粉煤灰基沸石分子筛的合成及应用进展

0 引 言

中国是世界最大的煤炭生产和消费国,2019年煤炭生产量为27.5亿t标准煤当量(tce)[1]。煤炭占中国一次能源生产和消费的比例分别为69.3%和57.7%[2]。虽然我国正在大力发展清洁能源和低碳能源利用技术,但煤炭在能源结构中的主体战略地位不会动摇,未来煤电仍将是中国最大的单一发电来源[3-4]。我国每年火力发电产生约6.8亿t粉煤灰,现存的粉煤灰质量累计超过30亿t[5]。废置的粉煤灰造成严重的水体污染、大气污染、土壤污染和土地占用等问题。粉煤灰常被用于道路回填、建筑材料和土壤改良,但近年来随着建材市场逐渐饱和以及农用土壤标准的提高,粉煤灰在建材、土壤等行业的利用受到了限制[6-8]。为了提高粉煤灰的治理效率和利用附加值,以粉煤灰为原料开发新型功能材料备受关注。粉煤灰富含SiO2和Al2O3,是理想分子筛的天然原材料,具有特定骨架结构和硅铝连接基序的分子筛材料在催化、吸附和离子交换等领域应用广泛。明晰粉煤灰基分子筛的晶化机理、杂原子迁移规律和骨架结构及硅铝连接基序的定向调控是实现其高附加值利用的关键。本文对粉煤灰的来源、组成、元素提取、杂质脱除、分子筛合成方法及其应用等方面的国内外进展进行系统的综述,并对发展前景进行展望。

1 粉煤灰

1.1 粉煤灰的形成过程

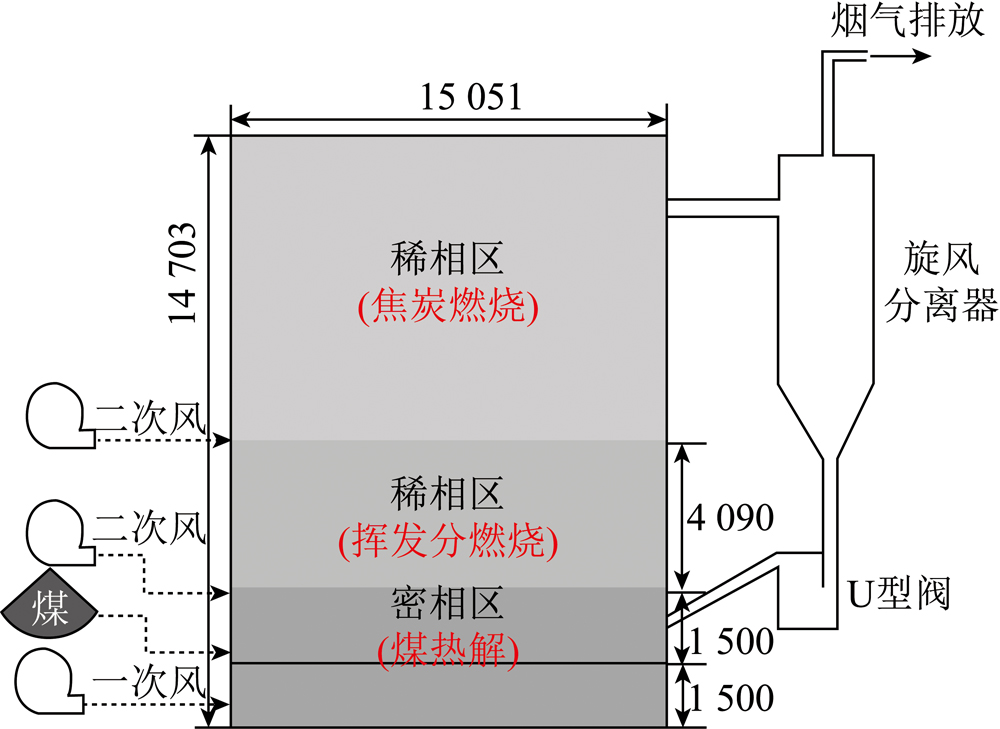

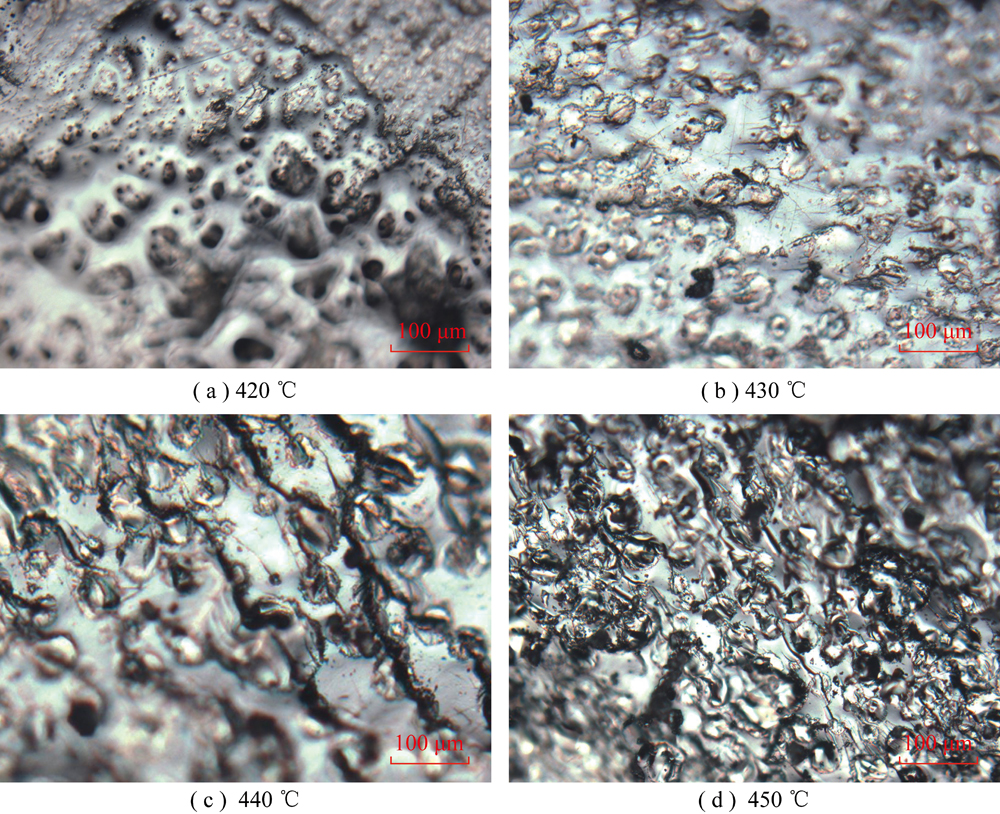

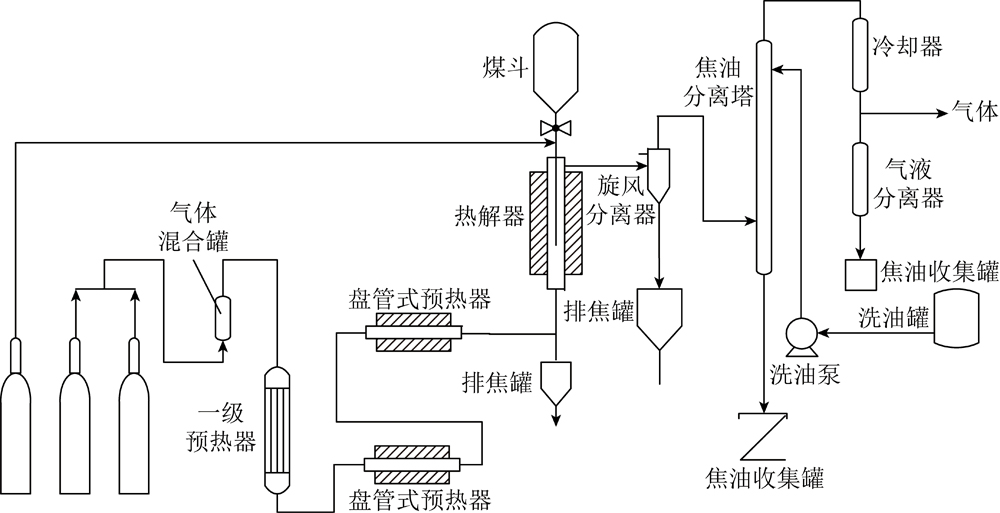

粉煤灰是燃料(主要是煤)燃烧过程中排出的微小灰粒。原煤经破碎、粉磨后,在粉煤炉或循环流化床的燃烧室内进行高温燃烧。煤中不可燃烧的颗粒物如SiO2、Al2O3、CaCO3、Fe2O3等以及未燃尽碳颗粒被裹挟在高温烟气中,在除尘装置中冷却富集,即形成粉煤灰[9-11]。在高温烟气中,矿物质受热熔融成球状,在流动扩散过程中,球状矿物质颗粒物相互黏结成新的球状颗粒物,同时,烟气中处于熔融状态的碱金属、碱土金属和气相中的Hg0、SO2、P2O5和NO与球状矿物质发生表面化学反应和黏附,形成成分复杂的复合物[12-15]。

