生物质基碳气凝胶光催化剂的制备与性能研究进展

0 引 言

我国对新能源主要界定为:以新技术为基础,已经开发但还未大规模应用的能源,或正在研究试验,尚需进一步开发的能源[1]。太阳光是一种广泛、清洁的能量来源,在我国西部地区,包括新疆、西藏南部、甘肃北部等地区拥有丰富的光照资源。与常规能源相比,太阳能具有储量丰富、可持续性、清洁环保以及普遍性。目前,光伏发电、太阳能取暖等产业在我国得到长期推广,而光催化反应是太阳能有效利用方法,但距离大规模应用仍需克服诸多困难。

光催化是指能够在光照条件下诱发光氧化-还原的现象,在制氢及污染物降解等领域前景广阔[2-5]。与常规反应相比,光催化反应利用光催化剂吸收光子能量,生成的光生电子与空穴对具有强氧化还原能力,能够在温和环境下实现原本需要在苛刻条件下才能实现的反应,使分解水制氢气、还原CO2等需高温高压等复杂条件的反应能够在常温常压的常规反应条件下实现。然而,光催化剂常出现活性低、易被光腐蚀、量子效率低、禁带宽度大、太阳光利用率低等问题,造成光催化技术难以广泛应用[6]。为得到性能优异的光催化剂,需对光催化剂改性,常规方法有改变晶体结构、表面光敏化、杂原子掺杂和复合半导体等[7]。纳米尺寸的光催化剂有较强的光催化活性,在光催化发展初期尝试用悬浮体系验证光催化能力,但在使用过程中需将光催化剂负载于大尺度、易回收的材料上来解决粉体催化剂不易回收、易团聚、易流失等缺点。适宜的载体可以增加反应有效比表面积,提供匹配的孔结构,提高催化剂的机械强度、热稳定性和抗毒性能,并降低催化剂的生产成本[8]。碳气凝胶具有碳材料的理化学性能稳定、导电性能优异,以及气凝胶材料比表面积高、孔隙率高等特点,能够拓宽复合光催化材料的光吸收波长范围,提高对太阳光的利用率,这些特点使碳气凝胶满足成为良好光催化剂载体的条件[9]。

碳气凝胶制备过程包括前驱体制备、干燥与碳化,其中前驱体的选择在碳气凝胶生产比重大,常见的碳气凝胶有以间苯二酚、间苯三酚和甲醛等为原料的聚合物基碳气凝胶[10-11]以及近年随石墨烯、碳纳米管技术的发展,基于二者技术的石墨烯碳气凝胶[12],但准备过程存在污染严重、成本高昂等缺陷,为解决此问题需寻找合适的替代材料。生物质材料富含纤维素、木质素、蛋白质等含碳大分子,以生物质材料为前驱体的制备方法工艺简单、原料来源广泛且廉价,符合大规模生产所需条件,成为碳气凝胶研究热点。

近年来,基于碳气凝胶的相关应用与研究成果不断增加,与之相关的光催化、吸附、油水分离等各方面综述大量出现[13-14],但以生物质基碳气凝胶为主题的综述文章较少,特别是其在光催化领域的进展缺乏总结讨论。目前,生物质基碳气凝胶已在吸附净化[15-16]、电化学[17]等领域得到验证,笔者着重介绍生物质基碳气凝胶在光催化剂负载方面成果,探讨生物质基碳气凝胶负载光催化剂的优势,分析其研究现状并探讨了其未来着力点与研究方向。

1 光催化研究现状

1.1 光催化的应用与改性

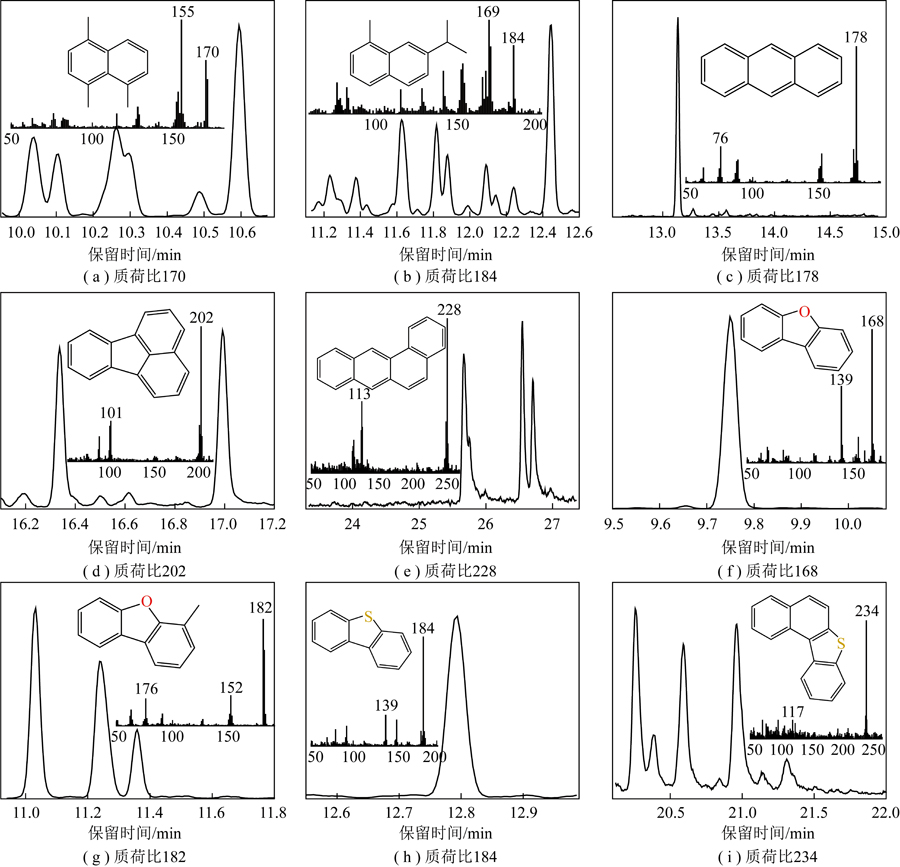

光催化起始于20世纪70年代,FUJISHIMA等[18]在Nature杂志上发表了TiO2单晶电极光催化分解水研究[19-21],如图1所示。一次光催化反应过程分为3部分:① 光照后价带上的电子受光激发跃迁到导带,导带形成光生电子,同时价带上产生空穴,光生空穴具有强氧化能力,而光生电子具有强还原能力;② 由于半导体导-价能带间存在禁带,使光生电子和空穴在复合前有足够长的寿命(Nanosecond)迁移到催化剂表面并与此处吸附的分子(OH-、O2、有机物等)发生能量和电荷交换,产生具有强氧化还原能力的 等物质;③ 这些基团参与直接氧化还原反应,产生氧化或还原产物[6]。

等物质;③ 这些基团参与直接氧化还原反应,产生氧化或还原产物[6]。

图1 光催化机理示意[19-21]

Fig.1 Schematic diagram of photocatalysis mechanism[19-21]

光催化主要研究方向有二氧化碳还原、产氢、水体污染物降解等,应用前景广阔但受限于反应条件苛刻[4,19-21],而光催化能有效降低其反应条件,是实现上述领域大规模工业化的重要途径。其中,光催化降解污染物在光催化研究中很广泛[22-26],已在环境治理、除菌等方面得到应用[2,27];光催化降解CO2能提供多种工业原料,这主要由于受光催化剂表面催化活性位点的影响会发生多步表面催化反应并产生多种产物,提高光催化反应的选择性和产率是重要课题[28-29];而催化分解水制氢技术是氢能源绿色发展领域的重要课题,与电解水等制氢方法相比具有能耗低、污染小等优势[30-33];近年来,还原分离放射性元素[34]、生物质原料转化[35]、光催化固氮[36]等新兴研究领域不断出现,成果丰硕。

光催化剂根据物质成分分为氧化物、硫化物、铋基材料、杂多酸、石墨相氮化碳及金属-有机骨架材料等[37]。氧化物类光催化剂包括TiO2、ZnO、Cu2O、Fe2O3等[38],其中TiO2最常见、研究最多,而硫化物中则以CdS、ZnS最具代表性[39]。铋基材料具有储量丰富、无毒、耐光腐蚀、禁带宽度小等优点,其中Bi2O3等包含Bi3 的半导体稳定性更好[40]。杂多酸(POM)是一种环境友好的固体酸,具有可溶解极性分子、电子易调谐、高富氧表面、强氧化能力等特性[41-43]。石墨相氮化碳是一种新颖的非金属光催化剂,有优良的耐磨性、化学稳定性、热稳定性[44-46]。金属有机骨架(MOFs)具有多样性、可设计性、可剪裁性及超高的比表面积,孔道结构规整有序,骨架可修饰等特点[47-49]。不同类型光催化剂性质不同,但距离实际应用较远,因此需对上述光催化剂进行修饰改性。

