生物降解疏水性VOCs现状分析

Situation analysis of biodegradation of hydrophobic volatile organic compounds

0 引 言

20世纪以来,空气中污染物不断增加[1],大气污染已成为最严重的问题之一[2-3]。挥发性有机物(VOCs)中,甲苯、乙苯、对二甲苯、异戊烷、乙酸乙酯、异丙醇、丙酮、正丙烷、正丁烷和苯乙烯是排放最多的物质[4],具有致癌性、诱变性、毒性,危害环境[2]。

挥发性有机化合物可分为亲水性和疏水性2类[5],疏水性VOCs通过各种工业活动进入大气环境[6],包括萜烯类、芳香族和脂肪族碳氢化合物等[7]。如苯、甲苯、乙苯和二甲苯(BTEX)被认为是最有害VOCs和疏水性VOCs的代表物质,广泛用于汽油生产和化石燃料的提取使用[8-9]。疏水性VOCs对人体健康和环境潜在危害巨大,需要高效和环境友好的处理技术[10]。

VOCs的降解技术分为化学法(如热氧化、催化氧化、臭氧化)、物理法(如冷凝、吸附、吸收)和生物法(使用生物滤池、生物滴滤器、生物洗涤器和其他生物反应器类型)[11]。虽然物理、化学法对VOCs去除效果显著,但存在成本高、能耗高、易产生二次污染等问题[12],难以满足我国节能减排和发展低碳经济的政策要求。相反,利用微生物新陈代谢过程对多组分的恶臭气体和VOCs进行降解[13],具有建设运行成本低、无二次污染、高效等优点,受到广泛关注[14-15]。研究表明,在处理低质量浓度VOCs(<3 g/m3)时,大部分生物反应器对恶臭气体和VOCs的去除效率超过90%,对某些污染物的去除率甚至可达99%[16]。虽然物理、化学法可有效去除VOCs,但在VOCs浓度较低时经济效益较差,且VOCs和恶臭气体浓度一般在低~中等[17]。生物法具有高效、低成本和环境友好等优势[18],是目前公认降解中低浓度VOCs的最佳方法。

目前生物降解疏水性VOCs主流工艺已中试,并取得了较好效果。LIANG等[19]使用中试规模生物滤池与喷雾塔结合,去除纺织印染废水处理厂排放的VOCs,结果表明该工艺对脂肪烃、芳香烃及卤代烃降解效率良好。YANG等[20]利用中试生物滴滤器处理化纤废水处理厂排放的VOCs,对甲醇、乙醇、乙酸甲酯、苯、二甲苯、环己烷、三氯乙烯的平均去除效率均高于90%。

利用生物反应器降解VOCs是一个复杂的过程[21],VOCs的生物利用度和传质是影响微生物降解污染物的关键因素[6]。然而,由于疏水性VOCs的低溶解性,导致其从气相到液相传质效率较低,限制了化合物对微生物的供给,导致去除效率较差[22-24]。因此提高疏水性VOCs在生物反应器的传质效率至关重要。

近年来,国内外学者对VOCs在生物反应器中的降解进行了大量研究,但对疏水性VOCs研究较少。笔者分析了影响疏水性VOCs降解率的因素,通过应用真菌、添加表面活性剂、利用亲水性化合物和新型生物反应器4方面改善疏水性VOCs的生物降解效率,以期指导疏水性VOCs在生物反应器中的去除。

1 疏水性VOCs在生物反应器中降解效率的影响因素

VOCs从气相到液/生物膜相的传质与亨利定律常数(Hc)有关[25]。亨利定律常数为VOCs在空气中的压力或浓度(Cg)与其在水中浓度(Cl)的比值,亨利定律系数越大,传质效率越低。因此提高疏水性VOCs的传质效率至关重要,对于亨利定律常数较高的VOCs,其在生物反应器中的降解能力有限[26]。疏水性VOCs降解效率主要受污染物传质、微生物群落及填料影响[27]。基于亨利定律常数的VOCs分类见表1,该常数可用于估算传质限制的强弱。

表1 基于亨利定律常数的VOCs分类[6,8,28-32]

Table 1 VOCs classification based on Henry′s law constant[6,8,28-32]