1.2 粉煤灰的组成和结构特性

粉煤灰的组成和结构受煤种和燃煤工艺的影响。根据燃烧方式不同,粉煤灰可以分为粉煤炉粉煤灰和循环流化床粉煤灰。粉煤炉粉煤灰占粉煤灰总量的90%左右,由煤粉被吹至高温炉膛内经高温迅速燃烧(1 300~1 400 ℃)后冷却而成[9,14,16]。由于燃烧温度高,灰分在燃烧炉中呈熔融状态,在表面张力作用下呈球状,粒径在几百纳米至几十微米,典型粉煤炉粉煤灰的SEM照片如图1所示。循环流化床是近20年发展起来的新一代清洁高效燃煤技术,具有燃烧效率高、燃料适应性广、氮氧化物排放量低、可直接脱硫等优点。循环流化床的燃烧温度为850~900 ℃,此温度范围内,灰分未被熔融,产物呈无定型块状颗粒物,几乎不存在球形颗粒[14]。

图1 粉煤炉粉煤灰的SEM照片

Fig.1 SEM image of fly ash in pulverized coal furnace

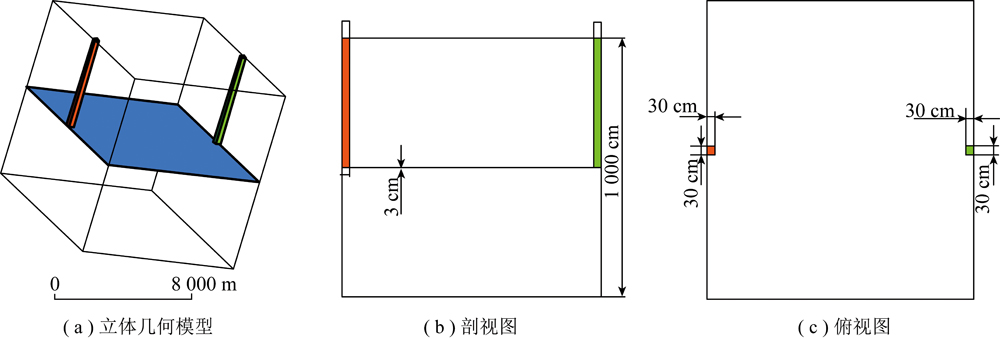

从矿物学角度,粉煤炉粉煤灰微球从外到内由3种物质组成(图2):最外层为无定型的硅铝酸盐玻璃体,SiO2质量分数超过70%;中间层为多晶石英(SiO2);最内层为高结晶度的莫来石(Al4Si2O10)[8]。粉煤灰的化学组成主要受燃煤工艺和煤种的影响(表1)。煤中的高岭石和伊利石等黏土成分在高温下分解形成的SiO2和Al2O3在高温下(约1 300 ℃)

图2 粉煤炉粉煤灰的组成和结构截面示意

Fig.2 Composition and structural section of fly ash in pulverized

coal furnace

表1 不同煤种的粉煤灰化学组成[19]

Table 1 Chemical composition of fly ash from different

coals[19]

进一步反应生成莫来石[17]。循环流化床燃烧时,通常添加钙基脱硫剂以降低燃煤烟气中的SO2浓度,因此,循环流化床粉煤灰中含有更多的生石灰(CaO)、石膏(CaSO4)、方解石(CaCO3)等含钙矿物质。此外,循环流化床的燃烧温度较低,未燃尽的残余碳含量较高[14]。

文献[18]发现粉煤灰主要由3类颗粒组成:球形题粒、不规则的熔融颗粒和炭粒,根据其组成和比例,可将粉煤灰分成4类:Ⅰ类粉煤灰,主要由球形颗粒组成;Ⅱ类粉煤灰,除含有球形颗粒外还有少量熔融玻璃体;Ⅲ类粉煤灰,主要由熔融玻璃体和多孔疏松玻璃体组成;Ⅳ类粉煤灰,由多孔疏松玻璃体和炭粒组成。美国材料试验协会(ASTM)根据粉煤灰的化学成分和煤的来源,将粉煤灰分为F类和C类。F类粉煤灰来自烟煤和无烟煤燃烧,氧化钙含量较低,在10%以下;C类粉煤灰来自褐煤和亚烟煤燃烧,具有一定的自硬性,氧化钙含量在15%以上。此外,要求F类粉煤灰中SiO2、Al2O3、Fe2O3之和占70%以上,C类粉煤灰中3者之和不得小于50%。

1.3 粉煤灰的危害和治理利用现状

废置的粉煤灰通常存储在灰池或地面废水池中,严重危害生态环境和人体健康[8-9,20]:① 占用土地资源。② 污染大气、土壤和水资源,露天堆放的粉煤灰造成扬尘天气,污染大气;粉煤灰会伴随降雨进入河流、湖泊,不仅污染地表水,还会渗入土壤,对地下水造成二次污染;扩散至土壤中的微量元素超过临界值时,土壤的结构、组成和功能会发生质变。③ 危害人体健康,粉煤灰中含有多种对人体有害的物质,如多环芳烃、重金属元素。微纳米级的粉煤灰可直接被吸入体内,进入肺部和血液,危及健康和生命。部分粉煤灰中CaO含量偏高,长期堆积会造成土地盐碱化[21-22],研究表明粉煤灰的浸出液具有很大的变异性,对水生生态系统产生不利影响,而固体物质可通过直接的外部反应对陆地生态系统造成危害[23]。

粉煤灰主要用于建筑材料、道路回填、土壤改性、矿物提取和合成分子筛等领域。在建材领域,粉煤灰主要用于水泥掺料、混凝土掺料、烧结砖、砖砌块、陶粒、微晶玻璃等产品。粉煤灰是一种轻质材料,适用于软土地区的路基建筑,可提高路堤的稳定性,粉煤灰含有大量的硅酸盐和部分氧化钙,可替代部分黏土用于生产水泥。将粉煤灰用于混凝土配料,能改善混凝土性能,节约水泥,提高混凝土质量,降低工程成本。以粉煤灰和废玻璃为主要原料,掺入黏结剂可用于烧制墙体材料,保温性能和强度皆优于市场上的产品。由于粉煤灰的独特颗粒形貌和酸碱度,去除有害元素后的粉煤灰掺入土壤,可使土质疏松,改善土壤pH值,提高土壤的可耕作性,有利于扩大耕地面积,提高农作物收成[15,24]。

以上属于粉煤灰的低附加值利用,其资源化技术含量低,产品附加值不高,因此需要提高粉煤灰的利用效率,开发高附加值利用途径。

1)粉煤灰可用来提取稀土元素,部分地区粉煤灰中稀土元素含量较高,可作为稀土资源的潜在替代品。Tang等[25]以碱熔法处理粉煤灰并从其中回收贵金属(Y、La、Ce、Pr和Nd),考察了碱的种类(NaCl、NaOH、Na2CO3、Na2O2、KOH、Ca(OH)2)对贵金属溶出的影响规律,研究表明,Na2CO3、Na2O2、NaOH和KOH均能破坏粉煤灰结构,有效提高粉煤灰中稀土元素的浸出效率;5种稀土元素的总浸出效率分别达到57.45%、49.25%、74.23%和64.93%。

2)我国粉煤灰中Al2O3含量较高,平均17%~35%,在内蒙古中西部、山西北部等地积存的高铝粉煤灰中Al2O3含量甚至超过40%,因此,可从粉煤灰中提取Al2O3。Li等[26]在焙烧过程中发现,SiO2和Al2O3相变不同,在碱溶液中表现出不同的溶解率,通过焙烧法预脱去粉煤灰中的硅,采用拜耳法回收脱硅渣中的Al2O3。Yang等[27]采用焙烧法,且以硫酸铵和硫酸作为混合助剂从粉煤灰中提取Al2O3。Fan等[28]利用Na2CO3和粉煤灰预焙烧,通过生物质Fe3 和硫酸提取粉煤灰中的Al和Ce。

3)粉煤灰中Si元素含量最多,提取Si元素制备SiO2或高纯硅分子筛将大大提高粉煤灰的附加值。Li等[29]采用粉煤灰和CaCO3在1 200 ℃下焙烧1 h预活化粉煤灰,活化后采用成熟的酸浸工艺,在控制反应参数的条件下,制备出比表面积达585.02 m2/g、孔容为0.54 cm3/g的介孔氧化硅。Liu等[30]以焚烧炉底灰为原料,高温下分别与NaOH、Na2CO3、LiBO2活化剂熔融,并溶解于水,取上清液合成介孔氧化硅材料。Li等[31]采用气化渣与NaOH混合于550 ℃的马弗炉中焙烧1 h,将熔融物酸浸溶解后过滤,提取滤液中的硅元素,合成了纯硅的MCM-41分子筛。

粉煤灰用于制备沸石分子筛。沸石具有较大的比表面积、孔径、分子筛性能和酸性,是吸附材料和催化剂的理想选择。因此使用粉煤灰合成沸石是一种高附加值的利用途径。粉煤灰是合成沸石的优良原料,其以铝硅酸盐和硅酸盐相为特征,通常SiO2和Al2O3含量在70%以上[32]。1985年,Holler等[33]首次研究了以粉煤灰为硅、铝源合成沸石。相继衍生出采用常规或碱熔融辅助水热法、多步处理、微波加热或超声处理等方法,从煤或生物质灰中合成沸石[34]。

2 粉煤灰活化

粉煤灰是结构稳定、成分复杂的球状玻璃体。从粉煤灰中提取有价元素和制备沸石分子筛,均需进行活化。粉煤灰的活化方式主要有机械活化、水热活化和碱(盐)熔融等方式[8,35]。

