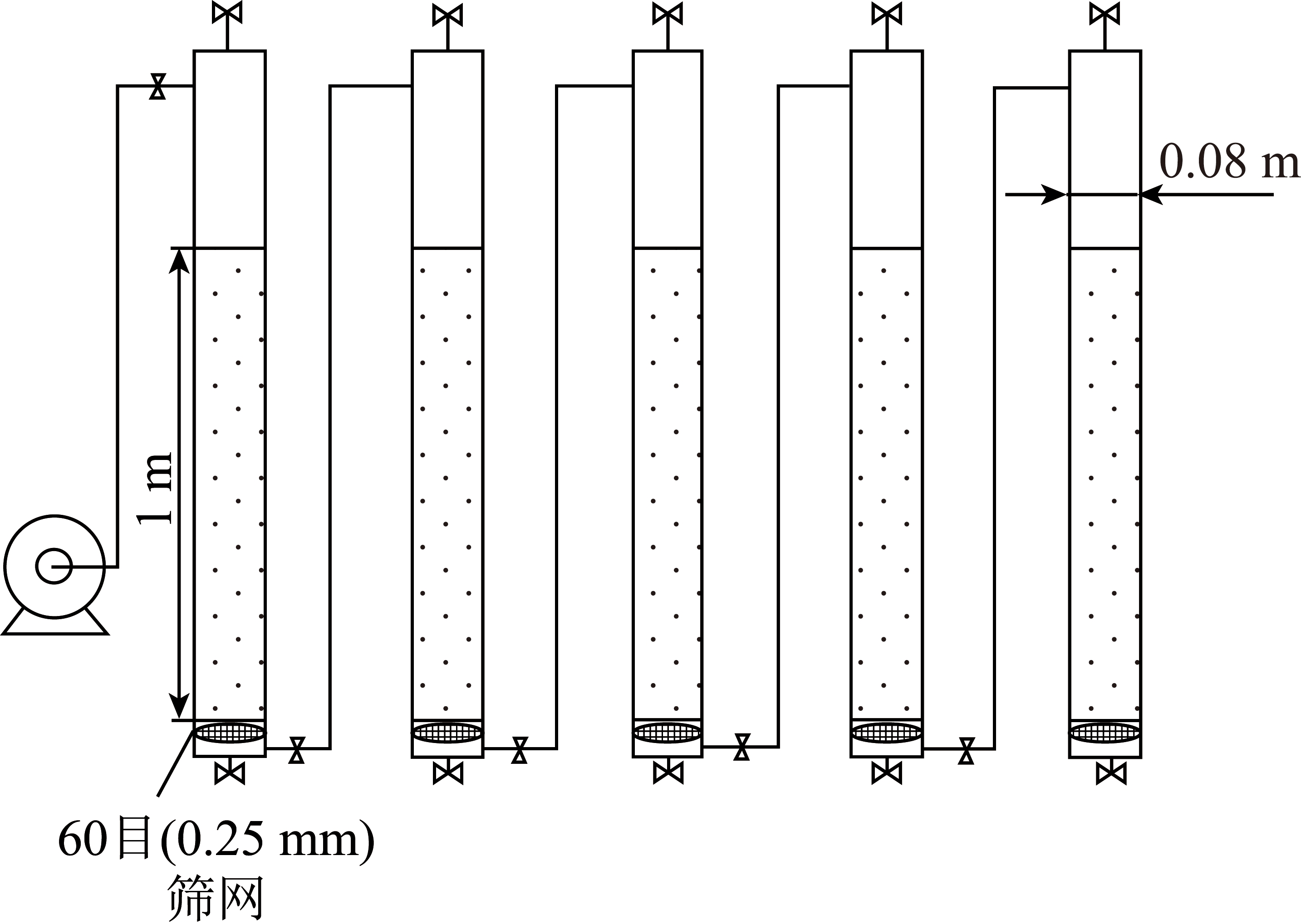

某电厂现有一台330 MWe之中作亚临界一次中间再热CFB锅炉,其结构如图1所示。

图1 某330 MWe亚临界CFB锅炉结构

Fig.1 Schematic of a 330 MWe subcritical CFB boiler

该锅炉采用M型布置,为单布风板、单炉膛结构,底部水冷风室为两侧进风。配有3台汽冷式旋风分离器,位于炉膛和尾部对流烟道之间,分离器下部各布置一台“J”阀回料器,回料器为“一分为二”结构。炉内布置有12片中温过热器管屏、6片再热器管屏和2片水冷蒸发屏。尾部为双烟道结构,前烟道布置了低温再热器,后烟道从上到下依次布置有高温过热器和低温过热器,继而前后烟道合成一个烟道,沿高度依次布置省煤器和空预器。炉前布置10个给煤口,炉后墙布置6个排渣口。BMCR工况下锅炉主汽温度和主汽压力分别为541℃和17.5 MPa,其余主要技术参数见表1。

锅炉早期燃料为煤泥和煤矸石的混煤,混合比例为15%∶85%。掺烧污泥压滤后水分控制在60%以下,先给入煤泥仓暂存,然后随煤泥一起以泵送方式送入炉膛上部,入炉燃烧。锅炉给料系统如图2所示。污泥掺烧比例为10%,替换部分煤矸石,即污泥、煤泥、煤矸石3者混合质量分数分别为10%、15%和75%。3种燃料工业和元素分析结果见表2。

表1 BMCR工况下锅炉主要参数

Table 1 Main operation parameters of the 330 MWe CFB boiler under BMCR condition

