富氧燃烧烟气净化工艺研究进展

Research and development on the purification technology for oxy-fuel combustion flue gas

0 引 言

化石燃料燃烧会产生大量CO2,过多CO2排放会导致温室效应,使全球气候变暖,减少CO2排放量已成为国际社会关注的焦点。当前全球气候变化形势不容乐观,1901—2012年,全球平均气温上升了0.89 ℃[1]。温度升高会导致冰川融化、海平面上升、珊瑚礁灭绝、全球粮食短缺等问题[2]。我国将近34.2%的CO2排放都来自燃煤发电,而燃煤发电在未来几十年依然是电力的主要来源[3]。2015年《巴黎协定》后中国就根据国情向全球作出“承诺”,宣布争取尽早实现2030年CO2达峰且单位GDP CO2排放比2005年下降60%~65%的目标[4]。碳捕集、封存和利用技术(Carbon capture,utilization and storage,CCUS)能有效应用于CO2减排,是应对气候变暖最有效的方法之一。常见的CO2捕集技术有燃烧前捕集、燃烧后捕集和富氧燃烧技术。燃烧前捕集用于煤气化联合循环发电(IGCC),燃烧后捕集指在煤粉或天然气联合循环发电厂的尾气侧捕获CO2。富氧燃烧技术又称空气分离/烟气再循环燃烧技术,具有相对成本低、易规模化、可改造存量机组、减排CO2力度大等诸多优势[5],被国内外认为是最具有发展前景和优势的直接CCUS技术之一[6]。

1 富氧燃烧碳捕集纯度标准

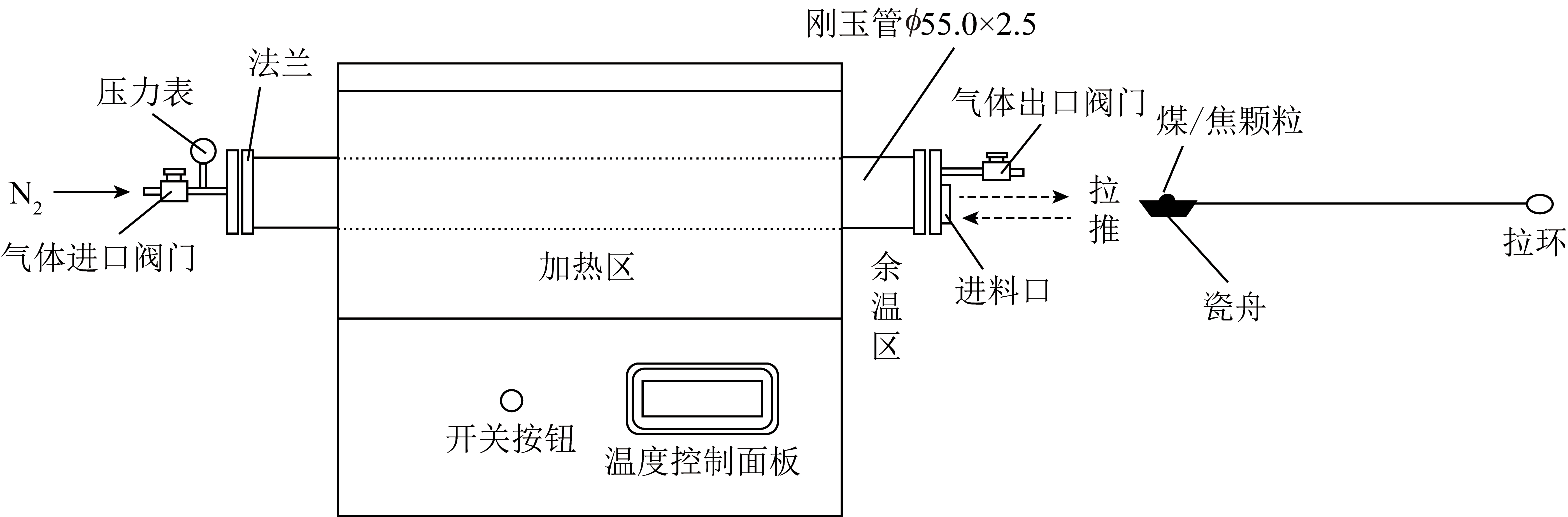

富氧燃烧技术系统示意如图1所示。该系统先由空气分离装置进行高纯度O2提取,按一定比例与循环回来的锅炉尾部烟气混合,进入锅炉燃烧后产生含有高浓度CO2的烟气,随后经过烟气净化系统,再进入烟气压缩纯化系统,最后得到高浓度的液态CO2产品用以运输、利用和封存。

与传统燃烧相比,在富氧燃烧下,燃烧产生的SOx、NOx总量减少,但由于大量烟气再循环,烟气排放量减少,导致酸性污染物浓度升高[7-9]。除SOx、NOx等常见污染物,捕集后CO2产品中还含有多种杂质,如O2、H2O、CO以及惰性气体等,O2浓度相比传统燃烧略有上升,而H2O浓度上升约10%,这些杂质可能会对管道运输、地质储存和提高采收率(EOR)产生负面影响[10]。表1列出了捕集后CO2纯度以及杂质的标准,由于管道运输、地质储存和提高采收率等影响,需CO2体积分数>95%;H2O体积分数<500×10-6,也有建议应<50 ×10-6;O2体积分数应在100×10-6~1 000×10-6,石油运营商认为应<10×10-6,但这些限制需要试验验证;惰性气体、CO、SOx、NOx浓度分别需<4%、<2 000×10-6、<50×10-6、<100×10-6。根据氧气含量要求,可采用各种工艺生产纯度95%~99.999%的CO2。纯度越高,CO2捕集率就越低,更高的纯度意味着更高的资本和运营支出。为了达到CO2纯度标准,如何廉价、高效捕集和资源化利用富氧燃烧烟气中的污染物杂质已成为研究热点,本文针对富氧燃烧CO2捕集过程中SOx、NOx、Hg污染物以及惰性气体脱除进行了探讨。

图1 富氧燃烧技术系统示意[5]

Fig.1 Schematic diagram of oxy-fuel combustion system[5]

表1 CO2纯度标准[10]

Table 1 CO2 purity standards[10]

2 SOx脱除技术

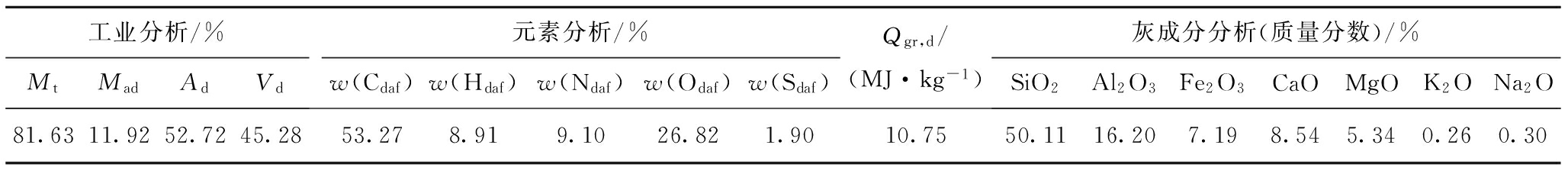

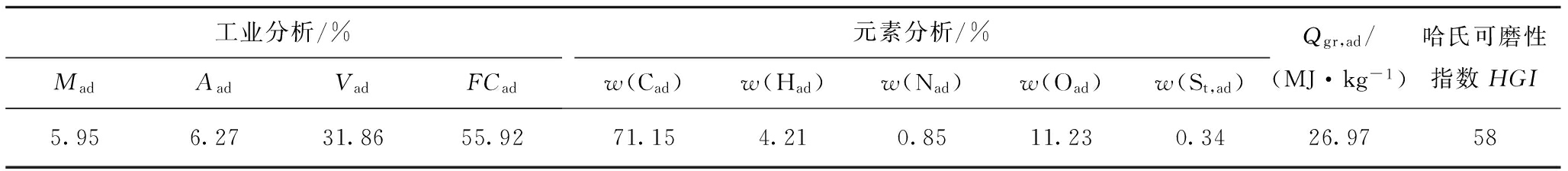

煤燃烧排放的烟气中存在酸性气体污染物SOx,主要以SO2形式存在,是酸雨形成的主要原因,因此需在排入大气前脱除。富氧燃烧系统中SOx一般在压缩前脱除,传统烟气脱硫可分为干法(DFGD)、半干法(SDFGD)以及湿法脱硫技术(WFGD),其优缺点见表2。阿尔斯通公司[19]在不同典型脱硫方法下,对进入压缩系统前的SOx浓度进行分析,结果如图2所示,发现用湿法脱硫技术和湿式静电除尘器有较好的脱除效果。