2.1 机械活化

机械活化是用研磨方式将粉煤灰粉碎成微小颗粒,是简单廉价的活化技术,适用于大规模原料的活化。在研磨过程中,颗粒形状和尺寸的变化有利于防治粉煤灰的黏附和团聚,提高颗粒活性。粉煤灰破损后,内部无定型的二氧化硅暴露出,将提高其在后续液相合成中与碱溶液OH-的接触,促进粉煤灰微球颗粒的分解和转化。颗粒的减小也有助于缩短液相离子在粉煤灰中的传质距离。机械研磨一般采用球磨机,容易造成粉尘污染,活化效果差,通常被应用于活化效果低的建材行业采用[35-37]。但是机械研磨均易造成较大的粉尘污染,并且活化效果较差,通常机械研磨后与其他活化方法结合使用或被活化效果要求低的大型建材行业采用。

2.2 水热活化

水热活化是将粉煤灰与碱溶液混合,在水热条件下活化。在矿化剂(OH-离子)作用下将粉煤灰微球溶解为硅铝酸盐溶胶或次级结构单元,碱金属离子作为无机结构导向剂,可将其进一步转变为沸石。Mondragon等[38]将粉煤灰在不同NaOH浓度、温度和时间的水热条件下进行处理,结果表明,粉煤灰中的活化产物主要为X型沸石,混有少量P型沸石。Lin等[39]研究了同时添加NaOH和KOH对不同温度活化产物的影响,结果表明,在低温下(约70 ℃)较易形成P型沸石,150 ℃较易形成方钠石,170 ℃时形成羟基方钠石,200 ℃时开始出现钙霞石。粉煤灰的中间层无定型易被水热活化转化,而内核莫来石很难被转化[40]。水热活化的温度、时间、碱溶液种类和浓度以及粉煤灰的化学成分、碱固比均影响活化产物的组成[34]。

在水热活化基础上,辅以超声和微波可缩短活化时间或提高活化效率。Inada等[41]研究了微波辐射对粉煤灰活化的影响,表明在活化初期,微波辐射会促进粉煤灰中SiO2和Al2O3的溶解,但继续施加微波,会抑制沸石的形成;此外微波有助于降低沸石产物的晶粒尺寸;超声处理也会促进粉煤灰中非晶成分中的Si和Al的溶解。Woolard等[42]采用超声水热法以粉煤灰为原料合成了羟基方钠石。Ojumu等[43]高强度的超声处理代替碱溶液,采用经10 min超声处理,在90 ℃下水热处理2 h,合成了A型沸石,但超声处理的活化率较低(约为24%),仅溶解了粉煤灰中的无定型相。水热活化粉煤灰合成沸石类型和结晶度的决定性因素包括水热时间、温度、粉煤灰化学成分、碱性氧化物类型,粉煤灰硅铝溶出浓度被认为是沸石结晶的关键因素之一。因此,粉煤灰水热活化过程中,硅铝溶出率低,活性元素数量有限,导致沸石产率偏低,最终产品中存在粉煤灰原料,这是水热法的主要缺点。

2.3 碱(盐)熔融活化

碱(盐)熔融是将粉煤灰与碱或碱与盐的混合物混合均匀后在高温下进行焙烧活化。Bhandari等[44]发现,粉煤灰的硅铝比会影响碱熔融活化产物的沸石类型,Si/Al=3.16时,产物为X型沸石;Si/Al=2.52时,产物为A型沸石。对粉煤灰进行碱熔融处理,有利于沸石合成,经碱熔融处理,粉煤灰可大部分转化为硅酸盐和硅铝酸盐,其在碱性溶液中易被溶解,可在水热环境下形成沸石。Park等[45-47]以混合盐(NaOH-NaNO3、NaOH-KNO3、NH4F-NH4NO3)为活化剂,在不添加水的条件下合成了方钠石和钙霞石。碱熔融法活化粉煤灰具有较高的活化率,但成本高、程序复杂、处理时间长。碱(盐)熔融联合酸浸和水浸可充分提取粉煤灰中的有价元素。Yan等[48]采用碱熔融法从粉煤灰中提取Na2SiO3,并用于纳米硅线的合成。Tang等[49]采用碱熔融联合酸浸法,从粉煤灰中提取稀土元素(Y、La、Ce、Pr和Nd),提取率较高,但碱耗量大,后续处理步骤繁琐。碱(盐)熔融法预处理粉煤灰的主要特征是增加后续水热溶液中Si、Al含量,不仅减少了粉煤灰中未反应的物质,也能合成纯度较高的沸石,但费用较高、程序复杂和处理时间较长。

3 粉煤灰基沸石分子筛水热合成方法

沸石分子筛通常是指具有均匀孔道结构的结晶态硅铝酸盐物质,分子筛的最基本结构单元是硅氧四面体或铝氧四面体,四面体通过共享顶点的氧原子,连接形成不同的次级结构单元(SBU)。同种分子筛可有多种次级结构单元,次级结构单元通过进一步相互连接形成不同的三维骨架结构[50-53]。常见分子筛的外观、电子显微图片和三维骨架结构如图3所示。由于分子筛具有独特的骨架结构、较大的比表面积、良好的水热稳定性和离子交换性能、表面可调的Lewis和BrØnsted酸性中心,可作为催化剂或催化剂载体、离子交换剂和吸附剂等,广泛应用于精细化工、石油化工和环境保护等领域。

图3 分子筛结构及其应用

Fig.3 Structure and application of molecular sieves

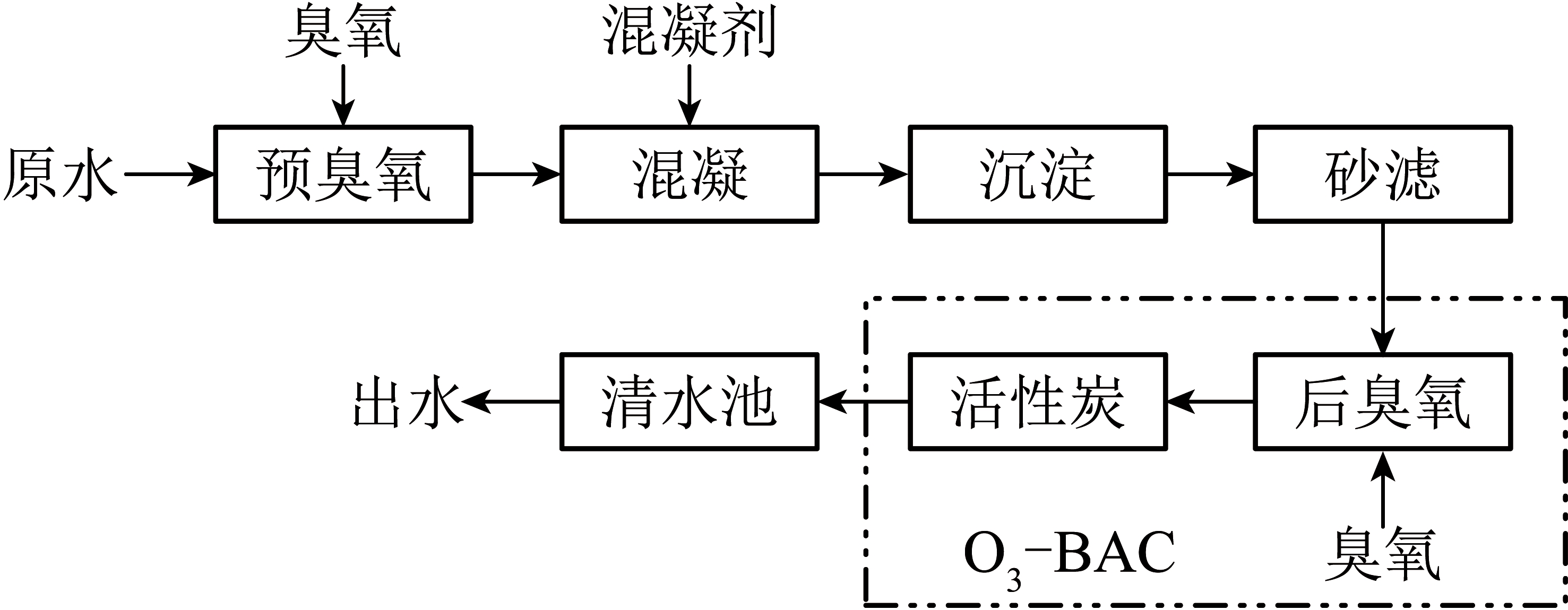

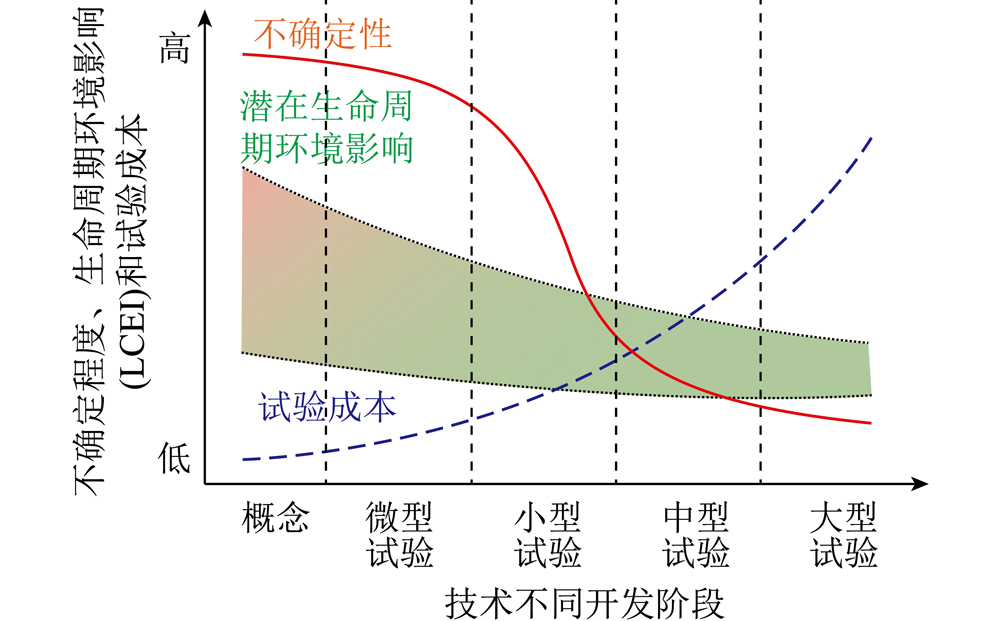

粉煤灰基分子筛的合成包括粉煤灰玻璃微球结构溶解和分子筛骨架结构重构2个过程[60]。沸石形成的类型受多条件和参数的影响,如粉煤灰种类、硅铝比、温度、压力、溶液pH值、固液比等[8,61-64]。粉煤灰基沸石分子筛的合成均基于液相合成过程,包括直接水热合成法(一步法和两步法)及由水热法演变的碱熔融-水热法、超声/微波-水热法、晶种法和转晶法等,其合成路线如图4所示。