图2 某330 MWe煤泥和污泥给料系统示意

Fig.2 Schematic of thecoal slime and sludge feeding system of the 330 MWe CFB boiler

表2 锅炉燃料煤工业分析和元素分析

Table 2 Proximate and ultimate analysis of the fuel burned in the 330 MWe CFB boiler

2 污泥掺烧对锅炉物料平衡影响

2.1 一维CFB模型简述和燃料性质

利用课题组先前开发的一维CFB数学模型,对该330 MWe CFB锅炉掺烧污泥前后的物料平衡特性作定量对比分析。模型中将CFB锅炉炉膛沿轴向划分为若干个小室,同时充分考虑炉内不同区域气固流动规律,如密相区两相流动、稀相区环核流动结构和颗粒团聚等。对每个小室每个粒径档和年龄档颗粒建立质量流平衡方程组,结合一系列半经验关联式描述特定工况下炉内床料流率、粒径分布、空隙率轴向分布、颗粒停留时间、气泡及颗粒团行为等CFB物料平衡特性。详细的模型结构、方程描述和求解方法可参考相关文献[12-14]。该简化CFB数学模型的求解精度不及CFD/CPFD方法,但高计算效率使其在工程计算特别是参数研究方面更具优势。在对物理和化学过程理解准确、子模型参数设置合理有据的前提下,建立的数学模型通常能够反映变量间的相互变化关系。该模型已在掺烧或纯烧煤泥、水煤浆、兰炭等非常规燃料CFB锅炉模拟上应用较多,模型预测结果与实测值均吻合良好[15-17]。