目前,石灰石/石膏湿法烟气脱硫是国内外应用最广泛的一种脱硫工艺,该工艺采用石灰或石灰石作为脱硫剂对燃煤烟气进行脱硫[21],工艺流程为:从塔底部进入的烟气与自脱硫塔顶部淋下的含CaCO3的浆液充分混合接触后,烟气中SO2被吸收生成Ca(HSO3)2,Ca(HSO3)2落入反应槽中,然后通过鼓入的空气使Ca(HSO3)2被氧气氧化为CaSO4,CaSO4进一步发生结晶反应生成石膏(CaSO4·2H2O)。相关的反应方程式如下:

表2 干法、湿法、半干法脱硫技术优缺点[20]

Table 2 Advantages and disadvantages of dry,wet and semi-dry desulfurization technologies[20]

图2 脱硫技术的典型选择[19]

Fig.2 Typical selection of desulfurization technologies[19]

CaCO3 2SO2 H2O![]() Ca(HSO3)2 CO2,

Ca(HSO3)2 CO2,

(1)

Ca(HSO3)2 O2 CaCO3 H2O![]() CaSO4·2H2O CO2。

CaSO4·2H2O CO2。

(2)

除了石灰石/石膏湿法脱硫技术外,氧化镁脱硫技术与氨法脱硫技术应用也比较广泛。氧化镁脱硫技术具有原料储备充足、脱硫效率高、不发生结垢、系统简单、能耗低、氧化镁可再生等优点[22]。反应机理为

MgO H2O![]() Mg(OH)2,

Mg(OH)2,

(3)

Mg(OH)2 SO2 xH2O![]() MgSO3·xH2O,

MgSO3·xH2O,

(4)

MgSO3 1/2O2![]() MgSO4。

MgSO4。

(5)

氨法脱硫技术中,SO2是气-液相或气-气相反应,传质阻力较小,因此反应速率快,脱硫效率最高可达98%,该过程相对简单,设备占地面积小,脱硫后副产品(NH4)2SO4是化肥的主要成分,回收后能降低运行成本[23-24]。相关反应如下:

2NH3 H2O SO2![]() (NH4)2SO3,

(NH4)2SO3,

(6)

SO2 (NH4)2SO3 H2O![]() 2NH4HSO3,

2NH4HSO3,

(7)

NH3 NH4HSO3![]() (NH4)2SO3,

(NH4)2SO3,

(8)

O2 2(NH4)2SO3![]() 2(NH4)2SO4。

2(NH4)2SO4。

(9)

