T91和Super304H钢材料高温腐蚀试验

0 引 言

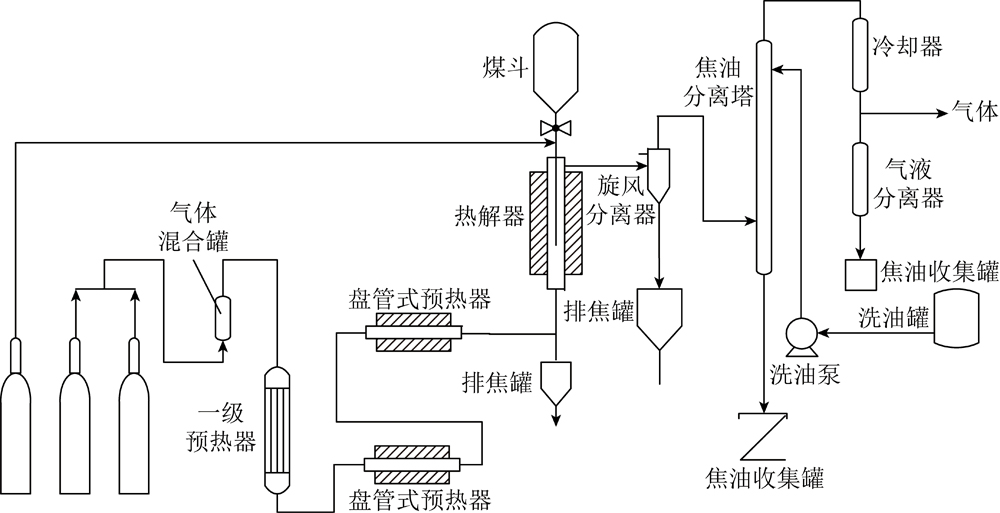

随着煤电行业全面实施超低排放,锅炉主燃区长期贫氧运行[1-2],高温腐蚀发生几率大幅增加,不同容量机组相继发生烟气侧高温腐蚀现象[3-5]。燃煤锅炉通常以硫腐蚀为主[6-8],腐蚀发生部位最常见的受热面为水冷壁[9-10],尤其是靠近分离燃尽风SOFA喷口的下方区域以及主燃烧器区域,最容易发生腐蚀[11]。这些区域水冷壁管外沉积物较厚,达4~5 mm,沉积物脱落时,水冷壁管会发生不同程度的腐蚀减薄现象[12] 。另外,过热器、再热器等受热面腐蚀也有报道,杨厚君等[13]分析了材质12Cr2MoWViTB(G102)的亚临界锅炉高温再热器的高温熔盐腐蚀现象;米子德等[14]探究了同样材质高温再热器的腐蚀情况,腐蚀与煤种变化直接相关;赵晴川等[15]研究了某亚临界锅炉屏式受热面高温腐蚀,认为煤中高硫和高碱金属含量对腐蚀有重要影响;蔡志强等[16] 分析了流化床高温再热器T91和Super304H组成的异种钢接头开裂失效原因。在高温腐蚀实验室研究方面,梁志远等[17]分析了超临界二氧化碳环境下耐热钢T91腐蚀行为机理,冯超等[18]研究了T91钢在5.0% NaCl中性盐雾中的腐蚀行为,刘武等[19]分析了Super304H钢在模拟烟气中的腐蚀行为。综上可知,T91和Super304作为典型的锅炉对流受热面用钢的研究报道较多,但在实验室开展腐蚀研究较少,尤其在同样腐蚀工况下,鲜见对腐蚀速率比较的报道。基于此,笔者针对2种耐热钢T91和Super304H,在实验室模拟烟气气氛下,比较分析了2种耐热钢的腐蚀特性差异,为锅炉耐热钢选型提供参考。

1 试 验

1.1 样品制备

试验材料T91和Super304H两种钢材均属于典型的对流受热面常用材料,主要成分见表1。2种钢材都富含金属Cr,但Super304H的Cr质量分数远大于T91,且Super304H中添加8.5%的Ni,而T91中Ni含量仅为0.3%。

表1 试验所用2种钢材的成分分析

Table 1 Composition analysis of two steel samples

首先采用线切割工艺从管材横截面上割取10 mm×10 mm×3 mm的腐蚀样品试片,用无水乙醇洗去表面油污渍。分别对试片各表面经0.075 0、0.025 0、0.012 5、0.007 5 mm(200、600、1 200、2 000目)砂纸打磨,将打磨后的试片浸泡于丙酮溶液经超声清洗1 h取出,用滤纸吸干后置于烘箱烘干,设定温度150 ℃,持续恒温烘干2 h后取出,置于洁净称量瓶中,将称量瓶置于干燥皿中储存备用。