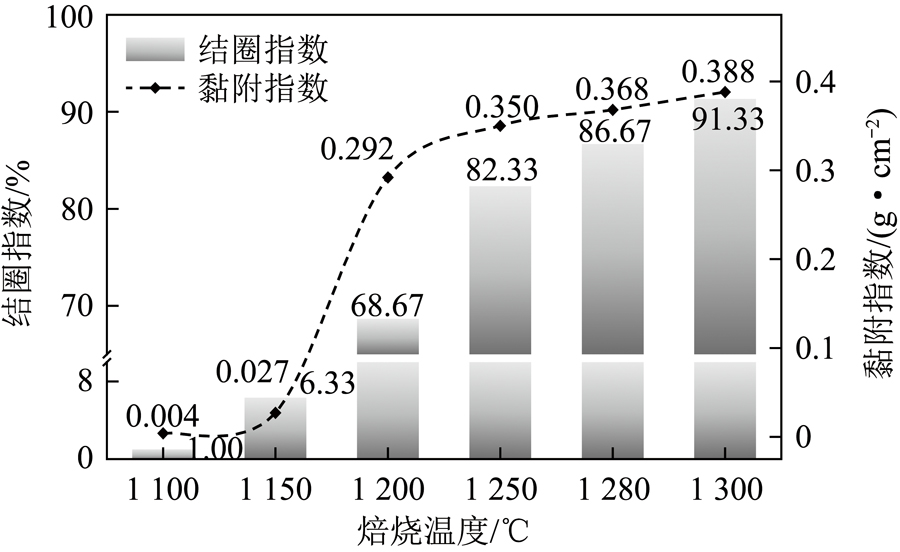

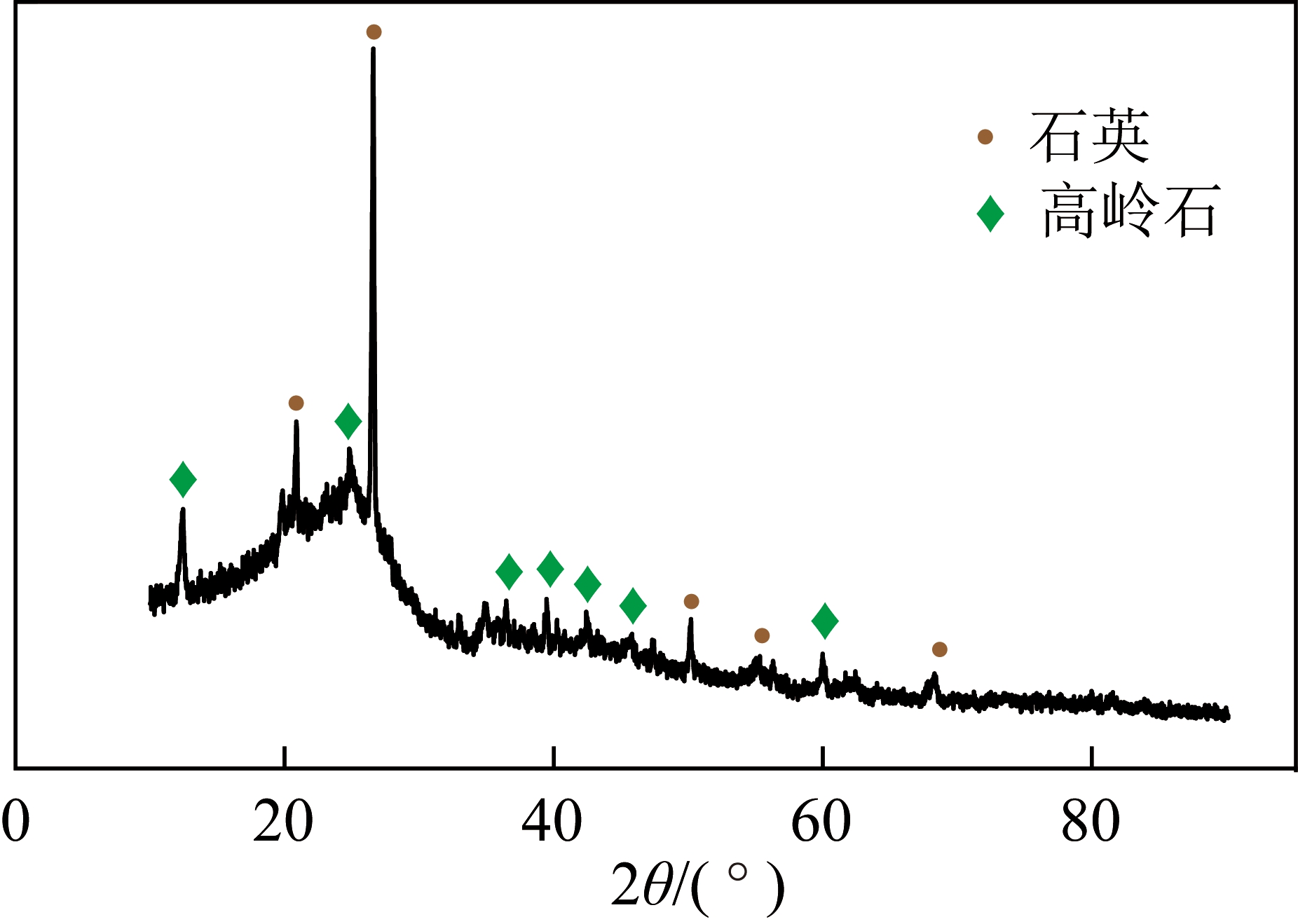

燃料的成灰磨耗特性对CFB锅炉物料平衡影响较大,且与燃料自身性质有关。利用“静态燃烧 冷态振筛磨耗”试验方法获得煤矸石成灰矩阵及灰颗粒磨耗速率常数[18],结果如图3所示。可以看出,煤矸石质地很硬,除小粒径档燃料颗粒(0~500 μm)外,大部分灰颗粒无明显破碎,成灰粒度与入炉煤矸石粒度相当。前期研究表明,煤泥初始粒度较小,燃烧过程中基本无爆裂导致的粒度变化,成灰粒度分布与煤泥原始粒度分布基本一致,可认为污泥的成灰特性与煤泥相似[17]。因此,计算中直接将入炉煤泥及污泥的粒径分布当作对应燃料初始成灰分布,而煤矸石初始成灰粒径分布按照成灰矩阵和实际给煤粒度折算得到。