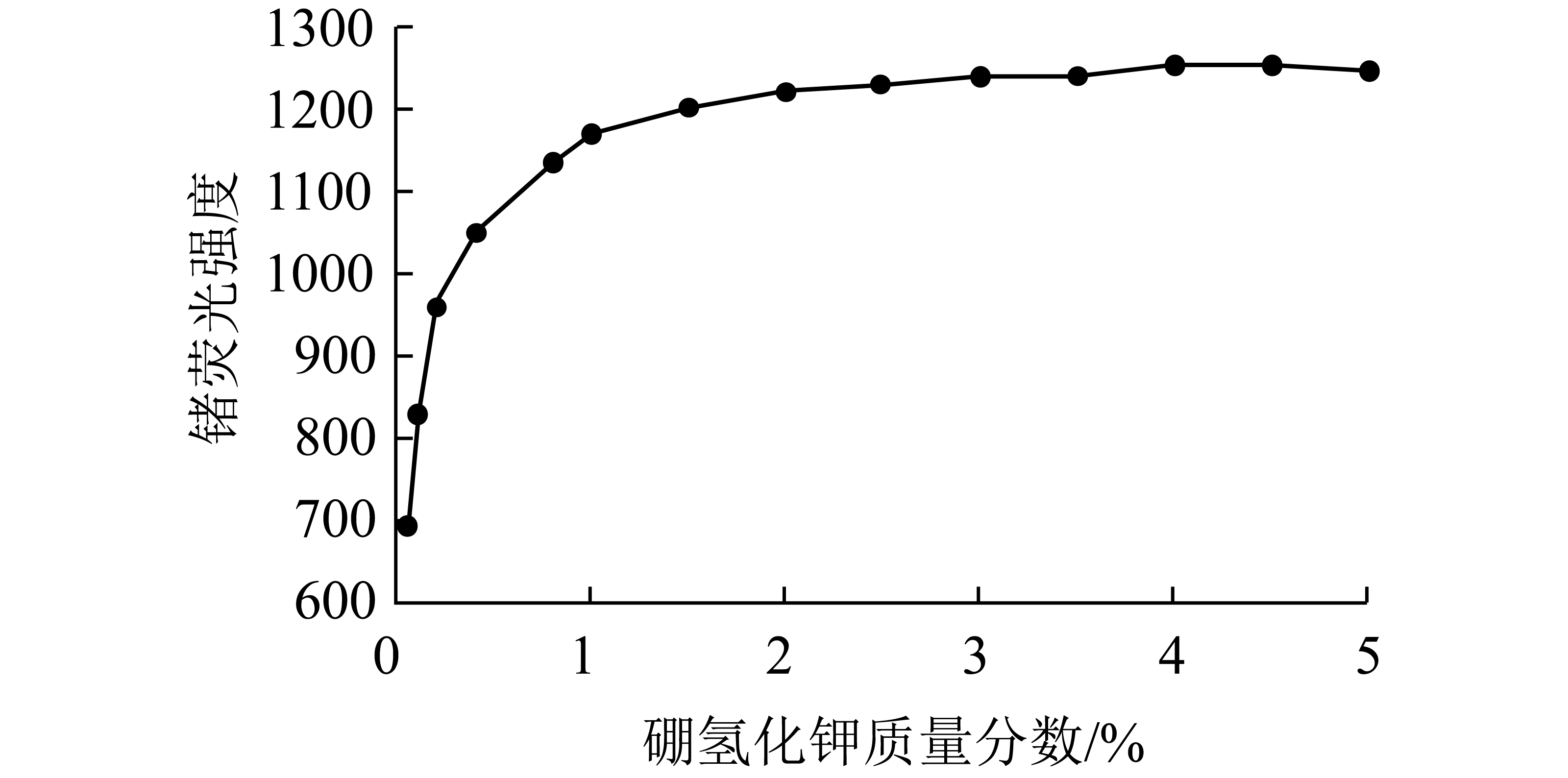

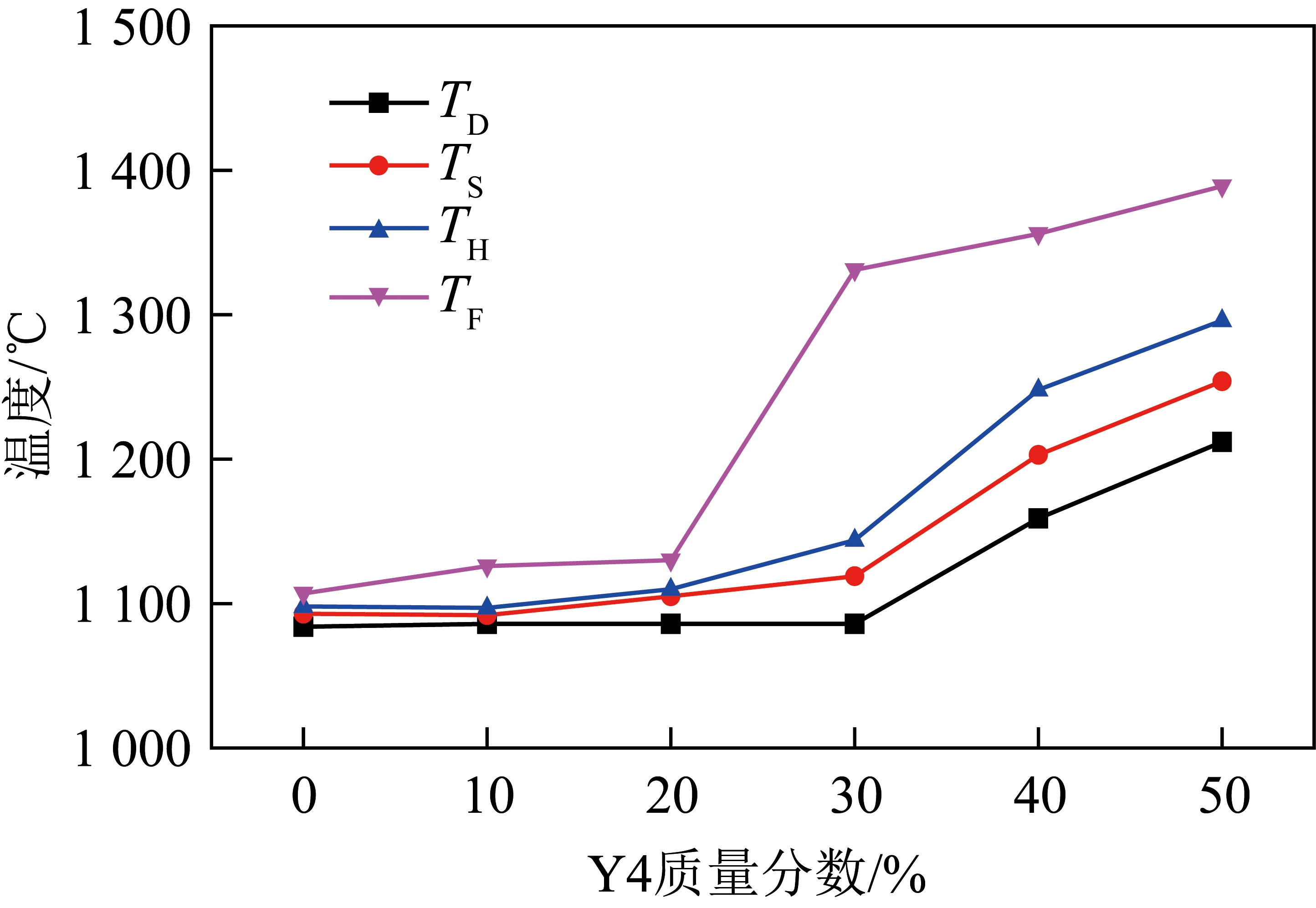

除上述常见脱硫剂外,NaOH溶液对于酸性气体的吸收也十分有效[25]。Liu等[26]在CO2压缩前对钠基水溶液吸收SO2进行动态研究,考察了CO2与N2气氛下吸收的区别,提出了SO2随pH变化的吸收特性曲线,并发现CO2气氛下SO2吸收速率相比N2气氛有所降低,如图3所示。Hansen等[27]在湿法烟气脱硫条件下进行了同时吸收SO2和CO2试验验研究,发现CO2的存在会改变石灰水的pH使脱硫效率发生改变。Wappel等[28]研究了气液平衡状态下SO2和CO2的相互作用,发现在SO2/CO2/K2CO3体系中,SO2优先与K2CO3反应,存在的主要物质是亚硫酸盐,且SO2吸收到K2CO3溶液中是一个不可逆反应,硫会在溶剂中积聚,导致CO2吸收能力下降。有/无CO2条件下SO2在NaOH溶液中的吸收机理如图4所示。无CO2条件下,在pH=12.22~9.65时,SO2与OH-反应生成![]() 随着SO2逐渐吸收,pH降至4.82且生成

随着SO2逐渐吸收,pH降至4.82且生成 低于4.82后,SO2与H2O反应生成H 和

低于4.82后,SO2与H2O反应生成H 和 有CO2存在条件下,SO2吸收反应的相应临界pH值发生变化,在pH=12.18~10.81,CO2被碱液吸收生成

有CO2存在条件下,SO2吸收反应的相应临界pH值发生变化,在pH=12.18~10.81,CO2被碱液吸收生成![]() 随后继续吸收CO2形成

随后继续吸收CO2形成 直到pH到达8.32,SO2开始与

直到pH到达8.32,SO2开始与![]() 反应生成

反应生成![]() 和CO2。Liu等[29]确定了一个pH窗口来提高SO2吸收率并能有效降低钠损失。Liu等[30]提出了一种基于双模理论的洗涤器用于富氧燃烧烟气中SO2的脱除,并对模型进行参数优化。

和CO2。Liu等[29]确定了一个pH窗口来提高SO2吸收率并能有效降低钠损失。Liu等[30]提出了一种基于双模理论的洗涤器用于富氧燃烧烟气中SO2的脱除,并对模型进行参数优化。

图3 不同溶液中SO2吸收速率与SO2分压的关系,并与计算得到的气相控制线进行比较[26]

Fig.3 Relationship between SO2 absorption rate and partial pressures of SO2 at different solutions and comparison with gas phase controlled lines[26]

加压条件下,烟气中部分SO2极易转化为SO3。空气气氛下SO3/SO2转化率为0.3%~1.1%,富氧燃烧方式下SO3/SO2转化率提高至1.3%~2.5%[31]。SO3的形成可以在FGD中进行控制,与SO2脱除技术相似,可以通过石灰石浆液、镁基吸收剂、钠基吸收剂进行脱除。采用湿式静电除尘器可显著去除烟气中的SO3。

3 NOx脱除技术

酸性气体NOx也是煤燃烧烟气排放污染物的一种。传统脱硝技术分为干法脱硝技术与湿法脱硝技术。选择性催化还原技术(SCR)以及选择性非催化还原技术(SNCR)是目前最常用的干法脱硝技术。两者都是利用氨作为还原剂选择性地将NOx转化为N2和H2O,只是SNCR不需要添加催化剂。其他方法还有分子筛、活性炭吸附、等离子体法等[32-33]。陈松涛等[34]对富氧燃烧条件下SCR催化剂脱硝活性进行研究,发现CO2的存在会降低催化剂的脱硝效率,且随着CO2浓度的增加而增强,但不会导致催化剂失活。

图4 有/无CO2存在下SO2吸收机理与临界pH值

Fig.4 Absorption mechanism and critical pH value of SO2 with or without CO2

富氧燃烧产生的NOx主要由NO组成,因为NO氧化为NO2的过程随着温度的升高而迅速下降,在高于700 ℃下(在锅炉内),平衡混合物中几乎不含有NO2[35],这使得NOx脱除具有挑战性。富氧燃烧控制NOx排放的技术手段有低氮燃烧、氧分级以及氧化吸收等。氧化吸收法较为常见,由于NO不溶于水,去除前需要氧化为NO2,然后再进行吸收脱除。NOx在水中氧化吸收机理如图5所示。湿法脱硝技术建立在此基础上且种类繁多,主要用一些强氧化剂来氧化NO生成NO2,然后被碱性溶液或水吸收,多应用于常压环境,但强氧化剂的使用成本较高。Yan等[36]采用4种氧化剂(NaClO2、NaClO、H2O2和KMnO4)和4种吸收剂(Ca(OH)2、CaCO3、NaOH和Na2CO3)研究NO氧化吸收过程的反应机理,发现NaClO2溶液为最佳氧化剂,在浓度为1.0%时,氧化率达100%,Ca(OH)2浆液的吸收性能最好。Hao等[37]研究了蒸发的H2O2与紫外光作用下NO的氧化机理,得出紫外能量密度和紫外波长对NO氧化有显著影响,降低pH值和增加O2浓度均可增强NO氧化的结论。美国BOC公司开发的LoTOx技术是将氧气/臭氧混合气体通入烟道中,利用臭氧的强氧化性将NO氧化为易溶于水的高价态氮氧化物,然后通过洗涤形成HNO3[38]。

图5 NOx在水中氧化吸收机理[39]

Fig.5 Mechanism of NOx oxidation absorption in water[39]

加压条件下对氮氧化物的吸收已经应用于硝酸的生产,说明在一定压力下能促进NO的氧化,且进一步提高NOx脱除率。罗哲林[40]对加压条件下NO单独脱除过程进行研究,发现增加压力、延长停留时间、提高O2浓度和初始NO2浓度有利于NO吸收以及硝酸转化,而温度升高则有负面影响。黄强等[41]在试验基础上应用Aspen Plus建立了加压单独脱硝模拟流程,也得出相同结论,提出烟气中N2的存在不利于加压脱硝过程。