1.1 污染物的传质

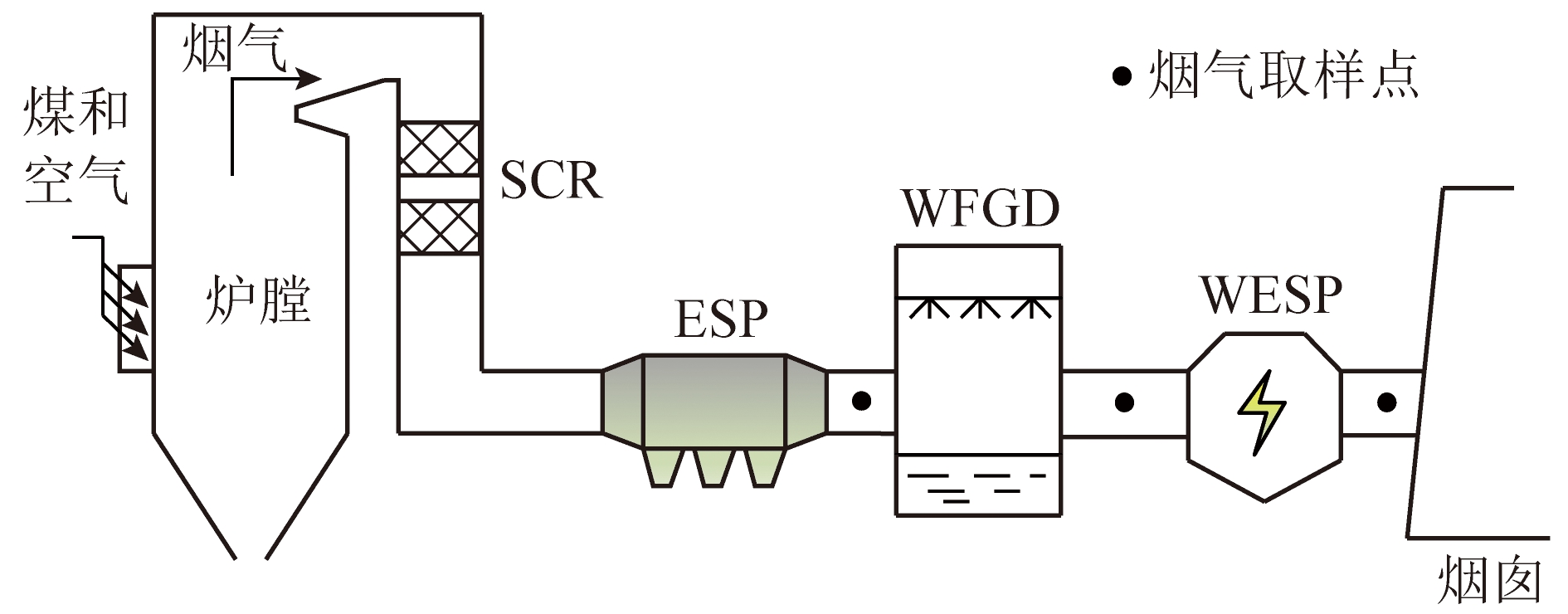

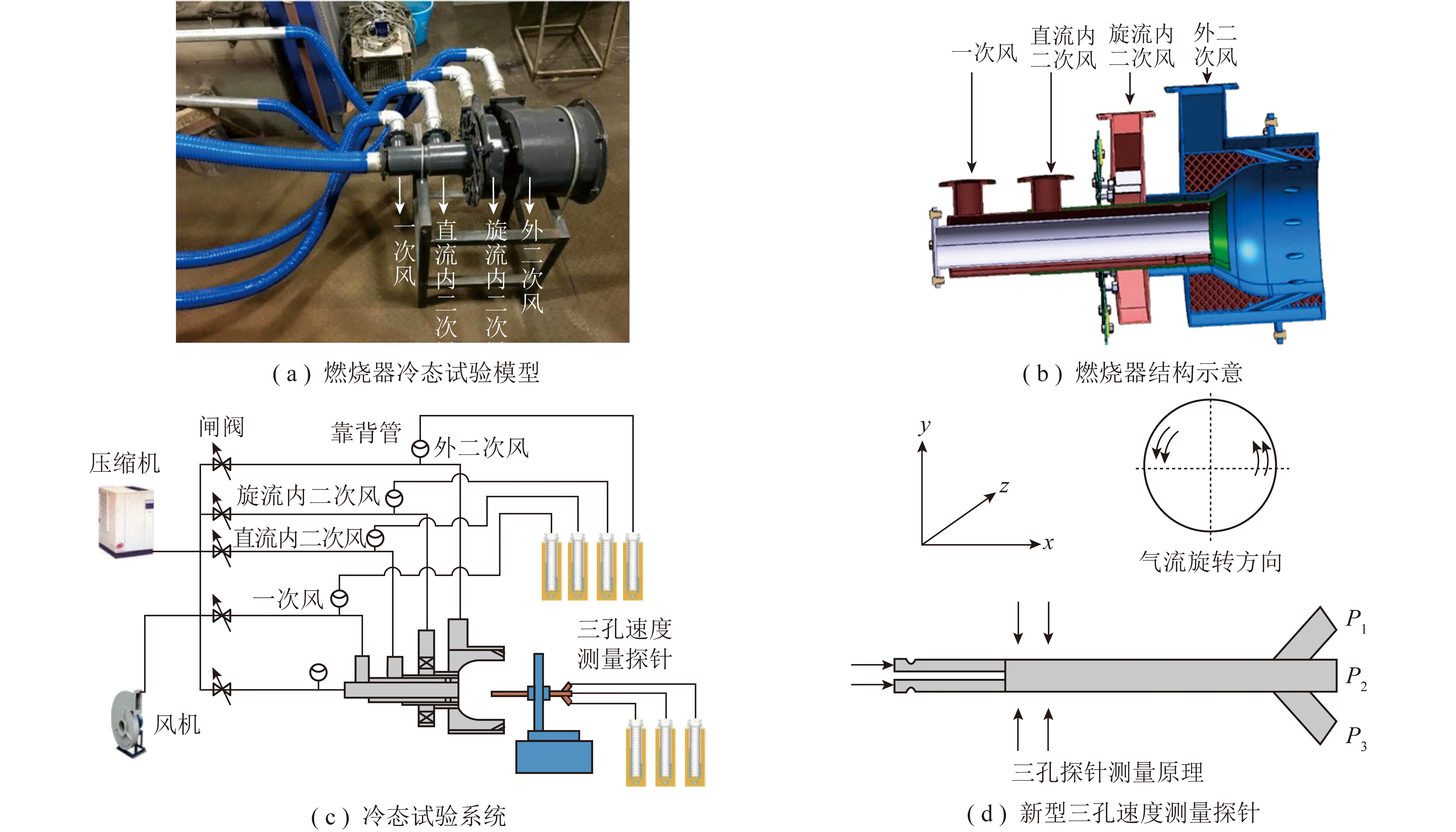

VOCs在生物反应器中的降解过程如图1所示。

图1 VOCs在生物反应器中的降解过程

Fig.1 Degradation process of VOCs in bioreactor

VOCs传质过程包括2个步骤:① 气态VOCs从气相到液相的吸收传质;② 通过液相与生物膜界面完成液相到生物膜的吸附传质。一般认为,传质在两相界面上处于平衡状态,其效率主要由传质系数、交换面积、排放浓度和流量决定[33]。适当的气体温度能提高气体水溶性,以达到最佳的微生物分解代谢速率。此外,非水相溶液也会改变VOCs在气相与液相界面之间的平衡,改变亨利系数,从而影响污染物在生物反应器中的传质过程。胡静涛等[34]在培养液中加入硅油,研究两相分配搅拌式反应器中硅油对正己烷传质的影响。结果表明,添加少量硅油就能极大增强液相对正己烷的吸收能力。这是因为VOCs在硅油中的溶解度高于在水中的溶解度,使亨利系数减小,增加疏水性VOCs向微生物传质的驱动力,从而显著提高疏水性VOCs的去除效率。同时,硅油还可降低污染物对微生物的抑制作用,增强气液传质效率[35]。

改善污染物在生物反应器中的传质效率尤为重要,未来疏水性VOCs在生物膜中的迁移和降解机理研究有待加强。

1.2 微生物群落

在生物反应器中,微生物附着在填料表面形成生物膜,以VOCs作为碳源和能源,通过新陈代谢作用使其降解。因此,微生物群落及其活性是生物反应器能有效去除VOCs的关键因素。生物膜一般由细菌、真菌、放线菌和藻类的混合物组成,在反应器中形成一个十分复杂的生态系统[36]。