常见的修饰改性方法有改善光催化剂结构、附着光吸收能力与活性更强的材料、多种光催化剂复合等。晶粒大小、晶面活性、晶相结构、比表面积等参数影响催化剂性能[50],通过微调催化剂尺寸结构,如改变反应条件、掺杂杂原子在晶相上产生缺陷或以具有复杂结构的材料作为模板,再用光催化剂替换。图2(a)先在具有复杂结构的木质素磺酸钠中填充ZnO,去除木质素磺酸钠得到具有复杂且规律结构的ZnO半导体[51]。表面贵金属沉积与表面光敏化是指将单质纳米颗粒或光活性化合物附着在半导体材料表面,能够提高对入射光的吸收能力,拓宽激发波长[52-53],如图2(b)所示。半导体复合是指将2种及以上的光催化半导体复合,形成n-n型、p-p型、p-n型3种异质结,其中p-n型的复合结构能提高光生载流子的分离作用,称反型异质结或p-n结[54-55],如Z型异质结ZnO@Cu2S的电荷分离过程[56](图2(c)),此方案中的每个半导体只负责1个氧化/还原反应,从而实现极大可见光吸收,增强氧化还原能力,提高光稳定性、电荷分离和光催化效率。

图2 光催化改性方法示意[51,53,56]

Fig.2 Schematic diagram of photocatalytic modification method[51,53,56]

虽然可通过探索光催化剂或尝试更多改性方法提高光催化效率,但提高光催化剂与反应物的接触面积,保护光催化剂仍是光催化实用化的难题,常见方法有直接改变光催化剂结构或形成致密的光催化薄膜负载在器物表面[57],而光催化剂负载是通过将粉末状、颗粒状的光催化剂负载到比表面积大的载体上,是实现光催化实用化的重要方法。

1.2 光催化剂的负载

非均相光催化反应中,为提高比表面积和光催化效率,常使用粉末状光催化剂,主要有悬浮体系和负载2种体系。悬浮体系简单方便,由于比表面较大,能更充分接触光解物,光解效率较高[58],在大量实验室研究和早期开发应用中采用[8]。但光催化剂粉末存在难以回收、易造成污染等缺陷,而负载技术的引入能在保证高比表面积的同时避免团聚和损失,是光催化研究上不可缺少的组成部分。

光催化剂载体包括玻璃类、金属类、矿物类、硅基类、碳基类、陶瓷、有机膜、气凝胶等。XUE等[59]将B-N-TiO2光催化剂包覆在珍珠岩上,提高了光催化剂与水体接触面积,可漂浮水面的特性使其能更好吸收光线,降低回收难度(图3(a));SIGLE等[60]使用金薄膜负载CdSe,使金膜和金纳米粒子夹住原子薄的CdSe,金纳米粒子中的电荷振荡在金属表面诱导镜像电荷,并使等离子体耦合成为可能,最终提高了CdSe的光催化能力(图3(b));LIU等[61]使用具有规则蜂窝结构的陶瓷作为负载材料(图3(c)),使负载TiO2纳米颗粒的蜂窝结构陶瓷板迎着光照,同时使有机化合物挥发气体(VOCs)进入并降解,最后通到气相色谱仪中检测气体成分变化,发现对甲苯气体降解率达97.8%,且经过24轮光催化降解后仍有96.7%的降解率。PARK等[62]将TiO2纳米粒子负载在聚偏二氟乙烯纤维素膜上(图3(d))得到可反复使用的光催化膜,降解亚甲基蓝后溶液颜色变化明显,且多次使用后水通量与降解率无明显变化。为将光催化剂附着到载体上,需采取合适的负载技术,负载方法主要有物理法和化学法,可结合使用。常见的物理负载法有粉末烧结工艺和热黏工艺等,化学法则包括溶胶凝胶法、化学气相法、液相淀积法、磁控溅射法、电泳沉积法、离子交换法、阴极氧化沉积法、微乳液法等。

图3 光催化剂负载影响示意[59-62]

Fig.3 Schematic diagram of the effect of photocatalyst loading[59-62]

目前,常见载体材料通常存在催化剂负载能力差、催化剂负载量小、活性位点少等缺点。气凝胶是由众多细颗粒和网络形成的三维多尺度多孔纳米材料,凭借高孔隙率、高比表面积、低密度等特点而具有优异的吸附效率,可延长底物与催化剂的接触时间,为光催化过程提供大量光催化活性位点并提高光催化性能。气凝胶负载光催化剂一般通过溶胶-凝胶法、自生成等化学方法负载光催化剂,因为可在气凝胶生成过程中负载,实现更高的负载量及更均匀的负载效果。特别在污染物降解领域,污染物在光催化剂表面的吸附行为起重要作用,而气凝胶材料的吸附能力能显著提高对污染物的处理能力[63]。在此基础上,碳气凝胶的轻质、非极性、无活性、无毒、与水易分离特点,使其更适用于废水处理[64-66]。

2 碳气凝胶负载光催化剂研究现状

2.1 碳气凝胶

气凝胶是一种具备三维纳米结构的多孔材料,在吸附分离、光-电催化、储能转化、吸声隔音等领域应用前景广阔[67]。碳气凝胶(CA)是气凝胶的分支,一般以有机气凝胶为前驱体,在惰性气体环境下,经高温碳化裂解后得到。最早的碳气凝胶由PEKALA[68]于1989年以间苯二酚和甲醛为原料,通过超临界二氧化碳干燥法制备出有机气凝胶,最后碳化后获得。碳气凝胶具有多孔的三维网络结构,具有低密度、高比表面积和优异的化学稳定性。碳气凝胶多孔的3D互连网络结构使离子、分子容易进入内部,而分层多孔结构提供了高比表面积和高反应活性接触面,电子可沿着碳气凝胶的三维碳骨架快速移动[69]。这些结构使碳气凝胶在非均相催化剂载体、吸附剂、电极材料、隔热材料等方面应用前景可观,如图4所示。

图4 碳气凝胶的前驱体、性能、应用

Fig.4 Precursors, properties and applications of carbon aerogels

根据前驱体碳气凝胶可分为以间苯二酚、间苯三酚和甲醛等为原料合成的聚合物基碳气凝胶[10-11],以及基于石墨烯、碳纳米管的石墨烯碳气凝胶[12]。然而上述2类碳气凝胶存在工艺复杂、生产周期长、生产规模小、成本昂贵、污染严重等问题,使碳气凝胶工业化生产和应用无法推广,寻找储量丰富、价格低廉、环保的前驱体替代物尤为重要。

2.2 碳气凝胶负载光催化剂

碳气凝胶疏水亲油且具有高孔隙率吸附,经过活化改性、金属或金属氧化物的纳米粒子掺杂后也能用于吸附重金属离子或有机染料等污染物。邵琰等[70]制备了碳气凝胶及纳米SiO2改性的(SiO2/RF)碳气凝胶,并使用硝酸钴浸渍改性,经测试发现Co掺杂后的碳气凝胶的亚甲基蓝吸附能力提高,而加入纳米SiO2改性的碳气凝胶其吸附能力变化相对较低;魏巍等[71]以西瓜皮为碳源,通过水热处理结合冷冻干燥法制备了碳气凝胶,对孔雀石绿和罗丹明B模拟的染料废水进行吸附试验,结果表明初始质量浓度10 mg/L、碳气凝胶加入量0.5 g/L、吸附温度为常温、初始废水pH为染料废水自然酸碱度、吸附时间1 h时,碳气凝胶对孔雀石绿的去除率为92.7%,对罗丹明B的去除率为67.2%。碳气凝胶的强吸附能力能够与光催化体系共同作用,将待处理的污染物吸附到光催化系统内提高污染物与光催化体系接触效率,最终提高光催化效率且不会对光催化剂活性产生过多影响。