图4 粉煤灰基沸石分子筛的合成路线

Fig.4 Synthesis route of fly ash based zeolite molecular sieve

3.1 直接水热合成法

水热合成法是常见的分子筛合成方法。文献[8,13]以粉煤灰为原料利用碱性水热溶液合成了X型和P型分子筛,NaOH浓度为2~13 mol/L,温度为90~100 ℃,时间为8~48 h。经HCl和H2SO4处理,可降低粉煤灰表面Fe和碱性氧化物含量。酸处理会促进分子筛合成,但会降低分子筛产物的吸附性能。采用水热法合成分子筛可先从粉煤灰中提取氧化硅或氧化铝,再以此为原料,添加铝源或硅源进一步合成分子筛,得到的分子筛纯度和结晶度较高,但步骤繁琐、分子筛产率很低[65-66]。水热法制备的粉煤灰基沸石SEM图如图5所示[67]。

图5 粉煤灰及水热法合成的4A沸石产物的SEM照片[67]

Fig.5 SEM photos of 4A zeolite products synthesized

by fly ash and hydrothermal method[67]

Chen等[68]以从粉煤灰中提取的Al(OH)3为铝源外加硅源,采用水热法合成了形貌规则、晶体尺寸可调的ZSM-5分子筛,并研究了晶体生长的动力学过程。发现沸石的形成可分为4步:硅酸根离子和铝酸根离子通过凝聚形成→颗粒生长和无定型硅铝酸盐的团聚→ZSM-5的晶化和晶体生长→沸石晶体达一定尺寸后开始发生熟化。由于粉煤灰结构稳定、成分复杂,一步法无法得到纯度高的沸石产物。Jha等[69]研究了三步水热法合成的NaP1型沸石产物,虽步骤繁琐,但相较一步法,沸石产物比表面积增长33.42%,离子交换率增长14%。Sun等[70]采用两步法在100 ℃时制备了高纯度的NaA和X型沸石,并具有较高的Cu2 吸附能力。Zhao等[71]分析了陈化和添加晶种对粉煤灰转化为沸石的影响,结果表明,陈化有利于Si和Al从粉煤灰中溶解出,并促进其转化为次级结构单元和组装为沸石。晶种种类决定了沸石产物的骨架类型,添加晶种可消除产物中的杂质,缩短晶化时间。

影响水热合成粉煤灰基沸石分子筛的因素包括处理时间、温度、粉煤灰原料组成、碱性氢氧化物类型、碱溶液浓度、液固比、从粉煤灰中溶出的Si和Al浓度。高温下的碱性水热溶液有助于Si和Al的溶出,但粉煤灰中的Si和Al不能完全溶出。粉煤灰内核中的莫来石难以被溶解,严重影响了水热法合成的沸石分子筛产物的纯度和产率[8,41,72]。

3.2 碱熔-水热合成法

碱融-水热合成法是传统的成熟合成方法,具备由粉煤灰制备沸石分子筛的规模化生产潜力。碱融-水热合成法是将碱熔融和水热合成2种方法相结合,利用碱性活性剂(包括NaOH、KOH、NH4F等)在水热环境中将粉煤灰中的Si、Al元素大量溶出,转化为低硅沸石相,再利用水热合成法将低硅沸石转化为高硅分子筛。Querol等[73]研究了14种粉煤灰的矿物学结构和物理化学性质,分析了影响粉煤灰合成沸石的主要影响因素,发现粉煤灰的晶粒较小、玻璃含量高、硅铝含量高、重金属含量低更有利于合成沸石,经水热处理后发现新形成的沸石类型与晶体大小取决于粉煤灰与溶液的比例、反应时间以及原料的化学组成。

Shigemoto等[74]用固体碱熔融法在550 ℃下将粉煤灰与NaOH混合焙烧,得到硅铝酸钠固体,无需搅拌即可通过水热过程合成NaX沸石。Shih等[75]通过碱熔融法联合水热法将粉煤灰转化为3种初级沸石产物:P型、A型和方沸石。碱熔融得到的硅酸钠和无定型硅铝酸钠易在碱性水热条件下溶解于液相。Rayalu等[76]研究了NaOH浓度对粉煤灰转化和沸石产物类型的影响,发现碱浓度不足时,会降低粉煤灰熔融后得到的硅铝酸盐含量,阻碍后续水热晶化过程;碱浓度过量时产物会全部转化为羟基钙钠石。经碱熔融处理可提高产物沸石的纯度。将粉煤灰与碱性氢氧化物混合熔融,得到硅酸盐和硅铝酸盐,这些活化产物易被溶解于碱性溶液,使液相中更多的Si和Al参与到沸石晶化过程,产物沸石的纯度较高,说明碱熔融-水热法是较好的粉煤灰沸石合成方法。但该方法的碱耗量很大,高温(500~600 ℃)处理增加成本。

3.3 微波/超声波-水热合成法

超声波促进了粉煤灰中硅和铝的溶出过程和凝胶的形成,为粉煤灰分子筛的合成提供了高温高压环境,进而加快分子筛的结晶速度。Belviso等[77]利用超声波法将粉煤灰转化为分子筛,在超声处理开始阶段,产物主要以方钠石相存在,同时含有少量的A型沸石和八面沸石,随着反应进行,A型沸石和八面沸石完全转化为方钠石晶相。超声-微波法相较于碱融-水热合成法,具有较快的结晶速度,且转化形式更稳定。

超声处理可降低水热合成温度,缩短晶化时间,提高沸石的晶化程度。其根本作用是提高原料的溶解度及成核速率。但目前尚无相关的放大研究报道,因此,该方法很难达到工业化规模。

Querol等[78]比较了传统水热合成法和微波辅助水热法对沸石产物和产率的影响。传统水热法的活化时间为24~48 h,微波后,活化时间仅为30 min。Inada等[42]采用微波辅助的水热合成法在碱性条件下制备了Na-P1沸石,结果表明,持续的微波照射会延迟沸石的晶化过程,而间歇性的微波照射效果更好。初期的微波照射有助于增强SiO2和Al2O3的溶解,但继续微波照射会阻碍中间相硅铝酸盐凝胶的成核,不利于沸石合成。Tanaka等[79]开发了一种采用微波辅助水热过程快速合成Na-A沸石的方法,即在水热作用下将粉煤灰溶解为无定型硅铝酸盐后,微波加热60 min,可快速合成沸石。

综上,微波可快速提供局部均匀的热效应,其主要优势是促进SiO2和Al2O3的溶解,减少沸石合成过程中的活化时间。微波热效应还可有效降低沸石晶体产物的尺寸,但该方法需特殊的装置,目前仅限于实验室研究,很难进行工业放大。

3.4 晶种法

水热合成过程中引入晶种,可代替昂贵的有机模板剂,缩短晶化时间,提高产物纯度。目前添加晶种合成分子筛的晶化机理和转晶机理尚不明确。晶种结构单元在转晶过程中起动力学控制的作用。晶种颗粒在前驱体溶液中被拆散为小的结构单元片段,作为成核点诱导前驱体复制晶种的结构单元,进行成核和晶体生长。因此添加晶种可缩短成核过程,提高结晶速率。Zhao等[71]通过添加晶种用水热法合成了粉煤灰基Y型沸石。添加晶种可跳过沸石晶化过程中的成核和诱导过程,缩短了晶化时间,提高了产物的结晶度。Wang等[61]通过添加晶种,以粉煤灰基方沸石为原料合成Cu-SSZ-13晶体,添加晶种减少了2/3有机模板剂用量,缩短了晶化时间,降低了产物的晶粒尺寸。Zeng等[80]在碱熔融水热法过程中引入晶种,合成了高纯度的A型沸石,发现添加晶种可缩短结晶过程的诱导期,并避免其他晶型杂质的出现。

晶种法和超声/微波-水热法均可缩短晶化时间,区别在于添加晶种主要是缩短晶体成核的诱导期,而微波/超声波效应主要是促进原料的溶解,但会抑制晶体的成核。若将二者结合可能会极大缩短沸石的晶化时间。相比于微波/超声-水热法,晶种法更易于被放大生产。