生物膜是反应器的关键组成部分,可通过不同类型的接种来实现,主要接种方式有利用废水处理厂的活性污泥和筛选高效菌。利用废水处理厂的活性污泥接种具有操作方便、运营成本低的优势,但有致病菌存在的风险,会降低生物反应器运行效果。通过筛选高效菌接种能规避该风险,还能确保生物反应器具有较短的启动时间[37],因此微生物的筛选尤为重要,不同微生物能降解的目标污染物也存在差异。如红球菌能够代谢甲苯、除草剂等化合物,Pseudomonas mendocina对正己烷具有高效的降解能力[38-39]。

利用细菌降解VOCs研究较多,以细菌为主的生物反应器对VOCs降解效果良好。如混合废气(丙酮、甲基乙基酮和苯)质量浓度低于3 000 mg/m3时,芽孢杆菌对其去除率可达98%以上[28]。但随着环境变化,如水分减少、pH降低,接种的细菌对VOCs的降解效率下降。而真菌对环境条件的变化耐受力较强。

1.3 填料

填料为反应器中微生物形成生物膜的附着载体,同时也是气液传输的介质,主要功能是促进污染物与微生物接触[40]。因此,填料会影响污染物在生物反应器中的传质及降解效率。理想的填料应具备以下特点[41]:① 比表面积大,能附着更多的微生物,加速生物膜的形成,提高污染物的降解效率;② 较高的孔隙率,有利于气相分布,防止填料堵塞;③ 高持水率,有利于生物膜保持一定湿度,提高微生物的代谢活性及反应器的降解效率;④ 机械强度良好,能维持填料的孔隙率,使用寿命更长;⑤ 填料无味;⑥ 填料廉价易得,降低运营成本。

填料主要分为有机物质和无机物质两大类。无机填料包括活性炭、陶瓷、拉西环、聚氨酯泡沫等;有机填料有泥碳、堆肥、甘蔗渣、花生壳、木屑等。有机填料可以提供微生物生长所需的部分营养成分,但机械强度低。无机填料具有较高的机械强度,但需额外添加营养物质。因此实际应用中常将有机和无机填料混合,使其性能更加完善[42]。ZHANG等[29]将聚二甲基硅氧烷(PDMS)与泡沫陶瓷复合后作为填料处理不同浓度的甲苯。结果表明,进气质量浓度为200~1 200 mg/m3时,甲苯在生物滴滤器中的去除率可达到100%。这是由于PDMS/泡沫陶瓷复合填料的高孔隙率能使微生物快速稳定地附着,增大气液接触面积,降低BTF的传质阻力。进气负荷较高时,一些难以降解的污染物可能对微生物代谢产生抑制作用,导致污染物降解效率显著下降,甲苯进气负荷对生物滤池消除能力的影响如图2所示。KUMAR等[43]将堆肥和活性炭的混合物作为填料,研究生物滤池对甲苯的降解性能。进气负荷高达6 000 g/(m3·h)时,甲苯去除率达到90%。气体浓度和流速较高时,生物过滤器中堆肥易压实和干燥,但颗粒活性炭为过滤床提供了更多的结构支撑,促进了污染物吸附,表明混合填料可以吸附高负荷甲苯,对甲苯的高效降解起关键作用。

图2 甲苯进气负荷对生物滤池消除能力的影响[43]

Fig.2 Effect of toluene loading rate on the

elimination capacity of the biofilter[43]

在生物反应器中,填料会影响微生物的附着和生物膜的形成,从而直接影响VOCs的降解效率。选择和开发合适的填料能为微生物群落的生长、代谢以及生物膜的发育提供良好的生态环境,为反应器长期稳定运行提供保障。

2 疏水性VOCs生物降解效率改进方法

2.1 真菌生物

微生物是VOCs和恶臭气体生物降解的催化剂[44],处理VOCs的微生物通常是细菌,但以细菌为基础的生物反应器在低水分、低pH和有限的营养浓度下,去除效率下降[45]。疏水性VOCs的低溶解性,限制了其在生物降解过程的传质和反应速率[7]。而真菌能在低湿度、低pH的环境中生存,对污染物有较好的降解能力[46]。与细菌相比,真菌具有气生菌丝的优势,气生菌丝在气相中能形成比细菌生物膜更大的表面积,有助于疏水性VOCs的吸收。疏水蛋白广泛存在于真菌气生菌丝,WOSTEN[47]阐述了疏水蛋白在真菌生长中的作用及其对真菌气生菌丝疏水性的影响,表明水的存在阻碍了气生菌丝的发育。丝状真菌在疏水-亲水界面(如气-水界面)分泌疏水蛋白,形成两亲涂层,降低表面张力,使菌丝突破水气界面。这种机制可以使真菌直接从气相吸收污染物,避免了液体中的传质阻力,因此在疏水性VOCs去除中应用更广泛[48]。部分真菌降解疏水性VOCs实例见表2。

表2 部分可降解VOCs的真菌

Table 2 Fungi that partially degrade VOCs

BARBARA等[56]发现Cladophialophora真菌能有效降解甲苯,并将其完全降解为CO2。MORALES等[57]处理疏水性混合废气(甲苯、甲醛、苯甲酚)时,在生物滤池上接种真菌Rhodococcus erythropolis和Fusarium solani。结果表明,在较大污染物进气负荷下,反应器对甲苯、甲醛和苯甲酚的去除率均较高,表明接种真菌的生物滤池能有效降解甲苯、甲醛和苯甲酚。LI等[58]利用生物滴滤池(BTF)降解苯乙烯,发现湿度7.7%,pH为2时,真菌Candida palmioleophila占主导地位,苯乙烯的去除率最高,达到95%。表明以真菌为主的BTF在低pH和低湿度条件下表现出良好的处理性能,具有降解苯乙烯的潜力。研究表明,采用混合菌种去除疏水性VOCs效果更好。CHENG等[59]对比了真菌生物滤池、细菌生物滤池和混合菌种生物滤池对甲苯的去除效率,结果表明混合菌种生物滤池对甲苯的去除率高20%。

微生物可以完全降解多种污染物。真菌的应用可以很大程度上改善疏水性VOCs在生物反应器中的降解效率,为更好地探索真菌与生物反应器降解效率之间的关系,有必要分析真菌群落结构。