以碳气凝胶作为基底负载光催化剂的研究广泛,其中光催化剂主要是TiO2及硫化物。JUSTH等[72-73]通过水热法、原子层沉积法将碳气凝胶与TiO2复合得到了CA/TiO2复合材料,且光催化降解效果显著;BAIL N-GARC

N-GARC A等[74]通过溶胶-凝胶法制备了一系列碳气凝胶-二氧化钛样品,对合成工艺进行改进;LU等[75]通过原位生长法制备了具有不同ZnS含量的新型空心球形硫化锌@碳质气凝胶(ZnS@CA)复合材料,对比发现质量分数55%的ZnS@CA能达到纯ZnS降解能力的1.7倍,产氢率8.1倍;PRASAD等[76]制备了碳气凝胶负载CdS纳米复合材料,具有更高的光物理性能、更大的比表面积和在纳米尺度上更理想的形貌;SHEN等[77]制备了具有三维多孔结构的ZnO/石墨烯(G)/氧化石墨烯(GO)/多壁碳纳米管(MCNT)复合气凝胶,降解试验表明ZnO/G/GO/MCNT对RhB的总降解率可达86.8%,是ZnO的3.3倍,并发现ZnO和G的协同作用有效阻止光生电子-空穴对复合,提高了光催化活性;ZHANG等[78]将二氧化钛量子点作为光催化活性位点负载在碳纳米管形成的碳气凝胶上,得到的CA@TiO2光催化剂的氢产率为纯TiO2光量子点的11倍,氢产率为2.1 mmol/g。

A等[74]通过溶胶-凝胶法制备了一系列碳气凝胶-二氧化钛样品,对合成工艺进行改进;LU等[75]通过原位生长法制备了具有不同ZnS含量的新型空心球形硫化锌@碳质气凝胶(ZnS@CA)复合材料,对比发现质量分数55%的ZnS@CA能达到纯ZnS降解能力的1.7倍,产氢率8.1倍;PRASAD等[76]制备了碳气凝胶负载CdS纳米复合材料,具有更高的光物理性能、更大的比表面积和在纳米尺度上更理想的形貌;SHEN等[77]制备了具有三维多孔结构的ZnO/石墨烯(G)/氧化石墨烯(GO)/多壁碳纳米管(MCNT)复合气凝胶,降解试验表明ZnO/G/GO/MCNT对RhB的总降解率可达86.8%,是ZnO的3.3倍,并发现ZnO和G的协同作用有效阻止光生电子-空穴对复合,提高了光催化活性;ZHANG等[78]将二氧化钛量子点作为光催化活性位点负载在碳纳米管形成的碳气凝胶上,得到的CA@TiO2光催化剂的氢产率为纯TiO2光量子点的11倍,氢产率为2.1 mmol/g。

此外,基于铋基材料、石墨相氮化碳、复合光催化剂等多种光催化剂的负载研究也在快速推进。2023年VADIVEL等[79]通过水热法与焙烧法制备了TbVO4、Nb2O5纳米粒子并通过一步法负载到碳气凝胶上,对磺胺甲恶唑的光催化去除效果良好,化学稳定性较好,90 min降解率为92.3%,分别为TbVO4和Nb2O5的5倍和7倍;ZHANG等[80]采用天然棉为前驱体,原位制备了Bi2O3负载碳纤维气凝胶,兼具较大的吸附能力和较好的光催化活性,在流动系统中可实现长时间连续稳定的污染物去除,有望成为一种可大规模去除工业废水中有机污染物的功能材料。

综上,碳气凝胶作为载体能够与多种光催化剂实现良好的协同效果,提高光催化效率的同时降低光催化剂的回收难度,且负载的光催化剂不会轻易脱落可重复使用,应用前景可观。随碳气凝胶与光催化研究的共同发展,碳气凝胶负载光催化剂的实践研究不断进步,光催化效率、催化剂负载的牢固程度、循环使用能力等不断提升。然而碳气凝胶制备困难长期阻碍着碳气凝胶的应用,而生物质基碳气凝胶以生物质材料为前驱体,兼具成本低廉、原料丰富、生物相容性良好、自掺杂杂原子等特点,因此研究广泛。

3 生物质基碳气凝胶负载光催化剂研究现状

3.1 生物质基碳气凝胶

生物质主要是由生物体及类生物体组成的生物质,包括植物、动物、真菌、细菌及各种废弃物。生物质资源最显著的特点是天然可再生、成本低廉、来源广泛。以秸秆资源为例,我国秸秆产量每年高达7亿多吨,其中水稻、小麦和玉米3种主要粮食作物的秸秆产量最大,分别为2.1亿、1.1亿、2.09亿t[81]。生物质材料能够为环境污染、不可再生资源消耗等带来新的解决方案。经高温碳化的生物质材料可应用于吸附污染物、催化剂负载等多种领域[82-85],如图5所示。生物质材料在国际上被称为化学工业的第3次革命,不仅可有效缓解环境压力,还能为人类提供新型性能优越的材料[86],是未来材料研究的重要方向。

图5 生物质材料来源与应用[85]

Fig.5 Source and application of biomass materials[85]

生物质资源拥有纤维素、淀粉、糖类、油脂等含碳大分子,以各种生物质材料为前驱体制备的碳气凝胶称为生物质基碳气凝胶[87-90],如图6所示。生物质碳气凝胶由具有多孔结构的生物质气凝胶经碳化得到,包括二次组装的生物质提取物以及经过处理的多孔性生物质材料本身[87,89-92]。由于生物质材料种类丰富、来源广泛,研究者尝试以多种生物质材料作为生物质基碳气凝胶的前驱体,包括植物[87]、动物、真菌、纤维素、蛋白质等。WAN等[93]从小麦的秸秆废弃物中提取纯化纤维素,使用冻融技术制备纤维素纳米晶/聚乙二醇复合的水凝胶,水凝胶经过冷冻干燥后在1 000 ℃氩气气氛下热解碳化生成碳气凝胶;YANG等[90]以藤条为原料,采用完全脱木素、碳化和化学活化相结合的方法,合成了一种新型的多孔纳米片状碳气凝胶(图6(d)),比表面积高,0.5 A/g下表现出优秀的比电容221 F/g,20 A/g下仍有80%电容保持率,具有出色的循环稳定性;WANG等[89]则以甲壳素和壳聚糖为碳源和氮源,经冷冻干燥和两步热解方法制备了氮掺杂生物质基碳凝胶(图6(c)),表现出优异的电磁干扰(EMI)屏蔽性能的同时,可通过控制前驱体含量和碳化温度,精确控制掺杂元素的含量、类型以及电导率,为开发具有可调EMI屏蔽性能的生物质基碳气凝胶开辟新途径;ZHENG[94]等以杏鲍菇为前驱体,并将核壳结构的FeCo@C纳米笼锚定在杏鲍菇生物质衍生碳的表面,表现出优秀的微波吸收能力,具有轻质、防腐、耐酸、耐碱、耐盐蚀性能,可在复杂环境承担吸波材料;MA等[87]则选择马铃薯淀粉为前驱体制备碳气凝胶(图6(a)),与无定形氧化钴组装成(CoOx/PSCA),避免过渡金属团聚,可直接用作电解析氢的自支撑催化剂;LIU等[88]以富含蛋白质的天然羽绒团簇(DC)为前驱体,通过低温碳化制备了羽绒生物质基氮掺杂碳纤维气凝胶(DCFA)(图6(b)),能实现高效的太阳能蒸发,DCFA的低密度和高孔隙率提高了总太阳能吸收率,达97.03%,并抑制了蒸发过程中的能量损失,DCFA 可在无外力作用下实现自漂浮,使其成为简便的蒸发器;戎西林等[95]以甘蔗渣作为前驱体,在氢氧化钠/脲溶液体系下低温溶解纤维素,并获得均匀的纤维素溶液,再通过水中再生、冷冻干燥、高温碳化获得甘蔗渣纤维素基碳气凝胶,表现出较好的轻质性(密度为33.4 mg/cm3)、高疏水性(水接触角为136°)和高比表面积(468.24 m2/g),对柴油、汽油、泵油、正己烷、甲苯、三氯甲烷具有较好的吸附能力(20.2~66.3 g/g);CHENG等[96]以细菌纤维素水凝胶为原料,通过定向冷冻干燥和高温碳化(800、1 000、1 200 ℃),得到了高机械弹性(最高压缩率可达99.5%)、高孔隙率的细菌纤维素基碳气凝胶,具有优异的油水分离选择性。