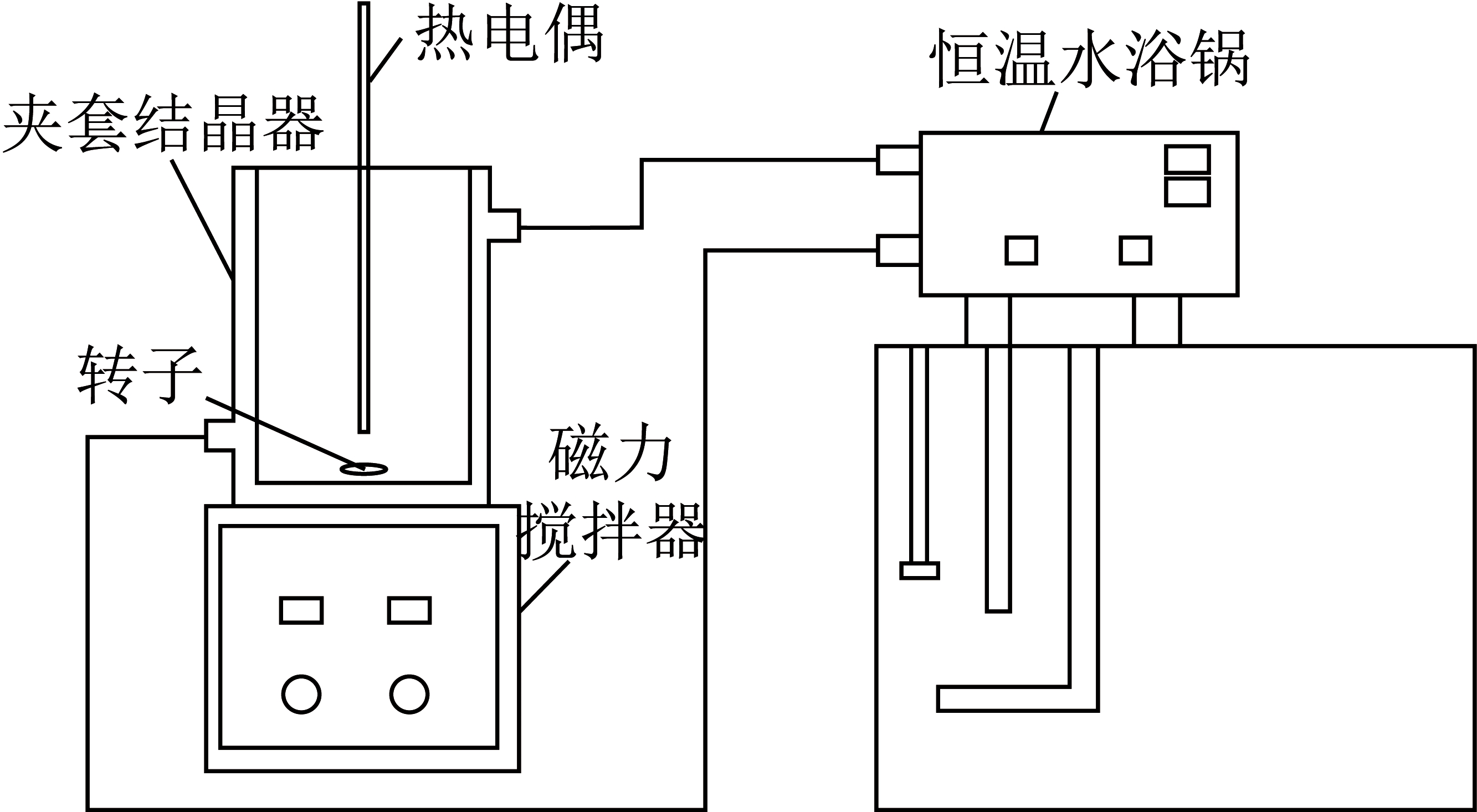

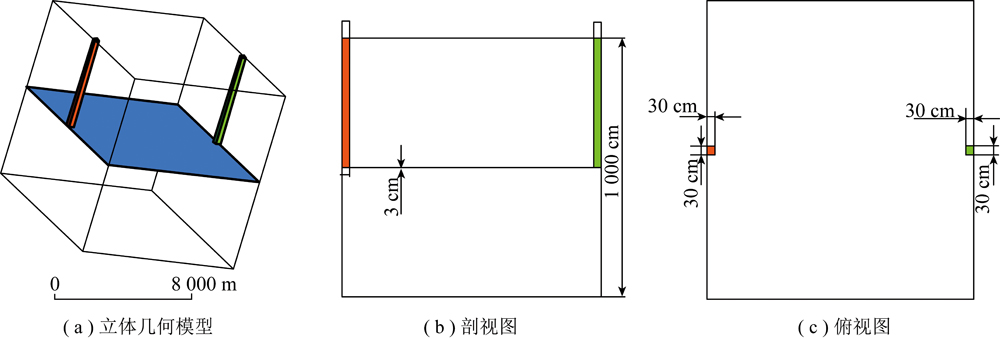

1.2 试验台设计

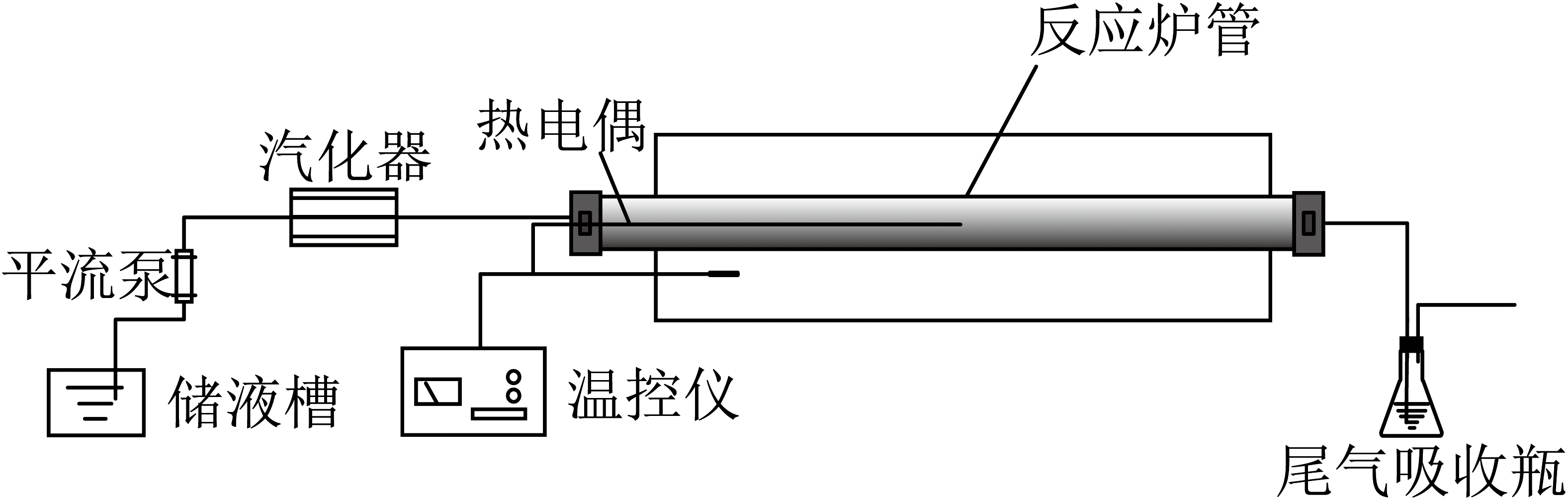

高温腐蚀试验台主要包括电加热管式炉,H2S、SO2等气源,待腐蚀钢材样品,尾气吸收瓶等装置,通过程序温控,设定目标温度650 ℃,如图1所示。腐蚀试验进行时,各路气体总流量控制在500 mL/min。每隔12 h,对样品进行一次称重。准备称重前,调节N2 流量为100 mL/min,并关闭其余气体流量,待试样自然冷却降至室温后分别对其称重,腐蚀试验完毕后,对样品进行XRD、SEM和EDS等表征分析。

图1 试验台整体布置示意

Fig.1 Schematic diagram of experimental platform

1.3 试验工况

试验配置了3种气氛进行试验,分别为空气、0.2% SO2、0.2% H2S,试验配置气氛具体工况见表2。

表2 试验配气工况

Table 2 Experimental conditions

1.4 抗氧化性能力评价

利用单位面积增重速率描述金属抗氧化性能力。根据GB/T 13303—1991《钢的抗氧化性能测定方法》定义:

(1)

式中,K为单位面积单位时间质量的变化,g/(m2·h);m1为试验后试样和坩埚的质量,g;m0为试验前试样和坩埚的质量,g;S0为试片原表面积,m2;t为测试时间,h。