2.2 表面活性剂

由于疏水性VOCs从气相介质传递到液相介质的效率较低,很大程度上限制了微生物的降解率,因此提高疏水性VOCs的传质效率至关重要。表面活性剂分为化学表面活性剂、生物表面活性剂,也可分为阴离子、阳离子、非离子和双电荷表面活性剂[35],可通过改变液-液或液-气界面上的分子力来降低表面张力[6]。研究表明,表面活性剂将疏水有机污染物分配到表面活性剂胶束的疏水核心以增加其溶解度,可以提高疏水性VOCs去除性能[60-61],表面活性剂促进污染物传质的过程如图3所示,其中卡车代表促进传质因素,如添加表面活性剂。部分表面活性剂在生物反应器中的应用见表3。

图3 生物降解过程中的传质和表面活性剂的作用[17]

Fig.3 Mass transfer and the function of

surfactants during the biodegradation[17]

表3 部分表面活性剂在生物反应器中的应用

Table 3 Some examples of surfactants used in bioreactor

SHOOKA等[62]研究了2种非离子表面活性剂(brij35和Tween 20)以及皂苷在自然和酸性微环境下对邻二甲苯(BX)降解效果。结果表明,添加brij35和皂苷增加了BX的去除效果。YANG等[60]研究了SDS、CTAB、Triton X-100、Tween 80四种表面活性剂对正己烷亨利系数的影响。结果表明,4种表面活性剂对正己烷均有较强的增溶能力,正己烷的亨利系数显著降低,有助于正己烷的降解。

与化学表面活性剂相比,生物表面活性剂具有环保、毒性小、可生物降解等优势,如皂苷、鼠李糖脂等皂苷,是一种具有代表性的生物表面活性剂[64],QIAN等[61]对比了加入皂苷的生物滤池(BTF1)与不加皂苷的生物滤池(BTF2)对乙苯的去除效果。结果表明,乙苯质量浓度为750~2 300 mg/m3,皂苷最佳质量浓度在40 mg/L时,BTF1的降解率从92.1% 降至60.8%,而BTF2的降解率从69.4%降至44.2%。与BTF2相比,添加了皂苷的BTF1获得了更高的去除率,说明添加皂苷可以促进BTF1对乙苯的生物降解。

氯化挥发性有机化合物(CleVOCs)是一种难降解、易挥发的污染物,属于疏水性VOCs。CleVOCs对人体危害极大,且CleVOCs破坏臭氧层、导致光化学烟雾和二次PM2.5的形成[65-66]。因此,提高CleVOCs生物降解效率十分重要。鼠李糖脂是一类重要的生物表面活性剂,能增强微生物活性和VOCs的溶解度[67-69]。SUN等[63]在2个相同实验室规模的生物滴滤池(命名为BTF1和BTF2)中考察鼠李糖脂和Mg(II)对1,3-二氯苯去除的影响。结果表明,鼠李糖脂能有效提高1,3-二氯苯在介质中的溶解度。2种添加剂均能显著促进氧转移,在适宜浓度下有利于微生物生长。

添加表面活性剂不仅可以显著提高疏水性VOCs在生物反应器中的降解效率,还会影响微生物的生长。然而,表面活性剂影响微生物生长过程机理尚不明确,应加强相关研究。

2.3 亲水性化合物

生物反应器降解VOCs的效果主要取决于VOCs在生物膜层中的溶解度及其亨利定律常数[70],因此,提高疏水性VOCs的溶解度和传质效率尤为重要。有学者将亲水性污染物和疏水性VOCs混合,使不同VOCs产生协同作用[71],从而提高疏水性VOCs的溶解度和生物利用度。CHENG等[72]以4-甲基-2-戊酮(亲水性VOC)为研究对象,探讨其对生物滴滤器(BTFs)去除正己烷的积极影响。结果表明,4-甲基-2-戊酮的存在促进了BTFs中正己烷的去除率。DIXIT等[73]研究了正丙醇和甲苯混合物在生物过滤器中的去除效果。结果表明2种污染物处理效果较好;同时处理时,低浓度正丙醇对甲苯的去除效果显著,这种增强机制尚不明确;而高浓度正丙醇(>1 g/m3)对甲苯去除有负面影响,可能是由于生物动力学竞争。图4显示了高负荷丙醇(>50 g/(m3·h))对甲苯的去除效果。L PEZ等[30]得到了同样的结论,研究BTFs降解甲醇、α-蒎烯、H2S混合气体时发现,亲水性化合物甲醇对α-蒎烯的降解产生拮抗抑制,而甲醇的去除不受α-蒎烯的影响。

PEZ等[30]得到了同样的结论,研究BTFs降解甲醇、α-蒎烯、H2S混合气体时发现,亲水性化合物甲醇对α-蒎烯的降解产生拮抗抑制,而甲醇的去除不受α-蒎烯的影响。

图4 丙醇负荷对甲苯脱除的影响[73]

Fig.4 Effect of propanol loading on toluene removal[73]

由此可见,不同特性VOCs混合处理时存在相互的拮抗、协同、交互作用[71],其相互作用是疏水性VOCs生物修复的关键。在实际工程中,VOCs处理并不是针对某个单一化合物,而是不同特性的混合气体。在处理混合气体时,亲水性化合物的存在会影响目标污染物的降解效率,探索其机理十分必要。

2.4 新型生物反应器

尽管现有生物处理技术能够降解大部分疏水性VOCs,但传统生物反应器对疏水性VOCs的降解效率较低。因此,有学者提出了新型生物反应器。如两相分配生物反应器(TPPBs),通常加入与水不混溶的非水相液体(NAPL)可以增强疏水性VOCs的传质[74-75],在去除疏水性VOCs方面优于常规生物反应器[21],其工作原理如图5所示。VOLCKAERT等[31]使用硅油作为NAPL,利用TPPBs去除废水中的二甲硫醚(DMS)、正己烷和甲苯。结果表明,TPPBs对疏水性VOCs和亲水性化合物有较好的去除效果,表明TPPBs是一种有效且可靠的新型生物反应器。目前,大多数对TPPBs的研究都集中在气相到非水相/水相的传质,而忽视了非水相到生物相和水相到生物相的传质。CHEN等[77]在硅油中加入壳聚糖及Pseudomonas mendocina NX-1,以提高正己烷的传质。结果表明,壳聚糖不仅明显提高了细胞表面的疏水性,还可能使疏水细胞在水相中直接捕获和降解正己烷,从而明显改善了气相到生物相的传质,TPPB1(含壳聚糖)对正己烷的降解效率比TPPB2(不含壳聚糖)提高约20%。