阎维平等[42]提出了一种富氧燃烧捕集CO2时加压降温的特殊工艺来回收NO,证明高压低温工况有利于NO氧化为NO2并转化为稀硝酸产品,得出压力为3 MPa、温度为30 ℃时NO的氧化率达到90%。陈曦等[43]对加压条件下氮氧化物的水吸收进行了研究,发现在高压(0.4~0.6 MPa)下氮氧化物的吸收率较高,且回收的硝酸的价值可以弥补气体压缩的成本。

一些学者进一步研究了高压下NO氧化动力学进。Cheng等[44]在压力0.1~3.0 MPa下对NO氧化进行研究,在已有试验结果和理论模型的基础上实现NO氧化动力学参数的回归。Liu等[45]研究了加压条件下的NO氧化并吸收到水中的动态过程,如图6(a)所示,NO2的传质主要由气相控制;图6(b)说明NO的吸收主要由液相控制;图6(c)发现在0.5~1.5 MPa,氧化速率常数随着压力的增大而减小,该现象可以用NO3或NO二聚体作为中间体的预平衡机制来解释,但随着反应器压力从1.5 MPa增加到2 MPa,NO氧化速率常数的增加暂时还无法解释,可能涉及到一些未知的链式反应;图6(d)表明随着反应器压力的增加,液体的最佳表面积减小,而液体体积增大。内表面上的液体可以通过3个过程产生:液体预加载、液体蒸汽冷凝和气体鼓泡夹带。随后的结果证明了反应器压力对液体夹带率的影响比较显著。

图6 氮氧化物吸收模型中最佳参数随压力的变化[45]

Fig.6 Optimum parameters change with reactor pressure based on absorption modeling of nitrogen oxides[45]

4 Hg脱除技术

汞及其化合物对环境和人体健康均有害,汞的去除一直是关注的焦点。元素汞的去除对富氧燃烧工艺过程有重要影响,其会与下游的液化材料(铜焊铝热交换器)发生反应导致设备腐蚀[46]。汞的形态对汞的去除十分重要,烟气中汞有3种形态:元素汞(Hg0)、氧化汞(Hg2 )和颗粒汞(Hgp)。煤燃烧过程中各种形态汞的转化过程如图7所示。氧化态Hg2 和颗粒结合态Hgp都可以被传统的烟气处理装置捕获,如湿法烟气脱硫和静电除尘器[47]。单质汞在水中溶解性差,稳定性好,难以去除。因此,有必要研究富氧燃烧条件下元素汞排放控制的方法。

图7 煤燃烧过程中汞的转化过程[48-49]

Fig.7 General mercury transformation process during coal combustion[48-49]

富氧燃烧烟气中的成分对汞的氧化脱除起一定作用。Wang等[50]研究了富氧燃烧中HCl、NO、水蒸气和SO2对汞排放及其形态的影响,发现上述物质都会导致Hg2 含量增加,且水蒸气浓度对汞的氧化有显著促进作用,HCl通过产生Cl自由基也能促进汞的氧化。Li等[51]对富氧燃烧CO2压缩过程中酸性气体脱除汞的机理进行研究,发现在高压下能促进NO氧化为NO2并与Hg0反应,可以有效去除烟气中的Hg0杂质,SO2不与Hg0反应,但影响Hg0和NO2的反应,抑制了汞的去除。Wu等[52]分别在O2/CO2和O2/N2气氛下进行了Cl2、HCl、NO、SO2均相氧化Hg0的试验研究,结果表明,Cl2能显著促进Hg0的氧化,NO对Hg0的氧化为5%~30%,取决于NO浓度并随温度升高而降低。

活性炭(AC)在汞控制中得到了广泛应用,被认为是一种成熟而有前途的脱汞技术。活性炭在高压和有氧气存在的条件下可能发生爆炸,因此在较低压力下产生作用[53]。影响活性炭吸附汞能力的因素很多,包括活性炭的表面积、颗粒大小、孔隙率以及烟气汞浓度、烟气温度、烟气成分等[54]。Min等[55]发现在基准气体条件下,汞的吸附效率随比表面积的增加呈线性增加。粒径增大会显著降低汞的吸附容量,而较高的初始汞浓度则导致汞吸收量增加[56]。Miller等[57]发现在107 ℃下,O2、CO2、N2和H2O气氛下褐煤基活性炭对汞的吸附效率仅为10%~20%,当加入HCl、NO、NO2其中一种时,汞的吸附效率达到了90%~100%。

Hg0在吸附剂上的吸附过程主要包括物理吸附和化学吸附,可以通过一些改性方法来增强吸附剂对Hg0的吸附过程,主要是改善吸附剂的表面孔结构来增加比表面积以及增加吸附剂表面的活性位点。活性炭的价格昂贵,为提高活性炭的利用效率,采用很多活性炭改性方法来提高汞的脱除效率,如图8所示,主要有卤化物和硫改性、酸和碱改性、金属和金属氧化物改性、微波和等离子体改性和复合改性[58]。一般情况下,汞脱除效果顺从AC < Cl浸渍AC < Br浸渍AC < I浸渍AC[59]。Sun等[60]用HNO3浸泡活性炭,以增强活性炭中的含氧官能团,试验发现改性后的吸附剂对Hg0的去除率显著提高。Li等[61]研究了Pd/活性炭吸附剂对烟气中Hg0和H2S吸附性能的影响,结果表明该吸附剂具有良好的除Hg0和H2S的性能。Xu等[62]制备并应用MnOx/石墨烯复合材料来提高烟气中元素汞(Hg0)的捕获能力,发现MnOx/石墨烯吸附Hg0的主要机理是催化氧化和吸附。Zhang等[63]研究了氧低温等离子体对活性炭(AC)表面性能和脱汞性能的影响,由于氧低温等离子体处理后增加了活性炭表面的酯基(C—O)、羰基(C![]() O)和吸附活化位,提高了元素汞的吸附。

O)和吸附活化位,提高了元素汞的吸附。

图8 活性炭改性方法[64]

Fig.8 Modification methods of activated carbon[64]

5 惰性气体净化技术

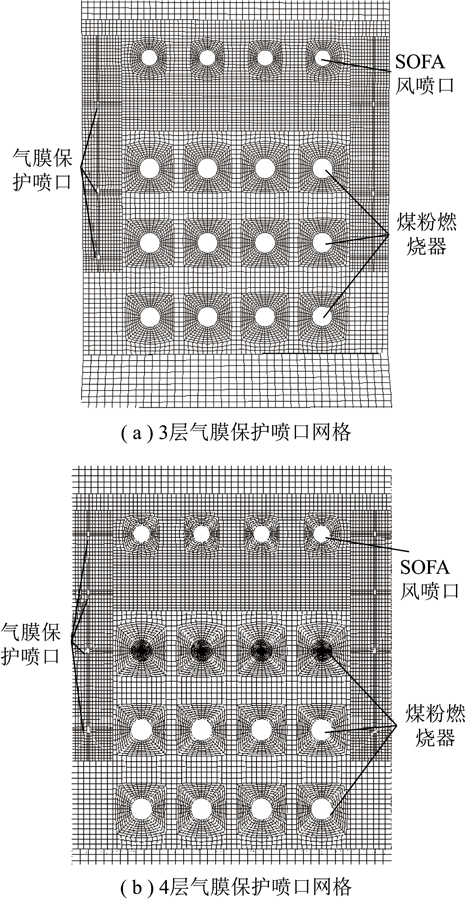

在CO2捕集中一定量的CO2会与惰性气体一起排出,这限制了CO2回收的效率与纯度,需要降低CO2气流中的惰性气体浓度。富氧燃烧烟气中的N2、O2、Ar等惰性气体的脱除方法理论上有:低温分离和变压吸附脱除。低温分离是利用CO2与N2、O2、Ar等杂质在低温下的不同沸点进行分离,从而得到高纯度的CO2产品。变压吸附方法(PSA)是通过改变压力来吸附和解吸附,不仅可以提高CO2回收效率,还降低了CO2气流中惰性气体去除成本,实现一部分惰性气体再次循环回锅炉中,提高CO2的捕获。Hack等[65]提出了一种零排放闭循环的系统,如图9所示。该系统中N2、O2、Ar等惰性气体采用变压吸附方法分离,剩下一部分排入空气分离装置进行下一次循环,实现了高纯度的CO2捕获。