图3 煤矸石成灰特性矩阵

Fig.3 Primary ash particle size distribution matrix for coal gangue

煤矸石、煤泥和污泥各自入炉粒度分别在0~7 000、0~10 000和0~200 μm,粒径分布曲线如图4所示。

图4 给料粒径分布曲线

Fig.4 Particle size distributions

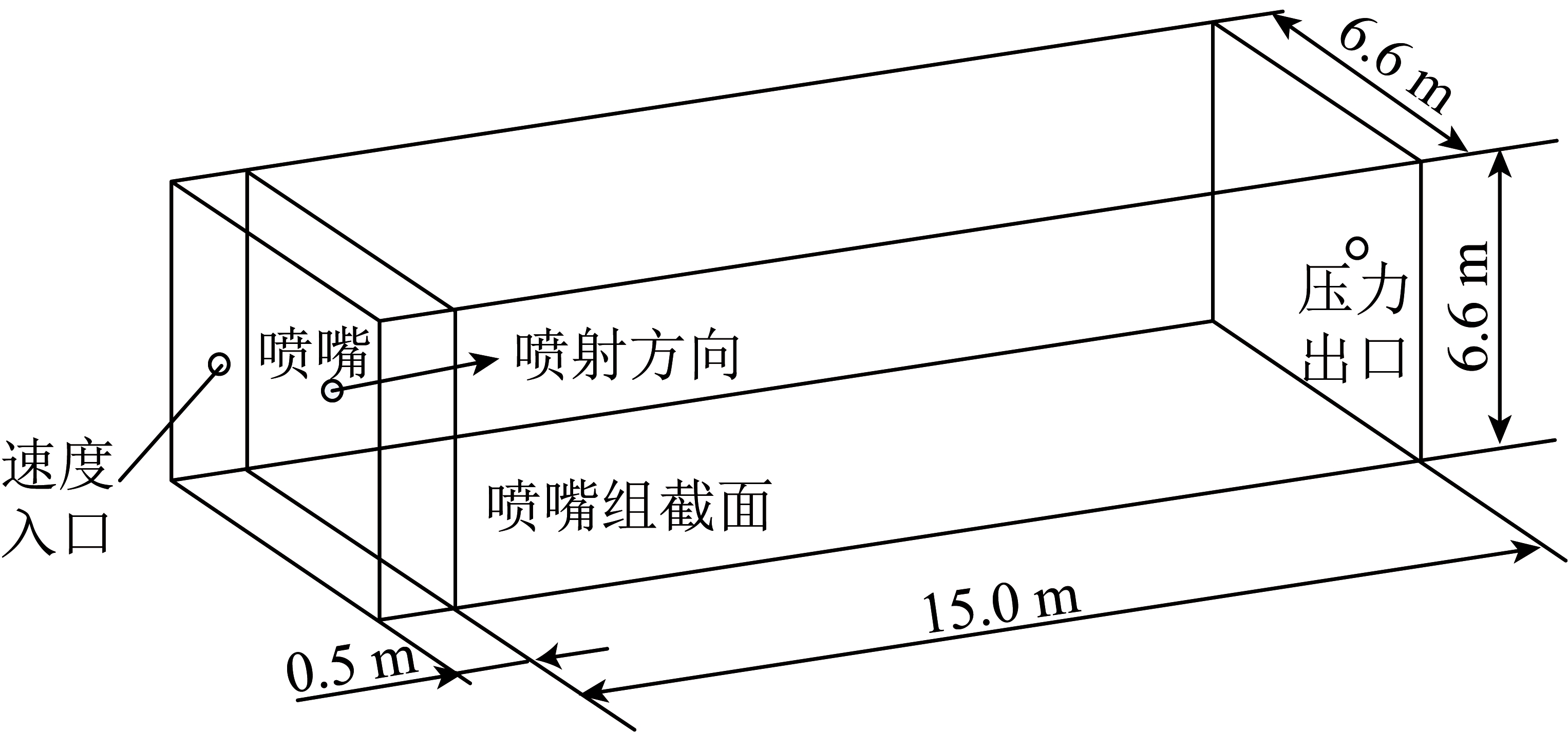

模型中需要关注煤泥和污泥混合燃料在炉内初始给入位置。该330 MWe CFB锅炉实际运行时,煤泥和污泥混合成团从炉顶给入,进入炉膛后,混合颗粒团边下落边干燥。初步研究表明,颗粒团到达底部密相区床面时,只有颗粒团表面一薄层完成干燥和热解,主体爆裂和燃烧基本发生在密相区,之后产生的细颗粒被烟气携带到炉膛上部。因此,从煤泥污泥炉内历程看,模型计算时可近似认为其以成灰粒径分布在密相区直接给入。

2.2 模型计算结果