图5 TPPB(两相分配生物器)工作原理[76]

Fig.5 Working principle of TPPB[76]

膜生物反应器(MBR)是一种替代传统生物反应器处理废气的新型工艺,其降解原理如图6所示。MBR提供了一个较大的气液界面和良好的传质条件,适合去除空气和废气中的疏水污染物[14]。在MBR中,两相(气相和液相)被膜分离。气体污染物通过膜的扩散,被附着在另一侧的微生物降解。膜的高分子材料被视为传质载体,从而改善了难溶性化合物的传质。MORRAL等[32]采用工业毛细微孔聚丙烯膜,在MBR中去除甲苯、异辛烷和己烷。结果表明,该微孔膜能有效去除不同的疏水性VOCs。其中对甲苯的去除效率最高,可达80%~99%。ZHAO等[78]研究了中空纤维膜生物反应器(HFMB)对甲苯和正己烷的去除效果。结果表明中空纤维膜生物反应器可有效降解甲苯和正己烷的混合物。

图6 膜生物反应器(MBR)工作原理[28]

Fig.6 Working principle of MBR[28]

生物电化学系统(BESs)是目前公认的一种新颖且有前景的环境修复技术,可将有机物转化为电能,已被用于去除气态VOCs[79]。微生物燃料电池(MFC)和微生物电解电池(MEC)是2种典型的BES[21]。CHEN等[80]建立了一种将紫外辅助光电化学催化与微生物燃料电池(UV-assisted PEC-MFC)相结合的新型体系,用于促进乙酸乙酯或甲苯的脱除和同时发电。在该系统中,甲苯的去除效率达90%以上。AGNESE等[81]采用MEC对阴极处的三氯乙烯、氯乙烯等含氯VOCs进行脱氯处理,结果表明,约96%的初始污染物得到有效降解。因此,新型生物反应器应成为未来主要研究方向。需要进一步研究新型生物反应器的基本机理和最佳运行条件,构建稳定的生物系统,提高疏水性VOCs的降解效率。

3 结语与展望

挥发性有机化合物(VOCs)会对生态环境和人体健康造成危害。生物反应器的低成本、高效益和环境友好特性,使其在废气处理领域得到广泛应用。相比于物理、化学法,生物法对VOCs去除有独特优势。生物法的主要缺点是对疏水性VOCs的传质效率低,未来应从以下方面进一步研究:

1)真菌生物可有效改善疏水性VOCs在生物反应器中的降解效率,但目前能降解疏水性VOCs的真菌生物较少,且真菌生物生长周期较长,导致降解速率降低。未来应致力于开发更多能降解疏水性有机化合物的真菌,通过控制操作参数加快真菌的生长速率。

2)大多数生物处理研究集中在表面活性剂对VOCs性能去除的影响。未来需探索表面活性剂对生物反应器中VOCs去除的影响机理。生物表面活性剂是更环保、毒性更小、更易生物降解的天然化合物,未来应加大对生物表面活性剂的研究,开发更多此类表面活性剂。

3)亲水性化合物也可以提高疏水性VOCs的去除率,但作用机制有待进一步研究。在实际处理疏水性VOCs时,并不是处理某种单一污染物,而是混合气体,探索其中的精准机制十分必要。

4)氯化挥发性有机化合物(CleVOCs)疏水性较强,降解过程中副产物有毒,对人体和环境危害很大,未来应加强对CleVOCs的研究。

5)一些新型生物反应器也用于降解疏水性VOCs,虽然新型反应器的降解效率明显提升,但整个降解过程的成本能耗都较高,需加强相关研究。

[1] DELHOMENIE M,HEITZ M. Biofiltration of air:A review[J]. Critical Reviews in Biotechnology,2005,25(2):53-72.

[2] ARRIAGA Sonia,REVAH Sergio. Improving hexane removal by enhancing fungal development in a microbial consortium biofilter.[J]. Biotechnology and Bioengineering,2005,90(1):107-115.

[3] ARRIAGA Sonia,REVAH Sergio. Removal of n-hexane by Fusarium solani with a gas-phase biofilter[J]. Journal of Industrial Microbiology & Biotechnology,2005,32(11/12):548-553.

[4] LIANG Xiaoming,SUN Xibo,XU Jiantie. Improved emissions inventory and VOCs speciation for industrial OFP estimation in China[J].Science of the Total Environment,2020,745:140838.

[5] VERGARA-FEMNANDEZ Alberto,REVAH Sergio,MORENO-CASAS Patricio,et al.Biofiltration of volatile organic compounds using fungi and its conceptual and mathematical modeling[J].Biotechnology Advances,2018,36(4):1079-1093.

[6] CHENG Yan,HE Huijun,YANG Chunping.Challenges and soluti-

ons for biofiltration of hydrophobic volatile organic compounds[J]. Biotechnology Advances,2016,34(6):1091-1102.

[7] RAQUEL Lebrero,ELISA Rodríguez,JOSÉ M Estrada,et al. Odor abatement in biotrickling filters:Effect of the EBRT on methyl mercaptan and hydrophobic VOCs removal[J]. Bioresource Technology,2012,109:38-45.

[8] BOLDEN Ashley L,KWIATKOWSKI Carol F,COLBORN Theo. New look at BTEX:Are ambient levels a problem?[J]. Environmental Science & Technology,2015,49(9):5261-5276.

[9] MOHAMMED A. HASHEMY El,HAZIM M. Characterization of BTEX group of VOCs and inhalation risks in indoor microenvironments at small enterprises[J]. Science of the Total Environment,2018,645:974-983.

[10] J RATE Repeckiene,JURGITA

RATE Repeckiene,JURGITA  vediene,ALGIMANTAS Paškevic-

vediene,ALGIMANTAS Paškevic-

ius,et al. Succession of microorganisms in a plate-type air treatment biofilter during filtration of various volatile compounds[J]. Environmental Technology,2015,36(7):881-889.

[11] KENNES C,VEIGA M C. Technologies for the abatement of odours and volatile organic and inorganic compounds[J]. Chemical Engineering Transactions (CET Journal),2010,23:1-6.

[12] ALIREZA Haghighat Mamaghani,FARIBORZ Haghighat,LEE Chang-seo. Photocatalytic oxidation technology for indoor environment air purification:The state-of-the-art[J]. Applied Catalysis B:Environmental,2017,203:247-269.