GB/T 13303—1991《钢的抗氧化性能测定方法》对相应的抗氧化性级别做了详细定义,不同K值对应不同的抗氧化性,为便于比较,对该标准中的单位进行换算,具体见表3。

表3 抗氧化性级别评定

Table 3 Oxidation resistance rank standards

2 结果与讨论

2.1 气氛对2种耐热钢腐蚀增重的影响

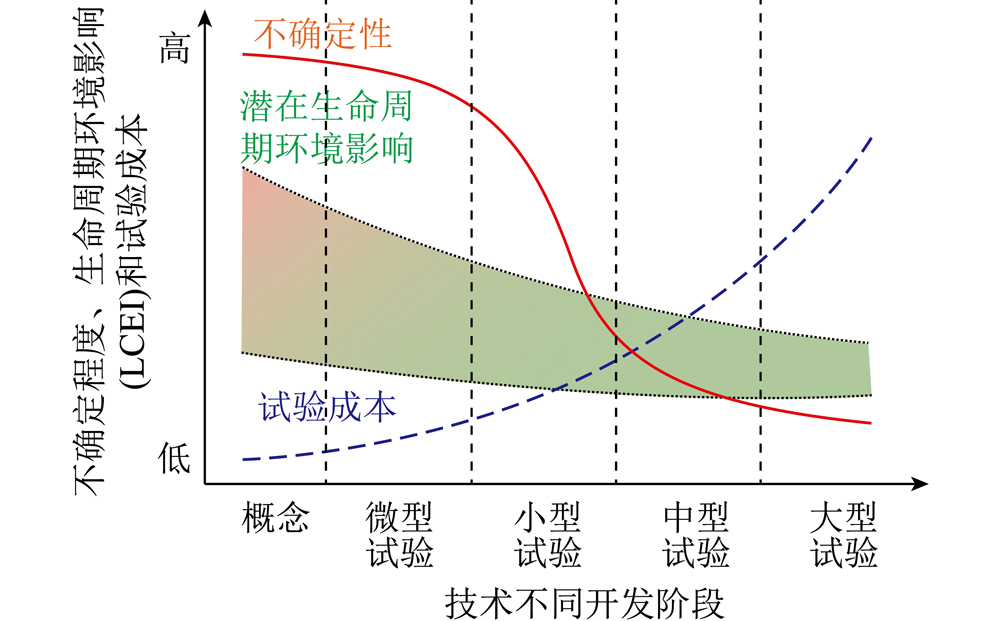

T91、Super304H在3种不同气氛下的腐蚀速率与时间的关系如图2所示。

图2 T91、Super304H在3种不同气氛下的腐蚀速率与时间的关系

Fig.2 Corrosion rate versus time of T91 and Super304H under three atmospheres

由图2可知,对T91钢而言,H2S气氛下腐蚀速率最大,且腐蚀速率在腐蚀试验初期最大,接近0.126 mg/(cm2·h),随腐蚀时间的增加,腐蚀速率逐渐减小,超过60 h后,腐蚀速率基本不变,为0.043 mg/(cm2·h),仅为腐蚀刚开始的1/3,属“抗氧化性”类别。在空气和SO2气氛下,腐蚀速率明显小于在H2S气氛下,最大值分别为0.035和0.018 mg/(cm2·h),属“抗氧化性”类别,并且腐蚀速率随腐蚀时间的变化规律与在H2S气氛下一致。Super304H钢在3种气氛下的腐蚀速率规律与T91钢类似,即H2S>空气>SO2,不同点在于H2S气氛下的腐蚀速率随时间增加变化不明显,几乎保持恒定,约0.022 mg/(cm2·h),属“抗氧化性”类别。Super304H钢在空气和SO2气氛下的腐蚀速率随时间变化逐步减小直至趋于恒定,这主要是由于Super304H钢在高温下,基体外表面形成的氧化膜起到了保护作用,阻止了腐蚀气体进一步向基体内部渗透,总体而言,Super304H钢腐蚀速率值很小,腐蚀性能非常好。