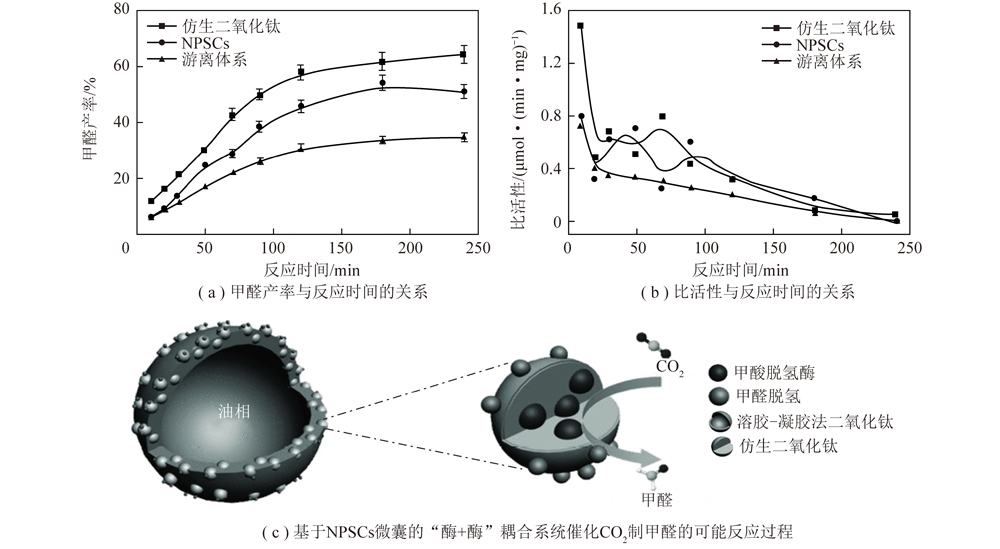

图5比较了该330 MWe锅炉掺烧污泥前后飞灰、底渣和循环灰粒径分布模拟结果。飞灰粒度主要由分离器效率决定,而底渣大部分来自于给料较粗、成灰较差的煤矸石,故掺烧污泥对飞灰和底渣粒度影响很小。而掺烧一定比例污泥混合加入后,在总输入热量维持不变时,煤矸石入炉质量减小、煤泥投入量略增加,随煤泥和污泥带入的细颗粒量明显增多。若不考虑结渣等因素,这些细灰颗粒绝大部分被烟气携带向上构成循环灰,也带动了少量较粗颗粒参与循环,故掺烧小比例污泥后循环灰粒度略增大,但增幅不明显。

图5 掺烧污泥前后飞灰、底渣和循环灰粒度比较(模型)

Fig.5 Comparison of particle size distributions of fly ash, bottom ash and circulation ash between the cases with and without additional sludge (model results)