[13] 苑宏英.生物净化挥发性有机化合物(VOCs)的研究进展[J].安全与环境学报,2004(S1):1-4.

YUAN Hongying.Study on biological treatment technology of volatile organic compounds(VOCs) and its advance[J].Journal of Safety and Environment,2004(S1):1-4.

[14] KRZYSZTOF Barbusinski,KATARZYNA Kalemba,DAMIAN Kas-perczyk,et al. Biological methods for odor treament:A review[J]. Journal of Cleaner Production,2017,152:223-241.

[15] YANG Chunping,YU Guanlong,ZENG Guangming,et al. Perfor-

mance of biotrickling filters packed with structured or cubic polyurethane sponges for VOC removal[J].Journal of Environmental Sciences,2011,23(8):1325-1333.

[16] VAN GROENESTIJN J W,KRAAKMAN N J R. Recent developments in biological waste gas purification in Europe[J]. Chemical Engineering Journal,2005,113(2/3):85-91.

[17] WU Hao,YAN Huayu,QUAN Yue,et al. Recent progress and perspectives in biotrickling filters for VOCs and odorous gases treatment[J]. Journal of Environmental Management,2018,222:409-419.

[18] HEE Wook-ryu,CHO Kyung-suk,LEE Tae-ho. Reduction of ammonia and volatile organic compounds from food waste-composting facilities using a novel anti-clogging biofilter system[J]. Bioresource Technology,2011,102(7):4654-4660.

[19] LIANG Zhishu,WANG Jijun,ZHANG Yuna,et al. Removal of volatile organic compounds (VOCs) emitted from a textile dyeing wastewater treatment plant and the attenuation of respiratory health risks using a pilot-scale biofilter[J]. Journal of Cleaner Production,2020,253:120019.

[20] YANG Zhuhui,LI Jian,LIU Jia,et al. Evaluation of a pilot-scale bio-trickling filter as a VOCs control technology for the chemical fibre wastewater treatment plant[J]. Journal of Environmental Management,2019,246:71-76.

[21] ZHANG Shihan,YOU Juping,CHRISTIAN Kennes,et al. Current advances of VOCs degradation by bioelectrochemical systems:A review[J]. Chemical Engineering Journal,2018,334:2625-2637.

[22] FERDOWSI Milad,AVALOS Ramirez Antonio,JONES J Peter,et al. Elimination of mass transfer and kinetic limited organic pollutants in biofilters:A review[J]. International Biodeterioration & Biodegradation,2016,119:336-348.

[23] CHENG Yan,HE Huijun,YANG Chunping,et al. Effects of anionic surfactant on n-hexane removal in biofilters[J]. Chemosphere,2016,150:248-253.

[24] HUI Qian,YAN Cheng,YANG Chunping,et al. Performance and biofilm characteristics of biotrickling filters for ethylbenzene removal in the presence of saponins[J]. Environmental science and Pollution Research International,2017,25(30):30021-30030.

[25] JALIL Ghobadi,DAVID Ramirez,SHOOKA Khoramfar,et al. Simultaneous absorption of carbon dioxide and nitrogen dioxide from simulated flue gas stream using gas-liquid membrane contacting system[J]. International Journal of Greenhouse Gas Control,2018,77:37-45.

[26] ZHU Xueqing,SUIDAN Makram T,PRUDEN Amy,et al. Effect of substrate Henry′s constant on biofilter performance[J]. Journal of the Air & Waste Management Association,2004,54(4):409-418.

[27] ELDON R Rene,MAR A C Veiga,CHRISTIAN Kennes. Combined biological and physicochemical waste-gas cleaning techniques[J]. Journal of Environmental Science and Health,Part A,2012,47(7):920-939.

A C Veiga,CHRISTIAN Kennes. Combined biological and physicochemical waste-gas cleaning techniques[J]. Journal of Environmental Science and Health,Part A,2012,47(7):920-939.

[28] QIANG L,BABAJIDE A E,PING Z,et al. Removal of xylene from waste gases using biotrickling filters[J]. Chemical Engineering & Technology,2006,29(3):320-325.

[29] ZHANG Yun,LIU Jia,XING Hehe,et al. Performance and fungal diversity of bio-trickling filters packed with composite media of polydimethylsiloxane and foam ceramics for hydrophobic VOCs removal[J]. Chemosphere,2020,256:127093.

[30] L PEZ M E,RENE E R,MALHAUTIER L,et al. One-stage biotrickling filter for the removal of a mixture of volatile pollutants from air:Performance and microbial community analysis[J]. Bioresource Technology,2013,138:245-252.

PEZ M E,RENE E R,MALHAUTIER L,et al. One-stage biotrickling filter for the removal of a mixture of volatile pollutants from air:Performance and microbial community analysis[J]. Bioresource Technology,2013,138:245-252.

[31] VOLCKAERT D,EBUDE D E L,VAN LANGENHOVE H. SIFT-MS analysis of the removal of dimethyl sulphide,n-hexane and toluene from waste air by a two phase partitioning bioreactor[J]. Chemical Engineering Journal,2016,290:346-352.

[32] MORRAL Eloi,LAO-LUQUE Conxita,GABRIEL David,et al. Capillary membrane bioreactor for abatement of low soluble compounds in waste gas[J]. Journal of Chemical Technology & Biotechnology,2017,93(2):548-556.

[33] KRAAKMAN Norbertus J R,ROCHA-RIOS Jose,VAN Loosdrecht Mark C M. Review of mass transfer aspects for biological gas treatment[J]. Applied Microbiology and Biotechnology,2011,91(4):873-86.

[34] 胡静涛,郄凌翔,章晶晓,等.正己烷在两相分配搅拌式反应器中的传质过程研究[J].高校化学工程学报,2020,34(3):679-687.

HU Jingtao,QIE Lingxiang,ZHANG Jingxiao,et al.Mass transfer of n-hexane in a two liquid-phase stirred reactor[J].Journal of Chemical Engineering of Chinese Universities,2020,34(3):679-687.

[35] LI Tong,LI Hao,LI Chunli. A review and perspective of recent research in biological treatment applied in removal of chlorinated volatile organic compounds from waste air[J]. Chemosphere,2020,250:126338.

[36] OTTENGRAF S P P. Biological systems for waste gas elimination[J]. Trends in Biotechnology,1987,5(5):132-136.