图6 生物质基碳气凝胶制备示意[87-90]

Fig.6 Schematic diagram of biomass-based carbon aerogel preparation[87-90]

相较传统方法,上述碳气凝胶制备方法的原料更廉价,制备过程环保、便捷,但仍需先制备前驱体气凝胶再碳化处理才能得到碳气凝胶,制备效率仍不足,具有复杂三维结构的生物质材料成为研究热点。NGUYEN等[97]以水葫芦为原料制备水葫芦基碳气凝胶,提取的分级多孔碳可用于去除溢油、重金属或废水营养物质,作为膜电容去离子(MCDI)技术用于微咸水淡化的电极;胡耀强等[98]使用西瓜皮为前驱体制备西瓜皮基生物质基碳气凝胶,对刚果红(CR)和孔雀石绿(MG)均表现出较好的吸附效果,且具有较好的抗共存离子影响的能力,在高浓度NaCl溶液体系中对CR和MG仍具有较高的吸附量;LEI等[99]以香蕉为原料制备香蕉基碳气凝胶。先将香蕉去皮切块后经过液氮冷冻干燥后得到香蕉气凝胶,再在氩气保护下碳化制备多孔氮掺杂香蕉碳气凝胶,具有超强的油水分离选择性,吸油容量达132~274 g/g,还可通过简单的吸收/燃烧方法重复使用,20次吸收/燃烧循环后仍保持高效的吸油能力和优异的超疏水性,可回收性和稳定性优越;HU等[100]以柚皮为前驱体制备碳气凝胶,采用三辛胺和γ-缩水甘油基丙基三甲氧基硅烷(KH560)浸渍法改性,制备的吸附剂在模拟盐水和油田盐水中对碘离子均有良好的吸附性能,在油田盐水中对碘离子的最高吸附量达0.58 mmol/g;ZHU等[101]以甘薯为前驱体制备碳气凝胶,用作改性锂硫电池的商用隔膜,碳气凝胶涂层既能抑制多硫化物中间体在循环过程中的穿梭效应,降低电池电阻,又能作为上电流收集器,结果表明碳气凝胶改性隔板电池具有良好的电化学性能。综上所述,基于三维多孔结构的生物质的简单处理和碳化得到碳气凝胶的方法可行。

3.2 生物质基碳气凝胶负载光催化剂

近年来,生物质基碳气凝胶的制备与研究较多,生物质基碳气凝胶负载光催化剂体系备受关注。大部分研究者选择从生物质材料中先提取各种含碳大分子,再经过组装与碳化后制备碳气凝胶,常见的含碳大分子包括纤维素、木质素、蛋白质、糖类等[102-105],如图7所示。部分国内外生物质基碳气凝胶应用于光催化剂负载的实例见表1[9,75,103-112]。DAI等[106]选择木质素作为碳源,制备了具有高光催化效率和优异循环性能的疏水性TiO2/木质素基碳纳米纤维复合材料(TiO2@CFs),与商业TiO2粉末相比,在静态和氙灯照射下,TiO2@CFs对亚甲基蓝溶液的降解率在30、15 min时分别提高了约2.62倍和3.02倍,并且在磁力搅拌下经过4个循环后TiO2@CFs对亚甲基蓝的去除率仍可达91.5%;JIN等[107]则将壳聚糖-醋酸溶液与CuO-Nb分散溶液混合作为前驱体,采用冷冻干燥-焙烧法制备了Cu/Cu2O/CuO@CA光催化剂,可将戊糖、己糖等单糖快速光催化重整为乳酸,表现出优异的稳定性和可重复使用性;QUAN等[104]从麒麟菜中提取卡拉胶制备水凝胶作为前驱体(图7(c)),并利用其中的天然硫元素与Cd 金属离子结合得到CdS光催化剂,再经过冷冻干燥和碳化得到CdS@CA光催化剂。

表1 生物质基碳气凝胶负载光催化剂实例

Table 1 Example of biomass-based carbon airgel supported photocatalyst

图7 生物质基碳气凝胶负载光催化剂示意[102-105]

Fig.7 Schematic diagram of biomass-based carbon aerogel supported photocatalyst[102-105]

而在生物质基底材料选择上,纤维素凭借来源广泛、储量丰富、价格低廉、碳含量高等优势,研究最多。LIU等[108]与CUI等[109]选择纤维素气凝胶为前驱体,制备了纤维素/CuO前驱体,经过煅烧制备了Cu/CA或Cu2O/CA复合材料,光催化试验表明,所制备的Cu2O/CuO@CA复合材料在可见光照射下能降解水溶液中的亚甲基蓝,且有效阻止了氧化亚铜/氧化铜复合材料的团聚,并对亚甲基蓝具有较高的光催化活性;赵欢欢[110]以棉短绒纤维素为前驱体,利用共沉淀原理制备ZnFe2O4,通过控制加入纤维素水凝胶体系中的Zn(NO3)2·6H2O和Fe(NO3)3·9H2O含量,从而调控纤维素对ZnFe2O4的负载量,经过碳化后得到铁氧体碳气凝胶复合材料,用亚甲基蓝溶液(MB)模拟污染物,具有优秀光催化活性的同时保留了铁氧体的磁性,有利于从水体中回收;LIU[105]从剑麻中提取纤维素制备纤维素气凝胶,经过碳化后再通过原位生长法与浸渍法得到了Na2Ti3O7@Cu2O@CA复合材料(图7(d)),表现出对重金属离子(Cd2 、Co2 、Pb2 、Cr3 )优秀的吸附能力,同时表现出优秀的光催化能力,模拟环境下降解率达99%,反复吸附-脱附测试后仍保持优秀的吸附与光降解能力;而YANG等[113]从丝瓜中提取纤维素作为前驱体制备生物质基碳气凝胶,并将其作为一种高效的无金属绿色碳基催化剂,用于活化过氧单硫酸盐(PMS)降解四环素(TC),最佳条件下90 min内TC去除率达93%;鲍杰等[111]以三聚氰胺、氯化铵为原料制备石墨相氮化碳(g-C3N4),以纤维素为碳源,采用溶胶-凝胶法结合碳化制备了石墨相氮化碳负载碳气凝胶并光催化降解四环素(TC),经过180 min降解率达92%。

以天然具有三维多孔结构的生物质材料为前驱体,经过处理和碳化得到的碳气凝胶研究较多,与先制备前驱体气凝胶再碳化的制备方法相比,主要难点在于如何将负载的光催化剂附着进气凝胶内部,目前主要方法是浸渍法。侍明近[9]以冬瓜为前驱体制备碳气凝胶,分别掺杂TiO2、AgBr、BiPO4光催化剂,并以亚甲基蓝模拟污染物,发现负载后的光催化效率均高于负载前水平,如负载前的商用P25 TiO2催化剂对亚甲基蓝溶液的降解率仅20%,而负载后降解率达82%,而纯BiPO4与BiPO4/CA在相同时间内降解亚甲基蓝,降解率分别为63.03%与93.51%;LU等[75]用萝卜作为生物质原料碳源,以Zn(NO3)2·6H2O为锌源,硫代乙酰胺为硫源,经混合、浸渍、反应后干燥并碳化合成ZnS@CA材料,在模拟500 W氙灯模拟日光下降解亚甲基蓝为纯ZnS效率的1.7倍,产氢能力为纯ZnS的8.1倍;WEI等[103]以冬瓜为前驱体制备的生物质基碳气凝胶为骨架结构,嵌入二维BiPO4纳米棒,成功设计并制备一种超轻2D-3D异质结复合材料(图7(b)),在可见光照射下对模拟染料具有优异的降解活性,是纯BiPO4的7.12倍;NGULLIE等[102]以柚橙为原料通过水热法制备碳气凝胶(图7(a)),又通过共沉淀法将Fe3O4负载到碳气凝胶上,最后通过水热法负载ZnO,得到Fe3O4与ZnO耦合的水热辅助磁性氧化锌/碳纳米复合材料,在兼具磁性的同时提高了光催化效率,对亚甲基蓝染料实现97.14%的降解率;ZHANG等[112]充分利用生物质材料的自然特点,利用棉花上的天然含氧基团吸附Bi3 离子,经碳化后原位结晶成Bi2O3纳米晶体颗粒,能够快速吸附和降解四环素。