CFB锅炉掺烧污泥后细床料变多;同时烟气含水量增加,炉膛上部流化风速由原来的5.22 m/s提高至5.36 m/s,导致物料循环量增大,稀相段颗粒悬浮浓度显著增加,如图6所示。表3进一步比较了床料中位径等部分物料平衡特征参数模型计算值。结果显示,与原工况相比,该锅炉掺烧10%污泥后,循环流率增加约28.5%,稀相区平均压降(与颗粒悬浮浓度相对应)增大约34.6%,飞灰占总灰渣份额也增加约1.5个百分点。

循环量、颗粒浓度等CFB锅炉物料平衡特性的改变,影响了受热面传热及能量平衡[19]。掺烧污泥前后颗粒炉内停留时间比较(模型)如图7所示,由于掺烧污泥后循环量增加,炉内床料返混增强,延长了颗粒在炉膛内的停留时间,对于提高大煤矸石颗粒的燃尽率、炉内石灰石脱硫效率具有积极意义。已有研究表明,提高循环量、增大颗粒悬浮浓度,有利于促进颗粒团聚并强化局部还原性气氛,继而减少NOx等污染物原始排放[20]。

图6 掺烧污泥前后颗粒浓度轴向分布比较(模型)

Fig.6 Comparison of axial distributions of solid suspension density between the cases with and without additional sludge (model results)

表3 掺烧污泥后部分物料平衡特征参数比较(模型)

Table 3 Comparison of some material balance characteristics between the cases with and without additional sludge(model results)

图7 掺烧污泥前后颗粒炉内停留时间比较(模型)

Fig.7 Comparison of particle residence time in furnace between the cases with and without additional sludge (model results)

3 污泥掺烧对锅炉性能的影响

在不同锅炉负荷下,对比分析了掺烧10%污泥前后床温、蒸气温度等锅炉性能参数实测结果如图8所示,可知各负荷下掺烧污泥后,锅炉床温均有所降低。首先,污泥含水量高,这些水分在炉内蒸发带走一部分烟气热量。另外,炉膛上部物料浓度显著增加,而流化风速也有所提高(图6和表3),从而强化了炉内受热面表面换热,进一步降低炉膛温度。但由于该330 MWe锅炉污泥掺烧比例较低(10%),总体上看掺烧前后床温变化并不明显,对炉内燃烧状态影响有限。

图8 掺烧污泥对锅炉床温影响

Fig.8 Comparison of bed temperatures between the cases with and without additional sludge

前文分析可知,掺烧污泥后烟气量增加、细颗粒变多,导致飞灰份额增加。烟气中灰颗粒浓度提高,导致尾部对流换热增强,故低温过热器及低温过热器出口蒸汽温度均有所提高,如图9所示。

图9 掺烧污泥对尾部对流受热面蒸气温度影响

Fig.9 Comparison of steam temperatures at outlet of convective heating surfaces between the cases with and without additional sludge

尽管炉膛上部物料浓度增加导致对流换热有所增强,但床温降低也使得炉内受热面表面辐射换热强度减弱。2者综合作用下,锅炉掺烧污泥后屏式过热器传热系数会有所降低,对出口蒸气温度有一定影响,如图10所示。考虑尾部对流受热面换热的强化作用,掺烧污泥后,过热器喷水量无明显变化。实际运行数据显示一级减温喷水量由30.6 t/h略减至33 t/h,二级喷水量则由18.72 t/h略减至16.5 t/h。

图10 掺烧污泥对屏式过热器蒸气温度影响

Fig.10 Comparison of steam temperatures at outlet of platen superheater between the cases with and without additional sludge

掺烧10%污泥时,锅炉排烟温度较原工况略有增加,如图11所示,这可归因于烟气含水量增加、炉膛温度降低及对流受热面传热增强。不过各负荷下排烟温度提高幅度均较小(温升小于3 ℃),对下游除尘设备的运行不会造成明显影响。

图11 掺烧污泥对锅炉排烟温度影响

Fig.11 Comparison of exhaust temperatures between the cases with and without additional sludge

4 结 论

1)利用一维CFB数学模型模拟了污泥掺烧对某330 MWe CFB锅炉物料平衡特性的影响。该锅炉原采用煤矸石与煤泥混烧,掺烧10%污泥后,飞灰和底渣粒度变化很小,而循环灰粒度略微增大。循环流率增加近30%,稀相区平均压降即颗粒悬浮浓度增大约35%,飞灰占总灰渣份额也增加约1.5个百分点,颗粒在炉膛内的停留时间也有所延长。