3.5 转晶法

转晶法是以一种已知结构的分子筛为原料,通过添加碱溶液、有机模板剂、补充硅源或铝源合成骨架类型和硅铝比不同的分子筛产物。转晶法作为一种绿色高效合成分子筛的方法已有大量研究[81-83]。以价格低廉的低(中)硅铝比分子筛为原料,通过调节硅铝比,制备分子筛。Goel等[84]建立了“复合结构单元”假说,即初始分子筛(parent zeolite)和产物分子筛(resultant zeolite)具有相同的基本结构单元,初始分子筛分解为复合结构单元,在模板剂作用下,组装为目标分子筛,如图6所示。一般情况下,通过转晶法制备的目标分子筛骨架密度低于初始分子筛[85-86]。通过添加不同的模板剂,可形成不同骨架类型的产物分子筛。分子筛转晶要经历母体分子筛结构的分解和产物分子筛的生成过程,要加入NaOH等碱性溶液,OH-起“拆解”母体分子筛作用,Na 起诱导形成目标分子筛作用[87]。Zhang等[88]通过紫外拉曼光谱研究了以FAU型分子筛为原料合成CHA型和MFI型分子筛的转晶过程。FAU与CHA具有相同的双六元环(D6R)结构单元,在高温碱溶液作用下,FAU分解为D6R单元后,组装为CHA结构单元。FAU和MFI具有不同的结构单元,FAU先生成2个S6R,再组装为MFI结构[88]。

图6 沸石分子筛转晶合成法示意[84]

Fig.6 Schematic diagram of conversion synthesis

method of zeolite[84]

水热转晶法适合以粉煤灰为原料合成分子筛材料。通过水热活化过程,将粉煤灰玻璃微球溶解重构为初级分子筛(如ANA型和FAU型分子筛),再在特定模板剂和碱溶液作用下,将初级分子筛溶解重构为目标分子筛。水热转晶是一个重结晶的过程,可使不纯的物质纯化,且可提高粉煤灰中Si、Al元素的利用率。利用水热转晶法以粉煤灰为原料制备的分子筛结晶度更高,产物中杂质原子含量更少。Wang等[60]研究了粉煤灰转晶制备CHA型分子筛过程中杂质原子的迁移规律(图7),发现水热活化产物中重金属等杂质原子含量仍较高,但经转晶合成为CHA型分子筛后,杂质含量低于1%。

图7 粉煤灰基沸石分子筛转晶过程中的过渡

金属杂质迁移规律(由XRF测定)[60]

Fig.7 Transition metal impurity migration of fly ash based

zeolite during crystallization process(measured by XRF)[60]

相较于其他常规水热合成沸石分子筛方法,转晶法对粉煤灰的利用更高效,使反应的晶化速率大幅提高,合成的沸石分子筛纯度较高。

4 粉煤灰基沸石分子筛的应用

沸石分子筛材料具有纳米限域的功能和可调节的酸性,在催化、气体分离、离子交换等领域具有不可替代的作用。目前,关于粉煤灰基沸石分子筛的文献报道主要集中于废水中重金属离子和氨氮离子的去除、氮氧化物选择性催化还原、VOCs的去除和CO2吸附捕集等[67,89]。

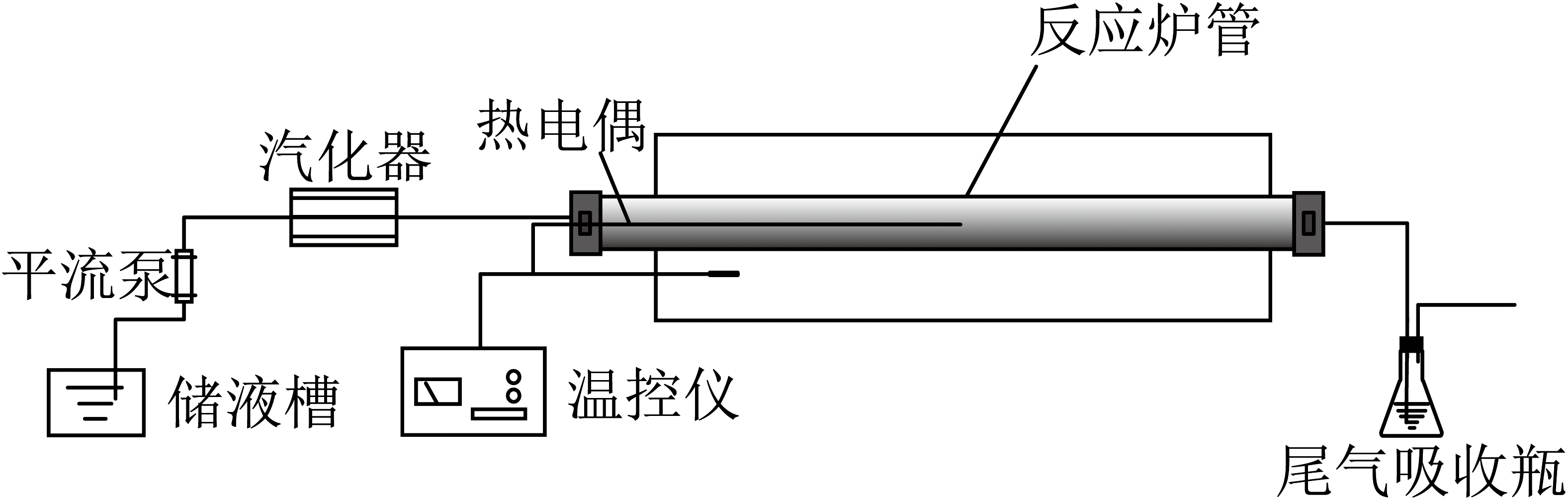

4.1 废水处理

电子、冶金、化工和印染等行业产生的工业废水中含有剧毒的汞、砷、铅、镉、铬等重金属离子和氨氮有机分子,需进行无害化处理。离子交换和电解沉积是最有效的重金属离子脱除方式[90-91]。沸石因具有纳米限域和表面酸性,对重金属具有较高的脱除率、选择性和脱除速率,是可循环利用的廉价高效离子交换材料。He等[92]以粉煤灰为原料合成了A型沸石,对废水中Ni2 的脱除率达94%。Yang等[93]以粉煤灰为原料,采用水热法在75 ℃下合成了Na-X型沸石,用于废水中As(V)的吸附脱除,pH=2.14时的最大吸附率为27.79 mg/g。理论计算计算表明,吸附过程是速率决定步骤。Zhang等[94]以从粉煤灰中提取的Si和Al为原料,制备了NaP型沸石,沸石纯度可由晶化过程的pH值调节。将该沸石用于废水中Zn2 脱除,在Zn2 离子浓度低于0.2 ×10-6水溶液中仍可达到吸附平衡。Cardoso等[95]以粉煤灰为原料在温和条件下合成了Na-P1型沸石,并用于废水处理,该沸石的Si/Al=2.5~2.9,对含As5 、Ni2 、Ca2 、Cu2 的废水均有很高的去除效率。Hui等[70]以粉煤灰为原料制备了高纯度4A型沸石,并研究了其对废水中混合金属离子(Co2 、Cr3 、Cu2 、Zn2 和Ni2 )的吸附脱除能力,结果表明,沸石对Co2 、Cr3 、Cu2 和Zn2 的吸附符合准一级动力学模型,对Ni2 的吸附符合准二级动力学模型;根据Langmuir模型平衡吸附量拟合结果,其对混合金属的吸附顺序为:Cu2 > Cr3 > Zn2 >Co2 > Ni2 。

4.2 NOx脱除

NOx是主要的大气污染物之一,会诱导细颗粒物和光化学烟雾等有害物质,对人体和气候均会造成不利影响[96]。Cu-SSZ-13和Cu-SAPO-34沸石分子筛在柴油车尾气NOx选择性催化还原方面有很好的催化效果[58]。Wang等[60]以粉煤灰基方沸石为原料,分别采用N,N,N-三甲基金刚烷、铜-四乙烯五铵和添加晶种法合成Cu-SSZ-13沸石分子筛,N,N,N-三甲基金刚烷、铜-四乙烯五铵为模板剂合成的Cu-SSZ-13的脱硝活性与商用沸石几乎相同。Wang等[97]研究了粉煤灰沸石分子筛对烟气中NOx和SO2的脱除性能,并发现该分子筛可用于汞蒸气的脱除。Jin等[98]以粉煤灰为原料制备了粉煤灰基沸石分子筛,用于选择性催化还原催化剂。Izquierdo等[99]以粉煤灰为原料制备了Cu2 和Fe2 掺杂的交换Y型沸石,用作SCR催化剂,具有较高的NOx脱除性能。

4.3 VOCs去除

挥发性有机化合物(VOCs)指常温下饱和蒸汽压>70 Pa、沸点常压下在50~260 ℃的有机化合物质,其对人类的健康危害很大。沸石转轮是处理大风量、低含量VOCs的主要方法之一,主流沸石分子筛为MFI型ZSM-5分子筛。He等[100]考察了不同硅铝比的HZSM-5分子筛对同种单组分VOC的吸附性能影响,蜂窝陶瓷型吸附剂以HZSM-5分子筛为涂层,考察不同涂覆量、VOCs种类(乙醇、正己烷、丙酮、乙酸乙酯)的影响,发现有机物的极性越大,其饱和吸附量越大。沸石转轮浓缩-耦合催化燃烧技术能高效、经济地去除VOCs,包括废气吸附、废气脱附和催化燃烧3个工艺流程[101],可处理大风量、低浓度的有机废气,具有反应温度低、净化效率高、运行费用低等优点。