4 结语及展望

近年来,国内外学者围绕碳气凝胶制备光催化剂,在染料的光催化降解、杀菌、氮氧化物处理等方向实现突破、验证并解释了碳气凝胶作为光催化剂负载材料的可行性。生物质基碳气凝胶凭借其污染小、成本低廉、加工过程简易、天然掺杂杂原子等优势,得到广泛关注。目前,对于生物质基碳气凝胶的探索主要集中在生物质的选择与处理上,包括纤维素、蛋白质、糖类等动植物提取物及天然的多孔性生物质,其中又以纤维素及富含纤维素的多孔性植物作为主要研究方向。而生物质基碳气凝胶光催化领域研究在国内外尚属早期,虽已验证了部分光催化剂与生物质基碳气凝胶负载的组合效果优异,但仍面对诸多不足。主要表现为多数研究成果为单个生物质基碳气凝胶与单类光催化剂之间的对应,缺少联系性;研究深度不足,缺少更广泛和全面的整理统计。针对上述生物质基碳气凝胶及其在光催化负载领域的研究现状,未来研究可注意以下方向:

1)目前生物质基碳气凝胶负载催化剂探索中,缺少适当的改性处理及其对光催化效果影响的相关研究,可尝试一些针对生物质来源的改性方法,如使用生物技术培育纤维素含量更高、显微结构更复杂的动植物作为生物质来源。

2)目前研究多止步于与纯光催化剂的催化能力对比,缺少传统碳气凝胶或其他负载材料与生物质基碳气凝胶各项性能对照,性价比缺少直观对比。

3)同类或不同天然生物质材料的特殊三维结构、天然元素、孔隙大小对碳气凝胶的结构以及光催化过程的影响研究较少,同时各类型、来源的生物质基碳气凝胶与不同种类光催化剂之间的协同效果缺少研究与统计。

4)生物质内自掺杂的N、P、S杂原子能对光催化过程造成影响,但其具体作用方式与效果缺乏系统整理与讨论。

5)以天然具有三维多孔结构的生物材料为前驱体时,光催化剂的负载方法主要为浸渍,可尝试探索更多不同的负载方法。

[1] 张海龙. 中国新能源发展研究[D]. 长春: 吉林大学, 2014.

[2] 张文凯, 王彦敏, 宋淑琴, 等. 光催化降解汽车尾气道路材料的应用研究进展[J]. 材料导报, 2022,36(S2): 1-9.

ZHANG Wenkai, WANG Yanmin, SONG Shuqin, et al. Research progress of road materials for photocatalytic degradation of automobile exhaust[J]. Materials Reports, 2022,36(S2): 1-9.

[3] 水博阳, 宋小三, 范文江. 光催化技术在水处理中的研究进展及挑战[J]. 化工进展, 2021, 40(S2): 356-363.

SHUI Boyang, SONG Xiaosan, FAN Wenjiang. Research progress and challenges of photocatalytic technology in water treatment[J]. Chemical Industry and Engineering Progress, 2021, 40(S2): 356-363.

[4] 郭彪, 赵晨灿, 刘芯辛, 等. 不同形貌的TiO2光催化制氢性能研究进展[J]. 沈阳师范大学学报(自然科学版), 2021, 39(2): 117-124.

BIAO Guo, ZHAO Chencan, LIU Xinxin, et al. Research progress on TiO2 with different morphologies for photocatalytic hydrogen evolution[J]. Journal of Shenyang Normal University(Natural Science Edition), 2021, 39(2): 117-124.

[5] GUO R, WANG J, BI Z, et al. Recent advances and perspectives of core-shell nanostructured materials for photocatalytic CO2 reduction[J]. Small, 2023, 19(9):2206314.

[6] 韩世同, 习海玲, 史瑞雪, 等. 半导体光催化研究进展与展望[J]. 化学物理学报, 2003,16(5): 339-349.

HAN Shitong, XI Hailing, SHI Ruixue, et al. Prospect and progress in the semiconductor photocatalysis[J]. Chinese Journal of Chemical Physics, 2003,16(5): 339-349.

[7] 张彭义, 余刚, 蒋展鹏. 半导体光催化剂及其改性技术进展[J]. 环境科学进展, 1997,5(3): 2-11.

ZHANG Pengyi, YU Gang, JIANG Zhanpeng. Review of semiconductor photocatalysis and its modification[J]. Chinese Journal of Environmental Engineering, 1997,5(3): 2-11.

[8] 贺飞, 唐怀军, 赵文宽, 等. 纳米TiO2光催化剂负载技术研究[J]. 环境污染治理技术与设备, 2001,2(2): 47-58.

HE Fei, TANG Huaijun, ZHAO Wenkuan, et al. Study on immobilization technology of nanosized titanium dioxide photocatalyst[J]. Chinese Journal of Environmental Engineering, 2001,2(2): 47-58.

[9] 侍明近. 生物质碳基气凝胶复合材料的可控制备及其光催化性能研究[D]. 镇江: 江苏大学, 2016.

[10] 陈龙武, 甘礼华. 气凝胶[J]. 化学通报, 1997(8): 22-28.

CHEN Longwu, GAN Lihua. Aerogel[J]. Chemistry, 1997(8): 22-28.

[11] 张拴勤, 王珏, 沈军, 等. 碳气凝胶/H2SO4双电层电容器的特性[J]. 功能材料与器件学报, 1999,5(1): 57-60.

ZHANG Shuanqin, WANG Jue, SHEN Jun, et al. Characteristics of carbon aerogel/H2SO4 electric double layer capacitors[J]. Journal of Functional Materials and Devices, 1999,5(1): 57-60.

[12] 邱军科, 王朋, 张迪, 等. 三维石墨烯基多孔碳材料的制备及对污染物的吸附性能研究进展[J]. 材料导报, 2020, 34(13): 13028-13035.

QIU Junke, WANG Peng, ZHANG Di, et al. Preparation of three-dimensional graphene-based porous carbon materials and their adsorption properties for pollutants: A review[J]. Materials Reports, 2020, 34(13): 13028-13035.

[13] WONG K J, FOO J J, SIANG T J, et al. Shining light on carbon aerogel photocatalysts: Unlocking the potentials in the quest for revolutionizing solar-to-chemical conversion and environmental remediation[J]. Advanced Functional Materials, 2023:202306014.

[14] JOSEPH A, VIJAYANANDAN A. Review on support materials used for immobilization of nano-photocatalysts for water treatment applications[J]. Inorganica Chimica Acta, 2023, 545:121284.

[15] BI H, YIN Z, CAO X, et al. Carbon fiber aerogel made from raw cotton: A novel, efficient and recyclable sorbent for oils and organic solvents[J]. Advanced Materials, 2013, 25(41): 5916-5921.

[16] CHEN W, ZHANG Q, UETANI K, et al. Absorption materials:Sustainable carbon aerogels derived from nanofibrillated cellulose as high-performance absorption materials[J]. Advanced Materia-ls Interfaces, 2016, 3(10):1600004.

[17] WANG L, SCHUTZ C, SALAZAR-ALVAREZ G, et al. Carbon aerogels from bacterial nanocellulose as anodes for lithium ion batteries[J]. RSC Advances, 2014, 4(34): 17549-17554.

[18] FUJISHIMA A, HONDA K. Electrochemical photolysis of water at a semiconductor electrode[J]. Nature, 1972, 238: 37-38.

[19] 李佳. 石墨相氮化碳(g-C3N4)的结构调控与光催化制氢增强机制研究[D]. 西安:西安理工大学, 2019.

[20] 兰蓥华, 林亚惠, 牛雅文, 等. 构建光催化氧化-还原体系的研究进展[J]. 化学通报, 2023, 86(5): 568-574.

LAN Yinghua, LIN Yahui, NIU Yawen, et al. Research progress in the construction of photocatalytic oxidation-reduction system[J]. Chemistry, 2023, 86(5): 568-574.

[21] 夏建强, 丁立勤, 张海明, 等. Cu-TiO2催化剂模拟太阳光光催化降解环丙沙星[J]. 广东化工, 2023, 50(13): 139-141.

XIA Jianqiang, DING Liqin, ZHANG Haiming, et al. Photocatalytic degradation of ciprofloxacin by simulating sunlight with Cu-doped TiO2 catalysts[J]. Guangdong Chemical Industry, 2023, 50(13): 139-141.