2.2 T91、Super304H抗腐蚀速率比较

T91和Super304H腐蚀速率如图3所示,可知3种气氛下,T91的腐蚀增重远大于Super304H。在空气气氛和SO2气氛下,T91与Super304H腐蚀速率比值均先增加后降低,这表明反应开始时,金属基体直接参与了氧化反应,但随着反应进行,氧化产物在金属基体外形成了保护膜阻止了氧化反应的继续进行,造成二者腐蚀速率比值降低。在H2S气氛下,二者腐蚀速率比值随时间单调下降,说明T91基体表面氧化膜可在很短时间内形成。就腐蚀速率比值来看,空气、SO2和H2S气氛下,腐蚀速率比值平均值分别为9.99、18.11、2.06,表明Super304H的抗腐蚀性能显著优于T91,主要是由于Super304H铁基体中富含合金元素Cr和Ni,其中Cr质量分数18%,远高于T91中9.5% Cr,Super304H中Ni质量分数8.5% 远高于T91中0.3%的Ni,均对抗腐蚀能力有贡献。合金元素Cr和Ni与氧形成致密的NiO、Cr2O3保护膜,能阻止腐蚀性气体进一步向基体内部扩散。根据金属的高温氧化理论[20] ,铁在570 ℃以上时形成FeO、Fe3O4和Fe2O3氧化膜。氧化膜具有保护作用的必要条件是氧化时生成的金属氧化膜的体积与生成这氧化膜所消耗的金属的体积之比(r)大于1,可用下式进行计算:

(2)

其中,M为金属氧化物的分子量;A为金属的原子量;n为金属氧化物中金属的原子价;ρm 为金属密度;ρOx为金属氧化物的密度。根据式(2),计算得到FeO、Cr2O3、NiO三种物质的r分别为1.77、1.99、1.52。