4.4 CO2吸附

CO2过量排放产生的温室效已在全球范围内引起气候变化,对CO2的捕集封存是粉煤灰基沸石的重要应用方向。Lee等[102]以粉煤灰为原料合成了Na-P1和Na-A型沸石分子筛,经Ca2 离子交换后,表现出较高的CO2吸附量。Margarita等[103-104]用粉煤灰合成了NaX沸石用于CO2吸附,粉煤灰原料中的Fe可部分转变为Fe2 /Fe3 ,原位吸附在沸石产物的酸性位上,沸石中Fe的形态决定了吸附性能,离子态的Fe可促进CO2的吸附。Gabriele等[105]以粉煤灰为原料合成了X型沸石用于CO2吸附,并研究了合成参数(NaOH/粉煤灰比、晶化时间和晶化温度)对CO2吸附性能的影响。当NaOH/粉煤灰比为1.4、晶化时间为7 h、晶化温度为80 ℃时CO2吸附量最佳(3.3 mol/kg)。Panek等[106]制备了MCM-41介孔硅粉煤灰基沸石分子筛,经聚乙烯亚胺(PEI)浸渍后用于CO2吸附,在负载60% PEI后,粉煤灰基沸石分子筛的CO2吸附量大于商用沸石,该吸附剂可快速达到90%的平衡吸附量。

5 结语与展望

粉煤灰是煤炭利用过程中产生的大宗工业固废,废置的粉煤灰造成严重的环境污染和资源浪费。对粉煤灰的无害化治理和高附加值资源化利用是我国目前的重大战略需求。粉煤灰制备沸石技术是有效的高附加值利用方式之一。粉煤灰含有大量As、Hg及Pb等重金属,成分复杂,研究粉煤灰合成沸石分子筛过程中重金属的迁移、提高粉煤灰基沸石分子筛的利用效率是未来研究的重要方向。制备高纯度、优异催化、吸附和离子交换性能的沸石分子筛材料,拓展其在环境保护、石油化工和医药等领域的应用可推动粉煤灰基沸石分子筛的工业化进程。

粉煤灰是结构稳定、成分复杂的微米级球状玻璃体,从粉煤灰中提取有价元素或以粉煤灰为原料合成沸石分子筛材料,首先要对粉煤灰进行活化,将其转化为易溶解的硅铝酸盐。相比于机械活化法,碱(盐)熔融和水热活化法具有较高的活化效率,但碱(盐)熔融法的碱耗量较大,且能耗大;水热活化碱耗量相对较少,且可循环使用,是更为适合的粉煤灰活化方法。粉煤灰合成沸石的过程(包括粉煤灰(或其活化产物)的溶解和目标沸石的成核与生长),均基于水热合成法。添加超声波或微波可促进粉煤灰(或其活化产物)的溶解,但会抑制沸石的成核过程;添加晶种可促进沸石的成核;转晶法有助于合成高纯度的沸石产物,并可拓展沸石产物的骨架类型和酸性位分布。目前粉煤灰基沸石的应用集中在CO2吸附封存、废水中重金属离子吸附脱除和NOx催化脱除等领域,拓展粉煤灰的骨架类型和在其他领域的应用是未来的研究重点。

[1] 中矿(北京)煤炭产业景气指数课题组. 2019—2020年中国煤炭产业经济形势研究报告 [J]. 中国煤炭,2020,46(3):5-12.

Chinese Mining(Beijing) Coal Industry Prosperity Index Research Group. 2019-2020 research report on the economic situation of Chinese coal industry [J]. Chinese Coal,2020,46(3):5-12.

[2] 张志华. NMR润滑油基础油结构的核磁共振表征[J] 石油炼制与化工,2019(2):50.

ZHANG Zhihua. NMR characterization of lube base oil structure [J] Petroleum Processing and Petrochemicals,2019(2):50.

[3] 冯培峰. 电厂粉煤灰高值化利用现状与最新进展 [J]. 中国资源综合利用,2020,38(11):100-104.

Feng Peifeng. Progress and development of high value utilization for coal fly ash from power plant [J]. China Resources Comprehensive Utilization,2020,38(11):100-104.

[4] 竹涛,韩一伟. 煤基固废高值化利用研究 [J]. 中国煤炭,2020,46(12):86-94.

ZHU Tao,HAN Yiwei. Research on high-value utilization of coal-based solid wast [J]. Chinese Coal,2020,46(12):86-94.

[5] 谭宏斌. 电厂粉煤灰制备莫来石晶须 [J]. 有色金属(冶炼部分),2010(3):25-41.

TAN Hongbin. Preparation of mullite whiskers by coal flyash [J]. Nonferrous Metals(Extractive Metallurgy),2010(3):25-41.

[6] 潘海斌,魏广鸿,赵志宏,等. 燃煤电厂粉煤灰综合利用途径适用性分析 [J]. 洁净煤技术,2020,26(1):262-267.

PAN Haibin,Wei Guanghong,ZHAO Zhihong,et al. Applicability analysis of comprehensive utilization of fly ash in coal-fired power plant [J] Clean Coal Technology,2020,26(1):262-267.

[7] 王彬宇,李莉,李菁,等. 用工业固体废料合成沸石分子筛的研究进展 [J]. 高等学校化学学报,2021,42(1):40-59.

Wang Binyu,LI Li,LI Jing,et al.,Recent progresses on the synthesis of zeolites from the industrial solid wastes [J]. Chemical Research in Chinese Universities,2021,42(1):40-59.

[8] BELVISO C. State-of-the-art applications of fly ash from coal and biomass:A focus on zeolite synthesis processes and issues [J]. Progress in Energy and Combustion Science,2018,65:109-135.

[9] BLISSETT R S,ROWSON N A. A review of the multi-component utilisation of coal fly ash [J]. Fuel,2012,97:1-23.

[10] LAXMIDHAR P,SUBHAKANTA D. Characterization and utilization of coal fly ash:A review [J]. Emerging Materials Research,2020,9(3):921-934.

[11] LI J,ZHUANG X,QUEROL X,et al. A review on the applications of coal combustion products in China [J]. International Geology Review,2018,60(5/6):671-716.

[12] LIEBERMAN R N,QUEROL X,MORENO N,et al. Physical and chemical changes in coal fly ash during acidic or neutral wastes treatment,and its effect on the fixation process [J]. Fuel,2016,184:69-80.

[13] 晋晓彤,鄢国平,纪娜,等. 粉煤灰合成分子筛的研究进展 [J]. 环境化学,2015,34(11):2025-2038.

JIN Xiaotong,YAN Guoping,JI Na,et al.Synthesis of zeolite from coal fly ash [J]. Environmental Chemistry,2015,34(11):2025-2038.

[14] 王恩. 煤粉炉粉煤灰与循环流化床粉煤灰矿物学性质比较 [J]. 洁净煤技术,2016,22(4):26-29.

WANG En. Mineralogy properties comparison of PC fly ash and CFB fly ash [J]. Clean Coal Technology,2016,22(4):26-29.

[15] 訾昌毓,李艳红,赵文波,等. 粉煤灰合成分子筛的研究 [J]. 硅酸盐通报,2018,37(12):4001-4006.

ZI Changyu,LI Yanhong,ZHAO Wenbo,et al.Synthesis of zeolites from coal fly ash [J]. Bulletin of the Chinese Ceramic Society,2018,37(12):4001-4006.

[16] GRELA A,HEBDA M, ACH M,et al. Thermal behavior and physical characteristics of synthetic zeolite from CFB-coal fly ash [J]. Microporous and Mesoporous Materials,2016,220:155-162.

ACH M,et al. Thermal behavior and physical characteristics of synthetic zeolite from CFB-coal fly ash [J]. Microporous and Mesoporous Materials,2016,220:155-162.

[17] YAO Z T,JI X S,SARKER P K,et al. A comprehensive review on the applications of coal fly ash [J]. Earth-Science Reviews,2015,141:105-121.

[18] 李涛.电厂粉煤灰物理化学特性研究及综合利用方案优化[J].节能技术,2003,21(6):25.

LI Tao.The study of physical and chemical properties of the coal ash of Harbin third power plant and synthesis use technology optimization [J]. Energy Conversion Technology,2003,21(6):25.

[19] 沈镭,刘立涛,王礼茂,等. 2050年中国能源消费的情景预测[J]. 自然资源学报,2015,30(3):361-373.

SHEN Lei,LIU Litao,WANG Limao,et al. 2050 energy consumption projection for China [J]. Journal of Natural Resources,2015,30(3):361-373.

[20] HONG J L X,MANEERUNG T,KOH S N,et al. Conversion of coal fly ash into zeolite materials:Synthesis and characterizations,process design,and its cost-benefit analysis [J]. Industrial & Engineering Chemistry Research,2017,56:11565-11574.

[21] HOWER J C. Petrographic examination of coal-combustion fly ash [J]. Int. J. Coal Geol.,2012,92:90-97.

[22] FRANUS W. Characterization of X-type zeolite prepared from coal fly ash [J]. Pol. J. Environ. Stud.,2012,21:337-343.

[23] BUKHARI S S,BEHIN J,KAZEMIAN H,et al. Conversion of coal fly ash to zeolite utilizing microwave and ultrasound energies:A review [J]. Fuel,2015,140:250-266.

[24] 陈彦广,徐婷婷,韩洪晶,等. 粉煤灰微波-水热合成法制备分子筛的研究进展 [J]. 化工进展,2015,34(8):2916-2924.

CHEN Yanguang,XU Tingting,HAN Hongjing,et al. Research development of zeolites preparation from coal fly ash by microwave-hydrothermal synthesis [J]. Chemical Industry and Engineering Processing,2015,34(8):2916-2924.