[22] STEVEN N F, ALLEN J B. Heterogeneous photocatalytic oxidati-on of cyanide and sulfite in aqueous solutions at semiconductor powders[J]. The Journal of Physical Chemistry, 1977, 81(15): 1484-1488.

[23] STEVEN, FRANK, ALLEN, et al. Heterogeneous photocatalytic oxidation of cyanide ion in aqueous solutions at titanium dioxide powder[J]. Journal of the American Chemical Society, 1977, 99(1): 303-304.

[24] OLLIS D F, HSIAO C Y, BUDIMAN L, et al. Heterogeneous photoassisted catalysis: Conversions of perchloroethylene, dichloroethane, chloroacetic acids, and chlorobenzenes[J]. Journal of Catalysis, 1984, 88(1): 89-96.

[25] SERPONE N, PELIZZETTI E, HIDAKA H, et al. Photocatalyticpurification and treatment of water and air[J]. Applied Catalysis B: Environmental, 1993, 3(2/3): N22-N23.

[26] OLLIS D F. Solar-assisted photocatalysis for water purification: Issues, data, questions[J]. Springer Netherlands, 1991,30: 593-622.

[27] FUJIJSHIMA A, ZHANG X, TRYK D A. Heterogeneous photocatalysis: From water photolysis to applications in environmental cleanup[J]. International Journal of Hydrogen Energy, 2007, 32(14): 2664-2672.

[28] VAHIDZADEH E, ZENG S, MANUEL A P, et al. Asymmetric multipole plasmon-mediated catalysis shifts the product selectivity of CO2 photoreduction toward C2 products[J]. ACS Applied Materials &Interfaces, 2021, 13(6): 7248-7258.

[29] 石志盛. Cu基、In2O3基催化剂的制备及其CO2加氢制甲醇性能研究[D]. 南京: 东南大学, 2021.

[30] 王保伟, 孙启梅. 可见光催化水解制氢催化剂概述[J]. 化学通报, 2012, 75(12): 1059-1068.

WANG Baowei, SUN Qimei. An overview of photocatalysts for water splitting producing hydrogen under visible-light irradiation[J].Chemistry Bulletin, 2012, 75(12): 1059-1068.

[31] 徐建华, 谈玲华, 寇波, 等. 类石墨相C3N4光催化剂改性研究[J]. 化学进展, 2016, 28(1): 131-148.

XU Jianhua, TAN Linghua, KOU Bo, et al. Modification of graphtic carbon nitride photocatalyst[J]. Progress in Chemistry, 2016, 28(1): 131-148.

[32] LU Q, YU Y, MA Q, et al. 2D Transition-metal-dichalcogenide-nanosheet-based composites for photocatalytic and electrocatalytic hydrogen evolution reactions[J]. Advanced Materials, 2016, 28(10): 1917-1933.

[33] XU J, TAN L, Bo K, et al. Modification of graphtic carbon nitride photocatalyst[J]. Progress in Chemistry, 2016, 28(1): 131-148.

[34] LI K, ZHENG B, DING L, et al. Integration of high visible-light-driven ternary dual Z-scheme AgVO3-InVO4/g-C3N4 heterojunction nanocomposite for enhanced uranium(VI) photoreduction separation[J]. Environmental Pollution, 2023, 334: 122168.

[35] WU X, XIE S, ZHANG H, et al. Metal sulfide photocatalysts for lignocellulose valorization[J]. Advanced Materials, 2021, 33(50): 2007129.

[36] HU T, JIANG G, YAN Y, et al. Facile synthesis of Fe single-atom porous photocatalysts via direct metal atomization achieving efficient photocatalytic nitrogen fixation[J]. Journal of Materials Science &Technology, 2023, 167: 248-257.

[37] 周锋, 任向红, 刘建友, 等. 光催化降解水体有机污染物的研究进展[J]. 材料工程, 2018, 46(10): 9-19.

ZHOU Feng, REN Xianghong, LIU Jianyou, et al. Development of photocatalytic degradation of organic pollutants in water[J]. Journal of Materials Engineering, 2018, 46(10): 9-19.

[38] GUSAIN R, GUPTA K, JOSHI P, et al. Adsorptive removal and photocatalytic degradation of organic pollutants using metal oxides and their composites: A comprehensive review[J]. Advances in Colloid and Interface Science, 2019, 272:102009.

[39] JIA L, TAN X, YU T, et al. Mixed metal sulfides for the application of photocatalytic energy conversion[J]. Energy &Fuels, 2022,36(19): 11308-11322.

[40] 张迪. 铋基Z型光催化剂的制备与性能[D]. 哈尔滨: 哈尔滨工业大学, 2021.

[41] LONG D, BURKHOLDER E, CRONIN L. Polyoxometalate clusters, nanostructures and materials: From self assembly to designer materials and devices[J]. Chemical Society Reviews, 2007, 36(1): 105-121.

[42] BUDYCH M J W, STASZAK K, BAJEK A, et al. The future of polyoxymetalates for biological and chemical apllications[J]. Coordination Chemistry Reviews, 2023, 493: 215306.

[43] 吴佳伦, 吴道新, 彭伟, 等. 杂多酸型光催化剂降解有机废水的研究进展[J]. 环境化学, 2021, 40(12): 3955-3966.

WU Jialun, WU Daoxin, PENG Wei, et al. Research progresses on degradation of organic wastewater by polyoxometalate-based photocatalysts[J]. Environmental Chemistry, 2021, 40(12): 3955-3966.

[44] 陈秀芳. 石墨相氮化碳的制备、表征及其光催化性能研究[D]. 福州: 福州大学, 2011.

[45] 吴星瞳. 石墨相氮化碳微纳米材料的制备及光催化性能研究[D]. 长春: 吉林大学, 2015.

[46] ZHANG M, YANG Y, AN X, et al. A critical review of g-C3N4-based photocatalytic membrane for water purification[J]. Chemical Engineering Journal, 2021, 412:128663.

[47] 王丽苹. 金属有机骨架材料在光催化反应中的应用研究进展[J]. 材料导报, 2017, 31(13): 51-62.

WANG Liping. Progress in application of metal-organic framworks in photocatalytic reactions[J]. Materials Reports, 2017, 31(13): 51-62.

[48] 黄刚, 陈玉贞, 江海龙. 金属有机骨架材料在催化中的应用[J]. 化学学报, 2016, 74(2): 113-129.

HUANG Gang, CHEN Yuzhen, JIANG Hailong. Metal-organic frameworks for catalysis[J]. Acta Chimica Sinica, 2016, 74(2): 113-129.

[49] XIE F, BIE C, SUN J, et al. A DFT study on Pt single atom loaded COF for efficient photocatalytic CO2 reduction[J]. Journal of Materials Science &Technology, 2024, 170: 87-94.

[50] 黄柏标, 王泽岩, 王朋, 等. 光催化材料微结构调控的研究[J]. 中国材料进展, 2010, 29(1): 25-36.

HUANG Bobiao, WANG Zeyan, WANG Peng, et al. Research on microstructure modulation of photocatalysts[J]. Materials China, 2010, 29(1): 25-36.

[51] LI Y, ZUO H, GUO Y, et al. Renewable lignosulfonate-assisted synthesis of hierarchical nanoflake-array-flower ZnO nanomaterials in mixed solvents and their photocatalytic Performance[J]. Nanoscale Research Letters, 2016, 11: 260.

[52] 焦小红. 光电催化全钒液流电池传质特性及性能强化[D]. 重庆: 重庆大学, 2018.

[53] SHARWANI A A, NARAYANAN K B, KHAN M E, et al. Photocatalytic degradation activity of goji berry extract synthesized silver-loaded mesoporous zinc oxide (Ag@ZnO) nanocomposites under simulated solar light irradiation[J]. Scientific Reports, 2022, 12(1): 100171.

[54] LI H, TU W, ZHOU Y, et al. Z-Scheme photocatalytic systems for promoting photocatalytic performance: Recent progress and future challenges[J]. Advanced Science, 2016, 3(11): 150038911.

[55] HUANG F, LI Z, XU Y, et al. Excellent anti-photocorrosion and hydrogen evolution activity of ZnIn2S4-based photocatalysts: In-situ design of photogenerated charge dynamics[J]. Chemical Engineering Journal, 2023, 473:145430.