图3 3种不同气氛下T91和Super304H腐蚀速率比较

Fig.3 Comparison of corrosion rate of T91 and Super304H under three atmosphere

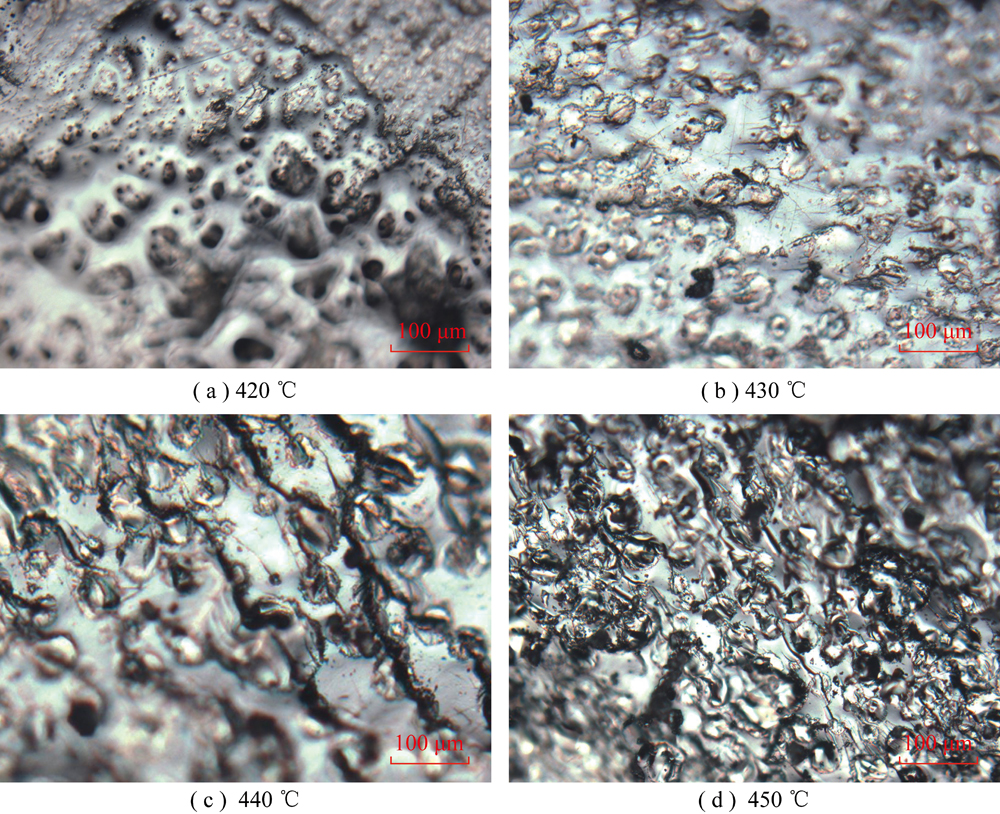

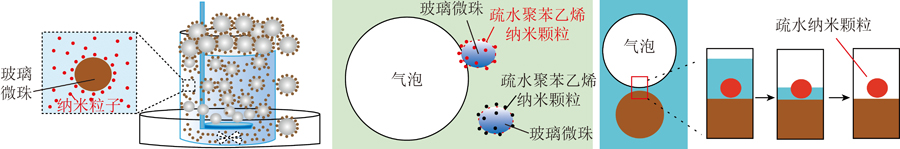

2.3 腐蚀产物形貌分析

3种腐蚀气氛下,2种钢的腐蚀行为差异较大,具体如图4所示。T91钢的基材表面均出现明显腐蚀后的波纹化痕迹,表面粗糙,尤其是在H2S气氛下,出现大量叶状腐蚀产物,且氧化膜之间裂纹变大,出现很多孔状结构,较大的针状腐蚀产物脱落趋势明显。Super304H钢表面相对平滑,未观察到大面积呈叶状的腐蚀产物;在空气和SO2气氛下,整体Super304H基材表面平整(中间的突起仍是基体,并非腐蚀物),在SO2气氛下,存在局部腐蚀的痕迹;在H2S气氛下,腐蚀较明显,腐蚀产物的表面有较多孔洞。

T91和Super304H钢在2种气氛下的EDS元素分析如图5所示。EDS分析表明,H2S能直接与金属反应,生成硫化物,但SO2气氛下钢材表面腐蚀物未发现硫化物,这表明硫并未参与金属的直接反应。文献[21]认为SO2体积分数需超过1%后才能直接与金属反应,SO2体积分数仅为0.2%,未达到参与反应的最小体积分数,因此,SO2气氛下,试样表面的腐蚀物是金属被氧气氧化的结果。

图4 T91和Super304H在3种气氛下的形貌

Fig.4 Morphology of the corroded T91 and Super304H under three atmospheres

图5 T91和Super304H钢在2种气氛下的EDS元素分析

Fig.5 EDS analysis of the corroded T91 and Super304H under two atmospheres

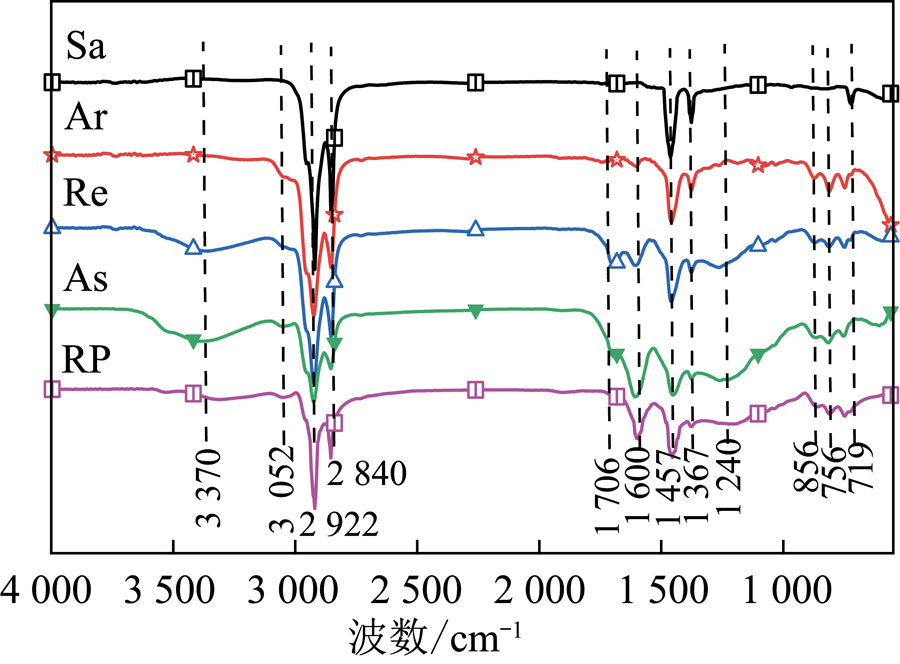

2.4 线扫描分析

由前述分析可知,2种钢材在H2S气氛中腐蚀速率最大,为观察到清晰的腐蚀层结构,选取H2S气氛腐蚀样品进行线扫描,如图6所示(样品用树脂包裹),对于T91样品,可观察到明显的内外2层腐蚀层,内层为Cr2O3,厚度为11.12 μm,外层为Fe2O3,厚度为23.68 μm,但腐蚀层内未观察到明显的硫元素,可能是腐蚀时间太短或H2S浓度太低所致,气相中硫未渗透到铁基体内部,仅在样品表面的形貌分析中观察到硫化物;对于Super304H样品,能观察到3层腐蚀层,NiO腐蚀层厚度为4.78 μm,Cr2O3腐蚀层厚度为4.78 μm,Fe2O3腐蚀层厚度为2.38 μm,合金元素Ni和Cr与氧结合的能力强于铁,因而腐蚀速率较慢,起到保护铁基体的作用。