图9 零排放闭环富氧燃烧系统[65]

Fig.9 Zero emission closed loop oxy-fuel combustion system[65]

6 联合脱除技术

近年来,在富氧燃烧CO2压缩过程中联合脱除SOx、NOx和Hg的技术得到了广泛研究。CO2压缩捕集时的加压降温过程为脱除SO2和NOx提供了有利条件,另外,由于SO2和NOx浓度高于空气燃烧,使得脱除效率高,并能够资源化回收硫酸和硝酸。Air Products公司提出了在CO2压缩过程中以硝酸和硫酸的形式除去NOx和SOx以及以Hg(NO3)2的形式去除Hg0的简化反应机理[66-67],如图10所示。该机理涉及4个步骤:NO与O2在高压下氧化为NO2;NO2与SO2反应生成SO3,在与H2O反应生成H2SO4;残余的NO2与水反应生成HNO3;Hg与HNO3反应生成Hg(NO3)2。

德国Linde公司开发了一种湿法洗涤方法:在CO2进入压缩机前,烟气脱硫系统除去95%~99%的SO2,随后烟气被压缩至1.8 MPa,使NO转化为NO2并在氨溶液中化学吸收以形成硝酸铵[68]。法国Air Liquide公司开发了一种常压去除SO2和高压去除NO的洗涤系统,该方法使用苛性碱溶液吸收SOx到较低浓度,然后烟气通过四级压缩系统除去NO[69]。普莱克斯公司设计了2套SOx、NOx、Hg的脱除方法用于高硫煤和低硫煤燃烧后的烟气净化[70]。烟气首先进入压缩机,冷凝过程中使一部分NO和SO2生成H2SO4和HNO3,随后送到活性炭床进行氧化(SO2→SO3,NO→NO2),饱和后用水洗涤使其再生(SO3→H2SO4,NO2→HNO3),几乎所有的NO都作为相应的酸被吸收和除去。美国Air Products公司提出的高压联合脱除技术由于简单、成本低和副产物具有资源化利用价值等优点,具有较大商业应用价值[71],该技术系统示意如图11所示。烟气首先进入压缩机被压缩至1.5 MPa,促进NO氧化为NO2,得到的NO2将SO2氧化为SO3,NO2同时被还原为NO,烟气经冷却器冷却后进入第1级逆流气液接触反应器,在该反应器中SO3与H2O充分接触生成H2SO4。根据铅室反应机理,在SO2完全被氧化生成H2SO4后,NO2开始与H2O反应生成HNO2和HNO3,同时Hg与HNO3发生反应以Hg(NO3)2形式脱除。脱硫后的烟气经压缩机压缩至3 MPa,再经冷却器冷却后进入第2级逆流气液接触反应器,该反应器中未除尽的NO被氧化为NO2并与H2O反应生成HNO2和HNO3,该反应系统可以达到100%的SO2脱除效率和>90%的NO脱除效率。该技术有4个特点:① 有效利用压缩过程能量,无须外部压缩能耗;② 具有较高SO2和NO脱除率,省去传统脱硫脱硝装置;③ 吸收后可以回收H2SO4和HNO3产品,降低系统成本;④ 烟气中的Hg以Hg(NO3)2形式脱除。

图10 富氧燃烧杂质去除机理[66-67]

Fig.10 Mechanism diagram of impurity removal in oxy-fuel combustion[66-67]

图11 富氧燃烧CO2压缩脱硫脱硝系统示意[67]

Fig.11 Schematic diagram of desulfurization and denitrification system in CO2 compression of oxy-fuel combustion[67]

除了上述公司开发的设备外,国内外学者也对联合脱除技术展开研究。SOx和NOx的去除取决于铅室反应的发生,可通过压缩和直接接触酸洗来去除。帝国理工学院[72]在实验室规模的工作中使用质量流量控制器合成模拟烟气,然后通过干式和湿式反应器进行高压下SO2和NOx的脱除。结果表明,压力的增加会促进NO氧化为NO2,在1.5 MPa和3.5% O2条件下,转化率可达87%,最终使得99%的SOx和90%的NOx被去除,并讨论了压力、温度、停留时间和水对脱除结果的影响。阎维平等[73]在NO单独氧化吸收试验中发现,随着压力的升高NO转化为HNO3的比率增大,达到3 MPa以上时,大于90%的NO转化为了稀硝酸。SO2与NO同时存在时,在SO2氧化过程中,NO只起到催化剂的作用。李伟等[74]在富氧燃烧下对鼓泡反应器高压联合脱除烟气中NOx和SOx进行了建模分析,通过龙格-库塔法进行求解,阐述了联合脱除过程的吸收机理,发现压力提高有利于 和HAMS(N-S化合物)的生成,同时也导致了N2O生成量增多。

和HAMS(N-S化合物)的生成,同时也导致了N2O生成量增多。

如果元素汞可以在富氧燃烧烟道气体压缩过程中与NOx气体结合捕获,这就提供了一种成本相对较低的清洁方案。Ting等[75]采用实验室规模的试验研究气态元素汞在硝酸中的吸收,以及2.5 MPa压力下由NO氧化生成的NO2与汞发生的气相反应。观察到硝酸对汞的吸收有限,降压后可能有部分汞发生解吸。另外,汞在气相中易与NO2发生反应,NO2对气态元素汞的氧化显著。Stanger等[69,76]对富氧燃烧压缩过程中同时去除SOx、NOx和Hg进行研究,结果表明,在压缩过程中,降低温度可以产生最大的NOx和Hg捕获。高压下反应主要发生在气相,且压力、停留时间以及NO2浓度对Hg的脱除都有影响,还发现没有NO2,在压缩系统中无法观察到Hg的脱除。

Hall等[77]与Snider等[78]对NO2与Hg的气相反应进行研究,虽然表面体积比不同,但2项研究的动力学结果一致,如图12所示(k′为速率常数),从本质上证明了Hg-NO2反应是气相反应。关于Hg与NO2反应生成的产物,一些文献认为只有Hg(II)盐形成,而另一些文献认为只有Hg(I)盐或同时存在Hg(I)盐和Hg(II)盐。汞盐受热容易分解并形成中间产物,一些学者对热解产物进行了研究[78-84],不过目前关于汞化合物的文献还不能够阐明Hg和NO2反应的产物。

图13为根据现有文献和Ting等[85]试验结果推测的汞产品成分分布,其中7%为I价或II价硝酸盐,6%为II价氧化汞,剩余87%为暂时未知的中间态汞化合物。

图12 Snider与Hall动力学拟合结果[78]

Fig.12 Kinetic fitting results of Snider and Hall[78]

图13 可能形成的Hg-NO2反应产物[85]

Fig.13 Possible formed Hg-NO2 product[85]

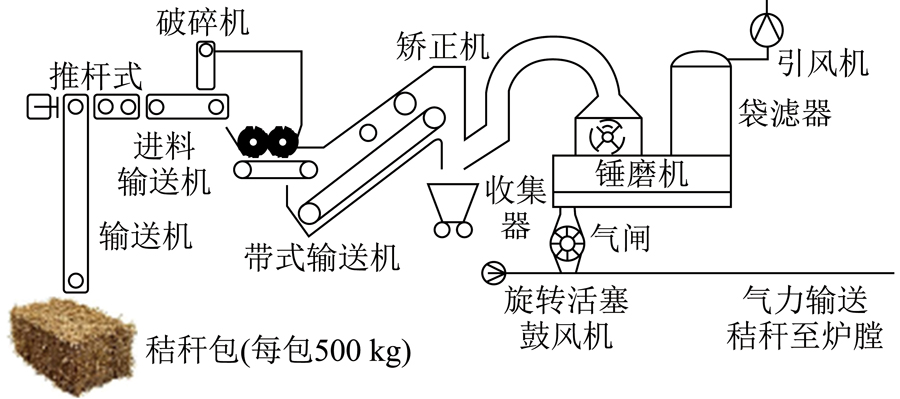

近年来,低温碳捕集技术(Cryogenic carbon capture,CCC)也有相关报道,低温碳捕集是去除二氧化碳的有效方法,该方法运用了烟气各成分的物理性质在加压低温下分离,有潜力取代洗涤器和其他烟气处理方法。Baxter等[86]用Aspen Plus对低温碳捕集系统进行了比较理想化的模拟,表3为CCC过程中简单体系(N2、O2、CO2)和复杂体系(烟气中包含S、N、Hg、Cl)下各数据的模拟结果,可知采用低温碳捕集技术各部分的能耗,且该技术使烟气中SOx、NOx、Hg的捕集效率达到100%,并能捕集到高纯度CO2。对于低温碳捕集技术目前还缺乏可行性的研究。