[56] SONI V, SINGH P, KHAN A A P, et al. Photocatalytic transi-tion-metal-oxides-based p-n heterojunction materials: Synthesis, sustainable energy and environmental applications, and perspectives[J]. Journal of Nanostructure in Chemistry, 2023, 13(2): 129-166.

[57] CHEN S, WEI Y, WANG G, et al. Mechanical behavior of laminated bamboo-timber composite columns under axial compression[J]. Archives of Civil and Mechanical Engineering, 2023, 23(2): 72.

[58] 蔡乃才, 王亚平, 曹银良. 负载型Pt-TiO2光催化剂的研究[J]. 催化学报,1999(2): 177-180.

CAI Naicai, WANG Yaping, CAO Yinliang. Study on supported Pt-TiO2 photocatalyst[J].Chinese Journal of Catalysis, 1999(2): 177-180.

[59] XUE H, JIANG Y, YUAN K, et al. Floating photocatalyst of B-N-TiO2/expanded perlite: A sol-gel synthesis with optimized mesoporous and high photocatalytic activity[J]. Scientific Reports, 2016, 6: 29902.

[60] SIGLE D O, ZHANG L, ITHURRIA S, et al. Ultrathin CdSe in plasnnonic nanogaps for enhanced photocatalytic water splitting[J]. Journal of Physical Chemistry Letters, 2015, 6(7): 1099-1103.

[61] LIU G, HAN L, WANG J, et al. Continuous near-complete photocatalytic degradation of toluene by V/N-doped TiO2 loaded on honeycomb ceramics under UV irradiation[J]. Journal of Materials Science &Technology, 2024, 174: 188-194.

[62] PARK M, KO Y T, JI M, et al. Facile self-assembly-based fabrication of a polyvinylidene fluoride nanofiber membrane with immobilized titanium dioxide nanoparticles for dye wastewater treatment[J]. Journal of Cleaner Production, 2022, 378:134506.

[63] YI Z, JIANG T, CHENG Y, et al. Effect of SiO2 aerogels loading on photocatalytic degradation of nitrobenzene using composites with tetrapod-like ZnO[J]. Nanotechnology Reviews, 2020, 9(1): 1009-1016.

[64] SHAO X, LU W, ZHANG R, et al. Enhanced photocatalytic activity of TiO2-C hybrid aerogels for methylene blue degradation[J]. Scientific Reports, 2013, 3: 3018.

[65] TYPEK J, GUSKOS N, PILARSKA M, et al. Magnetic prope-rties of TiO2/graphitic carbon nanocomposites[J]. Reviews on Advanced Materials Science, 2019, 58(1): 107-122.

[66] YANG S J, IM J H, KIM T, et al. MOF-derived ZnO and ZnO@C composites with high photocatalytic activity and adsorption capacity[J].Journal of Hazardous Materials, 2011, 186(1): 376-382.

[67] 吴晓栋, 宋梓豪, 王伟, 等. 气凝胶材料的研究进展[J]. 南京工业大学学报(自然科学版), 2020, 42(4): 405-451.

WU Xiaodong, SONG Zihao, WANG Wei, et al. Advances of aerogels materials[J]. Journal of Nanjing University of Technology(Natural Science Edition), 2020, 42(4): 405-451.

[68] PEKALA R W. Organic aerogels from the polycondensation of resorcinol with formaldehyde[J]. Journal of Materials Science, 1989, 24(9): 3221-3227.

[69] 王丽娜, 马晓军. 植物纤维素基碳气凝胶的制备及应用研究进展[J]. 生物质化学工程, 2021, 55(1): 83-90.

WANG Lina, MA Xiaojun. Preparation and application progress of plant cellulose-based carbon aerogel[J]. Biomass Chemical Engineering, 2021, 55(1): 83-90.

[70] 邵琰, 李亦彪, 汪红燕, 等. 碳气凝胶的改性探索及在染料废水中的吸附应用研究[J]. 无机盐工业, 2015, 47(8): 60-64.

SHAO Yan, LI Yibiao, WANG Hongyan, et al. Study on modification and adsorption application of carbon aerogels in dye wastewater[J]. Inorganic Chemicals Industry, 2015, 47(8): 60-64.

[71] 魏巍, 孙伟, 韩合坤, 等. 西瓜皮基碳气凝胶的制备及其吸附性能[J]. 化工环保, 2016, 36(4): 386-389.

WEI Wei, SUN Wei, HAN Hekun, et al. Preparation of carbon aerogel from watermelon peel and its adsorption properties[J]. Environmental Protection of Chemical Industry, 2016, 36(4): 386-389.

[72] JUSTH N, MIKULA G J, BAKOS L P, et al. Photocatalytic pro-perties of TiO2@Polymer and TiO2@Carbon aerogel composites prepared by atomic layer deposition[J]. Carbon, 2019, 147: 476-482.

[73] 任志凌, 袁磊, 杨睿戆, 等. 碳气凝胶复合TiO2光催化降解甲苯研究[J]. 能源环境保护, 2010, 24(1): 23-25.

REN Zhiling, YUAN Lei, YANG Ruigang, et al. Study on CRF-TiO2 photocatalytic degradation of benzene[J]. Energy Environmental Protection, 2010, 24(1): 23-25.

[74] BAILON-GARCIA E, ELMOUWAHIDI A, ALVAREZ M A, et al. New carbon xerogel-TiO2 composites with high performance as visible-light photocatalysts for dye mineralization[J]. Applied Catalysis B:Environmental, 2017, 201: 29-40.

[75] LU J, HU H, YANG S, et al. ZnS@carbonaceous aerogel composites fabricated in production of hydrogen and for removal of organic pollutants[J]. Journal of Materials Science: Materials in Electronics, 2018, 29(10): 8523-8534.

[76] PRASAD S, SHANMUGAM P, BHUVANESWARI K, et al. Rod-shaped carbon aerogel-assisted CdS nanocomposite for the removal of methylene blue dye and colorless phenol[J]. Crystals, 2020, 10(4): 300.

[77] SHEN Y, YUAN Z, CHENG F, et al. Preparation and characterization of ZnO/graphene/graphene oxide/multi-walled carbon nanotube composite aerogels[J]. Frontiers in Chemistry, 2022, 10: 992482.

[78] ZHANG H, LI Y, DENG L, et al. Porous carbon aerogel decorated with TiO2 quantum dots for highly improved photocatalytic H2 evolution[J]. ACS Applied Energy Materials, 2023, 6(13): 7274-7282.

[79] VADIVEL S, PAUL B, MOHAN H. Rational design of high temperature processed TbVO4/Nb2O5/carbon aerogel photocatalyst for prompt degradation of emerging pollutants[J]. Diamond and Related Materials, 2023, 136: 110035.

[80] ZHANG C, SONG S, CAO Q, et al. Improving the comprehens-ive properties of chitosan-based thermal insulation aerogels by introducing a biobased epoxy thermoset to form an anisotropic honeycomb-layered structure[J]. International Journal of Biological Macromolecules, 2023, 246: 125616.

[81] 毕于运, 王亚静, 高春雨. 中国主要秸秆资源数量及其区域分布[J]. 农机化研究, 2010, 32(3): 1-7.

BI Yuyun, WANG Yajing, GAO Chunyu. Straw resource quantity and its regional distribution in China[J]. Journal of Agricultural Mechanization Research, 2010, 32(3): 1-7.

[82] 程启明, 黄青, 刘英杰, 等. 花生壳与花生壳生物炭对镉离子吸附性能研究[J]. 农业环境科学学报, 2014(10): 2022-2029.

CHENG Qiming, HUANG Qing, LIU Yingjie, et al. Adsorption of cadmium(Ⅱ)on peanut shell and its biochar[J]. Journal of Agro-Environment Science, 2014(10): 2022-2029.

[83] 吴慧, 郑君宁, 左佑华, 等. 稻壳基碳材料负载钌催化剂的制备及其对氨硼烷水解制氢的催化性能[J]. 燃料化学学报, 2023, 51(8): 1201-1208.

WU Hui, ZHENG Junning, ZUO Youhua, et al. Preparation of rice husk-based carbon supported ruthenium catalyst for the hydrolysis of ammonia borane to produce hydrogen[J]. Journal of Fuel Chemistry and Technology, 2023, 51(8): 1201-1208.