[37] PIOTR Rybarczyk,BARTOSZ Szulczyński,JACEK Gębicki,et al. Treatment of malodorous air in biotrickling filters:A review[J]. Biochemical Engineering Journal,2018,141:146-162.

[38] BALTRENAS Pranas,ZAGORSKIS Alvydas,MISEVIC Ius Antonas. Research into acetone removal from air by biofiltration using a biofilter with straight structure plates[J]. Biotechnology,Biotechnological Equipment,2015,29(2):404-413.

[39] 郄凌翔,王莉宁,陈建孟,等.生物滴滤塔对疏水性VOCs气体的去除及其生物膜特性研究[J].环境科学学报,2020,40(7):2417-2426.

QIE Lingxiang,WANG Lining,CHEN Jianmeng,et al.Characteristics of biofilm using biotrickling filter to remove hydrophobic VOCs gas[J].Acta Scientiae Circumstantiae,2020,40(7):2417-2426.

[40] BENO T Anet,CATHERINE Couriol,THOMAS Lendormi,et al. Characterization and selection of packing materials for biofiltration of rendering odourous emissions[J]. Water,Air,& Soil Pollution,2013,224(7):1-13.

T Anet,CATHERINE Couriol,THOMAS Lendormi,et al. Characterization and selection of packing materials for biofiltration of rendering odourous emissions[J]. Water,Air,& Soil Pollution,2013,224(7):1-13.

[41] SRIKUMAR Malakar,PAPITA Das Saha,DIVYA Baskaran,et al. Comparative study of biofiltration process for treatment of VOCs emission from petroleum refinery wastewater:A review[J]. Environmental Technology & Innovation,2017,8:441-461.

[42] SCHROEDER E D. Trends in application of gas-phase bioreactors[J]. Reviews in Environmental Science & Biotechnology,2002,1(1):65-74.

[43] KUMAR M,GIRI B S,KIM K H,et al. Performance of a biofilter with compost and activated carbon based packing material for gas-phase toluene removal under extremely high loading rates[J]. Bioresource Technology,2019,285:121317.

[44] SANDEEP Mudliar,BALENDU Giri,KIRAN Padoley,et al. Bioreactors for treatment of VOCs and odours:A review[J]. Journal of Environmental Management,2010,91(5):1039-1054.

[45] JOSÉ M Estrada,SERGIO Hernández,RA L Mu

L Mu oz,et al. A comparative study of fungal and bacterial biofiltration treating a VOCs mixture[J]. Journal of Hazardous Materials,2013,250:190-197.

oz,et al. A comparative study of fungal and bacterial biofiltration treating a VOCs mixture[J]. Journal of Hazardous Materials,2013,250:190-197.

[46] 陆李超,贾青,成卓韦,等.真菌降解挥发性有机化合物的研究进展[J].环境污染与防治,2014,36(8):78-83.

LU Lichao,JIA Qing,CHENG Zhuowei,et al.Progress on biodegradation of volatile organic compounds by fungi[J].Environment Pollution and Control,2014,36(8):78-83.

[47] WOSTEN H A B. Hydrophobins:Multipurpose proteins[J]. Annual Review of Microbiology,2001,55:625-646.

[48] LI Kang,ZHOU Jiazhen,WANG Liping,et al. The styrene purification performance of biotrickling filter with toluene-styrene acclimatization under acidic conditions[J]. Journal of the Air & Waste Management Association,2019,69(8):944-955.

[49] GARC A-PE

A-PE A E I,HERN

A E I,HERN NDEZ S,FAVELA-TORRES E,et al. Toluene biofiltration by the fungus Scedosporium apiospermum TB1[J]. Biotechnology and Bioengineering,2001,76(1):61-69.

NDEZ S,FAVELA-TORRES E,et al. Toluene biofiltration by the fungus Scedosporium apiospermum TB1[J]. Biotechnology and Bioengineering,2001,76(1):61-69.

[50] INÉS García-Pe a,IRMENE Ortiz,SERGIO Hernández,et al. Biofiltration of BTEX by the fungus Paecilomyces variotii[J]. International Biodeterioration & Biodegradation,2008,62(4):442-447.

a,IRMENE Ortiz,SERGIO Hernández,et al. Biofiltration of BTEX by the fungus Paecilomyces variotii[J]. International Biodeterioration & Biodegradation,2008,62(4):442-447.

[51] GOPINATH M,MOHANAPRIYA C,SIVAKUMAR K,et al. Microbial abatement of toluene using Aspergillus niger in upflow bioreactor[J]. Ecotoxicology and Environmental Safety,2016,134(2):370-376.

[52] QI B,MOE W,KINNEY K.Biodegradation of volatile organic compounds by five fungal species[J]. Applied Microbiology and Biotechnology,2002,58(5):684-689.

[53] SONIA Arriaga,SERGIO Revah. Removal of n -hexane by Fusarium solani with a gas-phase biofilter[J]. Journal of Industrial Microbiology & Biotechnology,2005,32(11/12):548-553.

[54] RENE Eldon R, PACKOV

PACKOV Radka,VEIGA María C,et al. Biofiltration of mixtures of gas-phase styrene and acetone with the fungus Sporothrix variecibatus[J]. Journal of Hazardous Materials,2010,184(1/2/3):204-214.

Radka,VEIGA María C,et al. Biofiltration of mixtures of gas-phase styrene and acetone with the fungus Sporothrix variecibatus[J]. Journal of Hazardous Materials,2010,184(1/2/3):204-214.

[55] JIN Yaomin,GUO Ling,MAR A C. Veiga,et al. Fungal biofiltration of α-pinene:Effects of temperature,relative humidity,and transient loads[J]. Biotechnology and Bioengineering,2007,96(3):433-443.

A C. Veiga,et al. Fungal biofiltration of α-pinene:Effects of temperature,relative humidity,and transient loads[J]. Biotechnology and Bioengineering,2007,96(3):433-443.

[56] BARBARA B,CAROLINE P,TAMARA R,et al. Pathogenic yet environmentally friendly? black fungal candidates for bioremediation of pollutants[J]. Geomicrobiology Journal,2016,33(3/4):308-317.

[57] MORALES Paulina,C CERES Manuel,SCOTT Felipe,et al. Bi-

CERES Manuel,SCOTT Felipe,et al. Bi-

odegradation of benzo[α]pyrene,toluene,and formaldehyde from the gas phase by a consortium of Rhodococcus erythropolis and Fusarium solani[J]. Applied Microbiology and Biotechnology,2017,101(17):6765-6777.