表3 CCC过程中简单体系(N2、O2、CO2)和复杂体系(烟气中包含S、N、Hg、Cl)下的模拟结果[86]

Table 3 Simulation results under simple system(only N2,O2,CO2)and complex system(flue gas containing S, N,Hg,Cl impurities) in CCC process[86]

7 结语与展望

本文详细描述了富氧燃烧碳捕集过程中的烟气净化工艺,包括SOx、NOx、Hg和惰性气体的单独脱除技术,以及利用富氧燃烧碳捕集过程特有的烟气压缩液化环节,实现多种污染物的联合脱除技术。SOx脱除技术中,石灰石/石膏湿法脱硫技术脱硫效率高并能产生可回收的石膏,是目前应用最广泛的烟气脱硫技术。NOx脱除技术中,SCR运行费用高、氨易泄漏而且催化剂易失活;SNCR脱硝效率较低;氧化吸收法工艺简单、能耗少、成本低,已有较多研究;加压条件下的脱硝能产生具有经济效益的硝酸,有较高的研究价值。Hg脱除技术中,不同烟气成分对Hg的氧化有一定作用,利用活性炭及对活性炭改性控制Hg排放是目前主要研究方向。惰性气体净化技术中,采用变压吸附方法吸附和解吸附,降低了CO2气流中惰性气体去除的成本。联合脱除技术在烟气压缩液化系统中有效利用压缩过程的高压条件将SOx、NOx、Hg分别以硫酸、硝酸、Hg(NO3)2形式协同去除,该技术是富氧燃烧烟气净化技术的研究热点。

根据现有文献报告后续的研究重点为:

1)深入研究高压下的NO氧化动力学,对不同压力下NO氧化速率常数的变化趋势进行解释。

2)高压下NOx与SOx联合脱除的产物还需要进一步分析,包括N-S化合物HADS和HAMS,以及如何减少N2O生成,如何使高压下同时吸收的NOx和SOx以HNO3和H2SO4形式分离进行回收。

3)NO2与Hg的反应体系在高压下生成的产物尚不清楚,可以展开后续研究。

[1] 赵宗慈,罗勇,黄建斌.回顾IPCC 30年(1988—2018年)[J]. 气候变化研究进展,2018,14(5):540-546.

ZHAO Zongci,LUO Yong,HUANG Jianbin. Review IPCC 30 years(1988-2018)[J]. Climate Chang Research,2018,14(5):540-546.

[2] 叶晗,王超,张亚萍,等. 全球变暖争议问题辨析[J]. 陇东学院学报,2013,24(4):78-81.

YE Han,WANG Chao,ZHANG Yaping,et al. Analysis on the issues of global warming[J]. Journal of Longdong University,2013,24(4):78-81.

[3] 赵亚涛,南新元,贾爱迪. 基于情景分析法的煤电行业碳排放峰值预测[J]. 环境工程,2018,36(12):177-181.

ZHAO Yatao,NAN Xinyuan,JIA Aidi. Prediction of carbon emission peak in coal-fired power industry based on scenario analysis[J]. Environmental Engineering,2018,36(12):177-181.

[4] 曾俣琳. 不同商业模式下的国有燃煤电厂碳捕集、利用与封存(CCUS)项目投资决策研究[D]. 重庆:重庆工商大学,2020.

ZENG Yulin. Investment decision research on carbon capture,utilization and storage technology of coal-fired power plant under different business-model[D].Chongqing:Chongqing Technology and Business University,2020.

[5] 郑楚光,赵永椿,郭欣. 中国富氧燃烧技术研发进展[J]. 中国电机工程学报,2014,34(23):3856-3864.

ZHENG Chuguang,ZHAO Yongchun,GUO Xin. Research and development of oxy-fuel combustion in China[J]. Proceedings of the CSEE,2014,34(23):3856-3864.

[6] LIEMANS I,ALBAN B,TRANIER J,et al. SOx and NOx absorption based removal into acidic conditions for the flue gas treatment in oxy-fuel combustion[J]. Energy Procedia,2011,4:2847-2854.

[7] WALL T F,LIU Y,SPERO C,et al. An overview on oxyfuel coal combustion:State of the art research and technology development[J]. Chemical Engineering Research & Design,2009,87(8):1003-1016.

[8] CROISET E,THAMBIMUTHU K. NOx and SO2 emissions from O2/CO2 recycle coal combustion[J]. Fuel,2001,80(14):2117-2121.

[9] WALL T,STANGER R,LIU Y. Gas cleaning challenges for coal-fired oxy-fuel technology with carbon capture and storage[J]. Fuel,2013,108:85-90.

[10] ABBAS Z,MEZHER T,ABU-ZAHRA M R M. Evaluation of CO2 purification requirements and the selection of processes for impurities deep removal from the CO2 product stream[J]. Energy Procedia,2013,37:2389-2396.

[11] ABBAS Z,MEZHER T,ABUZAHRA M R M. CO2 purification. Part I:Purification requirement review and the selection of impurities deep removal technologies[J]. International Journal of Greenhouse Gas Control,2013,16:324-334.

[12] DE VISSER E,HENDRIKS C,BARRIO M,et al. Dynamis CO2 quality recommendations[J]. International Journal of Greenhouse Gas Control,2008,2(4):478-484.

[13] WHITE V,ALLAM R,MILLER E. Purification of oxyfuel-de-

rived CO2 for sequestration or EOR[J]. Energy Procedia,2006,1(1):399-406.

[14] FORBES S,VERMA P,CURRY T E,et al.Guidelines for carbon dioxide capture, transport,and storage[M]. Washington:World Resources Institute,2008:45.

[15] ANHEDEN M,ANDERSSON A,BERNSTONE C,et al.CO2 qua-

lity requirement for a system with CO2 capture,transport and storage[C]//Proceedings of the 7th International Conference on Greenhouse Gas Control Technologies.Vancouver:[s.n.],2004:2559-2564.

[16] YAN J,ANHEDEN M,BERNSTONE C. Impacts of non-condensable components on CO2 compression/purification,pipeline transport and geological storage[C]//1st Oxyfuel Combustion Conference.Cottbus:[s.n.],2009.

[17] RACE J,WETENHALL B,SEEVAM P,et al. Towards a CO2 pipeline specification:Defining tolerance limits for impurities[J]. Journal of Pipeline Engineering,2012,11(3):173-190.

[18] WANG J,RYAN D,ANTHONY E J,et al. Effects of impurities on CO2 transport,injection and storage[J]. Energy Procedia,2011,4:3071-3078.

[19] WANG W,GRUBBSTROM J,AHMAN S. Flue gas cleaning in oxyfuel combustion[C]//1st Oxyfuel Combustion Conference.Cottbus:[s.n.],2009.

[20] 董继红,李占印,吴俊,等. 燃煤电厂烟气脱硫技术综述[J]. 化工设计,2017,27(6):3-6,1.

DONG Jihong,LI Zhanyin,WU Jun,et al. Overview of flue gas desulfurization technology in coal-fired power plant[J]. Chemical Engineering Design,2017,27(6):3-6,1.

[21] 王国庆. 湿法脱硫烟气溶胶转化及其特性研究[D].济南:山东大学,2018.

WANG Guoqing. Research on aerosol conversion and characteristics of wet desulphurization flue gas[D]. Jinan:Shandong University,2018.

[22] 梁建华,罗明聪. 氧化镁法与石灰石-石膏法脱硫技术方案比较[J]. 科技创新与应用,2014(23):89-90.