[84] 王莹, 顾明言, 陈萍, 等. CaO耦合掺氮生物质炭对NO吸附的机理研究[J]. 燃料化学学报, 2023, 51(8): 1173-1181.

WANG Ying, GU Mingyan, CHEN Ping, et al. Study on the mechanism of NO adsorption by CaO coupled nitrogen-doped biochar[J]. Journal of Fuel Chemistry and Technology, 2023, 51(8): 1173-1181.

[85] LI Y E. Sustainable biomass materials for biomedical applications[J]. ACS Biomaterials Science &Engineering, 2019, 5(5): 2079-2092.

[86] 李琮. 生物基材料技术产业化渐行渐近[J]. 中国石油和化工, 2008(3): 23-24.

LI Cong. The industrialization of Bio-based material technology is gradually approaching[J]. China Petroleum and Chemical Industry, 2008(3): 23-24.

[87] MA G, GAO S, TANG G, et al. Development of starch-based amorphous CoOx self-supporting carbon aerogel electrocatalyst for hydrogen evolution[J]. Carbohydrate Polymers, 2023, 314: 120942.

[88] LIU X, HOU G, ZHAO J, et al. Self-interlocked down bioma-ss-based carbon fiber aerogel for highly efficient and stable solar steam generation[J]. Chemical Engineering Journal, 2023, 465: 142826.

[89] WANG M, ZHOU Z, ZHU J, et al. Tunable high-performance electromagnetic interference shielding of intrinsic N-doped chitin-based carbon aerogel[J]. Carbon, 2022, 198: 142-150.

[90] YANG X, KONG L, CAO M, et al. Porous nanosheets-bas-ed carbon aerogel derived from sustainable rattan for supercapacitors application[J]. Industrial Crops and Products, 2020, 145: 112100.

[91] TRANG D K, PHAM C K T, DO N H N, et al. Novel fabrication of coconut pith-based carbon aerogels as green adsorbents for oil and organic solvent removal[J]. Journal of Porous Materials, 2023,30(6):2023-2031.

[92] KUMARI P, TRIPATHI K M, AWASTHI K, et al. Biomass-derived carbon nano-onions for the effective elimination of organic pollutants and oils from water[J]. Environmental Science and Pollution Research, 2023, 30(27): 71048-71062.

[93] WAN C, LU Y, JIAO Y, et al. Fabrication of hydrophobic, electrically conductive and flame-resistant carbon aerogels by pyrolysis of regenerated cellulose aerogels[J]. Carbohydrate Polymers, 2015, 118: 115-118.

[94] ZHENG H, NAN K, LU Z, et al. Core-shell FeCo@carbon nan-ocages encapsulated in biomass-derived carbon aerogel: Architecture design and interface engineering of lightweight, anti-corrosion and superior microwave absorption[J]. Journal of Colloid and Interface Science, 2023, 646: 555-566.

[95] 戎西林, 崔葆, 黄秋梅, 等. 甘蔗渣纤维素基碳气凝胶的制备及吸附性能研究[J]. 无机盐工业,2022, 54(9): 126-135.

RONG Xilin, CUI Bao, HUANG Qiumei, et al. Study on preparation of bagasse cellulose based carbon aerogels and their adsorption properties[J]. Inorganic Chemicals Industry, 2022, 54(9): 126-135.

[96] CHENG Z, LI J, WANG B, et al. Scalable and robust bacterial cellulose carbon aerogels as reusable absorbents for high-efficiency oil/water separation[J]. ACS Applied Bio Materials, 2020, 3(11): 7483-7491.

[97] NGUYEN N T, DUONG T T T, PHAN T V T, et al. Water hyacinth as a green and sustainable material for carbon aerogel electrodes utilized in membrane capacitive deionization[J]. Clean-Soil Air Water, 2023, 51(8):2200396.

[98] 胡耀强, 房得珍, 叶秀深, 等. 西瓜皮基生物质碳气凝胶的制备及对染料的吸附[J]. 材料导报, 2021, 35(11): 11007-11012.

HU Yaoqiang, FANG Dezhen, YE Xiushen, et al. Preparation of watermelon peel-based carbon aerogel and its adsorption properties for dyes[J]. Materials Reports, 2021, 35(11): 11007-11012.

[99] LEI E, LI W, MA C, et al. CO2-activated porous self-templa-ted N-doped carbon aerogel derived from banana for high-performance supercapacitors[J]. Applied Surface Science, 2018, 457: 477-486.

[100] HU Y, GUO M, YE X, et al. Biomass carbon aerogel modified by N235 and KH560 for removal of iodide from oil field brine[J]. Journal of Wuhan University of Technology(Materials Science Edition), 2022, 37(4): 608-619.

[101] ZHU L, YOU L, ZHU P, et al. High performance lithium-sulfur batteries with a sustainable and environmentally friendly carbon aerogel modified separator[J]. ACS Sustainable Chemistry &Engineering, 2018, 6(1): 248-257.

[102] NGULLIE R C, BHUVANESWARI K, SHANMUGAM P, et al. Magnetically recoverable biomass-derived carbon-aerogel supported ZnO (ZnO/MNC) composites for the photodegrada-tion of methylene blue[J]. Catalysts, 2022, 12:10739.

[103] WEI W, HU H, HUANG Z, et al. BiPO4 nanorods anchored in biomass-based carbonaceous aerogel skeleton: A 2D-3D heterojunction composite as an energy-efficient photocatalyst[J]. Journal of Supercritical Fluids, 2019, 147: 33-41.

[104] QUAN F, ZHANG J, LI D, et al. Biomass as a template leads to CdS@Carbon aerogels for efficient photocatalytic hydrogen evolution and stable photoelectrochemical cells[J]. ACS Sustainable Chemistry &Engineering, 2018, 6(11): 14911-14918.

[105] LIU Y. Functional cellulose aerogel nanocomposites with enha-nced adsorption capability and excellent photocatalytic performance[J]. International Journal of Biological Macromolecules, 2023, 231: 123393.

[106] DAI Z, REN P, CAO Q, et al. Synthesis of TiO2@lignin ba-sed carbon nanofibers composite materials with highly efficient photocatalytic to methylene blue dye[J]. Journal of Polymer Research, 2020, 27(5): 108.

[107] JIN D, JIAO G, REN W, et al. Boosting photocatalytic perfo-rmance for selective oxidation of biomass-derived pentoses and hexoses to lactic acid using hierarchically porous Cu/Cu2O/CuO@CA[J]. Journal of Materials Chemistry C, 2021, 9(46): 16450-16458.

[108] LIU S, FU L, LIU Y, et al. Cu/C or Cu2O/C composites: Selective synthesis, characterization, and applications in water treatment[J]. Science of Advanced Materials, 2016, 8(11): 2045-2053.

[109] CUI R, JIN D, JiIAO G, et al. Cuprous oxide/copper oxide interpenetrated into ordered mesoporous cellulose-based carbon aerogels for efficient photocatalytic degradation of methylene blue[J]. Frontiers of Chemical Science and Engineering, 2023, 17(7): 918-929.

[110] 赵欢欢. 纤维素/铁氧体碳气凝胶复合材料制备及光Fenton性能研究[D]. 乌鲁木齐: 新疆大学, 2021.

[111] 鲍杰, 郑康, 龚文丽, 等. 纤维素基碳复合气凝胶的制备及其光催化性能研究[J]. 环境科学学报, 2023, 43(6): 340-349.

BAO Jie, ZHENG Kang, GONG Wenli , et al. Preparation and photocatalytic properties of cellulose based carbon composite aerogels[J]. Acta Scientiae Circumstantiae, 2023, 43(6): 340-349.

[112] ZHANG P, YIN L, YANG X, et al. Cotton-derived 3D carbon fiber aerogel to in situ support Bi2O3 nanoparticles as a separation-free photocatalyst for antibiotic removal[J]. Carbon, 2023, 201: 110-119.

[113] YANG H, DING Z, LIU Y, et al. Biomass-derived carbon aerogel for peroxymonosulfate activation to remove tetracycline: Carbonization temperature, oxygen-containing functional group content, and defect degree[J]. Industrial Crops and Products, 2022, 177:114437.

Advances in preparation and properties of biomass-based carbon aerogel photocatalysts

JIAO Yue,DING Jiaxuan,MEI Changtong,et al.Advances in preparation and properties of biomass-based carbon aerogel photocatalysts[J].Clean Coal Technology,2023,29(12):19-33.