[58] LI Kang,ZHOU Jiazhen,WANG Liping,et al. The styrene purification performance of biotrickling filter with toluene-styrene acclimatization under acidic conditions[J]. Journal of the Air & Waste Management Association,2019,69(8):944-955.

[59] CHENG Zhuowei,LU Lichao,CHRISTIAN Kennes,et al. Treatment of gaseous toluene in three biofilters inoculated with fungi/bacteria:Microbial analysis,performance and starvation response[J]. Journal of Hazardous Materials,2016,303:83-89.

[60] YANG Chunping,CHEN Fayuan,LUO Shenglian,et al. Effects of surfactants and salt on Henry′s constant of n-hexane[J]. Journal of Hazardous Materials,2010,175(1/2/3):187-192.

[61] QIAN Hui,CHENG Yan,YANG Chunping,et al. Performance and biofilm characteristics of biotrickling filters for ethylbenzene removal in the presence of saponins[J]. Environmental Science and Pollution Research,2018,25(30):30021-30030.

[62] SHOOKA Khoramfar,KIM D Jones,JALIL Ghobadi,et al. Effect of surfactants at natural and acidic pH on microbial activity and biodegradation of mixture of benzene and oxylene[J]. Chemosphere,2020,260:127471.

[63] SUN Zhuqiu,YANG Bairen,DING Cheng,et al. Enhanced removal of gaseous 1,3-dichlorobenzene in biotrickling filters by rhamnolipid and Mg(II)[J]. Journal of hazardous materials,2018,360:571-577.

[64] ZHOU Wenjun,YANG Juanjuan,LOU Linjie,et al. Solubilization properties of polycyclic aromatic hydrocarbons by saponin,a plant-derived biosurfactant[J]. Environmental Pollution,2011,159(5):1198-1204.

[65] TSAI Wen-Tien. Fate of chloromethanes in the atmospheric environment:Implications for human health,ozone formation and depletion,and global warming impacts[J]. Toxics,2017,5(4):23-36.

[66] AHSAN Mozaffar,ZHANG Yanlin. Atmospheric volatile organic compounds (VOCs) in China:A review[J]. Current Pollution Reports,2020,6(3):250-263.

[67] ZHANG Lu,SUN Xiangyang. Effects of rhamnolipid and initial compost particle size on the two-stage composting of green waste[J]. Bioresource Technology,2014,163:112-122.

[68] ZHONG Hua,JIANG Yongbing,ZENG Guangming,et al. Effect of low-concentration rhamnolipid on adsorption of Pseudomonas aeruginosa ATCC 9027 on hydrophilic and hydrophobic surfaces[J]. Journal of Hazardous Materials,2015,285:383-388.

[69] CHENG Yan,HE Huijun,YANG Chunping,et al. Effects of anionic surfactant on n-hexane removal in biofilters[J]. Chemosphere,2016,150:248-253.

[70] ZHU Xueqing,MAKRAM T Suidan,AMY Pruden,et al. Effect of substrate Henry′s constant on biofilter performance[J]. Journal of the Air & Waste Management Association,2004,54(4):409-418.

[71] 姜岩,张哲.不同亲水特性VOCs在生物滴滤工艺中的作用规律[J].化工学报,2020,71(7):2973-2982.

JIANG Yan,ZHANG Zhe.Interaction of VOCs with different hydrophilic properties in biotrickling filters[J].CIESC Journal,2020,71(7):2973-2982.

[72] CHENG Yeting,LI Xiang,LIU Haiyang,et al. Effect of presence of hydrophilic volatile organic compounds on removal of hydrophobic n-hexane in biotrickling filters[J]. Chemosphere,2020,252:126490.

[73] DIXIT R M,DESHMUKH S C,GADHE A A,et al. Treatment of mixtures of toluene and n-propanol vapours in a compost-woodchip-based biofilter[J]. Environmental Technology,2012,33(7):751-760.

[74] DUMONT E,ANDR S Y,LE Cloirec P. Effect of organic solvents on oxygen mass transfer in multiphase systems:Application to bioreactors in environmental protection[J]. Biochemical Engineering Journal,2006,30(3):245-252.

S Y,LE Cloirec P. Effect of organic solvents on oxygen mass transfer in multiphase systems:Application to bioreactors in environmental protection[J]. Biochemical Engineering Journal,2006,30(3):245-252.

[75] ANTONIO D Dorado,ERIC Dumont,RA L Mu

L Mu oz,et al. A novel mathematical approach for the understanding and optimization of two-phase partitioning bioreactors devoted to air pollution control[J]. Chemical Engineering Journal,2015,263:239-248.

oz,et al. A novel mathematical approach for the understanding and optimization of two-phase partitioning bioreactors devoted to air pollution control[J]. Chemical Engineering Journal,2015,263:239-248.

[76] HAN Mengfei,WANG Can,FU Yan. Treatment of hydrophobic volatile organic compounds using two-liquid phase biofilters[J]. Science of the Total Environment,2018,640:1447-1454.

[77] CHEN Dongzhi,LIU Haoyang,YU Yang,et al. Enhanced biodegradation of n-hexane in a two-phase partitioning bioreactor inoculated with Pseudomonas mendocina NX-1 under chitosan stimulation[J]. Journal of Hazardous Materials,2021,419:126330.

[78] ZHAO Kang,XIU Guangli,XU Lihang,et al. Biological treatment of mixtures of toluene and n-hexane vapours in a hollow fibre membrane bioreactor[J]. Environmental Technology,2011,32(6):617-623.

[79] ZHANG Yizhen,LIU Lifen,VAN DER Bruggen Bart,et al. Nanocarbon based composite electrodes and their applications in microbial fuel cells[J].Journal of Materials Chemistry A,2017,5(25):12673-12698.

[80] CHEN Qiyuan,LIU Lu,LIU Lifen,et al. A novel UV-assisted PEC-MFC system with CeO2/TiO2/ACF catalytic cathode for gas phase VOCs treatment[J]. Chemosphere,2020,255:126930.

[81] AGNESE Lai,FEDERICO Aulenta,MARINA Mingazzini,et al. Bioelectrochemical approach for reductive and oxidative dechlorination of chlorinated aliphatic hydrocarbons (CAHs)[J]. Chemosphere,2017,169:351-360.