2)锅炉实测结果表明,在50%~100%负荷下,掺烧10%污泥后,锅炉床温下降10 ℃左右,排烟温度升高3 ℃以内,低温过热器及低温再热器出口蒸气温度有所提高,而炉内屏式过热器出口蒸气温度则略降低。

3)模型和实炉运行结果显示,掺烧少量污泥有利于改善CFB锅炉物料循环性能,尾部烟道对流换热增强而炉内屏式过热器传热系数有所降低。但总体上看,在较宽负荷范围内,当污泥掺烧比例较低时,锅炉蒸汽参数等变化较小,对整体运行性能影响有限。

[1] 王飞,张盛,王丽花.燃煤耦合污泥焚烧发电技术研究进展[J/OL].洁净煤技术:1-39[2022-03-15].https://doi.org/10.13226/j.issn.1006-6772.CC22011001.

WANG Fei,ZHANG Sheng,WANG Lihua. Development of co-combustion technology of sludge in coal-fired power plant[J/OL]. Clean Coal Technology:1-39[2022-03-15].https://doi.org/10.13226/j.issn.1006-6772.CC22011001.

[2] 柯希玮,蒋苓,吕俊复,等. 循环流化床燃烧低污染排放技术研究展望[J]. 中国工程科学,2021,23(3):120-128.

KE Xiwei,JIANG Ling,LYU Junfu,et al. Prospects for the low pollutant emission control of circulating fluidized bed combustion technology[J]. Strategic Study of CAE,2021,23(3):120-128.

[3] JANG H N,KIM J H,BACK S K,et al. Combustion characteristics of waste sludge at air and oxy-fuel combustion conditions in a circulating fluidized bed reactor[J]. Fuel,2016,170:92-99.

[4] 柯希玮,张缦,杨海瑞,等. 循环流化床锅炉NOx生成和排放特性研究进展[J]. 中国电机工程学报,2021,41(8):2757-2771.

KE Xiwei,ZHANG Man,YANG Hairui,et al. Research progress on the characteristics of NOx emission in circulating fluidized bed boiler[J]. Proceedings of the CSEE,2021,41(8):2757-2771.

[5] 吴优福. 循环流化床锅炉SO2超低排放技术研究[J]. 洁净煤技术,2017,23(2):108-113,118.

WU Youfu. Study on SO2 ultra low emission technology on circulating fluidized bed boiler[J]. Clean Coal Technology,2017,23(2):108-113,118.

[6] 赵连勤,刘建国. 145 t/d油污泥循环流化床锅炉及其运行[J]. 工业锅炉,2010(2):45-48.

ZHAO Lianqin,LIU Jianguo. 145 t/d oily sludge CFB boiler and its operation[J]. Industrial Boilers,2010(2):45-48.

[7] 李博. 循环流化床锅炉掺烧城市污泥方案研究与改造实践[J]. 热力发电,2020,49(5):152-156.

LI Bo. Scheme research and reformation for sewage sludge blending in CFB boiler[J]. Thermal Power Generation,2020,49(5):152-156.

[8] 吴成军,段钰锋,赵长遂,等. 循环流化床内污泥与煤混烧时汞的浓度和形态分布[J].动力工程,2008,28(2):308-313.

WU Chengjun,DUAN Yufeng,ZHAO Changsui,et al. Distribution of mercury concentration and speciation during co-combustion of sludge and coal in circulating fluidized beds[J]. Journal of Power Engineering,2008,28(2):308-313.

[9] 张自丽,曾钦达,何宏舟,等. 燃福建无烟煤循环流化床锅炉掺烧污泥的可行性研究[J]. 工业锅炉,2017(3):10-14.

ZHANG Zili,ZENG Qinda,HE Hongzhou,et al. Research on the co-combustion of sludge and Fujian anthracite in CFB boilers[J]. Industrial Boilers,2017(3):10-14.

[10] 曹通,方立军,李鸿远. 循环流化床锅炉掺烧污泥的炉内燃烧数值模拟研究[J]. 锅炉技术,2017,48(2):30-35.