LIANG Jianhua,LUO Mingcong. Comparison of desulfurization schemes between magnesium oxide method and limestone gypsum method[J]. Technology Innovation and Application,2014(23):89-90.

[23] 靳晓悦,刘雅举. 湿法烟气脱硫技术综述[J]. 当代化工研究,2017(6):5-6.

JIN Xiaoyue,LIU Yaju. Summary of wet flue gas desulfurization Technology[J]. Chenmical Intermediate,2017(6):5-6.

[24] 杜翔. 国内燃煤锅炉烟气脱硫工艺现状与发展[J]. 硫磷设计与粉体工程,2011(5):13-21,5.

DU Xiang. Current status and development of smelter gas desulphurization process for coal-fired boilers in China[J]. Sulphur Phosphorus & Bulk Materials Handling Related Engineering,2011(5):13-21,5.

[25] BANDYOPADHYAY A,BISWAS M N. Modeling of SO2 scrub-

bing in spray towers[J]. The Science of the total environment,2007,383(1/3):25-40.

[26] LIU D,LIU Y,WALL T. CO2 quality control in oxy-fuel combustion:A dynamic study on the absorption of SO2 into sodium based aqueous solutions relevant to scrubbing prior to CO2 compression[J]. International Journal of Greenhouse Gas Control,2013,12:2-8.

[27] HANSEN B B,FOGH F,KNUDSEN N O,et al. Performance of a wet flue gas desulfurization pilot plant under oxy-fuel conditions[J]. Industrial & Engineering Chemistry Research,2011,50(8):4238-4244.

[28] WAPPEL D,JOSWIG S,KHAN A,et al. The solubility of sulfur dioxide and carbon dioxide in an aqueous solution of potassium carbonate[J]. International Journal of Greenhouse Gas Control,2011,5(6):1454-1459.

[29] LIU D,LIU Y,WALL T F,et al. CO2 quality control by scrubbing in oxy-fuel combustion prior to compression:Relating pH to the liquid composition from absorption of SO2 into sodium based solutions to identify an operational pH window[J]. International Journal of Greenhouse Gas Control,2013,19:462-470.

[30] LIU D,XIONG Z,JIN J,et al. Conceptual design of a packed bed for the removal of SO2 in oxy-fuel combustion prior to compression[J]. International Journal of Greenhouse Gas Control,2016,53:65-78.

[31] 刘仕尧,黄家玉,罗锦洪,等. 富氧燃烧方式下烟气中SO3和Hg的排放及控制研究进展[J]. 过程工程学报,2019,19(S1):115-122.

LIU Shiyao,HUANG Jiayu,LUO Jinhong,et al. Research progress on emission and control of SO3 and mercury in oxy-fuel combustion flue gas[J]. The Chinese Journal of Process Engineering,2019,19(S1):115-122.

[32] 张杰,蔡天凤,马骏,等. 离子交换法制备Ce-HY-SBA-15及其吸附脱氮性能研究[J]. 化学研究与应用,2018,30(8):1271-1276.

ZHANG Jie,CAI Tianfeng,MA Jun,et al. Studies on the adsorptive denitrification performance of studis on Ce-HY-SBA-15 prepared by ion exchange[J]. Chemical Research and Application,2018,30(8):1271-1276.

[33] 洪新,唐克. 杂原子介孔Co-MCM-41分子筛的制备及其吸附脱氮性能[J]. 燃料化学学报,2015,43(6):720-727.

HONG Xin,TANG Ke. Preparation and adsorption denitrification of heteroatoms mesoporous molecular sieve Co-MCM-41[J]. Journal of Fuel Chemistry and Technology,2015,43(6):720-727.

[34] 陈松涛,黄晓宏,柳朝晖,等. 富氧燃烧条件下SCR催化剂活性实验研究[C]//2016燃煤电厂超低排放形势下SCR(SNCR)脱硝系统运行管理及氨逃逸与空预器堵塞技术交流研讨会.杭州:[s.n.],2016.

[35] HILLIARD J C,WHEELER R W. Catalysed oxidation of nitric oxide to nitrogen dioxide[J]. Combustion and Flame,1977,29:15-19.

[36] YAN J,ZHOU F,ZHOU Y,et al. Wet oxidation and absorption procedure for NOx removal[J]. Environmental Technology & Innovation,2018,11:41-48.

[37] HAO R,ZHAO Y. Macrokinetics of NO oxidation by vaporized H2O2 association with ultraviolet light[J]. Energy & Fuels,2016,30(3):2365-2372.

[38] 齐俊华. 水泥窑烟气脱硝技术的发展与创新(下)[J]. 中国水泥,2015(12):79-81.

QI Junhua. Development and innovation of cement kiln flue gas denitration technology(II)[J]. China Cement,2015(12):79-81.

[39] COUNCE R M,PERONA J J. Scrubbing of gaseous nitrogen oxi-

des in packed towers[J]. Aiche Journal,1983,29(1):26-32.

[40] 罗哲林. 富CO2烟气压缩一体化脱硫脱硝的实验研究[D].武汉:华中科技大学,2013.

LUO Zhelin. Experimental study of simultaneous desulfurization and denitrification from CO2 enriched flue gas[D]. Wuhan:Huazhong University of Science and Technology,2013.

[41] 黄强,李军,陈珂. 富氧燃烧烟气加压脱硝过程动力学分析[J]. 湖北农业科学,2017,56(24):4752-4756.

HUANG Qiang,LI Jun,CHEN Ke. Dynamic analysis on denitration process of oxy-fuel combustion flue gas[J]. Hubei Agricultural Sciences,2017,56(24):4752-4756.

[42] 阎维平,鲁晓宇. 富氧燃烧锅炉烟气CO2捕集中回收NO的研究[J]. 动力工程学报,2011,31(4):294-299.

YAN Weiping,LU Xiaoyu. NO recovery during CO2 capture from flue gas of an oxygen-enriched coal-fired boiler[J]. Journal of Chinese Society of Power Engineering,2011,31(4):294-299.

[43] 陈曦,李玉平,韩婕,等. 加压条件下氮氧化物的水吸收研究[J]. 火炸药学报,2009,32(4):84-87.

CHEN Xi,LI Yuping,HAN Jie,et al. Study of pressurized absorption of nitrogen oxides in water[J]. Chinese Journal of Explosives & Propellants,2009,32(4):84-87.

[44] CHENG Q,LIU D,CHEN J,et al. Gas-phase oxidation of NO at high pressure relevant to sour gas compression purification process for oxy-fuel combustion flue gas[J]. Chinese Journal of Chemical Engineering,2019,27(4):884-895.

[45] LIU D,LI W,CHENG Q,et al. Measurement and modeling of nitrogen oxides absorption in a pressurized reactor relevant to CO2 compression and purification process[J]. International Journal of Greenhouse Gas Control,2020,100:103107.

[46] MITSUI Y,IMADA N,KIKKAWA H,et al. Study of Hg and SO3 behavior in flue gas of oxy-fuel combustion system[J]. International Journal of Greenhouse Gas Control,2011,5:S143-S150.

[47] PARK K,SEO Y,LEE S J,et al. Emission and speciation of mercury from various combustion sources[J]. Powder Technology,2008,180(1):151-156.

[48] ZHAO S,PUDASAINEE D,DUAN Y,et al. A review on mercury in coal combustion process:Content and occurrence forms in coal,transformation,sampling methods,emission and control technologies[J]. Progress in Energy and Combustion Science,2019,73:26-64.

[49] ZHENG Y,JENSEN A D,WINDELIN C,et al. Review of technologies for mercury removal from flue gas from cement production processes[J]. Progress in Energy and Combustion Science,2012,38(5):599-629.

[50] WANG H,DUAN Y,LI Y,et al. Investigation of mercury emis-

sion and its speciation from an oxy-fuel circulating fluidized bed combustor with recycled warm flue gas[J]. Chemical Engineering Journal,2016,300:230-235.

[51] LI X,HUANG Q,LUO C,et al. Effect of acid gases on elemental mercury removal in an oxy-fuel CO2 compression process[J]. Energy & Fuels,2018,32(4):4334-4340.

[52] WU H,LIU H,WANG Q,et al. Experimental study of homogeneous mercury oxidation under O2/CO2 atmosphere[J]. Proceedings of the Combustion Institute,2013,34(2):2847-2854.