[25] TANG M,ZHOU C,ZHANG N,et al. Extraction of rare earth elements from coal fly ash by alkali fusion-acid leaching:Mechanism analysis [J]. International Journal of Coal Preparation and Utilization,2019,261:1-20.

[26] LI D,JIANG X,WANG S,et al. Research on the alkali-digestion properties of alumina and silicon dioxide during phase transformation roasting process [J]. Fuel Processing Technology,2019,191:223-231.

[27] 杨敬杰,孙红娟,彭同江,等. 硫酸/硫酸铵混合助剂焙烧粉煤灰提取Al2O3 [J]. 硅酸盐学报,2016,44(10):1538-1542.

YANG Jingjie,SUN Hongjuan,PENG Tongjiang,et al.Alumina extraction from coal fly ash with ammonium sulfate and sulfuric acid [J]. Journal of the Chinese Ceramic Society. 2016,44(10):1538-1542.

[28] FAN X L,LV S Q,XIA J l,et al. Extraction of Al and Ce from coal fly ash by biogenic Fe3 and H2SO4 [J]. Chemical Engineering Journal,2019,370:1407-1424.

[29] LI C C,QIAO X C. A new approach to prepare mesoporous silica using coal fly ash [J]. Chemical Engineering Journal,2016,302:388-394.

[30] LIU Z S,LI W K,HUANG C Y. Synthesis of mesoporous silica materials from municipal solid waste incinerator bottom ash [J]. Waste Management,2014,34(5):893-900.

[31] LI C C,QIAO X C,YU J G. Large surface area MCM-41 prepared from acid leaching residue of coal gasification slag [J]. Materials Letters,2016,167:246-249.

[32] BELVISO C. State-of-the-art applications of fly ash from coal and biomass:A focus on zeolite synthesis processes and issues [J]. Progress in Energy and Combustion Science,2018,65:109-135.

[33] HÖLLER H,WIRSCHING U. Zeolite formation from fly ash [J]. Fortschritte Mineral,1985,63:21-43.

[34] LEE Y R,SOE J T,ZHANG S Q,et al. Synthesis of nanoporous materials via recycling coal fly ash and other solid wastes:A mini review [J]. Chemical Engineering Journal,2017,317:821-843.

[35] MA L,FENG Y,ZHANG M,et al. Mechanism study on green high-efficiency hydrothermal activation of fly ash and its application prospect [J]. Journal of Cleaner Production,2020,275:122-977.

[36] ALDAHRI T,BEHIN J,KAZEMIAN H,et al. Synthesis of zeolite Na-P from coal fly ash by thermo-sonochemical treatment [J]. Fuel,2016,182:494-501.

[37] BELVISO C,GIANNOSSA L C,HUERTAS F J,et al. Synthesis of zeolites at low temperatures in fly ash-kaolinite mixtures [J]. Microporous and Mesoporous Materials,2015,212:35-47.

[38] MONDRAGON F,RINCON F,SIERRA L,et al. New perspectives for coal ash utilization:synthesis of zeolitic materials [J]. Fuel,1990,69(2):263-266.

[39] LIN C F,HSI H C. Resource recovery of waste fly ash:Synthesis of zeolite-like materials [J]. Environmental Science & Technology,1995,29(4):1109-1117.

[40] QUEROL X,UMANA J C,PLANA F,et al. Synthesis of zeolites from fly ash at pilot plant scale. Examples of potential applications [J]. Fuel,2001,80(6):857-865.

[41] INADA M,TSUJIMOTO H,EGUCHI Y,et al. Microwave-assisted zeolite synthesis from coal fly ash in hydrothermal process [J]. Fuel,2005,84(12/13):1482-1486.

[42] WOOLARD C D,STRONG J,ERASMUS C R. Evaluation of the use of modified coal ash as a potential sorbent for organic waste streams [J]. Applied Geochemistry,2003,18(8):1159-1164.

[43] OJUMU V T,PIETER W D P,LESLIE F P. Synthesis of zeolite A from coal fly ash using ultrasonic treatment-A replacement for fusion step [J]. Ultrasonics Sonochemistry,2016,31:342-349.

[44] BHANDARI R,VOLLI V,PURKAIT M K. Preparation and characterization of fly ash based mesoporous catalyst for transesterifica-tion of soybean oil [J]. Journal of Environmental Chemical Engineering,2015,3(2):906-914.

[45] HWANG Y,BAE S. Nitrate reduction on surface of Pd/Sn catalysts supported by coal fly ash-derived zeolites [J]. Journal of Hazardous Materials,2019,374:309-318.

[46] PARK M,CHOI C,LIM W,et al. Molten-salt method for the synthesis of zeolitic materials I. Zeolite formation in alkaline molten-salt system [J]. Microporous and Mesoporous Materials,2000,37(1/2):81-89.

[47] AMEH A,FATOBA O,MUSYOKA N,et al. Transformation of fly ash based nanosilica extract to BEA zeolite and its durability in hot liquid [J]. Microporous & Mesoporous Materials,2020,305:110332.

[48] YAN F,JIAN J,LI K,et al. Green synthesis of nanosilica from coal fly ash and its stabilizing effect on CaO sorbents for CO2 capture [J]. Environmental Science & Technology,2017,51:7606-7615.

[49] TANG M,ZHOU C,ZHANG N,et al. Extraction of rare earth elements from coal fly ash by alkali fusion-acid leaching:Mechanism analysis [J]. International Journal of Coal Preparation & Utilization,2019,312:1-20.

[50] NA K,JO C,KIM J,et al. Directing zeolite structures into hierarchically nanoporous architectures [J]. Science,2011,333:328-332.

[51] OLSBYE U,SVELLE S,BJ RGEN M,et al. Conversion of methanol to hydrocarbons:How zeolite cavity and pore size controls product selectivity [J]. Angewandte Chemie International Edition,2012,51(24):5810-5831.

[52] VAN SPEYBROECK V,HEMELSOET K,JOOS L,et al. Advances in theory and their application within the field of zeolite chemistry [J]. Chemical Society Reviews,2015,44(20):7044-7111.

[53] BORFECCHIA E,BEATO P,SVELLE S,et al. Cu-CHA-A model system for applied selective redox catalysis [J]. Chemical Society Reviews,2018,47(22):8097-8133.

[54] JHA B,SINGH D N. A review on synthesis,characterization and industrial applications of flyash zeolites [J]. Journal of Materials Education,2011,33(1/2):65-132.

[55] SHEN B,CHEN X,CAI D,et al. Atomic spatial and temporal imaging of local structures and light elements inside zeolite frameworks [J]. Advanced Materials,2019,32(4):1906103.

[56] REMY T,PETER S A,TENDELOO L V,et al. Adsorption and separation of CO2 on KFI zeolites:Effect of cation type and Si/Al ratio on equilibrium and kinetic properties [J]. Langmuir,2013,29(16):4998-5012.

[57] JANSSENS T,VENNESTRM P N R. A molecular dance to cleaner air [J]. Science,2017,357:866-867.

[58] PAOLUCCI C,KHURANA I,PAREKH A A,et al. Dynamic multinuclear sites formed by mobilized copper ions in NOx selective catalytic reduction [J]. Science,2017,357:898-903.

[59] LI Jinzhe,WEI Yingxu,CHEN Jingrun,et al. Cavity controls the selectivity:Insights of confinement effects on MTO reaction [J]. ACS Catalysis,2014,5(2):661-665.

[60] WANG B,MA L,HAN L,et al. Assembly-reassembly of coal fly ash into Cu-SSZ-13 zeolite for NH3-SCR of NO via interzeolite transformations [J]. Chemical Engineering Science:X,2021,10:100089.

[61] CARDOSO A M,HORN M B,FERRET L S,et al. Integrated synthesis of zeolites 4A and Na-P1 using coal fly ash for application in the formulation of detergents and swine wastewater treatment [J]. Journal of Hazardous Materials,2015,287:69-77.

[62] IQBAL A,SATTAR H,HAIDER R,et al. Synthesis and characterization of pure phase zeolite 4A from coal fly ash [J]. Journal of Cleaner Production,2019,219:258-267.

[63] PERON D V,ZHOLOBENKO V L,DE MELO J H S,et al. External surface phenomena in dealumination and desilication of large single crystals of ZSM-5 zeolite synthesized from a sustainable source [J]. Microporous and Mesoporous Materials,2019,286:57-64.

[64] YAN F,JIANG J,TIAN S,et al. A green and facile synthesis of ordered mesoporous nanosilica using coal fly ash [J]. ACS Sustainable Chemistry & Engineering,2016,4(9):4654-4661.

[65] GUO R,YAO W,MA H,et al. Two-step hydrothermal synthesis of nano-kaolinite from fly ash:Thermodynamics and mechanism [J]. Journal of Cleaner Production,2020,271:122567.

[66] GUAYA D,VALDERRAMA C,FARRAN A,et al. Simultaneous phosphate and ammonium removal from aqueous solution by a hydrated aluminum oxide modified natural zeolite [J]. Chemical Engineering Journal,2015,271:204-213.

[67] HUI K S,CHAO C Y H,KOT S C. Removal of mixed heavy metal ions in wastewater by zeolite 4A and residual products from recycled coal fly ash [J]. Journal of Hazardous Materials,2005,127(1):89-101.

[68] CHEN Y,CONG S,WANG Q,et al. Optimization of crystal growth of sub-micron ZSM-5 zeolite prepared by using Al(OH)3 extracted from fly ash as an aluminum source [J]. Journal of Hazardous Materials,2018,349:18-26.