CAO Tong,FANG Lijun,LI Hongyuan. A numerical simulation of co-combustion of sludge on a circulating fluidized bed boiler[J]. Boiler Technology,2017,48(2):30-35.

[11] 张自丽,孙光,段伦博.煤与污泥混燃及污染物逸出特性研究[J/OL].洁净煤技术:1-13[2022-03-15].https://doi.org/10.13226/j.issn.1006-6772.CC21102701.

ZHANG Zili,SUN Guang,DUAN Lunbo. Combustion characteristic and pollutants emission behavior during co-combustion of coal and municipal sewage sludge[J/OL]. Clean Coal Technology:1-13[2022-03-15].https://doi.org/10.13226/j.issn.1006-6772.CC21102701.

[12] KE Xiwei,ENGBLOM M,ZHANG Man,et al. Modeling of the axial distributions of volatile species in a CFB boiler[J]. Chemical Engineering Science,2021,233:116436.

[13] KE Xiwei,LI Dongfang,LI Yiran,et al. 1-Dimensional modelling of in-situ desulphurization performance of a 550 MWe ultra-supercritical CFB boiler[J]. Fuel,2021,290:120088.

[14] YANG Hairui,YUE Guangxi,XIAO Xianbin,et al. 1D modeling on the material balance in CFB boiler[J]. Chemical Engineering Science,2005,60(20):5603-5611.

[15] 李静渊,柯希玮,蒋苓,等. 兰炭循环流化床锅炉燃烧性能模型研究[J/OL]. 洁净煤技术:1-8[2021-08-14].https://kns.cnki.net/kcms/detail/11.3676.TD.20210624.1543.002.html.

LI Jingyuan,KE Xiwei,JIANG Ling,et al. Research on the combustion performance of a semi-coke fired circulating fluidized bed boiler based on 1-D CFBB model[J/OL]. Clean Coal Technology:1-8[2021-08-14].https://kns.cnki.net/kcms/detail/11.3676.TD.20210624.1543.002.html.

[16] 柯希玮,张缦,杨海瑞,等. 水煤浆循环流化床锅炉物料平衡特性模型[J]. 中南大学学报(自然科学版),2021,52(1):86-95.

KE Xiwei,ZHANG Man,YANG Hairui,et al. Modeling of mass balance behavior in a coal water slurry fired circulating fluidized bed boiler[J]. Journal of Central South University (Science and Technology),2021,52(1):86-95.

[17] 张平,陈陆剑,江华,等. 300 MW循环流化床锅炉大比例掺烧煤泥试验研究[J]. 洁净煤技术,2020,26(1):66-70.

ZHANG Ping,CHEN Lujian,JIANG Hua,et al. Research on large proportion of coal slime co-combustion in a 300 MW CFB boiler[J]. Clean Coal Technology,2020,26(1):66-70.

[18] 杨海瑞,肖显斌,吕俊复,等. CFB锅炉内成灰特性的实验研究方法[J]. 化工学报,2003,54(8):1183-1187.

YANG Hairui,XIAO Xianbin,LYU Junfu,et al. Experimental technique on coal ash formation in CFB combustion[J]. CIESC Journal,2003,54(8):1183-1187.

[19] WANG Yu, LU Junfu, YANG Hairui, et al. Measurement of heat transfer in a 465 t/h circulating fluidized bed boiler[C]//Proceedings of the 18th International Conference on Fluidized Bed Combustion. Toronto:[s.n.], 2005: 327-335.

[20] 柯希玮,蔡润夏,杨海瑞,等. 循环流化床燃烧的NOx生成与超低排放[J]. 中国电机工程学报,2018,38(2):390-396.

KE Xiwei,CAI Runxia,YANG Hairui,et al. Formation and ultra-low emission of NOx for circulating fluidized bed combustion[J]. Proceedings of the CSEE,2018,38(2):390-396.

Operation characteristic analysis on co-combustion of sludge and coal in a 330 MWe circulating fluidized bed boiler

移动阅读

KE Xiwei,SUN Guorui,HUANG Zhong,et al.Operation characteristic analysis on co-combustion of sludge and coal in a 330 MWe circulating fluidized bed boiler[J].Clean Coal Technology,2022,28(3):102-108.