图6 T91和Super304H钢在H2S气氛下腐蚀物线扫描分析

Fig.6 Line scan analysis of T91 and Super304H in H2S atmosphere

3 结 论

1)T91、Super304H两种钢抗氧化性较好,均属于抗氧化性类型,但Super304H由于高Cr,高Ni,抗腐蚀性能更优于T91。

2)在3种气氛下,T91钢与Super304H 钢的平均腐蚀速率之比最小为2,最大为18。H2S气氛下,2种耐热钢的腐蚀速率最快,空气次之,SO2气氛最慢。

3)对于高温SO2和H2S腐蚀,T91、Super304H两种钢腐蚀产物均呈分层结构,T91主要为Cr2O3和Fe2O3两层腐蚀层,Super304H主要为Cr2O3、NiO和Fe2O3三层腐蚀层。对腐蚀层厚度而言,Super304H仅为11.94 μm,而T91为34.8 μm,说明添加Cr、Ni元素对Super304H的抗氧化性能具有显著的增强效应。

[1] 陈建伟,周臣,黄帮飞,等.某燃煤电站锅炉过热器腐蚀原因分析及防治措施[J].东北电力技术,2019,40(8):26-28.

CHEN Jianwei,ZHOU Chen,HUANG Bangfei,et al. Causes analysis and preventive measures for corrosion of boiler superheater in coal-fired power station[J]. Northeast Electric Power Technology,2019,40(8):26-28.

[2] 郎丽萍,李亚坤.屏式过热器高温腐蚀机理探究及防治[J].锅炉制造,2019(4):8-10.

LANG Liping,LI Yakun. Study on high temperature corrosion mechanism of platen superheater and its prevention[J]. Boiler Manufacture,2019(4):8-10.

[3] HUSSAIN T,SYED A U,SIMMS N J . Trends in fireside corrosion damage to superheaters in air and oxy-firing of coal/biomass[J]. Fuel,2013,113(6):787-797.

[4] SRIVASTAVA S C,GODIWALLA K M,BANERJEE M K . Fuel ash corrosion of boiler and superheater tubes[J]. Journal of Materialsence,1997,32(4):835-849.

[5] NIELSEN H P,FRANDSEN F J,DAM-JOHANSEN K. Lab-scale investigations of high-temperature corrosion phenomena in straw-fired boilers[J]. Energy & Fuels,1999,13(6):1114-1121.

[6] YU X,Gong B,Gao Q,et al. Investigation of fireside corrosion at water-cooled wall from a coal-fired power plant in China[J]. Applied Thermal Engineering,2017,127:1164-1171.

[7] 周亚明,王新宇,黄亚继,等.1 000 MW超超临界双切圆燃煤锅炉炉膛燃烧特性模拟[J].洁净煤技术,2021,27(6):76-84.

ZHOU Yaming,WANG Xinyu,HUANG Yaji,et al. Numerical simulation on combustion of a 1 000 MW ultra supercritical dual tangential circle boiler[J]. Clean Coal Technology,2021,27(6):76-84.

[8] YU X,Song P,HE X,et al. Influence of the combined-effect of NaCl and Na2SO4 on the hot corrosion behaviour of aluminide coating on Ni-based alloys[J]. Journal of Alloys and Compounds,2019,790:228-239.

[9] 杨振,朱宣而,黄亚继,等.贴壁风与碗式配风协同解决高温腐蚀问题的模拟研究[J].洁净煤技术,2021,27(6):170-179.

YANG Zhen,ZHU Xuaner,HUANG Yaji,et al.High temperature corrosion problem of offset cyclone boiler solved by near-wall air and bowl-type air distribution[J].Clean Coal Technology,2021,27(6):170-179.

[10] 李月华,李强.电站锅炉水冷壁区域高温腐蚀及横向裂纹原因分析[J].锅炉技术,2017,48(6):46-49.

LI Yuehua,LI Qiang. High-temperature corrosion and transverse crack analysis of water wall tube at power station boiler[J]. Boiler Technology,2017,48(6):46-49.

[11] 王毅斌,张思聪,谭厚章,等.劣质烟煤低氮燃烧模式下水冷壁高温腐蚀与硫化物沉积形成分析[J].中国电机工程学报,2020,40(24):8058-8066.