[69] JHA B,SINGH D N. A three step process for purification of fly ash zeolites by hydrothermal treatment [J]. Applied Clay Science,2014,90(2):122-129.

[70] 孙霞,黄丽平,钱小军,等. 粉煤灰制备单相态分子筛及对溶液中Cu2 的吸附 [J]. 化工环保,2010,30(6):539-543.

SUN Xia,HUANG Liping,QIAN Xiaojun,et al.Preparation of Single-phase molecular sieve from fly ash and its adsorption of Cu2 in solution [J] Environmental Protection of Chemical Industry,2010,30(6):539-543.

[71] ZHAO X S,LU G Q,ZHU H Y. Effects of Ageing and seeding on the formation of zeolite Y from coal fly ash [J]. Journal of Porous Materials,1997,4(4):245-251.

[72] REN X,QU R,LIU S,et al. Synthesis of zeolites from coal fly ash for removal of harmful gaseous pollutants:A review [J]. Aerosol and Air Quality Research,2020,20(5):1127-1144.

[73] CHIGONDO M,GUYO U,SHUMBA M,et al. Synthesis and characterisation of zeolites from coal fly ash(CFA) [J]. Synthesis,2013,3:714-718.

[74] SHIGEMOTO N,HAYASHI H,MIYAURA K. Selective formation of Na-X zeolite from coal fly ash by fusion with sodium hydroxide prior to hydrothermal reaction [J]. Journal of Materials Science,1993,28(17):4781-4786.

[75] CHANG H L,SHIH W H. A general method for the conversion of fly ash into zeolites as ion exchangers for cesium [J]. Industrial & Engineering Chemistry Research 1998,37(1):71-78.

[76] RAYALU S,MESHRAM S U,HASAN M Z. Highly crystalline faujasitic zeolites from flyash [J]. Journal of Hazardous Materials,2000,77(1/3):123-131.

[77] BELVISO,CLAUDIA. Ultrasonic vs hydrothermal method:Different approaches to convert fly ash into zeolite. How they affect the stability of synthetic products over time [J]. Ultrasonics Sonochemistry,2017,943:9-14.

[78] QUEROL X,ALASTUEY A,L PEZ-SOLER A,et al. A fast method for recycling fly ash:Microwave-assisted zeolite synthesis [J]. Environmental Science and Technology,1997,31(9):2527-2533.

[79] TANAKA H,FUJIMOTO S,FUJII A,et al. Microwave assisted two-step process for rapid synthesis of NaA zeolite from coal fly ash [J]. Indengchemres,2008,47(1):226-230.

[80] 曾小强,叶亚平,王明文,等. 粉煤灰分步溶出硅铝制备纯沸石分子筛的研究 [J]. 硅酸盐通报,2007(1):19-24.

ZENG Xiaoqiang,YE Yaping,Wang Mingwen,et al.Synthesis of pure zeolites by dissolved silicon and aluminum from fly ash by stages [J] Bulletin of the Chinese Ceramic Society,2007(1):19-24.

[81] JON H,IKAWA N,OUMI Y,et al. An insight into the process involved in hydrothermal conversion of FAU to *BEA zeolite [J]. Chemistry of Materials,2008,20(12):4135-4141.

[82] VALERYIA,KASNERYK,MARIYA,et al. Expansion of the ADOR strategy for the synthesis of zeolites:The synthesis of IPC-12 from zeolite UOV [J]. Angewandte Chemie International Edition,2017,129(15):4388-4391.

[83] MURAOKAK,SADA Y,ATSUSHI S,et al. Tracking the rearrangement of atomic configurations during the conversion of FAU zeolite to CHA zeolite [J]. Chemical Science,2019,10:8533-8540.

[84] GOEL S,ZONES S I,IGLESIA E. Synthesis of zeolites via interzeolite transformations without organic structure-directing agents [J]. Chemistry of Materials,2015,27(6):2056-2066.

[85] ZHANG J,CHU Y,DENG F,et al. Evolution of D6R units in the interzeolite transformation from FAU,MFI or *BEA into AEI:Transfer or reassembly [J]. Inorganic Chemistry Frontiers,2020,7(11):2204-2211.

[86] TENDELOO L V,GOBECHIYA E,BREYNAERT E,et al. Alkaline cations directing the transformation of FAU zeolites into five different framework types [J]. Chemical Communications,2013,49:11737-11739.

[87] XU L,YUAN Y,HAN Q,et al. High yield synthesis of nanoscale high-silica ZSM-5 zeolites via interzeolite transformation with a new strategy [J]. Catalysis Science & Technology,2020,10:7904-7913.

[88] ZHANG J,CHU Y,LIU X,et al. Interzeolite transformation from FAU to CHA and MFI zeolites monitored by UV Raman spectroscopy [J]. Chinese Journal of Catalysis,2019,40(12):1854-1859.

[89] HONG M,YU L,WANG Y,et al. Heavy metal adsorption with zeolites:The role of hierarchical pore architecture [J]. Chemical Engineering Journal,2019,359:363-372.

[90] BOLISETTY S,PEYDAYESH M,MEZZENGA R. Sustainable technologies for water purification from heavy metals:Review and analysis [J]. Chemical Society Reviews,2019,48(2):463-487.

[91] 李茹霞,钟文彬,谢林华,等. 金属有机框架材料对Cr(Ⅵ)离子的吸附去除研究进展 [J]. 无机化学学报,2021,37(3):385-400.

LI Ruxia,ZHONG Wenbin,XIE Linhua,et al. Recent advances in adsorptive removal of Cr(VI) ions by metal organic frameworks [J] Chinese Journal of Inorganic Chemistry,2021,37(3):385-400.

[92] HE X,YAO B,XIA Y,et al. Coal fly ash derived zeolite for highly efficient removal of Ni2 inwaste water [J]. Powder Technology,2020,367:40-46.

[93] YANG T,HAN C,LIU H,et al. Synthesis of Na-X zeolite from low aluminum coal fly ash:Characterization and high efficient As(V) removal [J]. Advanced Powder Technology,2019,30(1):199-206.

[94] ZHANG Y,CHEN Y,KANG W,et al. Excellent adsorption of Zn(II) using NaP zeolite adsorbent synthesized from coal fly ash via stage treatment [J]. Journal of Cleaner Production,2020,258:120736.

[95] CARDOSO A M,PAPROCKI A,FERRET L S,et al. Synthesis of zeolite Na-P1 under mild conditions using Brazilian coal fly ash and its application in wastewater treatment [J]. Fuel,2015,139:59-67.

[96] WANG B,WANG M,HAN L,et al. Improved activity and SO2 resistance by Sm-modulated redox of MnCeSmTiOx mesoporous amorphous oxides for low-temperature NH3-SCR of NO [J]. ACS Catalysis,2020,10(16):9034-9045.

[97] WANG S,WU H. Environmental-benign utilisation of fly ash as low-cost adsorbents [J]. Journal of Hazardous Materials,2006,136(3):482-501.

[98] JIN X,JI N,SONG C,et al. Synthesis of CHA zeolite using low cost coal fly ash [J]. Procedia Engineering,2015,121:961-966.

[99] IZQUIERDO M T,JUAN R,CASBAS A I,et al. NOx removal in SCR process by Cu and Fe exchanged type Y zeolites synthesized from coal fly ash [J]. Energy Sources Part A-Recovery Utilization and Environmental Effects,2004,38(9):1183-1188.

[100] 赫帅. HZSM-5型分子筛吸附及钯基催化剂催化氧化脱除VOCs的研究 [D]. 徐州:中国矿业大学,2019.

HE Shuai. The study of VOCs adsorbed on HZSM-5 zeolites and oxidized by palladium-based catalysts [D] Xuzhou:China University of Mining and Technology 2019.

[101] 刘强,卢文新,刘佳,等. 分子筛材料在VOCs治理中的应用研究进展 [J]. 化肥设计,2020,58(3):5-8.

LIU Qiang,LU Wenxin,LIU Jia,et al. Research progress of molecular sieve materials application in VOCs treatment [J]. Chemical Fertilizer Design,2020,58(3):5-8.

[102] LEE K M,JO Y M. Synthesis of zeolite from waste fly ash for adsorption of CO2 [J]. Journal of Material Cycles & Waste Management,2010,12(3):212-219.

[103] BOYCHEVA S,ZGUREVA D,V CLAV KOV M,et al. Studies on non-modified and copper-modified coal ash zeolites as heterogeneous catalysts for VOCs oxidation [J]. Journal of Hazardous Materials,2019,361:374-382.

[104] POPOVA M,BOYCHEVA S,LAZAROVA H,et al. VOC oxidation and CO2 adsorption on dual adsorption/catalytic system based on fly ash zeolites [J]. Catalysis Today,2020,357:518-525.

[105] VERRECCHIA G,CAFIERO L,CAPRARIIS B,et al. Study of the parameters of zeolites synthesis from coal fly ash in order to optimize their CO2 adsorption [J]. Fuel,2020,276:118041.

[106] PANEK R,WDOWIN M,FRANUS W,et al. Fly ash-deri-ved MCM-41 as a low-cost silica support for polyethyleneimine in post-combustion CO2 capture [J]. Journal of CO2 Utilization,2017,22:81-90.

Recent progress of synthesis and application of fly ash based zeolite

HE Guangyao,WANG Bing,SHI Pengcheng,BAO Weiren,et al.Recent progress of synthesis and application of fly ash based zeolite[J].Clean Coal Technology,2021,27(3):48-60.