[53] 黄强,张立麒,周栋,等. 富氧燃烧烟气压缩净化的研究进展[J]. 化工进展,2018,37(3):1152-1160.

HUANG Qiang,ZHANG Liqi,ZHOU Dong,et al. Research and development on the purification of oxy-fuel combustion flue gas in the process of compression[J]. Chemical Industry and Engineering Progress,2018,37(3):1152-1160.

[54] ZHOU W,EGGENSPIELER G,ROKANUZZAMAN A,et al. Prediction of activated carbon injection performance for mercury capture in a full-scale coal-fired boiler[J]. Industrial & Engineering Chemistry Research,2010,49(8):3603-3610.

[55] MIN H,AHMAD T,LEE S. Mercury adsorption characteristics as dependent upon the physical properties of activated carbon[J]. Energy & Fuels,2017,31(1):724-729.

[56] SKODRAS G,DIAMANTOPOULOU I,PANTOLEONTOS G,et al. Kinetic studies of elemental mercury adsorption in activated carbon fixed bed reactor[J]. Journal of Hazardous Materials,2008,158(1):1-13.

[57] MILLER S J,DUNHAM G E,OLSON E S,et al. Flue gas effects on a carbon-based mercury sorbent[J]. Fuel Processing Technology,2000,65:343-363.

[58] LIU Y,ADEWUYI Y G. A review on removal of elemental me-

rcury from flue gas using advanced oxidation process:Chemistry and process[J]. Chemical Engineering Research & Design,2016,112:199-250.

[59] DE M,AZARGOHAR R,DALAI A K,et al. Mercury removal by bio-char based modified activated carbons[J]. Fuel,2013,103:570-578.

[60] SUN P,ZHANG B,ZENG X,et al. Deep study on effects of activated carbon′s oxygen functional groups for elemental mercury adsorption using temperature programmed desorption method[J]. Fuel,2017,200:100-106.

[61] LI D,HAN J,HAN L,et al. Pd/activated carbon sorbents for mid-

temperature capture of mercury from coal-derived fuel gas[J]. Journal of Environmental Sciences-China,2014,26(7):1497-1504.

[62] XU H,QU Z,ZONG C,et al. MnOx/Graphene for the catalytic oxidation and adsorption of elemental mercury[J]. Environmental Science & Technology,2015,49(11):6823-6830.

[63] ZHANG J,DUAN Y,ZHOU Q,et al. Adsorptive removal of gas-phase mercury by oxygen non-thermal plasma modified activated carbon[J]. Chemical Engineering Journal,2016,294:281-289.

[64] XU W,HUSSAIN A,LIU Y. A review on modification methods of adsorbents for elemental mercury from flue gas[J]. Chemical Engineering Journal,2018,346:692-711.

[65] HACK H,FAN Z,SELTZER A. Advanced oxyfuel combustion leading to zero emission power generation[C]//Proceedings of the 35th International Technical Conference on Clean Coal & Fuel Systems.Florida:[s.n.],2010.

[66] WHITE V,TORRENTE-MURCIANO L,STURGEON D,et al. Purification of oxyfuel-derived CO2[J]. Energy Procedia,2009,1(1):399-406.

[67] WHITE V,TORRENTE-MURCIANO L,STURGEON D,et al. Purification of oxyfuel-derived CO2[J]. International Journal of Greenhouse Gas Control,2010,4(2):137-142.

[68] WINKLER F,SCHOEDEL N,ZANDER H,et al. Cold DeNOx development for oxyfuel power plants[J]. International Journal of Greenhouse Gas Control,2011,5(5):S231-S237.

[69] STANGER R,TING T,SPERO C,et al. Oxyfuel derived CO2 compression experiments with NOx,SOx and mercury removal:Experiments involving compression of slip-streams from the Callide Oxyfuel Project(COP)[J]. International Journal of Greenhouse Gas Control,2015,41:50-59.

[70] 黄卫军,李延兵,廖海燕,等. 富氧燃烧锅炉CO2纯化技术研究综述[J]. 中国煤炭,2014,40(S1):253-257,262.

HUANG Weijun,LI Yanbing,LIAO Haiyan,et al. Review of CO2 purification technology for oxy-fuel combustion boiler[J].China Coal,2014,40(S1):253-257,262.

[71] WHITE V,WRIGHT A,TAPPE S,et al. The air products vattenfall oxyfuel CO2 compression and purification pilot plant at Schwarze Pumpe[J]. Energy Procedia,2013,37:1490-1499.

[72] MURCIANO L T,WHITE V,PETROCELLI F P,et al. Sour compression process for the removal of SOx and NOx from oxyfuel-derived CO2[J]. Energy Procedia,2011,4:908-916.

[73] 阎维平,李海新,鲁晓宇. 基于碳捕集的富氧燃煤烟气联合脱硫脱硝试验研究[J]. 环境科学学报,2013,33(5):1382-1388.

YAN Weiping,LI Haixin,LU Xiaoyu. Experimental study on desulfurization and denitration of oxygen-enriched coal-fired flue gas with CO2 capture[J]. Acta Scientiae Circumstantiae,2013,33(5):1382-1388.

[74] 李伟,刘敦禹,陈军,等. 基于鼓泡反应器高压联合脱除富氧燃烧烟气中NOx和SOx的建模分析[J]. 环境工程,2019,37(7):135-141.

LI Wei,LIU Dunyu,CHEN Jun,et al. A modeling analysis on simultaneous removal of NOx and SOx in a bubbling reactor under high pressure for oxy-fuel combustion flue gas[J]. Environmental Engineering,2019,37(7):135-141.

[75] TING T,STANGER R,WALL T. Oxyfuel CO2 compression:The

gas phase reaction of elemental mercury and NOx at high pressure and absorption into nitric acid[J]. International Journal of Greenhouse Gas Control,2014,29:125-134.

[76] STANGER R,TING T,WALL T. High pressure conversion of NOx

and Hg and their capture as aqueous condensates in a laboratory piston-compressor simulating oxy-fuel CO2 compression[J]. International Journal of Greenhouse Gas Control,2014,29:209-220.

[77] HALL B,SCHAGER P,LJUNGSTRÖM E. An experimental study on the rate of reaction between mercury vapour and gaseous nitrogen dioxide[J]. Water,Air,and Soil Pollution,1995,81(1):121-134.

[78] SNIDER G,ARIYA P A. Kinetic and product studies of the reactions of NO2,with Hg0 in the gas phase in the presence of Titania micro-particle surfaces[J]. Water Air and Soil Pollution,2012,223(7):4397-4406.

[79] SAMANTA S,GOSWAMI S,CHAKRAVORTY A. On mercurous nitrite and a basic mercurous nitrate derivative[J]. Indian Journal of Chemistry - Section A,2011,50A(2):137-140.

[80] POTTS R A,ALLRED A L. Mercury(I) complexes[J]. Inorganic Chemistry,1966,5(6):1066-1071.

[81] TAYLOR G B,HULETT G A. Mercuric oxide[J]. The Journal of Physical Chemistry,1913,17(9):755-761.

[82] LVOV B V. Kinetics and mechanism of thermal decomposition

of mercuric oxide[J]. Thermochimica Acta,1999,333(1):21-26.

[83] OZA T M,EZEKIEL E I. The decomposition of mercuric nitrate[J]. Journal of Scientific and Industrial Research,1962,21B:536-539.

[84] OZA T M,JHA J C,EZEKIEL E I. Thermal decomposition of barium and mercury(II) nitrate[J]. Journal of Indian Chemical Society,1968,45(5):420-424.

[85] TING T.The removal of nitrogen oxides and mercury as condensates during the compression of oxyfuel flue gas[D]. Australia:The University of Newcastle,2014.

[86] BAXTER L,BENCE C,BURT S,et al. Cryogenic carbon capture

status[C]//Proceedings of the 35th International Technical Conference on Clean Coal & Fuel Systems.Florida:[s.n.],2010.

和HAMS(N-S化合物)的生成,同时也导致了N

和HAMS(N-S化合物)的生成,同时也导致了N and HAMS(N-S compounds),and also leads to the increase of N

and HAMS(N-S compounds),and also leads to the increase of N