WANG Yibin,ZHANG Sichong,TAN Houzhang,et al. Analysis of high temperature corrosion and sulfide deposits formed on water wall tubes under low NOx combustion mode for low qualities bituminous coal[J]. Proceedings of the CSEE,2020,40(24):8058-8066.

[12] 王毅斌,王萌,谭厚章,等.低氮燃烧模式下燃煤锅炉水冷壁沉积物与腐蚀层成分分析[J].洁净煤技术,2021,27(5):204-211.

WANG Yibin,WANG Meng,TAN Houzhang,et al. Compositional analyses of deposits and corrosive layer on water-walls inside a coal-fired boiler under low-NOx combustion mode[J]. Clean Coal Technology,2021,27(5):204-211.

[13] 杨厚君,李正刚,李朝志,等.DG1025锅炉高温再热器高温腐蚀原因分析与防止措施[J].中国电机工程学报,2003,23(11):212-214.

YANG Houjun,LI Zhenggang,LI Chaozhi,et al. Analysis on the causes of DG1025 boiler high temperature corrosion and the measures for it′s protection[J]. Proceedings of the CSEE,2003,23 (11):212-214.

[14] 米子德,梅东升,韩旭东.300 MW燃煤机组锅炉再热器高温腐蚀分析[J].华北电力技术,2006(2):7-9,13.

MI Zide,MEI Dongsheng,HAN Xudong. Analysis for high temperature corrosion of boiler reheater on a 300 MW coal-fired power plant[J]. North China Power Technology,2006(2):7-9,13.

[15] 赵晴川,周新刚,张徐东,等.低氮燃烧器改造对屏式受热面高温腐蚀的影响[J].山东电力技术,2016,43(4):46-50.

ZHAO Qingchuan,ZHOU Xingang,ZHANG Xudong,et al. Impacts of the low NOx burner retrofit on platen heating surface high temperature corrosion[J]. Shandong Electric Power,2016,43(4):46-50.

[16] 蔡志强,林雪松,邓永龙,等.高温再热器Super304H与T91异种钢接头开裂失效分析[J]. 四川电力技术,2016,39(2):88-90.

CAI Zhiqiang,LIN Xuesong,DENG Yonglong,et al. Cracking failure analysis of Super304H and T91 dissimilar steel joints of high temperature reheater[J]. Sichuan Electric Power Technology,2016,39(2):88-90.

[17] 梁志远,桂雍,王云刚,等.超临界二氧化碳环境下耐热钢T91腐蚀行为机理研究[J].热力发电,2020,49(10):73-78.

LIANG Zhiyuan,GUI Yong,WANG Yungang,et al. Corrosion behavior and mechanism of heat-resistant steel T91 in supercritical carbon dioxide environment[J]. Thermal Power Generation,2020,49(10):73-78.

[18] 冯超,彭碧草,谢亿,等.T91钢在5.0% NaCl中性盐雾中的腐蚀行为[J].腐蚀与防护,2018,39(6):431-436.

FENG Chao,PENG Bicao,XIE Yi,et al. The T91 corrosion behavior in 5.0% NaCl environment[J]. Corrosion Protection,2018,39(6):431-436.

[19] 刘武,鲁金涛,黄锦阳,等.Super304H钢在650 ℃模拟烟气侧腐蚀行为实验[J].热力发电,2018,47(6):78-84.

LIU Wu,LU Jintao,HUANG Jinyang,et al. Experment of the corrosion behavior of Super304H steel in simulative coal ash/flue gas environment at 650 ℃[J]. Thermal Power Generation,2018,47(6):78-84.

[20] 刘永辉,张佩芬. 金属腐蚀学原理[M]. 北京:航空工业出版社,1993.

[21] 刘柱晗,周屈兰,付家鹏,等. 一定拉应力条件下SO2对T91钢高温腐蚀影响的实验研究[J]. 动力工程学报,2018,38(1):80-84.

LIU Zhuhan,ZHOU Qulan,FU Jiapeng,et al. Effects of SO2 on high-temperature corrosion resistance of steel T91 under tension conditions[J]. Journal of Chinese Society of Power Engineering,2018,38(1):80-84.

High temperature corrosion experiment on T91 and Super304H steel materials

移动阅读

WANG Xiaolong,WANG Yongdong,LIU Junjie,et al.High temperature corrosion experiment on T91 and Super304H steel materials[J].Clean Coal Technology,2022,28(5):182-188.